Petrochemicals RPET Expansion LDPE 21-08-2021 - Arhive

Petrochemicals RPET Expansion LDPE

-LDPE gains momentum due to the tight fundamentals

Since mid-August, LDPE rebounds after consolidates for nearly two months, and its price rising form 10,300-10,500yuan/mt to around 11,000-11,500yuan/mt. A similar situation also occurred at the beginning of 2021, but then as traders stocked up too much cargoes, the advancing momentum of LDPE was not enough and market price slumped. So how will the market develop this time? Regardless of external factors, the current supply and demand is tight, and LDPE still has substantial upside space.

The above is the current China domestic LDPE plants, with a total production capacity of 3.48 million tons, of which 500kt/year plant of Jiangsu Sailboat and Shaanxi Yanchang ChinaCoal II are basically fixed in production of EVA, basically no possibility of switching to LDPE. In addition, the 200kt/year LDPE plant of Sinopec Yanshan PC is currently in production of EVA, which produces LDPE for an average of only half of the month. The 140kt/year LDPE plant of Sinopec Qilu PC has shut for maintenance and may restart in late Sep, the 300kt/year LDPE plant of Shenhua Yulin plans to shut on Aug 19 for around 25days and the 250kt/year LDPE of CSPC is scheduled to shut in late Oct. Regardless of the temporary short-term shutdown of some plants, the overall supply of LDPE is stable at around 2/3 of the full-open period.

-Brands invest in Evergreen’s RPET expansion project

Beverage giants and an investment firm have decided to put millions of dollars behind a Midwest PET reclaimer’s expansion project.

Evergreen (formerly Evergreen Plastics) is in the midst of a $22 million expansion at its Clyde, Ohio PET recycling facility. The company is owned by The Sterling Group, an investment firm that also owns Greenbridge, a plastic strapping producer that used to be called Polychem Corporation. Evergreen supplies recycled PET for use by Greenbridge. Petrochemicals RPET Expansion LDPE

On Aug. 12, the American Beverage Association (ABA), Ohio Beverage Association and investment firm Closed Loop Partners announced their combined $5 million investment. Half of the money comes from the Every Bottle Back initiative, which is a collaboration between Closed Loop Partners and the ABA, and the other half is from Closed Loop Partners’ Infrastructure Fund.

The Every Bottle Back initiative is funded by The Coca-Cola Company, Keurig Dr Pepper and PepsiCo, all of which are ABA members.

“This investment helps Evergreen evolve its business model, expanding its services to process recycled PET plastic into food-grade recycled rPET pellets used to manufacture new bottles, while creating a strong local market for recycled plastics,” the press release states.

-Hyosung Continues To Innovate With Eco-Friendly Partnerships And Products

With increasing numbers of brands and consumers becoming more proactive in seeking out eco-friendly products, Hyosung continues to further is sustainable programs and product offerings. Petrochemicals RPET Expansion LDPE

When it comes to developing sustainable technologies and programs, partnerships can provide many benefits for the companies and brands involved, as well as for the local communities being served. Four such recent examples are Hyosung’s regen Jeju, regen Seoul, regen Ocean and Mipan regen Ocean, all of which are based in South Korea.

To establish a new resource circulation system, Hyosung partnered with the Ministry of Environment (MOE), Jeju Provincial Government, and startup Korean-based fashion brand, Pleatsmama, to produce and launch a recycled polyester made from discarded PET bottles from South Korea’s Jeju Island. The result was regen Jeju, which was adopted by The North Face Korea earlier this year.

-Canada Plastics Pact welcomes 12 new partners as it moves towards 2025 targets

The Canada Plastics Pact (CPP) has welcomed 12 new partners including leading consumer goods organizations, industry associations, governments, converters and recycling stewardship organizations from across Canada.

The CPP now has over 65 partners that bring an eclectic set of perspectives to address collective challenges on the way towards ambitious 2025 targets to create a circular economy for plastics packaging in Canada where it stays in the economy and out of the environment. Petrochemicals RPET Expansion LDPE

Since the CPP launched earlier this year, partners have started work on a number of key initiatives to progress towards the 2025 targets. Significantly, last month the CPP announced it would lead the consultation and implementation of the Consumer Goods Forum’s Golden Design Rules for Plastic Packaging Design within Canada which provide a framework that will result in less plastics overall and better plastics to the recycling system. In addition, the CPP is currently working to develop a roadmap to achieve the 2025 targets along with a longer term vision for a circular economy for plastics in Canada that will be released this fall.

-Zume and Solenis partner on PFA-free molded fiber packaging and manufacturing playbook

Zume, the sustainability solutions company creating economically viable substitutes for single-use plastics, today announced a partnership with Solenis, a leading global producer of specialty chemicals, they are open sourcing a PFAS-replacement for food packaging manufacturing to food manufacturers and CPG brands across the global market. EIn conjunction, Zume is announcing it will no longer manufacture any products that contain PFAS from its California packaging facility effective immediately and the company is collaborating with its global partners to ensure that all production globally is PFA-free by the end of 2021.Petrochemicals RPET Expansion LDP

“Open sourcing our PFA-free solution creates a path for brands across the world to remove plastics and harmful chemicals from their consumer packaging and single-use goods,” said Zume CEO and Chairman Alex Garden. “Brands have made pledges to remove PFAS and this new launch will enable them to deliver on their promises.”

SABIC, a global leader in the chemical industry, today introduced NORYL™ AP2001G polyol for cast polyurethane (PU) applications. By partially replacing polypropylene glycol (PPG) or polytetramethylene ether glycol (PTMG), this oligomer of polyphenylene ether (PPE) improves the performance of cast PU systems by increasing both hardness and elasticity – properties that have been difficult to improve simultaneously until now. Petrochemicals RPET Expansion LDPE

In addition, NORYL AP2001G polyol provides resistance to oils, moisture, abrasion, tearing and heat, helping cast PU parts withstand extreme conditions and potentially lengthen their useful life. Potential applications include mining drill bits, screens and protective pipe liners for slurry transport; components for hydraulic, robotic and conveying equipment; and wheels, casters and rollers.

“The development of NORYL AP2001G polyol in cast polyurethanes illustrates SABIC’s ongoing commitment to advancing material science to fill unmet needs across the value chain,” said Dr. Antonello Cerullo, senior business development manager, SABIC. “This technology provides multiple benefits for stakeholders.

The adhesive enables PET bottle to bottle recycling in Sweden and Norway

In Scandinavia, demand for labels that enable PET recycling is growing and new regulations are prioritizing this type of packaging over glass. However, labeling technology for PET beverage bottles must follow guidelines established by the bottle deposit systems Returpack in Sweden and Infinitum in Norway.

Washes off without leaving any adhesive behind

Avery Dennison’s WB0030 wash-off adhesive has been approved by both organizations for recycling PET bottles, creating new opportunities for sustainable packaging. Petrochemicals RPET Expansion LDPE

The adhesive washes off in a 65°C caustic bath and leaves no residue behind, making it fully compatible with the current recycling process. Any adhesive that remains on the label does not reactivate at lower temperatures.

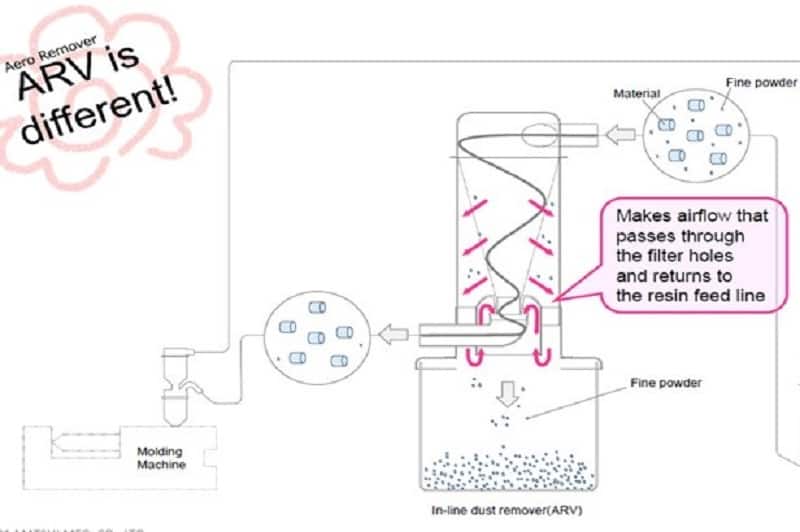

-Inline Dust Remover Eliminates Contamination from the Material Line

Matsui America says its new ARV Aero-Remover inline dust remover extends dedusting beyond vacuum transport to the material line itself.

Matsui America Inc. has introduced the new ARV Aero-Remover inline dust remover for eliminating powder and fines contamination from plastic pellets. The ARV Aero-Remover can be installed into any material line to remove resin powder and fines, leading to more consistent plasticizing and helping reduce product defects caused by incomplete melting. Petrochemicals RPET Expansion LDPE

In most traditional dedusting, powder and fines removal occurs during vacuum-transport of the resin with dust essentially shook off of the pellets. With ARV Aero-Remover, contamination removal occurs from the material line itself, not just the vacuum line. Due to its unique filtering design, the material flow blends both material and vacuum pathways to heighten contamination and dust removal.

-New Survey Shows Consumers Want Products Made from Recycled Materials

The survey commissioned by Core Hydration, a producer of bottled water, reveals that many consumers would be willing to pay a surcharge for products made from recycled materials. Petrochemicals RPET Expansion LDPE

Most people really do want to reuse their plastic containers, and 62% of Americans confess to being “plastic hoarders.” That’s one of the findings from a recent survey conducted by OnePoll on behalf of Core Hydration, a producer of bottled water sold in many retail outlets.

The study asked 2,000 nationally representative Americans about their plastic habits and what they want to improve on — notably getting rid of plastic after holding on to it for too long. Some of these items plaguing US homes include the “classic” bag of plastic bags (49%).

Count me in on that one! I have a huge plastic bag from a major clothing retailer that I’ve saved to fill with smaller retail bags, bread bags, and myriad other LDPE bags. When the bag “bag” is full, I take it to my local grocery store where they have a bin, which is usually overflowing, for recycling LDPE bags.

-Challenges and Opportunities in Sustainable Polyurethane Production

Major polyurethane (PU) suppliers and multiple startups are developing bio-based or recycled alternatives for PU feedstock, a trend that will strengthen in the years ahead. Petrochemicals RPET Expansion LDPE

There are more than 1,000 commercially available polymers. However, only a handful of materials, such as polyolefins, PVC, polystyrenes, and polyesters, command a major market share by volume. Among those materials, polyurethane (PU) has been a target of sustainability research. There are many drivers behind the research into sustainable PU and its subsequent commercialization. Based on ChemBizR’s deep experience in the polymer industry, end user markets, and sustainable products, the critical factors can be identified, as follows.

Massive presence in end markets

Through its various forms — rigid; flexible; coatings, adhesives, sealants, and elastomers (CASE); and others — PU is deeply entrenched in end markets, and it is well known that interest in sustainability gains traction the closer a material is to end consumer markets. Environmental awareness among consumers affects their consumption patterns, which has accelerated the pace of manufacturers’ migration toward raw materials and processes that are perceived to be more sustainable and environmentally friendly than alternatives.

Petrochemicals RPET Expansion LDPE