Pigments Petrochemicals WasteRecycling 03-07-2021 - Arhive

Pigments Petrochemicals WasteRecycling

-Consumer goods giant joins scheme to turn post-consumer packaging waste into food-grade rPP

Unilever (London / UK; www.unilever.com) has signed up to Nextloopp, an ambitious scheme developed by environmental consultancy Nextek (London, UK; www.nextek.org) to create food-grade recycled polypropylene from post-consumer packaging waste.

Nextloopp said its vision is to use this circular rPP in consumer products and cosmetics. Around 210,000 t/y of PP used in the UK is food-grade packaging, according to Nextloopp, “and yet no food-grade recycled PP is currently available for re-use into new packaging. To date, one of the main barriers to unlocking PP’s huge potential has been a lack of technology and a reduced infrastructure to produce food-grade recycled PP”.

Sanjeev Das, global packaging director at Unilever’s foods and refreshment division, said his firm supported the advancement of mechanical recycling infrastructure to produce food-grade rPP to complement other technology routes. “Unlocking the mechanical recycling route to produce food-grade rPP will help boost our efforts to keep plastics in a loop and out of the environment.”

-Nylon demand healthy in the off-season of 2021

Coming to the end of June, The traditional off-season is about to pass halfway, but some sectors of the nylon filament market have never been like in off-season. The average operating rate of nylon 6 textile filament plants has been kept as high as 87%, close to 90%, and there are so far no any scaled-plants have turnaround plans. But of course, the off-season characteristics of some nylon filaments are quite obvious, as their inventory has been accumulated high still. In a word, nylon 6 filament plants have maintained a high inventory and high operating rate still. What is this situation compared to other fibers? Pigments Petrochemicals WasteRecycling

The inventory of nylon filament was still growing in June, but slower than the previous month. Inventory accumulated was controlled mainly by two facts. First, some semi-dull nylon 6 high-speed-spinning chip plants had switched their production to dull chips, and thus expanded the supply of previously tight supply. Some filament plants had adjusted their production accordingly, to meet the robust demand for dull filament. Second, some filament plants altered product to fine-denier filament, and thus lubricated the general sales condition of NFY market. These methods helped NFY producers to roughly balance their high production and sales in the traditional off-season.

-Coca-Cola ends use of non-recycled plastic in all on-the-go bottles sold in Great Britain

Coca-Cola Great Britain (GB), in partnership with Coca-Cola Europacific Partners (CCEP), has today (30 June) announced that it is set to reach a significant milestone by using 100% recycled plastic in all on-the-go bottles across its entire range, as it continues its progress towards fully sustainable packaging.

The move means that all plastic bottles of 500ml or less in GB are to be made with 100% recycled plastic and will continue to be fully recyclable. The rollout commences in September, when the first 100% recycled 500ml bottles will start appearing on shelves.

It means Coca-Cola Great Britain will increase the amount of recycled plastic material in smaller bottles from 50% to 100%. Pigments Petrochemicals WasteRecycling

Coca-Cola’s use of recycled plastics in Great Britain now saves 29,000 tonnes of virgin plastic each year – the equivalent of 2,292 double decker buses, the company says.

The move part of Coca-Cola’s target towards 100% recycled or renewable plastic in all its bottles, and the creation of a circular economy for its PET packaging.

ChemistryCan influence our future / ChemistryCan deliver

ChemistryCan Driving the Circular Economy Pigments Petrochemicals WasteRecycling

From the ‘take, make, dispose’ model to ‘make, use, return’. A circular economy aims to maintain the value of products, materials and resources in the economy for as long as possible, and to minimise the generation of waste.

Chemistry is central to the ideal of the circular economy. Whether one’s talking about paper, battery or plastics recycling, the process is fundamentally chemical.

-New Method to Reuse Previously Non-Recyclable Plastic

Biodegradable plastics are meant to be environmentally friendly. However, they cannot be recycled as they are specifically made to degrade rapidly.

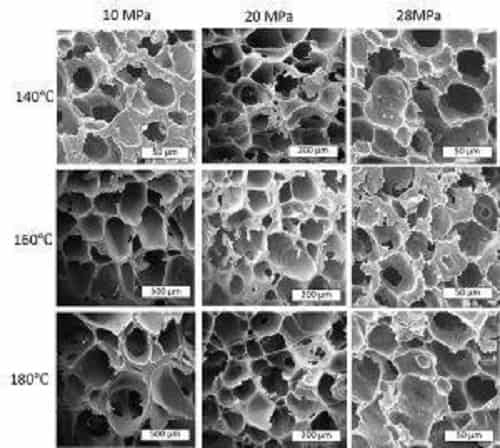

In the journal Physics of Fluids, by AIP Publishing, scientists from the University of Canterbury in New Zealand have designed a technique to convert biodegradable plastic forks, spoons and knives into foam that can be utilized as insulation in flotation devices or walls. Pigments Petrochemicals WasteRecycling

The cutlery was positioned by the investigators, which was earlier believed to be a “nonfoamable” plastic, into a chamber loaded with carbon dioxide. With the increase in pressure, the gas dissolved into the plastic.

When the pressure in the chamber was suddenly discharged, the carbon dioxide expanded inside the plastic, thereby creating foaming. According to author Heon Park, this process is similar to opening a can of soda and discharging the carbonation.

- VALERAS™ represents BASF’s plastic additives’ offerings with a high sustainability value;

- It includes the new range of products that help close the loop in plastics’ circularity;

- New website with emphasis on sustainable solutions.

VALERAS bundles the company’s longtime experience, innovative solutions, and regulatory support with the aim to increase the sustainability of plastics along the entire polymer value chain. Later this year, the portfolio will expand to include the company’s additive packages for mechanically recycled plastics and their applications.

“The trend towards sustainability has been accelerating, driven by consumer demand and more stringent legislation. Our customers are facing increasing pressure regarding sustainable innovations and challenges of plastics recyclability,” says Dr. Thomas Kloster, President, Performance Chemicals, BASF. “With VALERAS, we create new value for plastics by supporting our customers on their sustainability journey with novel solutions and services. VALERAS shows our broader ambition: to establish a platform that covers all our additive solutions that contribute to the sustainability goals of our customers.” Pigments Petrochemicals WasteRecycling

-NIFA Invests Over $5.4M in Bioprocessing, Bioengineering, Biofuels and Biobased Products Research

NIFA invests over $5.4 million in bioprocessing and bioengineering to fund projects aiming to stimulate new trade opportunities for the U.S. bioeconomy. Image courtesy of Getty Images.

The U.S. Department of Agriculture’s (USDA) National Institute of Food and Agriculture (NIFA) announced today an investment of $5.4 million in bioprocessing, bioengineering, biofuels and biobased products research. NIFA recently awarded $4.8 million for 12 Bioprocessing and Bioengineering grants(link is external) under NIFA’s Agriculture and Food Research Initiative, and more than $600,000 for six Biofuels and Biobased Products grants(link is external) under NIFA’s Small Business Innovation Research program. Pigments Petrochemicals WasteRecycling

“NIFA’s Bioprocessing and Bioengineering awards fund projects that will stimulate new trade opportunities for the U.S. bioeconomy,” said NIFA director Dr. Carrie Castille. “Additionally, these Small Business Innovation Research projects focused on biofuels and biobased products strengthen America’s entrepreneurial spirit and support a robust economy by guiding research and development needs across agriculture.”

Spanish plastics technology centre Aimplas (Valencia; www.aimplas.net) has helped develop a mobile chemical recycling plant capable of producing viable plastics feedstock from currently non-recyclable waste from the automotive, electrical and electronic, and packaging sectors.

Aimplas said it worked with the European “Life Ecomethylal” project on the pilot plant, which is capable of extracting up to half a kilo of methylal from every kilo of non-recyclable waste. Methylal can be used as a solvent and as a raw material to produce new polymers.

-Sun Chemical and DIC Corporation Finalizes Acquisition of BASF’s Global Pigments Business

DIC Corporation has closed on the acquisition of BASF’s global pigments business, known as BASF Colors & Effects (BCE).

The acquisition brings together the complementary portfolio of technologies, products, manufacturing assets, supply chain and customer service of the two companies to serve customers globally. Pigments Petrochemicals WasteRecycling

“We’re excited to close our acquisition of BCE and expand our product offering as one of the leading pigment suppliers globally” said Kaoru Ino, President and Chief Executive Officer of DIC. “BASF’s pigments portfolio is an important strategic addition in expeditiously meeting the goals we’ve outlined, which provide a clear growth path for DIC with the target to increase our sales to 1 trillion yen (approximately €8 billion) by 2025.”

The purchase will broaden Sun Chemical’s portfolio as a global manufacturer of pigments, including those for electronic displays, cosmetics, coatings, inks, plastics and specialty applications, by creating a world-class pigments supplier that offers customers an even wider range of versatile solutions.

“We’re pleased to welcome the valued and trusted expertise and engagement of BASF’s employees in the pigments business,” said Myron Petruch, DIC Executive Officer and President and CEO of Sun Chemical, a subsidiary of DIC Corporation. “This deal allows us to compete in the global marketplace more effectively going forward, while strengthening our pigment footprint in Europe. It underscores our commitment to delivering solutions tailored to meet the needs of our customers.”

-China Miracle to build Li2CO3, ternary precursor plant

Chinese automation engineering firm Miracle is on track to build a production facility for battery grade lithium carbonate and lithium-ion battery ternary precursors in Ganzhou city in south China’s Jiangxi province. Pigments Petrochemicals WasteRecycling

The 5bn yuan ($774mn) project will have designed capacity of 12,000 t/yr for battery grade lithium carbonate and 30,000 t/yr for ternary precursors. The firm’s subsidiary Jiangxi Miracle Jintaige Cobalt will be responsible for developing this project in the Longnan economic and technological development zone of the city.

The facility will be built in two phases, with the first phase scheduled to start construction in the fourth quarter of 2021 and launch production by the fourth quarter of 2023. The second phase is projected to begin construction in the fourth quarter of 2022 and start production by the fourth quarter of 2024.