Plastic Chemical Recycling Technology 16-09-2021 - Arhive

Plastic Chemical Recycling Technology

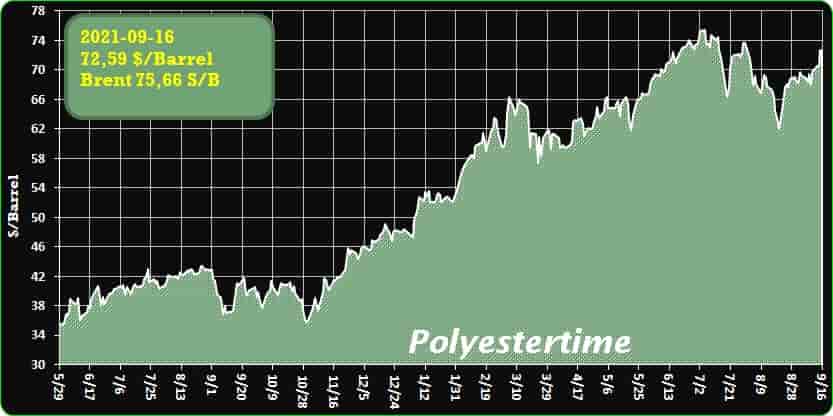

Crude Oil Prices Trend

-MEGlobal nominates ACP for October 2021 at USD880 per tonne

MEGlobal has announced its Asian Contract Price (ACP) for monoethylene glycol (MEG) to be shipped in October 2021, according to the company’s press release.

Thus, on 13 September, the company said ACP for MEG would be at USD880/MT CFR Asian main ports for arrival in October 2021, up by USD10/tonne from the previous month.

The October 2021 ACP reflects the short term supply/demand situation in the Asian market.

As MRC reported earlier, MEGlobal announced its September ACP for MEG at USD870/MT CFR Asian main ports, up by USD30/tonne from August.

MEG is one of the main feedstocks for the production of polyethylene terephthalate (PET).

-China to ramp up recycling, incineration in new plastic pollution push

China will boost its plastic recycling and incineration capabilities, promote “green” plastic products and take action against the overuse of plastic in packaging and agriculture, it said in a 2021-2025 “five-year plan” published on Wednesday.

The National Development and Reform Commission (NDRC), the top state planning agency, said in a notice that China needed to improve “the entire chain of plastic pollution control”, which it described as a “worldwide problem”.

“The essence of plastic pollution is that plastic waste leaks into natural environments like soil and water and is hard to degrade, causing visual pollution, soil damage, microplastics and other environmental hazards,” an NDRC spokesman said.

The new five-year plan will encourage retailers and delivery firms to cut “unreasonable” plastic packaging and raise waste urban incineration rates to around 800,000 tonnes per day by 2025, up from 580,000 tonnes last year.

Plastic Chemical Recycling Technology

-circular biobased delta : Chemical Recycling Technology

Chemical recycling is an innovative processing technology for plastic packaging waste. Depolymerization, pyrolysis and gasification are important technologies for the realization of the climate objectives, both from the point of view of circular raw material use and CO2 reduction. In the Plastics Transition Agenda, the ambition is defined to realize 250 kt of output from chemical recycling annually by 2030. Several great initiatives have already been started in the Netherlands in recent years. But there are still bumps to take. With the Chemical Recycling Network we want to support entrepreneurs to seize the opportunities that this new industry offers. The network was launched just before the summer and already has more than fifteen members, so there is strong momentum. Who wants to join these frontrunners is welcome, see bottom of this article. Plastic Chemical Recycling Technology

Members of the Network can participate in network and knowledge events to inform themselves about the latest developments, to exchange experiences and to suggest issues that should be addressed jointly. Examples include permits, financing, insurance, product standardization, value chain optimization, consortium formation and market analyses. Our business development managers coordinate and initiate these activities and add their expertise. The initiation of subsidy projects and lobbying is also part of the membership offerings of the Network Chemical Recycling.

Marcel van Berkel: “In this way, the network wants to promote and accelerate the development of pyrolysis technology and other forms of chemical recycling in the region. After all, it is very important for circular economy. It is an end-of-life solution for problematic plastics that can otherwise only be incinerated or landfilled. The technology is therefore in the spotlight and is developing strongly.”

-Nylon/Modified PPE Resin for Demanding Automotive Applications in Hot and Humid Conditions

SABIC’s new Noryl GTX 9500 resin boasts superior dimensional stability, retaining improved balance of mechanical properties when exposed to heat and humidity in underhood and other applications. Plastic Chemical Recycling Technology

The newest addition to the range of unfilled Noryl GTX family of nylon and modified PPE resins from SABIC is said to deliver superior dimensional stability under hot and humid conditions in highly demanding automotive applications. Noryl GTX 9500 has been shown to retain a better balance of mechanical properties when exposed to heat and humidity typical of automotive underhood environments, than nylons 6 and 66 resins, along with comparable high-flow and high-temperature performance.

Its dimensional stability and mechanical property retention under a wider range of temperatures and humidity – together with high flow performance – can open opportunities for thin-wall designs that reduce weight.

-Recyclable PVC to remain polymer of choice for medical devices

PVC is the most used polymer for single use medical devices and will retain its position in the years to come, according to a new market study conducted by Global Market Insights Inc. Plastic Chemical Recycling Technology

Recyclable PVC to remain polymer of choice for medical devices

PVC is the most used polymer for single medical devices.

The high volume and PVC’s recyclability indicate that hospitals should start with PVC in recycling schemes for plastics-based medical devices.

Almost 30 per cent of plastics-based medical devices are manufactured using PVC, which makes the material the most used polymer for bags, tubing, masks and other disposable medical devices. The remaining share is divided between ten different polymers. The study also forecasts that PVC will retain its number one position until at least 2027.

PVCMed Alliance Project Manager Ole Grøndahl Hansen said: “COVID-19 has highlighted the crucial role played by single-use plastic medical devices in the prevention and control of infection in hospitals. The negative side-effect of this success has been growing amounts of hospital plastic waste. We believe recycling is part of the solution. Fortunately, the most used plastic in healthcare is also the most recyclable plastic, and we therefore urge hospitals to start their recycling activities with PVC.

The LYCRA Co. has introduced LYCRA® ADAPTIV fiber. This fiber allows garments to have a better fit for various lifestyles, movements and different body types. The accompanying new brand identity — LYCRA ADAPTIV — was created to communicate these new and beneficial motion attributes. Plastic Chemical Recycling Technology

Made from a revolutionary polymer, this patent-pending, adaptive fiber has a unique chemistry that allows it to adjust to a wearer’s functional needs in a hybrid manner. This means that when the wearer is at rest, the polymer adapts its compressive holding force to deliver the right fit, shape and control. And when the wearer is in motion, the polymer adapts its elasticity to deliver improved comfort in motion and a second-skin effect allowing the garment to stay in place better. Garments made with fabrics containing LYCRA ADAPTIV fiber are durable and are also easier to put on and take off.

-ExxonMobil Presents High-Loft, Ultra-Soft Nonwovens at Index 20

The petrochemicals giant worked with Reifenhäuser Reicofil to develop the nonwovens and address demand for differentiated hygiene product components.

In collaboration with Reifenhäuser Reicofil, a global supplier of nonwoven, meltblown, and composite production lines, ExxonMobil has developed high-loft, ultra-soft nonwoven fabrics that can be tailored to specific applications. The “breakthrough solution” will be presented at the Index 20 nonwovens trade show on Oct. 19 to 22 in Geneva. Plastic Chemical Recycling Technology

“Working collaboratively with Reifenhäuser Reicofil has resulted in a new benchmark for high-loft, soft nonwovens to meet growing market demand globally, and particularly in Asia Pacific,” said ExxonMobil’s Olivier Lorge, Global Market Manager, Polypropylene, Vistamaxx and Adhesions Business. “Addressing the hygiene market’s desire for innovative, differentiated soft nonwovens, this solution will unlock business opportunities for ExxonMobil customers across the value chain.”

-Swiss firm Bluesign introduces new concept for critical solvents

Bluesign, a Switzerland-based solution provider for a sustainable textile production, has introduced management and phase-out concept for critical solvents. A significant reduction in the use and emissions of carcinogenic, mutagenic or toxic to reproduction (CMR) solvents is expected when the concept is fully implemented before the end of 2024. Plastic Chemical Recycling Technology

The concept is being launched as part of Bluesign’s strong commitment to reducing impact on people and planet, improving occupational health and safety and providing the highest level of consumer safety.

-Ceresana Research: Bioplastics Market Report

Analysts expect revenues from bioplastics to rise to approx. USD 8.1 billion by 2030

Compostable disposable tableware, mulch films that rot on the field, or fishing nets that simply disintegrate over time: are bioplastics the solution to waste problems? High hopes are being placed in plastics made from sugar cane, potato starch or other renewable raw materials. Biopolymers are conquering an increasing number of application areas and achieve significantly higher growth rates than conventional standard plastics. Ceresana has analyzed the dynamically growing global market for “green” polymers for the sixth time: Analysts expect revenues from bioplastics to rise to approx. USD 8.1 billion by 2030. Plastic Chemical Recycling Technology

Biobased and Biodegradable Plastics

In this study, two groups of materials are considered to be “bioplastics”. These two groups can overlap but don’t have to be identical:

biodegradable plastics, which decompose in the wild or can at least be composted in industrial facilities,

biobased plastics, which are produced from renewable raw materials.

Some bioplastics meet both conditions: for instance, PLA made from polylactic acid, PHA from sugar and TPS from starch are biobased and biodegradable. However, there are also plastic made from biogenic raw materials that are not compostable (e.g. PEF from fructose or bio-PE based on sugar cane). In contrast, some petrochemical plastics, i.e. plastics produced from crude oil or natural gas, may well be biodegradable (e.g. PCL, PBAT, PBS). As long as biobased plastics have the same chemical structure as their fossil counterparts, they can be recycled.

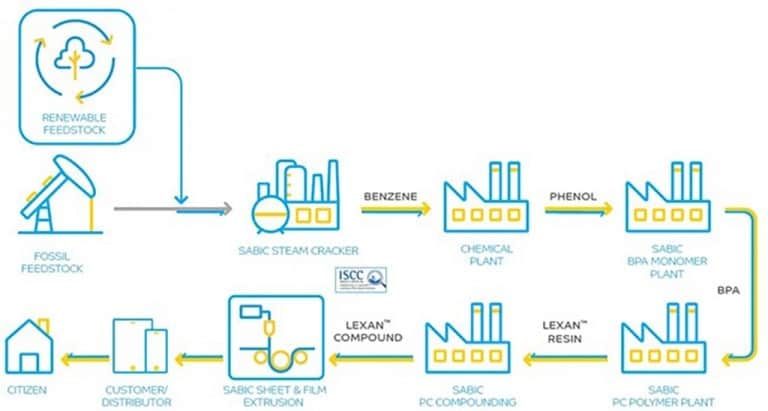

As the industry’s first supplier of polycarbonate structured forms and shapes, SABIC Functional Forms is offering a range of LEXAN film and sheet products based on polycarbonate resin partially sourced from certified renewable feedstock.

SABIC’s Functional Forms plant in the Netherlands has been accredited under the International Sustainability & Carbon Certification (ISCC) PLUS scheme for providing a new range of LEXAN film and sheet products based on certified renewable feedstock. Plastic Chemical Recycling Technology

The new film and sheet product offering connects with the company’s existing TRUCIRCLE initiative and responds to a globally growing demand for further sustainable material solutions in an increasingly more circular plastics economy.

Plastic Chemical Recycling Technology