Plastic chemicals recycling carbon fibre 21-11-2018 - Arhive

-China – Polyethylene Terephthalate PET and its chain are weak.

PET Bottle grade export 1,070/1,110 $/ton – PET Bottle grade domestic market 8,150/8,250 yuan/ton – PET Filament grade SD domestic market 7,950/8,050 yuan/ton – PET Filament grade BR domestic market 7,950/8,050 yuan/ton

PTA Taiwan 870/880 $/ton – PTA domestic market 6,450/6,600 yuan/ton – MEG $ 670/680 $/ton – MEG domestic market 5,750/5,900 yuan/ton – PX Korea 1,080/1,095 $/ton

POY 150D/48F domestic market 8,750/8,900 yuan/ton – DTY 150D/48F domestic market 10,550/10,650 yuan/ton – PSF domestic market 9,000/9,100 yuan/ton

-Time for industry to put a plastics circular economy into practice, piece by piece

When it comes to creating a plastics circular economy, collaboration is key.

But with a global political consensus on implementing a new plastics economy so far off, perhaps it is time for industry to lead on putting theory into practice, one piece at a time.

The fact is, technology exists to design and manufacture reusable plastic products in a profitable way, through recycling and reintroducing them into the value chain rather than disposing of them.

-Additives: Metallic-Look Colorants for a Broad Range of Molded Products

Ampacet’s FauxFoil molded-in color masterbatches offer a total lower-cost option to metallization and coating processes.

A new special-effects colorant technology designed for a range of polymers, including HDPE, PP, PET, PC, ABS and PS, is said to provide molded-in metallic effects for PET (injection stretch blow molded) bottles, extrusion blow-molded bottles, sheet and thermoforming processes and injection-molded components. The FauxFoil masterbatch technology from Ampacet Corp., Tarrytown, N.Y., is said to offer a total lower-cost alternative to vacuum metallization and coating processes and mimics the gloss and shine of metal in a single step.

-Crude Oil Prices Trend

-Plastic tray market to surpass $7 billion in 2018 Plastic tray fiber based tray

Introduction of eco-friendly alternatives to the plastic trays such as fiber-based trays, bagasse or sugarcane trays, paper trays, and plant-based plastics are emerging as a threat in the growth of the plastic tray market.

The plastic tray market is projected to expand at a very slow phase with the global sales of plastic tray surpassing US$ 7 billion by the end of 2018, according to the latest research by Fact.MR.

-Middle East PE, PP demand stays weak as Asian markets tumble

Polyolefin demand across the Middle East continued to be weak, tracking the sluggish Asian markets, as the year is drawing to a close.

Buying appetite for finished goods and resins typically wanes in November, while polyolefins end-users are bent on keeping stocks lean at the end of each financial year.

December offers are expected to emerge late this month but offtake is likely to remain limited as a result of curtailed year-end demand.

On 16 November, high density polyethylene (HDPE) film prices in the Gulf Cooperation Council (GCC) stood at $1,220-1,260/tonne DEL (delivered) GCC; while polypropylene (PP) raffia prices were at $1,240-1,300/tonne DEL GCC, both unchanged from the week before, according to ICIS data.

-Bilayer Graphene on the way to becoming a superconductor

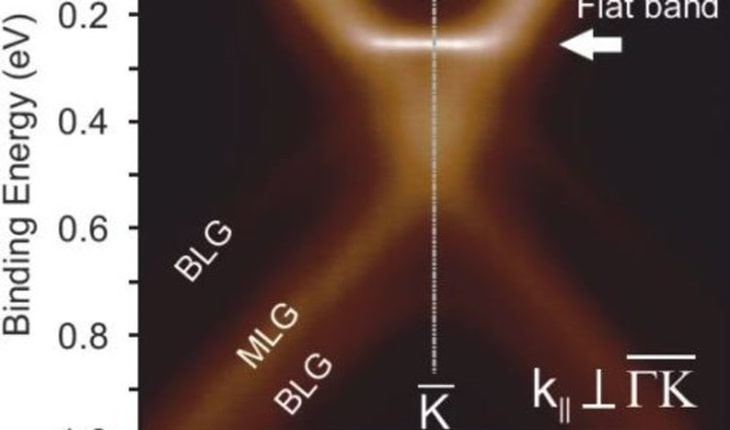

Scientists at HZB have found evidence that double layers of graphene have a property that may let them conduct current completely without resistance. They probed the bandstructure at BESSY II with extremely high resolution ARPES and could identify a flat area at a surprising location.

Above – The data show that In the case of the two-layer graphene, a flat part of bandstructure only 200 milli-electron volts below the Fermi energy. Credit: HZB

A complicated option for superconductivity

-Pivoting to Technical Textiles

Companies are seeking to avoid the low-margin trap by moving into this technically demanding segment of the industry.

As the days are gone when fabric could be cut and sewn in Taiwan at competitive costs, its textile sector has been shifting toward technical textiles for which production relies on automation rather than human labor.

In this segment of the industry, in addition, the ability to deliver customized solutions trumps the ability to churn out huge volumes at cheap prices.

-KraussMaffei anniversary machine for Wirthwein is a one-of-a-kind look

To celebrate 180 years of KraussMaffei and the 180th injection moulding machine for Wirthwein, the two companies took this opportunity to give the anniversary machine a one-of-a-kind look.

Ralf Spitzer, a well-known European graffiti artist lent a street art flair to the GX 900-4300 BluePower with his airbrush technique.

Illustrations on the machine include the faces of company founders Georg von Krauss and Joseph Anton von Maffei and Walter Wirthwein.

-P2T process positioned for recycling

British company Prodrive Composites (Milton Keynes, UK) recently issued a press release about a process, called P2T (Primary to Tertiary), for manufacturing recyclable composite components that can satisfy future end-of-life requirements without any compromise in performance.

British company Prodrive Composites (Milton Keynes, UK) is known for design and manufacture of advanced lightweight structural and non-structural composites for a wide range of applications across the automotive, motorsport, aerospace, marine, defense and other sectors.

-Kellogg Announces New Global Sustainable Packaging Goal

Company Aims for 100 Percent Reusable, Recyclable, or Compostable Packaging by the End of 2025

Kellogg Company announced today that it is expanding its Global Sustainability Commitments to include a goal of working towards 100 percent reusable, recyclable or compostable packaging by the end of 2025.

-Why plunging oil prices now hurt—yes hurt—the U.S. economy

Drivers rejoice, but relief at the pump no longer offsets hit to capital spending: economist

Not everyone celebrates lower prices.

Falling oil prices are usually greeted with cheers, especially at the gas pump. But for the economy, the equation has changed thanks to the transformation of the U.S. back into a major oil producer courtesy of the shale revolution.

The EU as a whole is showing promise when it comes to meeting recycling targets. But some member states still send a lot of waste to landfill instead. [Shutterstock]

European Union members will have to recycle at least 70% of packaging by 2030, under new rules brokered earlier this year. But there are complex mechanisms behind the recycling curtain and not all countries are ready yet to keep up with the pace.

EU lawmakers want the continent’s disparate recycling systems to be more effective and, as a result, more profitable, as there are still ambitious plans to set up an ‘internal market for recycling’.

-EFI Introduces Next-generation Single-pass Reggiani BOLT Textile Digital Printer

The brand-new, next-generation, single-pass EFI™ Reggiani BOLT textile digital printer from Electronics For Imaging, Inc. (Nasdaq:EFII) made its debut this week during an open house event at the EFI Reggiani facility in Bergamo, Italy.

The advanced, ultra-high-speed digital single-pass printer has the potential to revolutionize the textile printing market, providing users with high uptime and reliability, outstanding performance, superior printing uniformity and accuracy, long printhead life and minimal maintenance needs.

The EFI Reggiani open house has created huge interest in global textile market opportunities, with nearly 300 customers and journalists attending to see the new BOLT in action.