Plastic Petrochemicals recycling biodegradable 03-11-2018 - Arhive

Robots and digital technology deliver speed plus larger, more complex parts,

while generative 3D winding obviates mandrels and waste for automotive applications.

Filament winding, one of the oldest composite manufacturing processes, was used to produce solid rocket motor cases after World War II. By the early 1960s and ‘70s, commercial winding machines were also being used to fabricate fiber-reinforced pipes, pressure vessels and streetlight poles. Well-suited to automation, filament winding is fast, cost-effective and creates lightweight, high-performance structures.

Traditionally, filament winding impregnated fibers in a resin bath just prior to application on a rotating mandrel (tool) while keeping them in tension. Though wet winding is still popular, processes have also been developed to use prepreg tapes, towpreg or dry fibers, the latter serving as preforms for liquid molding processes.

-Plastic tax ‘discriminatory’, likely to increase prices – PlasticsEurope

A tax on plastics proposed this week in the UK could increase final consumer prices and would be discriminatory against the industry, an executive at European trade group PlasticsEurope said on Thursday.

Kim Christiansen, north region director at the trade group, added, however, that plastics are “high on the political agenda” and argued that polymers producers are already taking steps to increase the circularity of their products.

This week, the UK announced that it aims to introduce a tax on plastics with less than 30% recycled material from 2022 onwards, a tax opposed by the industry’s trade group the British Plastics Federation (BPF), according to its director general in an interview with ICIS.

The CEO of Austria’s polymers major Borealis also told ICIS this week that a plastic tax would not be efficient to increase recycling rates, and said the EU should develop further schemes like the Extended Producer Responsibility (EPR).

-DowDuPont sees ‘short and shallow compression’ in PE cycle in 2019

DowDuPont expects a relatively mild and quick downturn in the polyethylene (PE) cycle in early 2019 amid stable inventories and high operating rates, a senior executive said on Thursday.

“There are some predictions out there that everything is going to collapse. I’m not sure I believe that,” said Jim Fitterling, CEO of Dow Chemical (Materials Science division of DowDuPont), on the company’s Q3 earnings call.

“We’ve seen that inventories are relatively under control. They’re actually down at the end of the third quarter slightly. Inventories are at 42 days, and that’s basically what you need to run the supply chain,” he added.

-EU moves closer to ban on single-use plastics

After the European Commission and the European Parliament, representatives of EU Member States agreed at a meeting in Brussels on Wednesday on a common position with a view to banning or reducing consumption of single-use plastics that often litter oceans and beaches.

On 6 November, the European institutions will begin efforts to reach a common position.

The Commission had proposed in May to ban a dozen disposable products for which there are already alternative solutions. These include cotton swabs, plates, cutlery, balloon sticks, and stirrers.

The Parliament, which discussed a report by Euro-parliamentarian Frédérique Ries (Reformist Movement, MR) two weeks ago, added polystyrene food and drink containers, along with plastic wrapping and straws that are oxy-degradable, i.e. break down into small bits, but are not entirely biodegradable.

-Asia naphtha drops below $600/tonne on sharp crude oil losses

Asia’s naphtha prices plummeted to their lowest level in seven months, dragged down by steep losses in crude oil futures overnight and amid a supply glut.

Oilfield workers prepare supplies for oil rigs in Liaodong Bay of the Bohai sea in Tianjin, China.(Photo by Lou Linwei/REX/Shutterstock)

On Friday morning, open-spec naphtha prices for second-half December delivery stood at $593.75/tonne CFR (cost & freight) Japan, down by 2% from the previous day’s close.

Current prices are at levels not seen since April, according to ICIS data.

January ICE Brent crude oil futures were trading lower at $72.56/bbl early on Friday, following news of record crude production by Russia, Saudi Arabia and the US.

-Chemours’ TiO2 volumes falling faster than expected – CEO

Chemours’ titanium dioxide (TiO2) volumes are declining faster than expected in the second half of 2018, due to destocking throughout the whole TiO2 chain across global regions, the CEO of the US-based producer said in an update on Friday.

Full-year 2018 volumes for Chemours’ Ti-Pure brand pigment are expected to be down in the mid-single digits, compared with “a very robust 2017”, Mark Vergnano told analysts during the company’s Q3 earnings call.

As a result, Chemours now expects total full-year 2018 adjusted earnings before interest, tax, depreciation and amortisation (EBITDA) to come in at the lower end of its $1.70bn-$1.85bn guidance, the CEO said.

-Textile Flame Retardant Chemicals

Avocet manufactures a range of high performance, textile flame retardant chemicals marketed under the name CETAFLAM®. They can be applied during the dyeing process, by backcoating or padding to a wide range of textile fibres and their blends. Some are also OEKO-TEX® accredited “active chemical products”.

Avocet manufactures a range of high performance, textile flame retardant chemicals marketed under the name CETAFLAM®. They can be applied during the dyeing process, by backcoating or padding to a wide range of textile fibres and their blends. Some are also OEKO-TEX® accredited “active chemical products”.

Our philosophy is to innovate and develop products which have high flame retardant performance, low environmental impact, low energy use and are reliable.

-U.S. And OPEC Flood Oil Market Ahead Of Midterms

OPEC and the U.S. are together adding enormous volumes of new supply, which together have softened the oil market.

In October, OPEC hiked oil production to the highest level since 2016, back before the oil production cuts went into effect, according to a recent Reuters survey. The higher output, led by Saudi Arabia and the UAE, come just as Iranian oil is going offline. Also, Libya saw a sharp rebound in production, although the country is not part of the OPEC+ production cuts.

The 15 countries in OPEC produced an average 33.31 million barrels per day in October, the highest since December 2016. That was also up 390,000 bpd from September. “Oil producers appear to be successfully offsetting the supply outages from Iran and Venezuela,” said Carsten Fritsch of Commerzbank.

Russia, which is not part of OPEC but part of the OPEC+ coalition, continues to produce at post-Soviet record highs.

-Indorama Ventures Expands Presence In Brazil With Entry Into Fiber Market

Indorama Ventures Public Company Limited (IVL), a global chemical producer, has announced that it has entered into an agreement to acquire M&G Fibras Brasil, in Cabo de Santo Agostinho, Brazil.

The Cabo plant manufactures and supplies Polyester Staple Fiber, with total polymerization capacity of 75,000 tonnes/annum.

The transaction is expected to be completed in the fourth quarter 2018, subject to regulatory approvals.

This acquisition fills an important gap in IVL’s global footprint in fibers by establishing capacity in South America’s largest economy, Brazil.

It also offers IVL an opportunity to participate in the domestic market along with strategic and logistic advantages from established free trade agreements with other Latin America countries.

The demand in Brazil is expected to grow in response to a recent recovery in consumption.

-Plastic packaging waste upcycled into technical materials

Multilayer packaging – good for food, tricky for recycling

A new recycling process for low-grade packaging plastics promises to produce high quality technical materials. If commercialised, this could make plastic recycling more economically attractive and reduce plastic pollution.

Multilayer packaging is an excellent barrier to oxygen and moisture, making it an ideal material for food packaging. It can contain a range of polymers such as polyethylene, polyamide and ethylene vinyl alcohol, so is difficult to recycle into anything of value – much of the associated waste is incinerated or sent to landfill.

-Paper packaging solution to plastics crisis

Timber and plant-based packaging from recycled, certified and responsibly managed forests can replace plastic packaging.

Ever since Blue Planet II hit our screens last winter, plastic – and plastic packaging – has been at the forefront of the national and international policy debate. Indeed, Forest Stewardship Council (FSC) research suggests as many as 88 percent of people want to reduce their consumption of plastic packaging.

One of the great questions in the quest to reduce waste plastic is whether paper or card offers a solution to the plastic crisis. We know some products need to be packaged in plastic for food safety reasons, to increase shelf life or for ease of transportation. But for those items that don’t need plastic, do paper or card offer a credible alternative?

-HeiQ And Patagonia Expand Their Partnership With HeiQ Fresh Tech

The Swiss textile technology innovator HeiQ and sustainable outdoor clothing brand Patagonia expand their 2017 partnership to include HeiQ Fresh Tech odor control technology, with best-in-class performances.

Recent consumer research shows that 72% of shoppers are interested in odor control technology in activewear. As we are social animals, humans want to be close to others without having to worry about bad smell on our apparel from ourselves or our surroundings.

To expand on the Patagonia/HeiQ partnership, and as part of the R&D partnership launched in 2017, Patagonia will begin using HeiQ Fresh Tech odor control in their Fall 2019 collection.

-Developing environmentally friendly materials

The materials engineers are developing environmentally friendly materials

A new research article introduces a nanofiber material produced by the electrospinning device at the Laboratory of Polymers and Textile Technology in Tallinn University of Technology, and a range of applications.

The article, titled “A method for producing conductive graphene biopolymer nanofibrous fabrics by exploitation of an ionic liquid dispersant in electrospinning,” was published in Carbon.

It is not possible to produce fibers with a diameter smaller than a micrometer by using conventional fiber spinning methods.

However, via electrospinning technology, researchers can fabricate nanofibers by applying high voltage to a polymer solution. In recent years, there has been a surge of interest in electrospinning.

-Idle BioAmber facility buyer exploring new products

BioAmber’s plant in Sarnia is shown in this file photo. Courts in Canada and the U.S. have approved the sale of the idle plant to LCY Biotechnology. PAUL

The plant manager with LCY Biosciences, the company that has taken over the idle former BioAmber manufacturing site in Sarnia, says it will be several months before production begins again.

The bio-succinic acid plant, which opened in 2015, was sold last month during a court-supervised liquidation process to LCY Biotechnology, a new company formed by Visolis and LCY Group.

“It’s going to be a little bit slow for a while,” said plant manager Trevor Macleod.

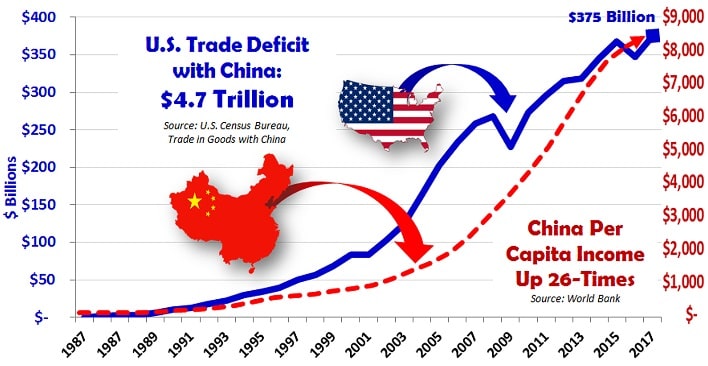

-Dow CFO says global operations can mitigate US-China trade war risks

Chemical giant DowDuPont does not expect tariffs imposed amid simmering trade tensions between the US and China to have a notable effect on its businesses during the fourth quarter, CFO Howard Ungerleider said Thursday.

The US has imposed $250 billion in tariffs on Chinese imports, prompting China to retaliate with $110 billion in tariffs on US products.

The second and third rounds of those tariffs were petrochemical-heavy from both sides.

In the August round, China’s tariffs on US products included two grades of polyethylene that make up more than 90% of 10.8 million mt in new publicly announced US PE production starting up, under construction or planned from 2017 through 2027.

All or most of that new output is targeted for export, and Asia — led by China and India — has the most demand growth.