Plastic Petrochemicals recycling Textile 22-10-2018 - Arhive

-Crude Oil Prices Trend

-Polymers Polyester Yarn PET Petrochemicals Prices

-Plastic recycling industry’s problems costing councils up to £500,000 a year

Chinese ban on waste imports is significantly affecting UK councils’ ability to collect and recycle plastic

Major problems in the plastic recycling industry are costing local councils in England up to £500,000 extra a year, as they struggle to deal with the continuing fallout from import bans imposed by countries who are no longer able to take the UK’s waste.

A survey by the Local Government Association (LGA) revealed nearly half of councils who responded (52) say China’s ban is having a significant impact on their ability to collect and recycle plastic, due to rising costs. Fourteen councils across the country say their recycling costs have increased by an average of half a million pounds a year, in part because of rising processing charges per tonne.

-Magna opens seating plant in Czech Republic to serve BMW in Europe

With a production area measuring 6,000 square meters, the plant has the capacity to produce more than 360,000 seat sets per year.

Magna officially opens its new seating facility in Chomutov, Czech Republic, to support new BMW Group business.

Magna International Inc. has opened its second seating business and facility with BMW Group, this one located in Chomutov, Czech Republic.

The new plant, which will employ about 300 workers by the end of next year, will be supplying seating systems in various configurations for several BMW models for the European market. With a production area measuring 6,000 square meters, the plant has the capacity to produce more than 360,000 seat sets per year, Magna said in a statement.

Frierichshafen, Germany — Radici Group is focused on new applications for its nylon resins, and officials don’t seem concerned about a global shortage of feedstocks used to make nylon 6/6.

The Bergamo, Italy-based materials firm is enjoying double-digit sales growth so far in 2018, Davide Preti, the company’s Nordic and Eastern European regional sales manager, said at an Oct. 17 press event. Erico Spini, global marketing manager, addressed new growth opportunities for the firm, which derives around half of its plastics sales from the automotive market.

For electric vehicles, Spini said that the introduction of hybrid and fully sized electric vehicles is creating opportunities for Radici’s nylon 6/6, 6/10 and 6/12 materials to be used in recharger plugs, sockets and high-voltage system components.

Demand for electrical vehicles is expected to grow, especially in Europe, where new carbon dioxide emission standards will be in place by 2021.

-Oerlikon’s texturing research at Suzhou site gets awarded20

The years of intensive research and development in the field of texturing, which Oerlikon Barmag is doing at the Suzhou site in China, has been recognised. On October 12, 2018, the new R&D centre was officially inaugurated. Around 80 guests took part in the ceremony. Government representatives and the top management level of the company attended the event.

The award is a tribute to the research and development work done so far in the field of texturing machines. For example, Oerlikon holds 34 patents granted, several more are currently in the grant stage. The award also reflects the reorientation in the area of texturing.

-Asahi Kasei forges ahead toward record $1.8bn profit

Tight market for petrochemicals boosts margins

Asahi Kasei is on track to post a record operating profit for the fiscal year ending March 2019.

Japanese chemical company Asahi Kasei is on track to reap a operating profit of more than 200 billion yen ($1.78 billion) for the first time ever this fiscal year, thanks in large part to the rising price of a key petrochemical used in plastics and fibers.

The profit would mark a 1% increase on the year, a turnaround from the 4% decline to 190 billion yen that the company had predicted. Sales for the year ending March 2019 are expected to rise 8% to just over 2.2 trillion yen, beating projections by about 45 billion yen.

The company is expected to upgrade its full-year guidance when it releases its first-half results on Nov. 2.

Acrylonitrile, used to make acrylic and carbon fibers, is the main driver behind its boost. Demand for the product is brisk, even as stricter environmental regulations in China has reduced supply.

-U.S. Tariffs on Textile Imports From China Leads to Trade Opportunities Elsewhere

With new tariffs being placed on textiles coming from China, many U.S. fabric importers are scrambling to find new textile trading partners whose goods are not subject to the recently imposed 10 percent tariff that could rise to 25 percent at the beginning of the year.

“I would expect to see sourcing shifts away from China to other countries or an increase in prices for goods that either can’t be sourced elsewhere or for which the cost of shifting is greater than the increase in duties,” said Elise Shibles with the San Francisco–based international law firm Sandler, Travis & Rosenberg.

-Industry 4.0 specialist TIG opening U.S. office

FRIEDRICHSHAFEN, Germany—An Austrian company that specializes in manufacturing execution systems for injection molders plans to open an office in the U.S.

Technische Informationssysteme GmbH, more commonly known as TIG, initially is setting up shop in York, Pa., where its parent company Engel Holding GmbH has a facility. But TIG is looking for a permanent site for the local office, which it expects to be somewhere in the northeastern U.S.

“Most of our customers are already there, so our first priority is to be near them,” Patric Lampert, TIG’s head of strategic project management, said in an interview at Fakuma.

TIG currently has 10 U.S. customers, and the local office will service them while recruiting more. The office will have four employees in 2019, headed by Erol-Kurt Yurtluk, who is currently sales manager.

-Plastribution to discuss a sustainable future for plastics

Polymer materials distributor, Plastribution, is set to advise customers on how to develop a sustainable future using plastics in an upcoming webinar.

To be held on October 23, the webinar will address the increasing levels of environmental awarenes that is leading to growing pressure on the plastics industry to respond positively on the long term importance of sustainable polymers development.

“In providing solutions for the future, evaluating the environmental credentials of a ‘sustainable’ material or product is often complicated and sometimes difficult to judge,” explained Mike Boswell, Managing Director of Plastribution.

-Esg, Thai Acrylic Partner for Outdoor Yarn Range

European Spinning Group (ESG) has partnered with Thai Acrylic Fibre to develop a new generation of solution dyed acrylic yarns for outdoor applications. This yarn range is marketed under brand name ‘ESG RA Outdoor’ powered by Durashine fibre suitable for various outdoor applications including awnings, outdoor-furniture, carpets and marine exterior etc.

ESG is a leading specialty yarn producer for weaving and knitting fabrics in various markets and applications. Due to focus on innovation, sustainability and creativity and a partnership approach with all key stakeholders, ESG has established itself as a preferred yarn supplier across six continents.

Thai Acrylic is fifth largest producer of Acrylic Fiber globally and part of Aditya Birla Group, Fortune 500 Company.

“We are proud to be associated with ESG for this innovative product range with our Durashine Fibre, which I’m sure will create a strong market connect in coming days not only in Europe but across the globe,” Satyaki Ghosh, CEO Thai Acrylic Fibre, said.

-Novamont boosts bioplastics capacity

Italy’s Novamont has increased production at its Mater-Biopolymer plant south of Rome by 25 per cent in order to manufacture more Origo-Bi biopolyesters and components of Mater-Bi compostable bioplastics.

The €70 million ($80m) investment, which could rise to €100m ($115m) within three years, will boost production capacity from 120,000 tonnes a year to 150,000t. The 140,000 sq m site employs 90 staff and applications for the materials include coffee cups and pods, carrier bags, straws and food packaging.

-Lenzing launches Veocel Lyocell fibre for wipes20

Lenzing has announced the launch of the new Veocel Lyocell fibre with eco disperse technology which is designed for use in flushable wipes. This new fibre demonstrates enhanced biological disintegration performance. The inclusion of the fibre enables more diverse design opportunities while providing exemplary wet strength and disintegration performance.

Versatile and tailor-made for daily care routines, the new Veocel Lyocell fibre with Lenzing’s eco disperse technology offers optimised flushability and represents the most advanced fibre under the Veocel brand portfolio, Lenzing said in a press release.

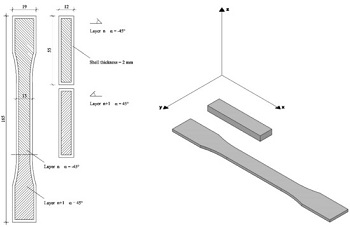

-The Effect of Temperature on 3D Printed PLA Clay Nanocomposites

In a paper entitled “3D Printing of PLA/clay Nanocomposites: Influence of Printing Temperature on Printed Samples Properties,” a group of researchers investigate the possibility of using a layered silicate-reinforced PLA in 3D printing applications. In particular, they examine the influence of printing temperature in 3D printing clay/PLA nanocomposites.

“For this reason, two PLA grades (4032D and 2003D, D-isomer content 1.5 and 4, respectively) were melt-compounded by a twin screw extruder with a layered silicate (Cloisite 30B) at 4 wt %,” the researchers explain. “Then, PLA and PLA/clay feedstock filaments (diameter 1.75 mm) were produced using a single screw extruder.”

The researchers 3D printed dog-bone-shaped and prismatic specimens using FDM 3D printing at three different temperatures, which were progressively increased from the melting temperature (185–200–215 °C for PLA 4032D and 165–180–195 °C for PLA 2003D). The PLA and PLA/clay specimens were characterized using thermogravimetric analysis (TGA) dynamic mechanical analysis (DMA), differential scanning calorimetry (DSC), and tensile tests.

-EDITORIAL: Time for Japan to lose its plastic dependency and save the oceans

Plastic bottles and other waste collected by a cleanup boat in Tokyo Bay (Asahi Shimbun file photo)

The Environment Ministry has worked out a draft proposal to reduce plastic waste focused on recycling and cutting usage of single-use plastic products.

The strategy calls for a 25-percent reduction in the consumption of disposable plastic products, such as supermarket checkout bags and straws, by 2030 while ensuring that 60 percent of plastic packaging will be reused or recycled.

This is the first time the government has set such numerical targets to deal with the pollution scourge. The targets should be achieved through a well-planned, energetic policy drive.

Paal Kibsgaard, CEO of Schlumberger, said that in addition to a shortage of pipeline capacity that was slowing growth in the Permian Basin of Texas and New Mexico, the heart of the US shale boom, there were other problems that could mean some forecasts of future output would have to be revised down.

-Motan Innovation Awards winner announced

The Motan Colortronic Innovation Award was handed in great ceremony to this year’s winner at a glittering event at the Dornier Museum in Friedrichshafen on the occasion of Fakuma 2018.

The shortlist for the Innovation Award included affiliates and employees of Motan Colortronic across the generations: Stefan Endres (Adaptive central vacuum control; Objective: More efficient plant utilisation and higher production security), Peter Haupt (Regulated transport of bulk goods; Objective: To measure speed and optimise promotion processes), Reinhard Herro (GAK system [gravimetric suction box]; Objective: Automation, control and monitoring of suction conveyor systems), Philipp Mählmeyer (system control on a mobile device; Objective: Query status information specifically via QR codes), Bernd Michael (System METRO-Lay; Objective: Efficient creation of routes for material and vacuum lines), and Karl Wolfgang (Repeater; Objective: Material-protection conveying in the vacuum area).

Digitalisation, industry 4.0, the Circular Economy and the skills gap were prevailing themes at Fakuma 2018 and the inspiration behind choosing this year’s winner had to be mindful of all of these trends affecting plastics now and for a long time yet to come.

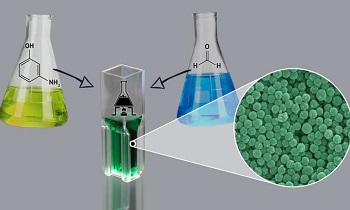

-Chemists develop method to obtain catalyst-, surfactant- and template-free polymeric nanoparticles

A chemist from RUDN proposes a simple technology for producing polymeric nanoparticles from only two organic substances. By changing the temperature of the reaction and the ratio of initial substances, the scientists can obtain particles of any given size. The new method was described in Macromolecules.

To create nanoparticles of identical size and shape, laboratories all over the world have been using the synthesis of benzonaxine group polymers from different monomers. Usually, polymerization and formation of homogeneous nanoparticles require special templates, catalysts and additions. Rafael Luque, a visiting scholar at RUDN, together with his colleagues from China and Pakistan, suggested a simple method for obtaining nanoparticles.

-Open Letter on the Benefits of Plastics

We live in the plastic age and various excellent impacts on our life and planet continue to come from plastics.

‘Plastics’ covers a remarkable set of families of materials which we in the Polymer IRC research laboratories at the University of Bradford are helping to develop further.

Typically we use the manufacturing process to develop improved properties in plastics so achieving a ‘double whammy’ of making precision items and enhancing their properties at the same time. This has opened up new markets worldwide.

Some examples are products made by exploiting in a controlled way orientation of the molecules which make up solid plastics.

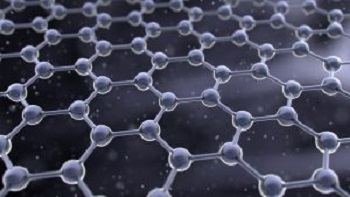

-Can Graphene Be Mass Manufactured?

Since the isolation of graphene in 2004, the high mobility and unique transport properties of 2-dimensional semiconductors have tantalized physicists and materials scientists. Their in-plane carrier transport and lack of dangling bonds potentially can minimize line/edge scattering and other effects of extreme scaling.Graphene Mass Manufactured nano sheet stacks

While 2-D materials cannot compete with silicon at current device dimensions, their performance may degrade less quickly as feature sizes shrink. According to Iuliana Radu, distingished member of the technical staff at Imec, 2-D semiconductors may be the only alternative for sub-15 nm devices.

-US Government Promotes Foam Made From Lignin

Carbon foam — a stiff, porous structure formed from a web of carbon atoms — is the stuff of manufacturers’ dreams. The breakthrough material is strong but lightweight, non-flammable and able to maintain its performance at high temperatures, and capable of absorbing sound and radiation. This unique combination of traits means carbon foam is brimming with potential applications across military, aerospace, and commercial industries. It is ideal for aircraft and ship insulation, wall panels, stealth technology (to avoid radar detection) and more.

However, developing this extraordinary technology is not without challenges. It can be difficult for manufacturers to produce a strong, lightweight, environmentally-friendly carbon foam while keeping costs low.

-Huvis Indorama Advanced Materials Launching Operations In Spartanburg

Huvis Indorama Advanced Materials, a 50-50 joint venture between Indorama Ventures Public Company Limited and South Korea-based Huvis Corporation, is launching new manufacturing operations at Auriga Polymers, Inc.’s campus in Spartanburg County. The $48 million investment is projected to create 50 new jobs.

-Showcases Portfolio of Silicone Masterbatches at Fakuma

Dow Performance Silicones, a global business unit of DowDuPont Specialties Products division, is exhibiting at Fakuma 2018 at Nexeo Solutions’ stand (#A3-3217), its broad portfolio of silicone-based masterbatches for polyethylene (PE), polypropylene (PP), polyamide (PA) and polycarbonate/acrylonitrile-butadiene-styrene (PC/ABS) resins and compounds.

These industry-leading solutions have been engineered to enhance processing, extend properties and reinforce materials to address the latest trends in a range of industry applications, including flexible food and non-food packaging, automotive interior and under-hood components, wire & cable insulation and jacketing, and appliance gears and other high-wear parts.

Dow Performance Silicones continues to expand its portfolio with new, differentiated solutions, such as its new DOW CORNING™ MB25-235 Masterbatch for form-fill-seal (FFS) packaging production, being launched today at Fakuma.

![]()

Solvay Performance Polyamides has announced that manufacturer of cleaning technology Kärcher is using Technyl 4earth high-quality environmental solution.

The recycled polyamide is now the material of choice for moulding spray lances of Kärcher’s high-pressure cleaners.

Technyl 4earth is a range of PA6.6 engineering plastics born out of the Move4earth project supported by the European Commission (LIFE+ program).

A patented process transforms stable sources of technical fabrics, such as automotive airbag cushions, into prime quality polyamide.

-Dow Silvadur Finish Gets Certification

Dow Microbial Control, a global business unit of DowDuPont Specialty Products Division, has announced its patented anti-microbial technology for textiles and apparel called Dow Silvadur Antimicrobials has been certified by the Bluesign system.

The Collegeville, Pennsylvania-based company says this is an important indication to manufacturers of the technology’s safety.

Silvadur is a fabric finish that can be used on ticking. It is applied either through padding, exhaustion or spray methods.

Managed by St. Gallen, Switzerland-based Bluesign Technologies AG, the Bluesign system is a solution for a sustainable textile production.

According to its website, the system “eliminates harmful substances right from the beginning of the manufacturing process and sets and controls standards for an environmentally friendly and safe production.”

-Milacron launches new advanced thinwall Packaging Hot Runner System at Fakuma 2018

At Fakuma 2018, Milacron’s Mold-Masters product brand has launched a new advanced thinwall packaging hot runner system – ThinPAK, and is exhibiting new hot runner technologies.

The Mold-Masters ThinPAK-Series hot runner has been specifically engineered for producing exceptionally high-quality thin wall packaging products. ThinPAK-Series has the strength and durability to mold with complete reliability even in high pressure applications up to 2,800 bar.

-Can carbon fiber car panels double as energy storage materials?

Carbon fiber as we know it is one of the most impressive materials in our toolkit. Its incredible lightness and strength has seen it take hold in everything from competitive cycling, to supercar design to cutting edge aircraft.

But could it also play a role in energy storage? One team of scientists has been exploring the possibilities, and say that carefully engineered forms of the material do indeed boast the necessary electrochemical properties, raising some interesting possibilities for weight-saving vehicle design.