Plastic petrochemicals rPET circular economy 07-12-2018 - Arhive

-China – Polyethylene Terephthalate

PET and its chain are in good health.

PET Bottle grade export 1,060/1,100 $/ton – PET Bottle grade domestic market 8,500/8,600 yuan/ton – PET Filament grade SD domestic market 8,050/8,150 yuan/ton – PET Filament grade BR domestic market 8,100/8,200 yuan/ton

PTA Taiwan 850/860 $/ton – PTA domestic market 6,650/6,750 yuan/ton – MEG $ 715/730 $/ton – MEG domestic market 5,850/6,000 yuan/ton – PX Korea 1,025/1,040 $/ton

POY 150D/48F domestic market 8,500/8,650 yuan/ton – DTY 150D/48F domestic market 10,350/10,450 yuan/ton – PSF domestic market 8,900/9,000 yuan/ton

The spot prices for monoethylene glycol (MEG) in the European market continue to go down this week after a significant drop in the December contract price of ethylene, ICIS said . Monoethylene glycol MEG prices Europe

The negotiations on the December contract price of MEG have not yet gained full force, but prices are expected to decline on the contract market.

-Crude Oil Prices Trend

Hanwha Total Petrochemical, a 50/50 joint venture between Total and Hanwha, will invest nearly $500 million to further expand its Daesan integrated refining and petrochemical complex in South Korea Hanwha Total Petrochemical, a 50/50 joint venture between Total and Hanwha, will invest nearly $500 million to further expand its Daesan integrated refining and petrochemical complex in South Korea

-US to investigate polyester yarn from China, India

The US International Trade Commission (USITC) has determined that there is a reasonable indication that the US industry is materially injured by reason of imports of polyester textured yarn from China and India that are allegedly subsidised and sold in the United States at less than fair value.

The US department of commerce will continue its investigations.

“As a result of USITC’s affirmative determinations, the US department of commerce will continue with its antidumping and countervailing duty investigations concerning imports of this product from China and India, with its preliminary countervailing duty determinations due on or about January 11, 2019, and its preliminary antidumping duty determinations due on or about March 27, 2019,” USITC said on its website.

-US PET resin makers appeal anti-dumping decision

Three U.S. PET resin makers are appealing a federal decision that declined to place anti-dumping duties on PET imported from five countries.

DAK Americas LLC, Indorama Ventures USA Inc., and Nan Ya Plastics Corp. America filed the appeal Nov. 30 with the U.S. Court of International Trade.

The domestic producers have requested the court’s review of the U.S. International Trade Commission’s Oct. 18 ruling that the U.S. industry was not damaged or threatened by PET imported from Brazil, Indonesia, South Korea, Pakistan and Taiwan.

-Coats invests in revolutionary sustainable digital thread dyeing technology

Coats, the world’s leading industrial thread manufacturer, has become a strategic investor in Twine Solutions, an Israeli based technology start-up which has developed a revolutionary digital thread dyeing system.

Coats is investing $5m for a 9.5% share in the company and a seat on the Board.

Twine has created the world’s first standalone digital thread dyeing system which applies the features of small scale digital printing to the traditional dyeing process. The plug and play machine dyes thread using digital printing technology and can produce any length and colour, whenever or wherever they are needed. The technology is based on waterless dyeing and will feature inbuilt colour software integrated with Coats ColourStitch.

-UK, Europe chemicals face more uncertainty amid Brexit parliamentary chaos

The UK chemical industry and its trading partners face more uncertainty about the eventual format of Brexit as the government suffered a series of defeats in parliament ahead of a crucial vote to approve the deal on offer.

After three votes against the government on 4 December, UK Prime Minister Theresa May’s deal, approved last weekend by the EU, now looks more likely to be thrown out by members of parliament in a vote on Tuesday 11 December.

If it is rejected, the entire Brexit process could be thrown into disarray. With the likelihood of a disorderly ‘no deal’ Brexit now increasing, the industry could be left in a regulatory vacuum without time to recreate or find a replacement for the Reach regulation which governs trade in chemicals across the EU.

-Gore to unveil new PFC-free DWR products

The new PFCEC Free DWR has been on the market with Gore-Tex 2-Layer products since A/W18. © W. L. Gore & AssociatesW. L. Gore & Associates will unveil its new Gore-Tex 3-Layer laminate at ISPO 2019 in Munich, from 3-6 February 2019.

The launch of this innovative product is the next step in Gore’s journey to develop fit-for-use performance fabric offerings that improve the environmental footprint of outdoor apparel, while meeting expectations regarding durable comfort and protection.

-SABIC signs MoU with UK-based Plastic Energy for recycled feedstocks supply

SABIC has signed a memorandum of understanding (MoU) with UK-based Plastic Energy Ltd., a pioneer in chemical plastics recycling, for the supply of feedstock to support SABIC’s petrochemical operations in Europe.

The companies intend tobuild a first commercial plant in the Netherlands to refine and upgrade a valuable feedstock, known as TACOIL, which will be produced from the recycling of low quality, mixed plastic waste otherwise destined for incineration or landfill.

-Prime giant to install pyrolysis plant

Bales of mixed plastics for recycling.SABIC, one of the world’s largest chemicals producers, will install a demonstration unit to recycle mixed plastics into feedstock for crackers.

Saudi Basic Industries Corp. (SABIC), a publicly owned manufacturer of plastics and various other chemical products based in Saudi Arabia, will install the demonstration unit at its facility in The Netherlands, according to chemical industry journal ICIS.

Abdulrahman Al-Fageeh, SABIC’s executive vice president of petrochemicals, told ICIS the plant would produce a pyrolysis oil from contaminated, mixed-streams of plastics otherwise headed for incineration or landfill. The final product will serve as feedstock for the company’s European crackers, which are units that break molecules to create new products.

-How a materials recovery facility will sort flexible plastics

Inside of the materials recovery facility.Flexible packaging isn’t going away anytime soon, and an upcoming pilot project seeks to ensure it doesn’t go to landfill.

In coming months, additional sorting equipment will be installed at the TotalRecycle materials recovery facility (MRF) in Birdsboro, Pa. The retrofit will allow the facility to begin generating bales of post-consumer flexible packaging, defined as single-layer or multi-material films such as chip bags, stand-up pouches, candy wrappers, retail bags and more.

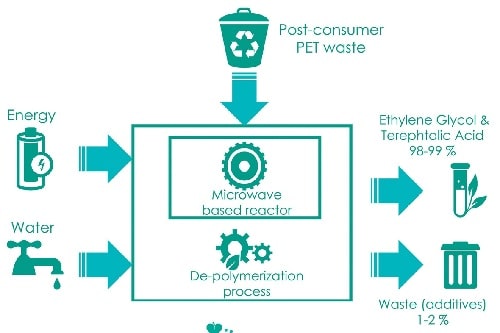

-Not so difficult after all: microwaves target PET

Contaminated and composite plastics in the waste stream – such as food trays, opaque bottles and textiles containing polyester – are currently in the ‘difficult’ or even ‘impossible’ to recycle category.

Much of this material ends up in landfill or incineration after being discarded, which removes it from the materials cycle for ever.

-Europe PE Dec prices down sharply on feedstocks, but producers aim to retain margin

European polyethylene (PE) prices are dropping for December, but the amount of the price decrease in freely negotiated accounts is not yet clear.

“I’ve been offered minus 50 [€/tonne],” said a buyer, “but it should end up more than that.”

Ethylene-linked deals will automatically drop by €110/tonne, in line with the drop in the December ethylene contract.

However, most producers are trying to hold on to some margin, and for the moment it looks as though they will be at least partially successful.

-US crude oil reserves rise to record despite production boom

US crude oil reserves hit record levels at the end of 2017, as annual reserve additions outstripped production for the eighth time in nine years, government data published last week shows.

Reserve growth is the main reason predictions about future oil shortages have been repeatedly proved wrong.

US policymakers have long fretted about the damage to the economy and national security of exhausting domestic oil reserves (“Oil scarcity ideology in US national security policy”, Stern, 2012).

-Prices rise for some recycled resins

Average selling prices for several grades of recycled resins have increased in North America since July, as more processors use the materials to meet sustainability goals set by their customers.

Regional prices for post-consumer, natural-color high density polyethylene pellets have seen prices increase by 10 cents per pound, according to market sources contacted by Plastics News. Prices for clear, post-consumer PET pellets and for recycled polypropylene flake each are up an average of 5 cents per pound.

-SOCAR lets contract for Baku refinery revamp

State Oil Co. of Azerbaijan Republic (SOCAR) has let a contract to Honeywell UOP LLC to provide technology to support modernization and expansion works under way at the Heydar Aliyev refinery at Baku.

Honeywell UOP will deliver technology licensing for its proprietary pressure-swing adsorption (PSA) technology for two PSA units at the refinery, both of which will be controlled by Honeywell Process Solutions C300 distributed control systems, the service provider said.

The new units—which will supply high-quality hydrogen at the site and help Azerbaijan meet growing domestic demand for transportation fuels meeting Euro 5 standards—come as part of SOCAR’s Heydar Aliyev modernization and upgrading program that aims by 2021 to expand crude capacity to 150,600 b/d from 120,500 b/d (OGJ Online, June 9, 2017).