Plastic-recycling- Possibility-recession 16-06-2022 - Arhive

Plastic-recycling- Possibility-recession

Crude Oil Prices Trend

-Can advanced recycling support flexible packaging’s quest for circularity?

Sreeparna Das spoke to Bob Powell, CEO of Brightmark, to understand the role advanced recycling – also known as chemical recycling – can play in supporting the demands of the flexible packaging sector, the key growth areas, and the existing challenges to scaling up advanced recycling.

As demand for more recycled content, commitment to meet environmental objectives and consumer expectations converge, significant increases in recycling capacities are needed. Advanced recycling is a pathway receiving significant capital investment and seeing numerous high-profile partnerships emerge. Plastic-recycling- Possibility-recession

Brightmark has signed a memorandum of understanding with bp to jointly evaluate opportunities to develop next generation plastics renewal plants in Belgium, Germany and the Netherlands; and recently become ISCC+ certified and active in CEFLEX to work more closely across the whole flexible packaging value chain.

SD: Can you shed some light on recycling choices and the possible pathways to a circular economy?

BP: There are a number of steps on a mission to reimagine waste and hopefully, in the end, create a world without waste. Thinking of this as ‘it takes a village’ is really important here. Reduction in use is one of the important solutions and we advocate the reduction of plastic waste by lowering consumption. And before post-consumer plastic products get to us, there need to be the right incentives and the ecosystem in place to avoid plastics entering the environment.

Specific to mechanical or advanced recycling pathways, an important aspect is to determine how much of the post-use waste stream can each technology process in the most efficient way. There is a high value in mechanical recycling of plastic waste streams like water bottles – and in reference to the one to seven plastic categories – the ones, some of the twos, and some of the fours.

Specific to mechanical or advanced recycling pathways, an important aspect is to determine how much of the post-use waste stream can each technology process in the most efficient way. There is a high value in mechanical recycling of plastic waste streams like water bottles – and in reference to the one to seven plastic categories – the ones, some of the twos, and some of the fours. Plastic-recycling- Possibility-recession

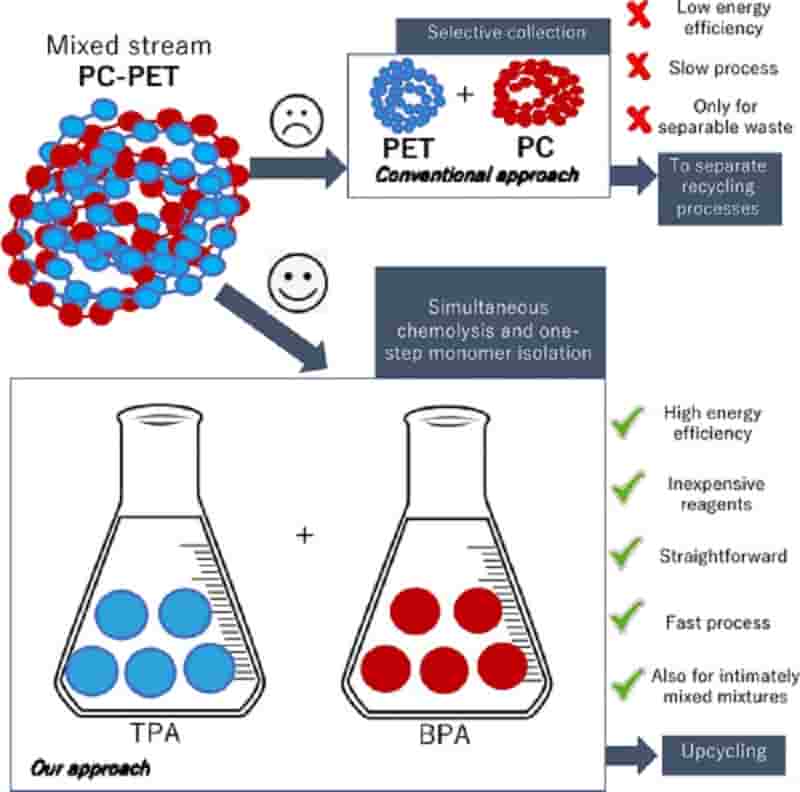

Going the simplest way: Easy, fast, inexpensive and energy efficient depolymerization of mixed streams of PC and PET, to obtain pure TPA and BPA is carried out in a one-step process. The combination of a strong depolymerization agent with microwaves in tightly sealed vessels and a simple separation of products abolishes the need for selective collection and separable waste. Plastic-recycling- Possibility-recession

Mixed plastic waste-streams are a main obstacle to a more extensive implementation of polymer recycling. Separating mixed-plastic waste streams demands time and effort at collection or in the recycling plant, while many products consist of multiple polymers that cannot be readily separated. Chemical recycling could provide the key to overcome this issue by targeting specific chemical bonds, enabling selective depolymerization of a single polymer class in a mixture.

This work explores the depolymerization of polycarbonate (PC) and polyethylene terephthalate (PET) in separate and in mixed streams.

Selective depolymerization of mixed streams composed of PET and PC and one-step separation of their constituent monomers are carried out with outstanding energy efficiency through an inexpensive KOH-in-methanol hydrolysis (KMH) process developed for instantaneous PET hydrolysis.

The activation energies for depolymerization of PC and PET pellets are 68.6 and 131.4 kJ mol−1, respectively.

Randomly mixed streams are fully depolymerized within 2 min at 120 °C using 30 mL of depolymerization solution per gram of polymer. Plastic-recycling- Possibility-recession

The separation of bisphenol A and terephthalic acid is demonstrated in a one-step separation process, yielding 98 and 97 % purity without any secondary reactions detected.

-Netstal establishes subsidiary in Italy and appoints Alberto Rossi as Managing Director

Alberto Rossi has taken over the position of Managing Director at the recently re-established subsidiary Netstal Italia S.r.l. Alberto Rossi thus indirectly succeeds Andrea Bottelli, who had successfully built up the former Netstal Italia S.r.l. since 1995 and then further developed the Italian market for both brands as Managing Director of KraussMaffei Italia from 2013 to 2020. From the new location in Gerenzano (VA), Alberto Rossi and his team will provide support to customers throughout Italy.Plastic-recycling- Possibility-recession

Alberto Rossi has more than 30 years of experience in various roles with several market players in the plastics industry. His career began with a leading international manufacturer of plastic packaging, where he first encountered Netstal injection moulding machines to produce PET preforms and closures as a production engineer. From 1999 to 2008, he served as a sales and service engineer at Netstal Italia. After a stopover as Production Manager at a Netstal customer, he returned to KraussMaffei Italia in 2016 and acted in the same function for both the KraussMaffei brand and Netstal.

“I am honored to continue the work of Andrea Bottelli, who laid the foundation in Italy for the further development of our great brand. We want to ensure that all customers and potential new customers appreciate the performance of our machines through greater innovation, which can add value to our customers’ budgets through lower production costs. The added value of our service and consultancy will bring many benefits to those who choose us as a partner. The continuous evolution of the market, which demands ever faster cycles, highest precision, stable high-performance, as well as low energy consumption, will be the key to a future of continuous growth in the Italian market”, says Alberto Rossi.Plastic-recycling- Possibility-recession

Renzo Davatz, CEO of Netstal and member of the Executive Committee of the KraussMaffei Group, states: “Building a subsidiary is one thing. Handing over a healthy foundation with a stable customer base to the next generation is another thing. And that is exactly what Andrea Bottelli has done successfully. I am very pleased that Alberto Rossi is now taking over Andrea’s legacy and will further develop the company together. Alberto and his experienced team will continue to support all our customers in Italy with the same spirit that Andrea has given them over many years. We are delighted that the successful history of Netstal Italia is now writing a new chapter.”Plastic-recycling- Possibility-recession

-Berry’s PCR Initiatives Support Customer Sustainability Objectives

Berry has announced a number of initiatives both to support its customers’ sustainability goals and to help them meet the requirements of the UK Plastic Packaging Tax.

The company says that the majority of its standard products have now been tested and qualified incorporating a minimum of 30% post-consumer recycled (PCR) plastic. Berry is also working closely with its customers to support the incorporation of PCR into their specific productsPlastic-recycling- Possibility-recession

Both moves will be further supported later this year by the availability of additional quality rPP mechanical recycled FDA grade material through the establishment of a new Berry Global polymer recycling unit in the UK.

The new facility employs the company’s proprietary CleanStream® technology, which delivers a closed-loop system to mechanically process domestically recovered household waste polypropylene back into consumer packaging. Used plastics are washed, sorted and sifted to produce food-grade materials with a remarkable target purity standard of 99.9%.

These latest developments are in line with Berry Global’s published Impact 2025 sustainability strategy which aims to work with customers to support all aspects of their sustainability objectives, focusing on areas including product design, material selection, recycling and manufacturing excellence.Plastic-recycling- Possibility-recession

The ability to incorporate at least 30% PCR into packs, meanwhile, will provide exemption to the Plastic Packaging Tax, which was introduced into the UK in April on all plastic packaging either manufactured or imported into the UK.

-SK’s LG Chem, GS EPS partner on biomass plant

South Korean chemicals firm LG Chem has signed a letter of intent with domestic independent power producer (IPP) GS EPS to work together on a biomass-based eco-friendly energy project.Plastic-recycling- Possibility-recession

Both companies will work towards the construction of a joint wood-based biomass plant at a Yeosu complex on South Korea’s southern coast in 2025. The proposed power plant plans to use waste wood to produce industrial steam and electricity.

Both companies will also collaborate on establishing a power purchase agreement for renewable energy with Korea Power Exchange, the agency under the Ministry of Trade, Industry and Energy (Motie) responsible for the country’s electric power system, as well as look into more opportunities in the renewable energy sector.

South Korea’s biomass market is expecting to see growing demand for woody biomass as the government has adopted a more aggressive stance on renewable energy. Motie plans to raise the country’s renewable portfolio standard (RPS) to 25pc in 2026 from 2022’s 12.5pc. Plastic-recycling- Possibility-recession

-Possibility of recession weighs heavy on Europe chemicals distribution sector

European chemicals distributors face tough times in coming months as consumer demand is weighed down by ever-increasing prices, with the sector bracing for a negative impact.

Chemicals supply chain executives discussed the issue at a roundtable conducted by ICIS and the European Association of Chemical Distributors (FECC) on Monday, where speakers discussed logistics and supply chain pressures.Plastic-recycling- Possibility-recession

“It’s probably true that we’re going to be heading into some kind of recession, however big, long, or short, the recession that might be, said , Phillip Gibbons, CEO at UK-headquarted chemicals distributor Cornelius.

“And, obviously, that will impinge on demand. I suspect some of us might even have seen one or two early signs of that happening. So, it’s going to be a case of making sure that you look after the fundamentals of your business during a tougher economic time.”

Meanwhile, the managing director of Germany’s IMCD Group, Lars Wallstein, concurred that rising costs are set to have an impact on demand, although conceded it is hard to know how consumers will respond to the high-inflation environment.

“Inflation was driven by energy [in previous months] but it has now moved through to the production processes … And it is here to stay for some time,” said Wallstein.

“Because it is not only about transportation and our prices, but also about the services sectors and a serious lack of competition.”Plastic-recycling- Possibility-recession

IMPORTS

As a net importer, Europe could be at particular risk from not receiving materials made in other regions, due to fraught supply chains, with China as the dominant region for chemicals production.

Andreas Frueh, CEO at Germany’s TER Chemicals Distribution Group, said that while Europe owns its dependency on China for production, several things would need to change to make Europe’s independence in sourcing raw materials a reality.

“In the long-term, we are looking for alternative suppliers [to China]. But in a short-term perspective, we should be in a place of restocking of material again to avoid shortages, so our customers have the security that we are able to supply them if needed,” said Frueh.

-Borealis help Uponor create the first cross-linked polyethylene pipes

In line with its EverMinds initiatives to work with partners along the value chain and accelerate action on circularity, Borealis has been collaborating with pipe specialist Uponor to enhance the sustainability of cross-linked polyethylene (PE-X) pipes.

The resulting PEX Pipe Blue is the world’s first pipe portfolio made from PEX with renewable feedstock accredited by mass balance accounting under the International Sustainability & Carbon Certification Plus (ISCC PLUS) scheme.

Based on Borealis’ Bornewables polyethylene (PE) derived from second-generation natural resources, such as waste from pulp production or residues from food processing oils, the new PEX Pipe Blue products boast an unprecedented carbon footprint reduction of up to 90% when compared to conventional fossil-based PE-X pipes.

This also marks a major step forward to help customers in the building and construction industry achieve their sustainability targets in plumbing, heating, ventilation and air-conditioning (HVAC) installations.Plastic-recycling- Possibility-recession

At the same time, it serves as an outstanding example of Borealis’ and Borouge’s commitment to pipe solutions ‘Enabling life’s essentials’.

Setting a new industry standard with Bornewables

Since introducing PE-X pipes to the world 50 years ago, Uponor has continuously improved their product offering and processes. “The fact that we can now offer our customers 100% renewable based PEX Pipe Blue means that they can greatly reduce the climate footprint of their installations and meet tomorrow’s regulations for a more circular and renewable construction industry, today”, explains Robert Molund, managing director, Uponor AB. “With the use of Bornewables feedstock and the huge CO2 reduction opportunity, we are convinced that PEX Pipe Blue will soon be the new reference standard in this important market.”Plastic-recycling- Possibility-recession

-European recyclers warn of plastics shortage

Too little sorted plastic waste is available to meet demand from recyclers across Europe, trade body Plastics Recyclers Europe (PRE) has warned.

It said too much plastic went to incineration or landfill and said it would be “critical” to divert more material to recyclers.

President Ton Emans said: “This situation could slow down the transition towards a full plastic circularity.”Plastic-recycling- Possibility-recession

He said recent EU policy and global developments had boosted investments in plastic recycling capacities on the continent, and in 2020 the plastic recycling industry invested €1.5bn giving a total of €4.9bn (£4.2bn) since 2017.

This was equivalent to 1.1 million tonnes of additional installed capacity, he said.

But without stable, high-quality input materials “the industry’s efforts to reach the new recycling targets might be hindered”, Emans warned.

“Robust sorting and collection infrastructure is a must to increase stable feedstocks for European recyclers.”

The dearth of plastic had been unexpected as the EU had for several years registered a decline in waste exports driven by China’s ban on waste imports and the strengthening of controls in the Basel Convention.

PRE said that despite these developments and an increase in the price of sorted material, “no substantial additional quantities of waste are being sent to recyclers today”

It said some 9.0 million tonnes of plastic waste was collected for sorting out of a 30.0 million tonnes total and the remaining 21.0 million tonnes was either incinerated or landfilled.Plastic-recycling- Possibility-recession

Plastic-recycling- Possibility-recession