Plastic-Waste – Packaging – rPET 20-12-202 - Arhive

Plastic-Waste – Packaging – rPET

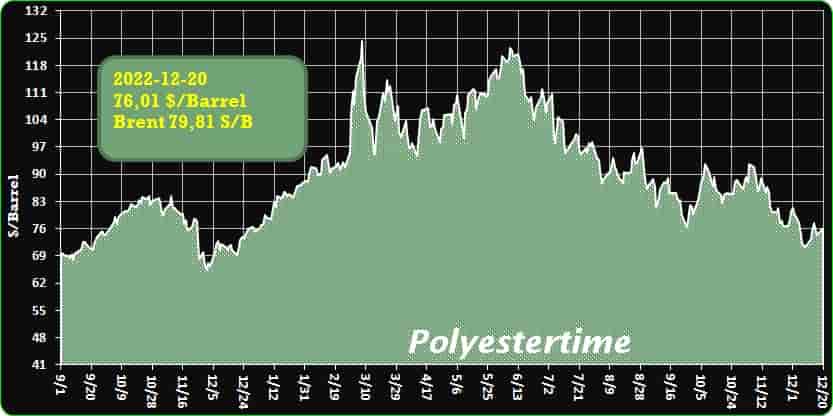

Crude Oil Prices Trend

Crude Oil Prices Trend Polyestertime

-PLASTICS CEO Seaholm Urges Congress to Partner with Industry to Combat Plastic Waste

The core problem is that recycling rates are too low, said Seaholm, and the solution is to build a robust recycling infrastructure, not eliminate plastics.

Matt Seaholm, President and CEO of the Plastics Industry Association (PLASTICS), defended the industry and proposed solutions to the plastic waste problem in his testimony to Congress on Thursday, Dec. 15. His testimony was in response to “unfair and poorly informed” legislation introduced Dec. 1 by two US senators and two members of the US House of Representatives, which the industry previously addressed.

His testimony was to the US Senate Committee on Environmental and Public Works. The hearing was titled, “Examining the Impact of Plastic Use and Identifying Solutions for Reducing Plastic Waste.”

“There’s a saying in our industry: We love plastic; we hate plastic waste,” Seaholm said. “Any molecule of plastic material that leaves the economy is truly a waste. We need to collect, sort, and ultimately reprocess more material. And that goes for all substrates, not just plastic.” Plastic-Waste – Packaging – rPET

Seaholm provided five examples of plastics that help save lives, including plastic fibers in vehicle airbags; diabetics who rely on sterile, interchangeable plastics that support treatments for loss of kidney function; and hurricane-ravaged neighborhoods without safe drinking water that rely on delivery of water in plastic bottles.

“The list can go on and on, and before it’s suggested these aren’t the types of applications truly at the heart of the discussion, I would point to three proposed pieces of legislation in this Congress that call for the stoppage of production of the plastics used in each of these scenarios,” Seaholm said. “If there’s one thing a pandemic and now a war on the European continent has taught us, stable supply chains are imperative. Producing plastic in America is a good thing that I believe should be embraced as essential, not abruptly stopped.”

Plastic is the preferred material in many applications because of its outstanding performance and because it uses the fewest number of resources to manufacture and transport, he said.

“However, we must also acknowledge that the incredible innovations in plastic materials and products have outpaced our ability to recycle them because infrastructure has not kept up,” Seaholm said. “Our nation’s recycling rates are too low. That is why companies across our supply chain work tirelessly to improve recyclability and invest billions of dollars in the prevention of waste and the technologies to recycle. However, our industry does not control the entire value chain of recycling in America and that is why we need partners to help get these rates where we all want them.”

He said Congress is an important partner in this process and he made the following policy suggestions:

- Increase investment in critical recycling infrastructure to ensure that collection, sorting, and processing can keep up with the complexities of all materials in the marketplace.

- Promote end-market development for the variety of plastic resins to ensure demand remains for recycled materials. Reasonable and attainable recycled content requirements can help spur investment and guarantee markets for recyclable material.

- Encourage innovations in recycling technologies to ensure materials that cannot economically be recovered through traditional methods can still be recycled, moving toward a more circular economy.

- Avoid stifling innovation and promising new technologies that are needed.

“There is already real value in post-consumer plastic. These policies will help us better capture it and keep it in our economy,” Seaholm said. “Plastic is essential. Plain and simple. We need it in our lives. But America does not recycle enough of it. Our industry wants to recycle more. Working together I know we can get these rates up. And “together” is the most important word in that sentence. I hope that is the spirit of today’s discussion.”

Other testimonials

Also testifying before Congress Thursday were Eric Hartz, co-founder and President of Nexus Circular; John Peterson “Pete” Myers, PhD, founder, CEO, and Chief Scientist at Environmental Health Sciences; and Judith Enck, President of Beyond Plastics.

Hartz said Nexus Circular is a molecular recycling business based in the Atlanta area that processes hard to recycle plastics, including films, into virgin-equivalent plastics.

After light sorting for suitability, all plastics can be mixed together and heat is used to depolymerize plastics and convert them into liquids that can be reused, he said.

“There is no burning, gasification, or incineration,” Hartz said. While some people equate this to incineration, that’s not correct because this process would fail with oxygen present.

“Our facility meets all state and federal laws. I invite you to visit us.” He added that this type of advanced recycling complements mechanical recycling, which melts and reforms plastics, and both methods are needed to address the plastic waste problem.

Myers said that plastics and the additives that are infused into plastics, are a huge source of endocrine-disrupting chemicals (EDCs) that get into the air, soil, and water and when ingested interfere with the normal function of a body’s endocrine system.

EDCs “hack hormone signaling” and cause a variety of serious health issues, including an increase in infertility and autism, he said. They also have been linked to an increase in cancer rates and immune disorders, he added.

Myers encouraged Congress to begin a testing program for the chemicals that are infused into plastics. Plastic-Waste – Packaging – rPET

Enck said plastics are part of the climate change issue, and in the next decade, greenhouse-gas emissions from plastics will exceed that of coal.

“Recycling has been an abysmal failure because less than 10% of plastics are recycled,” she said. “We don’t need a magical breakthrough. We need less plastic production and refill and reuse.

-Reduced costs of naphtha and LPG led to an increase in the profitability of MEGs in Europe

Lower costs for naphtha and liquefied petroleum gas have led to an increase in the profitability of MEG production in Europe, ICIS reports.

The margin of monoethylene glycol (MEG) production in Europe rose last week due to lower prices for raw materials. Despite the improvement in the situation, manufacturers using naphtha as a raw material are still operating on negative margins.

So, last week, the cost of naphtha decreased by 7%, and the cost of liquefied petroleum gas (LPG) decreased by almost 11%. The margin of MEG contracts based on naphtha went to minus USD124 per ton. The margin of MEG contracts based on liquefied petroleum gas almost tripled to USD132 per ton. Plastic-Waste – Packaging – rPET

Spot MEG prices in Europe declined as demand remained low. Meg’s December contract remains uncoordinated after the first agreement for a November contract appeared two weeks ago.

Earlier it was reported that MEGlobal, the world leader in the production of monoethylene glycol (MEG) and diethylene glycol (DG), nominated the January contract price of MEG for Asia at USD820 per ton, which is USD20 per ton higher than in December.

MEG, along with terephthalic acid (TPA), is one of the main raw materials for the production of polyethylene terephthalate (PET).

According to the SknaPlast review, the estimated consumption of PET in September of this year increased by 32% compared to a year earlier and amounted to 78.81 thousand tons. According to the results of the first nine months of this year, 621.61 thousand tons of PET were processed in Russia, which is 1% more than the same indicator in 2021.

-Unique Crude-to-Chemicals Technology Set to Deploy in First Commercial Development

Innovative technology will help operators meet their needs for lower carbon footprint and greater energy efficiency, and adapt to the evolving petrochemical market

Lummus Technology, a global provider of process technologies and value-driven energy solutions, today announced that its licensed TC2CTM crude-to-chemicals technology will move forward in its first commercial deployment through S-Oil’s Shaheen Project in South Korea.

S-Oil recently confirmed its final investment decision on the Shaheen Project. Once complete, Shaheen will be one of the world’s largest ethylene plants and the first commercial deployment of TC2C, a breakthrough technology that transforms whole crude into value-added chemicals.

“TC2C increases chemical yield more than any other crude-to-chemicals technology currently under development, while also enhancing energy efficiency, reducing carbon intensity and lowering operating costs,” said Leon de Bruyn, President and Chief Executive Officer of Lummus Technology. “As we reach milestones such as S-Oil’s final investment decision, we are grateful for our partnership with Saudi Aramco Technologies Company and Chevron Lummus Global. These milestones put us closer to revolutionizing petrochemical production and transitioning to more sustainable processes.”

S-Oil’s new plant will deploy several Lummus and Chevron Lummus Global (CLG) technologies to process crude to produce ethylene, propylene, butadiene and other basic chemicals. Upon completion, the plant will have an annual production capacity of up to 3.2 million tons of petrochemicals.

TC2C converts crude into value-added chemicals in a uniquely integrated process combining Lummus’ ethylene technology with Saudi Aramco’s separation and catalyst technologies and CLG’s hydroprocessing catalysts and reactor technologies. TC2C maximizes conversion of crude at lower carbon intensity, higher energy efficiency and lower capital than conventional refinery/petrochemical complexes. Unlike any other crude-to-chemicals technology, TC2C processes low-value refinery streams such as slurry oil and pyrolysis oil, and it can be tailored to maximize olefins, aromatics or any combination.

Saudi Aramco is the majority shareholder of S-Oil. In 2018, Saudi Aramco Technologies Company, Lummus and CLG entered into the joint development agreement for the development, commercialization and marketing of TC2C.

About Lummus Technology

Lummus Technology is the global leader in developing process technologies that make modern life possible and focus on a more sustainable, low carbon future. Lummus is a master licensor of clean energy, petrochemical, refining, gas processing and renewable technologies, and a supplier of catalysts, proprietary equipment, digitalization and related lifecycle services to customers worldwide. To learn more about Lummus, visit www.LummusTechnology.com.

About Chevron Lummus Global

Chevron Lummus Global (CLG), a joint venture between Chevron U.S.A. Inc. and Lummus Technology, is a leading process technology licensor for refining hydroprocessing technologies and alternative source fuels, as well as a global leader in catalyst system supply. CLG offers the most complete bottom-of-the-barrel solution for upgrading heavy oil residues. Our research and development experts are continuously seeking advancements in technology and catalysts that will improve operating economics for your next project. For more information, visit www.chevronlummus.com.

Contacts:

Lummus Technology

Matt Braud

Marketing and Communications, Lummus Technology

+1 281 368 3116 (direct)

+1 225 335 3392 (cell)

-Puncture-proof tyres made from plastic bottles tested in Singapore

That yogurt cup or disposable plastic bottle you put in the recycle bin today could return as a new puncture-proof tyre, and Singapore is playing a part in its development.

French tyre company, Michelin, is testing this prototype technology here in partnership with logistics company DHL Express.

Michelin, which aims to start selling these puncture-proof tyres in 2024, said motorists will not have to worry about the impact of road conditions on the tyres, or about risks such as losing control of the vehicle or stopping by the roadside because of a flat tyre.

Images of the tyres fitted on a DHL Express delivery van were briefly shared on the Facebook page of a local event company on Dec 1 before they were removed.

When asked, DHL confirmed that the vehicle in the pictures was theirs, but would not give details on the tyres or the reason the van was fitted with the tyres. Michelin also declined to comment. Plastic-Waste – Packaging – rPET

The Land Transport Authority said it was aware of the testing of these tyres, and has been working with the parties to ensure relevant safety measures are in place.

The Straits Times understands that there was at least one test involving such tyres in Singapore at the Changi Exhibition Centre in July 2022. The photos shared on Facebook are likely from a more recent test event in November.

The tyres are puncture-proof because they do not use pressurised air to stay in shape.

Instead, these airless tyres have what looks like rubbery strut structures extending from the edge of the wheel to prop the tyre.

Until now, airless tyres were only used on lighter vehicles, such as the silver and orange shared bicycles used by Mobike when the company was operating in Singapore.

In 2019, Michelin had rolled out a prototype tyre similar to the one on the DHL van at a trade event in Montreal, Canada. It also showcased the tyre in September 2021 at a motor show in Munich, Germany.

The company has said the prototypes will be tested in real-life conditions in different parts of the world during its development.

Michelin also said it will start to use materials recycled from yogurt cups and plastic bottles in its tyres, including the airless tyre, from 2024.

In addition to giving more convenience and enhancing safety, making a tyre immune to punctures and blowout means it can be used to its maximum lifespan – which makes the technology environmentally sustainable, said Michelin.

Research that it conducted between 2012 and 2015 found that 20 per cent of all tyres scrapped annually were those that punctured or had uneven wear because they did not have the right amount of air pressure.

By that calculation, Michelin said switching to airless tyres can save up to 200 million tonnes of waste each year. Plastic-Waste – Packaging – rPET

-Biden’s China tech crackdown leaves Xi with few ways to hit back

The U.S. has sharpened its assault on China’s technology industry with a flurry of export bans and stifling restrictions on companies, an escalation that leaves Beijing with few options to retaliate.

Washington’s moves are part of a longer-term strategy to prevent China from dominating the industries of the future and arming its military with advanced weaponry, while also securing its tech supply chain by enticing chipmakers to set up shop in the U.S.

President Joe Biden’s administration this week escalated those efforts to hobble its main geopolitical competitor, blacklisting dozens of Chinese tech firms, while signs emerged Japan and the Netherlands are aligning with U.S. restrictions on selling crucial chipmaking equipment to China, a major blow to Beijing’s ambitions to produce advanced semiconductors. Plastic-Waste – Packaging – rPET

In response, China has accused the U.S. of protectionism, lodged a complaint with the World Trade Organization and courted chip-making powerhouse South Korea, a key U.S. ally. Beijing is also reportedly preparing a multibillion-dollar aid package for its semiconductor industry, a crucial sector for the global economy given the widespread use of chips in everything from cars and mobile phones to guided missiles.

But China doesn’t have many options, or incentives, to go further.

Similar to Beijing’s actions during the trade war with former President Donald Trump’s administration — when it failed to follow through on threats to add U.S. companies to a so-called unreliable entities list — any moves to block American investment threatens an economy already reeling from President Xi Jinping’s zero-tolerance COVID policies, which are only now being rolled back.

“China’s lack of good options is precisely why the U.S. is striking hard and fast now with export controls,” said Reva Goujon, a director at the Rhodium Group who advises corporate clients on U.S.-China relations and industrial policies.

The tech battle comes as U.S.-China relations have eased since hitting a low point earlier this year following a visit to Taiwan by House Speaker Nancy Pelosi. After Biden and Xi met at the Group of 20 summit in Bali last month, the U.S. watered down a legislative proposal that would’ve named Taiwan a “major non-NATO ally,” a sign that Washington is trying to avoid another showdown that risks derailing the relationship.

The U.S. has “abused” export controls and import restrictions, while the new sanctions on Chinese companies “violate the commitment” that Biden made to Xi in Bali, Liu Pengyu, the spokesman for China’s embassy in Washington, said in a Friday briefing.

“From the U.S. side, they are now building walls and barriers, pushing for decoupling and severing supply chains,” Liu told reporters. “We call on the U.S. side to stop disrupting the trade of high-tech products and maintain normal China-U.S. economic and trade exchanges.”

Yet Beijing’s response to the recent U.S. moves on semiconductors has been “very reserved,” according to Henry Wang Huiyao, founder of the Center for China and Globalization, a policy research group in Beijing. The Biden-Xi talks and an upcoming visit to China by U.S. Secretary of State Antony Blinken have laid the groundwork for more understanding and hopefully some relaxation of sanctions, Wang added.

The new actions unveiled this week — which follow export controls announced in October aimed at preventing China’s access to machines and knowhow to make high-end chips — placed a number of Chinese companies on a so-called entity list, requiring suppliers to get difficult-to-obtain U.S. government licenses. Plastic-Waste – Packaging – rPET

Among the most notable firms on that list is emerging chip equipment-maker Shanghai Micro Electronics Equipment Group Co., or SMEE, which could stifle Beijing’s efforts to create next-generation semiconductors. The machines that make semiconductors are among the most complicated devices produced by humans and defy reverse engineering, making it difficult for China to develop its own domestic capabilities if it can’t get the equipment elsewhere.

“Having SMEE on the entity list is a major blow for China’s chip sector,” said Martijn Rasser, a former analyst at the Central Intelligence Agency who’s now a senior fellow at the Center for a New American Security think-tank.

“It’s the one company that Beijing saw as having potential to produce advanced chipmaking machines, which is essential for China to be a competitive force in the global semiconductor ecosystem,” he said. “Those hopes are now greatly diminished, if not dashed altogether.”

Under the Biden restrictions, China is severely limited in its ability to buy those chipmaking machines from abroad. The critical American gearmakers Applied Materials Inc., Lam Research Corp. and KLA Corp. can no longer sell their advanced equipment to Chinese customers. But a complete blockade requires cooperation from Japan’s Tokyo Electron Ltd. and Dutch lithography specialist ASML Holding NV.

Those U.S. efforts gathered momentum this week with Japan and the Netherlands nearing an agreement to join Washington in tightening controls over the export of up-to-date chipmaking machinery to China. The two governments are considering a ban on the sale of machinery capable of fabricating chips that are at least three generations behind the latest advances available on the market, in line with the rules Washington set out in October.

Also on the blacklist is China’s leading memory chipmaker, Yangtze Memory Technologies Corp., which was once close to a deal to supply Apple Inc., and is a competitor to Samsung Electronics Co. and Micron Technology Inc. for mobile phone and personal computer components.

Even if China wins the WTO case, the U.S. can veto any ruling by bringing it to the trade organization’s appellate body, which the Trump administration paralyzed in 2019.

China’s best option may be to pour money into developing its own high-tech chips. Beijing is preparing to unleash a $143 billion aid package for its chip industry, according to Reuters. But it’s not clear how much impact this will have, given the mixed results from the tens of billions that China has already funneled into the sector.

“They can invest more, but the issues right now are not really a lack of resources,” Adam Segal, chair in emerging technologies and national security at the Council on Foreign Relations. “It’s these technological chokepoints they are still vulnerable to.”

There’s a risk that unilateral actions could eventually alienate key U.S. partners, said Jon Bateman, a senior fellow at the Carnegie Endowment for International Peace. As well, Beijing hasn’t yet shown a willingness to leverage its dominance of rare earth minerals or its role as a manufacturing hub because it “has more to lose than to gain,” he said, but that could change. Plastic-Waste – Packaging – rPET

-Coca-Cola Pakistan launches fully recycled plastic bottles

In a collaboration, Coca-Cola Beverages Pakistan Ltd (CCI Pakistan) and The Company have launched PET bottles made from 100% recycled plastic, a new packaging innovation for Coca-Cola in Pakistan.

Initially launched in Sindh, where 2.25-liter Coca-Cola bottles will be made using food-grade recycled plastic (rPET), the initiative will be rolled out in other provinces, as well.

Working closely with Pakistani provincial food authorities, Coca-Cola Iceck Pakistan has created a cycle through which used plastic bottles are collected for subjecting into a unit operation. This process ensures thorough cleaning and washing of the plastic while breaking them into small pallets. The pellets are eventually converted into food-grade packaging for Coca-Cola Pakistan Plastic-Waste – Packaging – rPET

Earlier in 2022, CCI announced its “Sustainability Pledge for 2030”. Under the pledge, CCI, as a group, is taking action to use at least 50 percent recycled plastics in all its packaging. The pledge also aims to evaluate and initiate multiple projects falling under 6 categories including Packaging, Water Stewardship, Climate Change, Human Rights, Diversity and Inclusion, and Community.

Speaking about this achievement, Ahmet Kursad Ertin, GM CCI Pakistan, said that sustainability is a fundamental and indispensable aspect of our business. It is embedded in our vision and goals. “We integrate sustainability principles into all our operations.

The use of RPET packaging is a step towards honouring our Packaging related commitment. We are thrilled to incorporate 100% PET packaging for our products and will continue to take responsibility in line with CCI’s Sustainability Pledge for 2030”, he added.

As part of its World Without Waste vision, the Company has committed to using 50% recycled material in its packaging by 2030. Currently, the company offers 100% rPET bottles in more than 25 markets. Plastic-Waste – Packaging – rPET

Fahad Ashraf, Vice President of the Coca-Cola Company said, that through this rollout starting in Karachi, Company aims to create a looping, circular economy, where all bottles are made from recycled plastic and are 100 percent recyclable.

-EcoBlue’s Bottle Grade rPET is now European Food Safety Authority (EFSA) approved for use in food contact packaging

The EFSA Panel has concluded that the three steps, extrusion, crystallization and SSP, are critical in determining the decontamination efficiency of the process.

The Panel has concluded that the recycled PET obtained from this process, which is being followed at EcoBlue, is not of safety concern when used at up to 100% for the manufacture of materials and articles for contact with all types of foodstuffs for longterm storage at room temperature, with or without hotfill.

EcoBlue is Thailand’s first Bottle grade rPET resin producer with a capacity of 15,000 tons per annum, which is on track to be doubled to 30,000 tons per annum. EcoBlue’s bottle grade rPET is available with Intrinsic Viscosity (IV) of 0.76/0.80/0.84 dl/gm and it can be used in 100% for manufacturing of bottles for beverages – Water, CSD, personal care, cosmetics and home care, among other applications. The resin can be traced back to 100% Post-Consumer PET waste material through its Global Recycled Standard Certification process. Plastic-Waste – Packaging – rPET

www.ecoblue.co.th www.efsa.europa.eu

Plastic-Waste – Packaging – rPET