Plastic Waste Recycling Sustainable Rubber BOPP Film Hydrogen PP 26-11-2021 - Arhive

Plastic Waste Recycling Sustainable Rubber BOPP Film Hydrogen PP

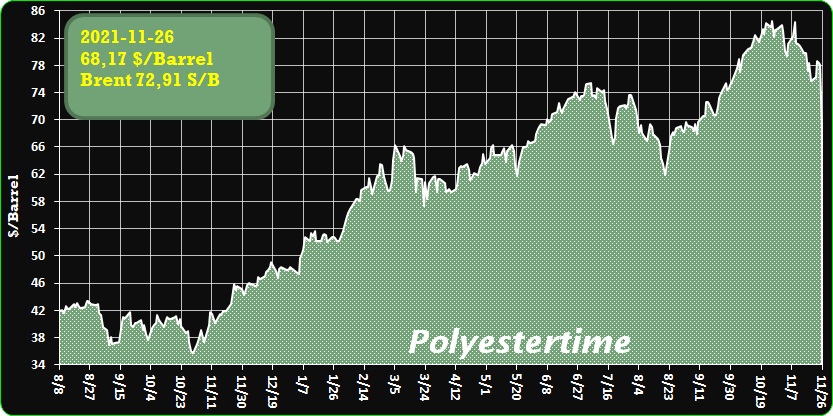

Crude Oil Prices Trend

-LANXESS to expand high-tech plastics production in China

- Investment of EUR 30 million on strong market demand

- Capacity expansion by 30,000 metric tons

- Further strengthening footprint in Greater China

LANXESS will expand its production network in China: The specialty chemicals company will build a second compounding line for Durethan- and Pocan-branded high-tech engineering plastics at its manufacturing site in Changzhou. An important investment of around EUR 30 million will increase the capacity in Changzhou by 30,000 metric tons per year. Together with existing facilities in Changzhou and Wuxi, this will bring the company’s total compounding capacity in China to 110,000 metric tons per year. The new line is planned to go on stream in the first quarter of 2023. “This expansion caters to the strong demand we experience from the growing Chinese automotive industry. As e-mobility is booming, it is driving new requirements for lightweight applications and continuously increases the share of electronic components used in cars”, says Hubert Fink, Member of the Board of the Management of LANXESS. “The new production line marks another vital step in enlarging our footprint in Greater China.”

Solutions for e-mobility

LANXESS sees e-mobility as a major field of application for its polyamide (PA) 6 and PA 66 compounds Durethan, polybutylene terephthalate (PBT) compounds Pocan and the endless fiber-reinforced composites Tepex. The company already offers a wide range of products that meet the most challenging standards and norms of the electrical and electronics industry worldwide in terms of flame retardance, electrical properties and ecological behavior.

Durethan and Pocan high-performance plastics also allow the construction of components that can replace metal parts in motor vehicles and in this way contribute to reducing weight, energy consumption and related emissions. The innovative materials are used, for example, in engine applications, door structures, body reinforcement, pedals, front ends and cross car beams. Depending on the part, the lightweight design contributes to a weight-saving of up to 50 percent.

-American Chemistry Council supports global agreement to eliminate plastic waste

Secretary Antony Blinken has made remarks in support of a multilateral agreement to end plastic waste in the environment. According to Joshua Baca, vice president of plastics for the American Chemistry Council (ACC):

“ACC appreciates the U.S. Department of State’s continued leadership in the United Nation’s Environment Assembly (UNEA) to address many of the major environmental challenges facing the globe today, including plastic waste in the environment. We are supportive of a global agreement among nations that will accelerate a transition to a more circular economy by expanding systems and infrastructure to collect and repurpose plastic resources. Plastic Waste Recycling Sustainable Rubber BOPP Film Hydrogen PP

“In September, America’s Plastic Makers along with the International Council of Chemical Associations and World Plastics Council announced 5 Principles to eliminate plastic waste, accelerate a circular economy, and serve as the basis for a global agreement. They are:

- Have all nations agree on eliminating plastic waste, while providing flexibility and support to help meet the needs of individual nations.

- Achieve widespread access to waste collection.

- Recognize the role plastics play in a lower carbon future.

- Support innovation in product design and recycling technology.

- Measure progress.

-Asahi Kasei to make sustainable rubber for tires in Singapore

Major Japanese chemical firm Asahi Kasei Corp. will buy butadiene derived from plastic waste and biomass from a Singaporean arm of oil giant Royal Dutch Shell Plc to make sustainable synthetic rubber for eco-friendly tires.

Asahi Kasei said Wednesday that it concluded an agreement with Shell Eastern Petroleum (Pte) Ltd. on Tuesday to purchase the butadiene to manufacture and market sustainable solution-polymerized styrene-butadiene rubber, or S-SBR for short, in the city-state.

The Tokyo-based chemical firm said it will start producing S-SBR, used mainly for high-performance and fuel-efficient tires, by March next year, aiming for an annual output of several hundred tons for the time being.

S-SBR is the world’s first synthetic rubber made from butadiene deriving from plastic waste, and Asahi Kasei said it is the first Japanese firm to make S-SBR originating from biomass. Plastic Waste Recycling Sustainable Rubber BOPP Film Hydrogen PP

Asahi Kasei did not release a contract figure or the amount of butadiene it plans to procure from Shell.

Nusaned Investment™ a wholly-owned subsidiary of SABIC that operates as an autonomous investment company, has signed an investment agreement through Nusaned Fund, managed by

Al-Bilad Capital, with Green Kingdom Industries (GKI) and Italian Industrial group (AMUT) to set up a PET recycling plant in Rabigh, as part of its commitment to invest in industrial SMEs and contribute to the successful achievement of Vision 2030.

Under the new partnership, the plant will produce recycled PET flakes for food-grade usage to serve the local and Global markets.

Faisal Al-Bahair, CEO, Nusaned Investment, said: “We are proud of achieving another milestone in our efforts to align strategically with the objectives of Saudi Arabia as well as SABIC to support local content and enhancing the Kingdom’s competiveness globally. It also support SABIC’s commitment to establish a circular economy and meeting its wider sustainability goals.” Plastic Waste Recycling Sustainable Rubber BOPP Film Hydrogen PP

Fahad AlNaeem, Chief Investment Officer, Nusaned Investment, commented: “We are sustainable rubberconfident that our investment in the PET recycling plant will bring economic value to Saudi Arabia. We are hopeful of more such investments that help the Kingdom’s transformation into an important export hub.”

-Cosmo Films launches barrier metalized BOPP Film

Cosmo Films Ltd., a global leader in specialty films for flexible packaging, labeling and lamination applications as well as synthetic paper, has launched Enhanced Barrier Metalized BOPP Film specially designed for packaging applications with very high moisture and good oxygen barrier properties and high metal bond, said the company.

A film specially innovated for applications like flexible packaging for lamination, packaging of biscuits, snacks, bakery products, chocolates and personal care products like shampoo sachets; the film can be used as a sandwich layer in multilayer laminate structures. The BOPP Filmend pack can be used for all food and personal care applications where moisture barrier is of utmost importance.

With a thickness range of 15& 18 ?m, the film is suitable for adhesive lamination, which provides a good heat seal strength and facilitates cold seal adhesive reception on the non-metallic side. Plastic Waste Recycling Sustainable Rubber BOPP Film Hydrogen PP

Talking about the product launch, Mr. Pankaj Poddar, Group CEO, Cosmo Films Ltd. said, “We carefully evaluate the expectations of our customers, and engineer products which are best suited for them. The Enhanced Metalized BOPP Film is an apt addition to our range of barrier films which not only improve the shelf life of the packaged product, but also help in creating mono material eco-friendly structures.”

Cosmo Films Limited, a Global Leader in Films for Packaging, Labelling, Lamination and Synthetic Paper and an emerging player in Specialty Chemicals, Polymers & Pet care announced expansion by setting up the world’s largest BOPP film production line at Aurangabad with annual rated capacity of 67,000 MT.

As MRC informed earlier, Cosmo Films introduced BOPP based heat resistant (HR) films. The films have been engineered to work as printing layer replacing BOPET film in multi-layer laminates for various packaging applications in both food and non-food segments. The company has also launched a barrier version of the film.

-Asahi Kasei hydrogen generator to slash costs

Asahi Kasei, the Japanese materials and healthcare conglomerate, plans to market a generator for making green hydrogen at a third of the current cost in 2025, reports the Nikkei.

Hydrogen generators, each capable of producing 10MW, are already being tested. The company is working on linking systems to make 100MW units.

The generators use electrolysis to make hydrogen from an aqueous potassium hydroxide solution. One unit can produce enough hydrogen each day to fill 850 fuel cell vehicles with 5kg tanks. Plastic Waste Recycling Sustainable Rubber BOPP Film Hydrogen PP

The company aims to lower the per-kilowatt price of the equipment to $430 by 2030, down from the current estimate of $1,730.

This will cut the current Japanese market price of roughly $95 per kg to $2.86.

-Household plastics recycling collections during pandemic reached 41%

Plastics recycling association RECOUP has revealed 584,000 tonnes of plastic packaging was collected for recycling from households in 2020, a 4% increase over the previous year.

RECOUP’s annual Household Plastics Collection Survey, which examines local authority performance, said the overall rate was 41%. It called this a “positive performance” in the wake of the Covid-19 pandemic and Brexit.

But it warned that to reach the UK’s target of 70% by 2025, an extra 400,000 tonnes of material would need to be recycled.

The survey revealed PET drinks bottle collection for recycling stood at 75%, with natural HDPE milk bottles reaching 78%.

RECOUP said these rates would need to improve as the materials ‘outperform’ other grades of plastics. Plastic Waste Recycling Sustainable Rubber BOPP Film Hydrogen PP

The rate for non-drinks bottles stood at 45%, with pots, tubs and trays reaching 36%. Plastic film recycling was just 4%, as relatively few local authorities offer recycling services for that material.

RECOUP said future collection rates would be impacted by the introduction of a plastics packaging tax, deposit return scheme, extended producer responsibility, restrictions on single-use plastics and consistency in council collections.

Steve Morgan, RECOUP head of policy and infrastructure, said: “There are a multitude of varied high impact policies floating around and they’re going to come together at different times and provide different dynamics.

“Like a whirlpool, they’re going to be thrown together, probably at speed, and how they settle will direct the capability of the UK to manage our waste and recycling systems, possibly for a generation.

-Polypropylene (PP) prices drift lower in Asia

This week PP prices journeyed southward in Asia. The price fall was triggered by bearish regional demand trends and lower import offers from overseas suppliers.

Reports of ample product availability in the region and weaker propylene feedstock values further pressured prices lower across Asia.

In Far East Asia, PP raffia and PP injection prices were assessed at the USD 1130-1180/mt CFR levels, a week on week drop of USD (-10/-20/mt). PP film prices were assessed at the USD 1150-1190/mt CFR levels, while BOPP prices were also assessed at the USD 1150-1190/mt CFR levels, both down USD (-10/-20/mt) from last week. PP block copolymer prices were assessed at the USD 1160-1200/mt CFR levels, a week on week drop of USD (-10/mt). Plastic Waste Recycling Sustainable Rubber BOPP Film Hydrogen PP

In China, a Middle Eastern producer has offered its PP raffia and PP injection grades at USD 1130/mt CFR levels, for shipment in December 2021. A producer from Saudi Arabia has offered its PP raffia and PP injection grades at the USD 1180/mt CFR levels, for shipment in December 2021.

In Southeast Asia, PP raffia and PP injection grade prices were assessed at the USD 1250-1300/mt CFR levels, a week on week fall of USD (-20/mt). PP film prices were assessed at the USD 1270-1310/mt CFR levels, while BOPP prices were also assessed at the USD 1270-1310/mt CFR levels, both down USD (-20/mt) from last week. PP block copolymer prices were assessed lower at the USD 1280-1320/mt CFR levels, a week on week drop of USD (-20/mt).

In Vietnam, a South Korean producer has offered its PP raffia and PP injection grades at the USD 1260/mt CFR levels, for shipment in December 2021. A Middle Eastern producer has offered its PP raffia and PP injection grades at the USD 1300/mt CFR levels, for shipment in December 2021. A Thai producer has offered its PP raffia and PP injection grades at the USD 1310/mt CFR levels, for shipment in December 2021.

In India, PP raffia and PP injection prices were assessed at the USD 1430-1480/mt CFR levels, a tumble of USD (-60/mt) from last week. BOPP prices were assessed at the USD 1450-1510/mt CFR levels, while PP film prices were also assessed at the USD 1450-1510/mt CFR levels, both down (-50/mt) from the previous week. PP block copolymer prices were assessed at the USD 1470-1540/mt CFR levels, a week on week plunge of USD (-50/mt).

In India, Middle Eastern producers have offered their PP Homopolymer grades in the range of USD 1450-1500/mt CFR levels, for shipment in December 2021. Demand and pricing trends remained bearish amid sufficient product availability in the open markets of India.

In Pakistan, PP raffia and PP injection grade prices were assessed at the USD 1470-1510/mt levels, a week on week plunge of USD (-70/mt). BOPP prices were assessed at the USD 1490-1540/mt CFR levels, while PP film prices were also assessed at the USD 1490-1540/mt CFR levels, a tumble of USD (-70/mt) from last week. PP block copolymer prices were assessed at the USD 1500-1580/mt CFR levels, a steep week on week drop of USD (-70/mt).

Plastic Waste Recycling Sustainable Rubber BOPP Film Hydrogen PP

PCR Film Plastic Recycled Fibers Traceability Polylactic Acid Circular Economy Car 25-11-2021