Plastic waste – Solid-state batteries 14-03-2023 - Arhive

Plastic waste – Solid-state batteries

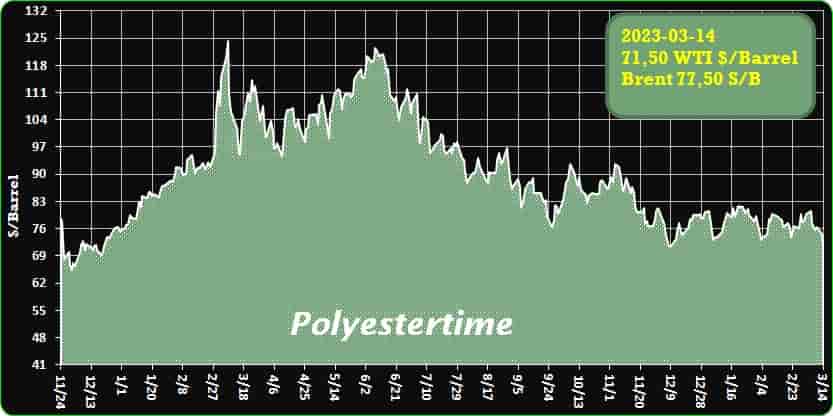

Crude Oil Prices Trend

Crude Oil Prices Trend Polyestertime

-Bio-on to get a second chance

Maip Group’s proposal accepted by Bologna court

Having languished in limbo since 2019, the assets of the bankrupt Italian PHA manufacturer Bio-on are now in the process of being acquired by the Turin, Italy headquartered Maip Group.

The Group has submitted a proposal for a bankruptcy arrangement that has been approved by the Court of Bologna.

Maip Group has created a new company called Haruki specifically for this purpose, the company said, although it has not ruled out that in the future it will revert to the name Bio-On.

Haruki, in which MAIP Compounding holds a 75% stake and Plastotecnica a 25% share, will receive starting assets of about € 20.000.000 to guarantee the execution of the composition proposal and to allow the full restart of operations of the Castel San Pietro facility.

Both MAIP Compounding and Plastotecnica are MAIP Group member companies.

Maip Group has formulated a five-year plan aimed at a swift relaunch of Bio-on’s PHA production, based on the proprietary technology developed by Bio-on that uses agricultural waste or agro-industrial by-products, such as sugar cane, beet, glycerol from biodiesel as feedstock.

The Group sees considerable synergies resulting from the deal. It has been researching the potential of PHA for 12 years, and already produces its own IamNature PHA-based compounds. which the company customises for individual customers. Over the years, these have included ABB – the company won the Bioplastics Award in 2018 for its Mylos Ethic recyclable wiring accessories cover frame made from an IamNature compound – as well as seating and table designers Andreu World. Maip is also working with SIS and Flexgrass, the world’s leading company for top quality sports pitches, on the development of the first football pitches made with IamNature biofiber.

The present deal and relaunch of Bio-on will give it access to its own supply of PHA resin for the production of these compounds.

Bio materials, said the company, are expected to show very robust growth in the next 30 years , with the market for PHA, in particular, to show significant development globally in the next 5 years.

-UAE: Single-use plastic waste upcycled using new non-toxic process

Bags, masks turned into ‘carbon dots’ nanomaterial that has several uses in medical field

A team of researchers at NYU Abu Dhabi (NYUAD) has developed a process to upcycle single-use plastic bags and disposable masks into “carbon dots”, a carbon-based nanomaterial. The single-step hydrothermal process is non-toxic because it does not require any organic solvents, and it converts polyethylene-based plastic bags and polypropylene-based surgical masks into carbon dots. These can then be used for purposes of environmental monitoring, disease diagnosis, and treatment.

An estimated 26,000 tonnes of pandemic-related plastic waste – from medical waste to online shopping packaging – have been released into the world’s oceans, making it even more urgent to find efficient methods to upcycle this non-degradable material.

One solution is to convert the single-use plastic into so-called carbon dots, which are carbon nanomaterials that are biocompatible, and are highly favoured for applications in the fields of biological imaging, environmental monitoring, chemical analysis, targeted drug delivery, disease diagnosis and therapy, and anti-counterfeiting.

Existing methods to upcycle plastic into carbon dots involve multiple, time-consuming steps, and require the use of toxic chemicals. Plastic waste – Solid-state batteries

Study findings

In the NYUAD study titled ‘High-yield, One-pot Upcycling of Polyethylene and Polypropylene Waste into Blue-Emissive Carbon Dots’, which was published in the journal Green Chemistry, the Abu Dhabi-based researchers presented the development of a new synthesis method. The process presents a “simple, cost-effective, and scalable” approach to upcycling plastic waste. This oxidative degradation method can also upcycle plastics contaminated with organic waste such as food scraps, which poses a significant challenge to traditional recycling technologies.

An estimated 26,000 tonnes of pandemic-related plastic waste – from medical waste to online shopping packaging – have been released into the world’s oceans, making it even more urgent to find efficient methods to upcycle this non-degradable material.

-Nissan developing solid-state batteries for electric vehicles

– Plans to introduce cheaper solid-state batteries before 2028

– Aims to bring the cost down by 50 per cent

Nissan is developing next-gen battery technology which will make use of solid-state batteries instead of conventional lithium-ion units. The next-gen Leaf is most likely to receive these solid-state batteries as the development is already underway and mass production is expected as early as 2028. Plastic waste – Solid-state batteries

With these solid-state batteries, the Japanese carmaker aims to bring down the cost by 50 per cent, while doubling the energy density and increasing the charging speed to three times. Under current development in Japan, the small button cells of the new battery technology are 10cm in size. But in the final development stage, these cells will increase to the size of a laptop.

Nissan is working with scientists from the University of Oxford to develop solid-state batteries.

-Plastics Recycling Conference 2023: Analyzing trends in plastic recycling

Analysts comment on the trends influencing plastic recycling and pricing.

Analysts from ICIS, Wood Mackenzie and PetroChem Wire spoke to the trends influencing plastic recycling during a session at the 2023 Plastics Recycling Conference, hosted by Resource Recycling in partnership with its parent company, the Association of Plastic Recyclers (APR). Plastic waste – Solid-state batteries

“Everyone wants recycled material,” said Andrew Brown of Wood Mackenzie, headquartered in London. “It’s a good problem to have.”

That demand is driven by decarbonization efforts by companies throughout the plastics value chain, he said, adding that recycling is an economically viable and immediate means for doing so.

Roughly 25 million tons of polyethylene terephthalate (PET) are used annually in packaging applications, with recyclate demand growing in Western countries, Brown said. Led by the U.K.-based Ellen MacArthur Foundation in collaboration with the UN Environment Programme, consumer packaged goods companies that are signatories to the Global Commitment have targeted including 26 percent recycled content in their packaging by 2025. Plastic waste – Solid-state batteries

Apparel accounts for 36 million tons of polyester demand, he said, with demand for recycled content primarily centered in Asia. Textile Exchange, Lamesa, Texas, has set a target of 45 percent recycled content in textiles by 2025, with companies such as Adidas, Banana Republic, H&M Group and Madewell among the brands that have signed on to this goal.

Brown said that while 3 million tons of rPET capacity are forecasted to be added by 2025, nearly five times that amount will be needed to meet the Ellen MacArthur and Textile Exchange targets.

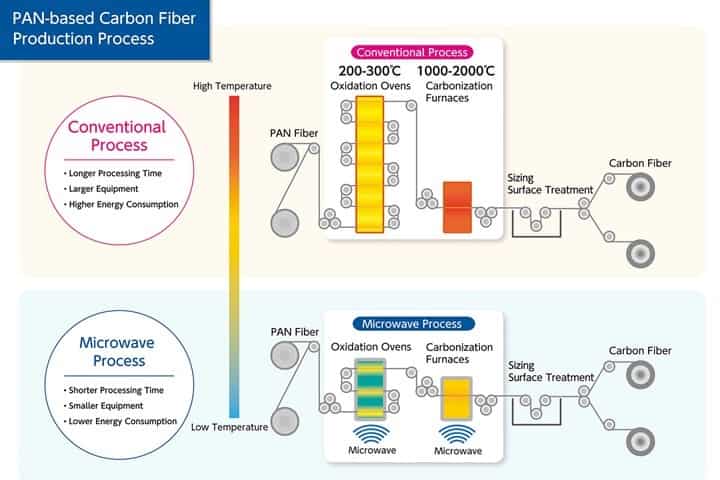

-Microwave heating for more sustainable carbon fiber

Skeptics say it won’t work — Osaka-based Microwave Chemical Co. says it already has — and continues to advance its simulation-based technology to slash energy use and emissions in manufacturing.

Microwave Chemical Co. has applied its microwave heating technology to carbon fiber production, reportedly cutting energy use by 50% and CO2 emissions by 90%. Photo Credit: MWCC Plastic waste – Solid-state batteries

Microwave Chemical Co. (MWCC, Osaka, Japan) was founded in 2007. It currently has 60 employees, and its mission is to innovate the chemical industry and revolutionize manufacturing using its microwave technology to “create a world we have never seen.”

Microwave Chemical Co. (MWCC) has demonstrated and commercialized its microwave technology with the world’s top chemical companies — e.g., BASF (#1), Mitsubishi Chemical (#11), Sumitomo Chemical (#19), Mitsui Chemicals (#29) — as well as companies pioneering sustainable materials (e.g., Taiyo Kagaku Co., Futamura Chemical) and PeptiStar, which produces peptide-pharmaceuticals used to treat cancer, diabetes, HIV and other immune diseases. Photo Credit: Microwave Chemical Co

Over the past 15 years, MWCC has worked with the world’s top chemical companies and pioneers in sustainable materials and processes to prove that its microwave technology reduces energy use by up to 70%, heating time by up to 90% and equipment footprint by up to 80% compared to current fossil fuel-based industrial systems.

Plastic waste – Solid-state batteries

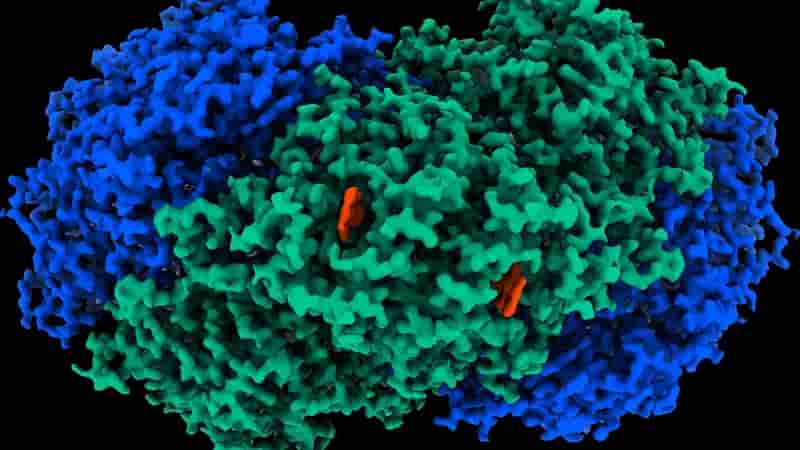

-Out of thin air. This enzyme can turn hydrogen in the atmosphere to energy

It could be used to power small electronics someday, the researchers said

A group of microbiologists in Australia have discovered an enzyme that converts hydrogen into electricity, which could one day be used to create a source of energy literally out of thin air. The enzyme, which they named Huc, is used by a bacterium to take energy from atmospheric hydrogen, allowing it to tackle harsh environments.

Bacteria remove over 70 million tons of hydrogen every year from the atmosphere, a process that shapes the composition of the air we breathe. The researchers estimate that 60% to 80% of these bacteria could have enzymes like Huc, which means there’s a significant amount of electricity that could one day be taken from biological sources

“We’ve known for some time that bacteria can use the trace hydrogen in the air as a source of energy to help them grow and survive, including in Antarctic soils, volcanic craters, and the deep ocean,” Chris Greening, microbiologist and a contributor to the new study, said in a statement. Plastic waste – Solid-state batteries

“But we didn’t know how they did this until now.

A potential new source of power

Huc was found inside the bacteria Mycobacterium smegmatis, which often used in the laboratory by researchers to study the cell wall structure of its relative, Mycobacterium tuberculosis. M. smegmatis uses Huc to grow in extreme environments, such as volcanic craters or the deep ocean. But how it does this has been a pervading mystery — until now.

This enzyme can turn hydrogen in the atmosphere to energy

-Packaging sector leads plastics recycling surge

The global plastics recycling market is expected to reach US$ 56.8 billion (EUR 53.2 billion) by 2029, up from around US$ 25.5 billion in 2022, a compound annual growth rate of 9.3% over the forecast period. Plastic waste – Solid-state batteries

The North American market currently has the biggest market share (43%) in the global plastics recycling arena. This is mostly due to its fast-growing packaging sector, which has launched various recycling schemes.

Exactitude Consultancy Market Research says other growth factors for waste generation as well as recycling potential are the booming numbers regarding food to-go and online shopping.

The US Environmental Protection Agency estimates that around 15 million tonnes of plastic containers and packaging are generated every year, which represents less than 1% of America’s municipal solid waste. The recycling rate of polyethylene (PET) bottles is at the top in the plastics segment, at almost 30%.

Meanwhile, Canada’s beverage container recycling programmes collect and recycle more than 5.7 billion containers annually. However, glass bottles have a far higher recycling rate of 75% compared to roughly 12% for PET bottles. Plastic waste – Solid-state batteries

The main themes in the new report from Exactitude Consultancy Market Research include: automotive plastics, plastics used in the construction industry, non-food packaging plastics, and niche recycling markets.