Plastic Waste to Chemicals 11-09-2021 - Arhive

Plastic Waste to Chemicals

-Shell invests in plastic waste-to-chemicals technology company BlueAlp

The investment will help deliver Shell’s ambition to recycle 1 million tonnes of plastic waste a year in its global chemicals plants by 2025

BlueAlp technology will support early use of pyrolysis oil in Shell’s European and Asian facilities

Shell to deploy its proprietary technology to upgrade pyrolysis oil purity

The Hague − Shell Ventures BV and BlueAlp Holding BV today announced a strategic partnership to develop, scale and deploy BlueAlp’s plastic waste to chemical feedstock technology. The technology transforms plastic waste which is tough to recycle into a recycled feedstock (i.e. pyrolysis oil) that can be used to make sustainable chemicals. Shell has taken a 21.25% equity stake in BlueAlp as part of the agreement.

“With BlueAlp’s innovative technology and Shell’s size and experience we can advance the plastic waste recycling technology needed to meet growing customer demand for sustainable chemicals. This partnership is one of the important steps Shell is taking to reach our ambition of recycling one million tonnes of plastics waste a year in our global chemicals plants by 2025,’’ said Robin Mooldijk, Executive Vice President of Shell Chemicals and Products.

“We are also working across the value chain to provide our customers with a secure supply of high-quality circular products including collaborating with industry partners to drive the development of the infrastructure needed to collect and sort plastic waste.”

-Hydrogen megatrend: green hydrogen the fuel of the future?

Great hopes are being placed in hydrogen as an energy carrier. Hydrogen seems to be the solution, especially for economic and industrial sectors that are difficult to decarbonize today and are burdened with high greenhouse gas emissions. As an all-rounder, hydrogen can be used in many different ways. It is not only an energy carrier, but is also used as a raw material for industrial purposes. However, its current production is very energy-intensive and associated with high emissions.

In the future, hydrogen could be produced in large quantities through the use of renewable energies. Technical processes that make this possible have been tested and are already in use. Thus, climate-neutral hydrogen could become the driving force behind a burgeoning hydrogen economy. We are taking a closer look at its many uses and applications and are inviting experts to contribute to an objective dialog on the subject of hydrogen. Plastic Waste to Chemicals

The topic of hydrogen is not new. Research into hydrogen technologies has been going on for a long time. Since its discovery in the 18th century there have been various applications. But where does hydrogen technology stand today and what applications are currently being pursued? These are the questions we address in this special topic. One focus is on the contribution that climate-neutral hydrogen makes to the energy transition.

-Michelin to roll out tires with recycled plastics by 2024

Michelin is aiming to incorporate waste plastic into its tires by as early as 2024 as part of a drive to solve the “society’s plastic problem.”

MUNICH, Germany — Group Michelin is aiming to incorporate waste plastic into its tires by as early as 2024 as part of a drive to solve the “society’s plastic problem.”

Michelin claims “high-tech” recycling processes it is developing will have the potential to recycle 4 billion PET (polyethylene terephthalate) bottles into raw materials that can be used in reinforcing fibers for tires.

“In one tire, we can process up to 143 yogurt cups and around 12.5 PET bottles with the high-tech recycling processes,” Anish Taneja, CEO of Michelin’s Northern Europe region, said ahead of the German transportation mobility show IAA, which runs through Sept. 21 in Munich. Plastic Waste to Chemicals

In a symbolic gesture, Michelin is conducting a plastic-collection campaign in Munich, with the participation of its top management and employees.

“Together, the company wants to create awareness that today’s garbage will become a valuable resource for tomorrow’s tires,” the tire maker said.

As part of its sustainability commitment, Michelin has set itself a target of incorporating 40% sustainable materials such as natural rubber or sunflower oil into its tires by 2030.

By 2050,, Michelin tires should be completely sustainable, using raw materials such recycled PET.

At the IAA, the French tire maker has set up a “REGEN’Lab,” where visitors can see recycling processes and how raw materials for new tires are obtained from wood, PET plastic or packaging waste.

-European plastics producers call for mandatory EU recycled content target

PlasticsEurope endorses the objective of preventing and reducing excessive packaging and packaging waste and welcomes the revision of the Packaging and Packaging Waste Directive (PPWD). Plastic Waste to Chemicals

European plastics producers also support the European Commission’s proposal for a mandatory EU recycled content target for plastics packaging. The industry is now calling for a target of 30 per cent for plastics packaging by 2030.

PlasticsEurope members are already working towards this target by investing in increased high-quality supply of recycled plastics and leading-edge technology solutions. Ramping up chemical recycling is essential to achieve such a mandatory target. For example, our members’ planned investments in this vital technology and infrastructure range from €2.6bn by 2025 to €7.2bn by 2030 in Europe.

Dr Markus Steilemann, President of PlasticsEurope and CEO of Covestro, said: “The world must embrace the circular economy concept as the key to climate neutrality, resource conservation and environmental protection. The call for a regulated recycled content target for plastics packaging in the EU demonstrates our commitment to accelerate the transformation to a circular economy, helping implement the EU Green Deal and Circular Economy Action Plan.”

-Kazakhstan building $2.6-bn plant to produce polypropylene

Kazakhstan is building a $2.6-billion plant to produce polypropylene with a capacity of 500,000 tonnes per year, according to the ministry of energy, which said projects for the production of polyethylene terephthalate, methanol, polyethylene, butadiene and base oils are at various stages of development. The total cost of these projects is about $12 billion.

Russia-Kazakh cooperation in the petrochemical sector is also on the rise, the Kazakh energy ministry said in a press release. Plastic Waste to Chemicals

Kazakh energy minister Nurlan Nogayev, who recently participated in the opening of the petrochemical forum in Russia’s Tatarstan republic, said that earlier this year, Kazmunaigaz and Tatneft, the largest oil and gas companies of Kazakhstan and Russia respectively, signed an agreement on the basic terms of interaction on the production of butadiene and its derivatives, a Russian news agency reported.

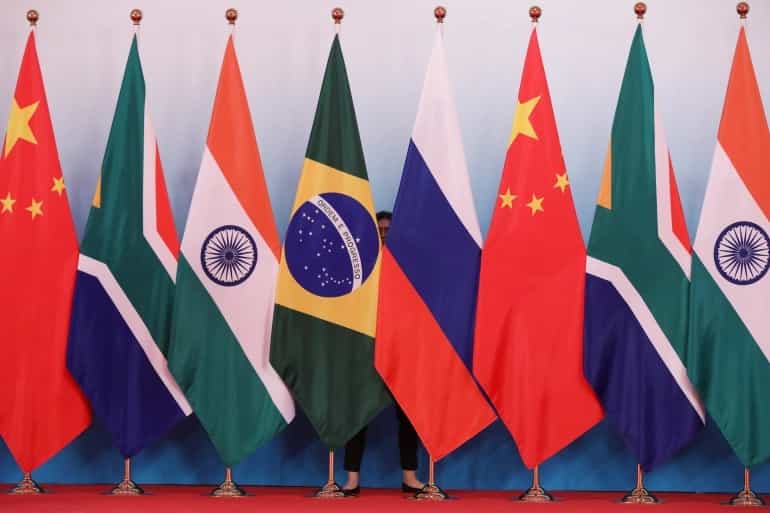

-BRICS Summit: Afghanistan likely to dominate discussions

The COVID-19 pandemic, security and Afghanistan are likely to dominate conversations at this year’s virtual BRICS Summit.

While the alliterative theme of this year’s BRICS Summit is “cooperation for continuity, consolidation and consensus”, conversations are likely to be dominated by the COVID-19 pandemic, security and Afghanistan.

For the second year running, Thursday’s annual gathering of the world’s leading emerging economies – including Brazil, Russia, India, China, and South Africa (comprising the acronym BRICS) – will be held virtually due to the pandemic.

The summit will be chaired by India’s Prime Minister Narendra Modi. Brazil’s President Jair Bolsonaro is slated to attend, along with President Xi Jinping of China, Russian President Vladimir Putin, and South Africa’s President Cyril Ramaphosa.

The attendance of Xi, who is selective about his appearances, is especially significant.

“China is sending a signal that it is still pursuing a multi-polar world,” Ian Johnson, senior fellow for China studies at the Council on Foreign Relations, told Al Jazeera. “It’s also part of China’s continuing foreign policy to water down US influence in the world by pursuing other groupings of countries, such as BRICS.”

-LG Electronics increases goal to use recycled plastic by 2030

The company aims to use 600,000 metric tons of recycled plastic in its products by 2030.

LG Electronics, headquartered in Seoul, South Korea, has set a goal to use about 600,000 metric tons of recycled plastic by 2030. The company says the goal is part of LG’s larger initiative to create a takeback ecosystem for electronic scrap and increase the use of postconsumer recycled materials in its consumer electronics and home appliance products. Plastic Waste to Chemicals

In 2020, LG used about 20,000 metric tons of recycled plastic in its products, according to a news release from the company. While recycled plastic is currently used in LG TVs, monitors, speakers, washing machines, refrigerators and air conditioners, LG will expand the use of recycled plastic to the exterior of its products as well.

The company reports that it also wants to reduce the use of virgin plastic throughout its operations. This year, 18 LG OLED TV models will be produced using less virgin plastic, reducing as much as 10,000 metric tons of virgin plastic use.

-Continental presents sustainable vehicle interior of the future

Continental has shown off its Ambienc3 concept at IAA Mobility (Munich), a vehicle with an interior that the company says revolves around driving, working and relaxing. The manufacturer predicts that these three activities will merge in vehicles of the future, leading it to try and design the ‘perfect’ interior. Plastic Waste to Chemicals

The concept makes use of a range of new materials and sustainable vehicle solutions, and the very vehicle that the interior sits within, a classic VW T2 microvan, is in keeping with the upcycling and environmentally friendly theme of the concept.

“With the Ambienc3 we are connecting a globally renowned icon of the automotive world with new, intriguing surfaces and future-focused technologies, whose attributes assist driving, working and relaxing as effectively as possible and distinguish them through color, design and material,” commented Ralf Imbery, global director innovation, transformation and design, Continental’s surface experts.

-European industry backs 30% plastics target

European plastics producers have called call for a mandatory EU-wide recycled content target for plastics packaging of 30% by 2030.

Trade body PlasticsEurope said the revision of the EU Packaging and Packaging Waste Directive was key to the transition to a circular economy for plastics.

It has supported the European Commission’s proposal for a mandatory target and has now said this should be set at 30%. Plastic Waste to Chemicals

Ramping up chemical recycling would be essential to achieving this and members companies planned investments in this in Europe ranged from €2.6bn by 2025 to €7.2bn by 2030.

Markus Steilemann, president of PlasticsEurope said: “The call for a regulated recycled content target for plastics packaging in the EU demonstrates our commitment to accelerate the transformation to a circular economy, helping implement the EU Green Deal and Circular Economy Action Plan.”

-Engie, Scatec To Produce Green Hydrogen In South Africa

France’s Engie has signed a contract with Release by Scatec, a subsidiary of Norwegian independent power producer (IPP) Scatec, to produce green hydrogen for the Mogalakwena platinum mine in Limpopo Province of South Africa.

The two partners aim to be the first to begin commercial production of green hydrogen in Africa.

Engie has already signed an agreement with UK miner Anglo American to produce green hydrogen at the Mogalakwena mine.

Release by Scatec is to provide modular solar power generation solutions for the project for an initial two years. The containerised technology installed at the Mogalakwena mine will offer 616 kW of solar capacity.

“We are proud to support Engie and Anglo American in this important project. This is Scatec’s first involvement in powering hydrogen production, and further demonstrates the potential of pre-assembled and containerised solar PV in the mining industry,” says Hans Olav Kvalvaag, senior vice-president Release at Scatec. The electricity generated will be converted via electrification into green hydrogen to power Anglo American’s facilities.

Research and development of green hydrogen production is gaining momentum in South Africa, and elsewhere in Africa, with projects brought in by major groups such as Siemens, Man and Eni in Egypt.

In South Africa, green hydrogen is also being developed by Sasol. The chemical giant wants to set up green hydrogen transport solutions.

A recent study from IHS Markit found that South Africa was well-placed to pursue a national strategy based on low-carbon hydrogen.

Plastic Waste to Chemicals