Plastics-recycling – Polyester-textiles 28-12-2022 - Arhive

Plastics-recycling – Polyester-textiles

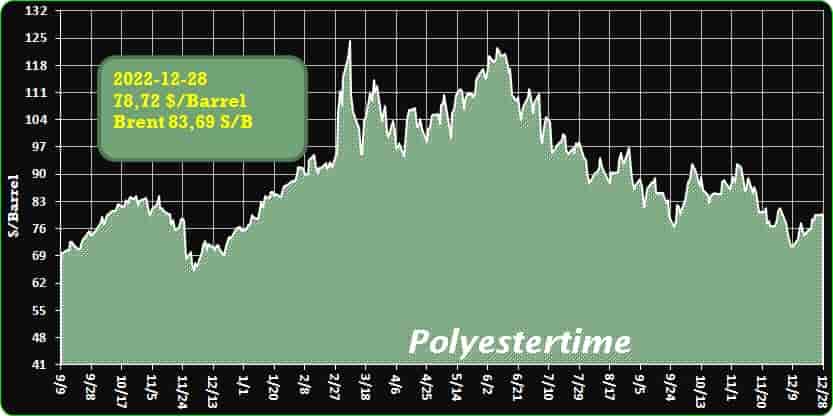

Crude Oil Prices Trend

Crude Oil Prices Trend Polyestertime

-Amcor sells factories in Russia

Amcor announced it completed the sale of its three factories in Russia to HS Investments, a Russian-based investor, after receiving all necessary regulatory approvals and cash proceeds, including receipt of closing cash balances, said the company.

The cash and debt free consideration value is EUR370 million. This follows Amcor’s previously announced decision to pursue the orderly sale of its Russian business while continuing to support its people and customers as well as preserving value for shareholders. Plastics-recycling – Polyester-textiles

The Russian business produces flexible and cartons packaging from one site in St. Petersburg and two sites in Novgorod and employs approximately 900 people. Amcor’s three sites in Russia generated approximately 2% of total Amcor sales in fiscal 2022.

Cash proceeds are expected to be used primarily for debt repayment and share repurchases. The transaction is not expected to have a material impact on the outlook for fiscal 2023. Plastics-recycling – Polyester-textiles

We remind, Amcor, a global leader in responsible packaging solutions, on 15 Dec 2022 announced the opening of its new state-of-the-art manufacturing plant in Huizhou, China. With an investment of almost USD100 mln, the 590,000-sq-ft plant is the largest flexible packaging plant by production capacity in China, further strengthening Amcor’s ability to meet growing customer demand throughout Asia Pacific.

-US’ NREL team finds cheaper way of recycling waste polyester textiles

Scientists from US’ National Renewable Energy Laboratory (NREL) have discovered enzymes that could make it cheaper to recycle waste polyester textiles and bottles than making them from petroleum. The NREL-led team discovered variants of plastic-eating enzymes that adapt to deconstructing all varieties of polyethylene terephthalate (PET)—even durable crystalline varieties.

The team was able to discover the enzymes using advanced methods in machine learning, NREL said in a press release.

Created from petroleum refining, PET is a material known for its durability and versatility. It is easily moulded into airtight containers, woven into durable carpets, or spun into polyester clothing. Plastics-recycling – Polyester-textiles

“The reality is that most PET products—especially PET clothing and carpeting—are not recycled today using conventional recycling technologies,” explained Gregg Beckham, senior research fellow at the NREL and CEO of the US Department of Energy BOTTLE Consortium. “The research community is developing promising alternatives, including enzymes designed to depolymerise PET, but even these options have tended to lean on energy-intensive and costly preprocessing steps to be effective.”

As a result, most PET produced today eventually finds its way into landfills or the environment—even PET products that actually make it into the recycling bin.

Still, Beckham said that narrative is changing quickly. Advanced methods in machine learning and synthetic biology have given scientists an unprecedented look into the fundamental biology of PET-deconstructing enzymes. As detailed in an article published in Nature Communications, Beckham and colleagues at University of Portsmouth and Montana State University used these methods to discover new enzyme variants that show promise at deconstructing even the toughest PET without extra preprocessing.

“Not only could that mean we are on the cusp of enzymatic recycling for all forms of PET, including carpeting and clothing—it means it could soon be cheaper to recycle PET than making it from scratch with petroleum,” NREL said on its website.

Cleaning, shredding, and heating—steps needed to prepare PET for deconstruction—are among the most important sustainability drivers of an industrial-scale enzymatic recycling facility, according to Beckham.

“Minimising these preprocessing steps is critical for making enzymatic recycling cost competitive with creating PET resin from petroleum,” Beckham explained.

In follow-up experiments, the team noted that some of the enzymes flagged by their machine learning methods were equally effective at breaking down crystalline and amorphous PET. Those enzymes simply did not need preprocessing to help soften the bonds of the plastic. Plastics-recycling – Polyester-textiles

-Turkiye’s central bank maintains policy rate at 9% amid inflation

Turkiye’s central bank has announced that it has fixed its policy rate at 9 per cent, which ended a four-month interest-rate cutting cycle in spite of a rise in inflation. The Central Bank of the Republic of Turkiye (CBRT) slashed interest rates by 500 basis points from August to November 2022. Plastics-recycling – Polyester-textiles

“Leading indicators point to the continuation of recession concerns in developed economies as a result of ongoing geopolitical risks and interest rate hikes. The high level of energy prices and the likelihood of a recession in main trade partners keep the risks on current account balance alive,” the CBRT said in a press release on interest rates.

The country reflected an inflation rate of 84.4 per cent in November 2022, which was a decrease from the 85.5 per cent jump in October—the first drop in the annual inflation rate since May 2021, as per local media reports.

The rate of credit growth and allocation of funds for real economic activity purposes are being closely monitored. The Monetary Policy Committee (MPC) will continue to use the tools supporting the effectiveness of the monetary transmission mechanism and the entire policy toolset, particularly funding channels, will be aligned with liraisation targets.

The MPC evaluated that the current policy rate is adequate after considering the increasing risks regarding global demand. The credit, collateral and liquidity policy actions, of which the review process is finalised, will continue to be applied to reinforce the effectiveness of the monetary policy transmission mechanism. Plastics-recycling – Polyester-textiles

“The CBRT will continue to use all available instruments decisively within the framework of the liraisation strategy until strong indicators point to a permanent fall in inflation and the medium-term 5 per cent target is achieved in pursuit of the primary objective of price stability. Stability in the general price level will foster macroeconomic stability and financial stability through the fall in country risk premium, continuation of the reversal in currency substitution and the upward trend in foreign exchange reserves, and durable decline in financing costs,” added the release.

-Romgaz exploring Romania’s green hydrogen production opportunities.

Romanian natural gas producer Romgaz opened a 1.39 million lei ($302,000/ 284,000 euro) tender for a study to assess local green hydrogen production opportunities.

Romgaz expects the study to identify investment opportunities for the green hydrogen segment within a period of six years, according to specifications accompanying the tender notice published on Romania’s electronic public procurement system, SEAP.

Thus, Romgaz seeks to gain a strategic position on Romania’s emergent green hydrogen production market, as part of its 2021-2030 plan to produce energy with low carbon dioxide emissions through large-scale use of renewable sources.

Tendering for the study is open until January 25. Plastics-recycling – Polyester-textiles

Romgaz is the largest natural gas producer and the main supplier in Romania, in which the state owns a 70% stake.

Shares in Romgaz traded 0.88% higher at 40.35 lei as at 1137CET on Friday on the Bucharest Stock Exchange.

Earlier this month, Swedish energy systems manufacturer Metacon said that it has entered into a master supply agreement with Romania’s Ground Investment Corp for a 10 MW containerised hydrogen generation plant worth 16.13 million euro ($16.9 million).

In August, the European Commission approved a 149 million euro Romanian funding scheme made available through the Recovery and Resilience Facility to support the production of renewable hydrogen.

In June, Romanian majority state-owned hydro power producer Hidroelectrica said it is seeking consultants to draft a feasibility study for the construction of a 300 MW photovoltaic plant and a green hydrogen production plant on Olt river.

(1 euro=4.8981 Romanian lei)SNGN Romgaz SA is among the biggest companies in SEE, for more reference take a look at Top 100 companies

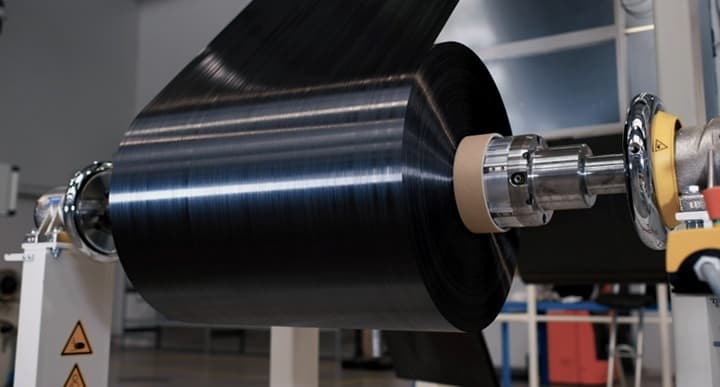

-Inside Teijin’s thermoplastic tape expansion

Teijin is qualifying its second thermoplastic tape line in Heinsberg, Germany, that will significantly expand the company’s presence in this material segment.

It is expected that thermoplastic composites will play a larger and critical role in the fabrication of primary structures for a variety of next-generation aircraft, ranging from large commercial jetliners to small electric vertical takeoff and landing (eVTOL) aircraft that will be the core of the emerging advanced air mobility (AAM) market.

Meeting this demand will require development and manufacture of thermoplastic tapes — unidirectional (UD) and multiaxial — that meet increasingly stringent quality requirements.

It was with these challenges in mind that Teijin Carbon Europe GmbH (Wuppertal, Germany) recently installed and commissioned a second thermoplastic tape line in its Heinsberg, Germany, facility. P lastics-recycling – Polyester-textiles

The first line, commissioned in 2011 and qualified for a Boeing application, is designed to provide thermoplastic tapes in quantities and widths adequate for research and development (R&D) and low-volume production purposes.

The Now and Next In Composites

The composites industry is constantly being shaped and reshaped by myriad forces – people, markets, technologies – all stimulating innovative new ways to apply fiber-reinforced materials in everything from boats and wind blades to airplanes and automobiles. CW Trending is a monthly video podcast that takes a closer look at these composites forces and helps you make sense of them. CW Trending features subject-matter experts, material suppliers, technology mavens and CW’s own editors to explore the ideas, technologies, trends and innovations in development or already in the marketplace. Join us and be a part of the conversation.

The second line, commissioned in 2019, uses the same manufacturing technologies as the first line, but at a scale, speed and consistency that represents a significant improvement across the board in manufacturing capability. Willem Jan ter Steeg, general manager development at Teijin Carbon Europe, introduced CW to the company’s new carbon fiber thermoplastic tape line via video and walked us through the system and its capabilities.

Wide, fast, long, repeatable

As he starts his tour of the line, ter Steeg notes that the process control offered in the new line provides Teijin unprecedented ability to quickly and consistently manufacture thermoplastic tapes that meet stringent quality standards for width, thickness, areal weight, resin distribution, fiber volume fraction (FVF), crystallinity and porosity.

First, and most notably, the new line can produce tapes in widths — 12 or 24 inches — not commonly found in the thermoplastic composites supply chain. Second, ter Steeg notes, the new line offers substantial flexibility, including up to 220 creel positions and the ability to adjust humidity, temperature, spreading parameters, tensioning and matrix content. “We have the possibility to go between 34 and approximately 40 or 42% matrix content,” ter Steeg says. “Theoretically we can go to 50%, but there is no request for this.” The line typically produces tapes with fiber areal weights (FAW) of 97-200 gsm; FAW of more than 200 gsm has been demonstrated.

UD carbon fibers are the primary reinforcement processed on the new line, though other materials like aramid can also be used. The carbon fibers come from Teijin directly, which is among the largest manufacturers of carbon fiber in the world.

As fibers emerge from the creels and are tensioned into the line, they enter the impregnation unit. Here, ter Steeg notes that the impregnation unit disperses the resin matrix as a powder that is then mixed with an emulsifier and applied to the fibers. The company favors this method — as compared to melt impregnation — as it provides a more consistent and even dispersion of the polymer. Plastics-recycling – Polyester-textiles

Teijin is primarily prepregging polyetheretherketone (PEEK) and polyphenylene sulfide (PPS) on this line, with low-melt polyaryletherketone (LMPAEK) and polyetherketonketone (PEKK) processed less frequently. Other resin matrix systems, ter Steeg notes, can be processed as well, but only if they are compatible with the emulsifier in the slurry.

Alfonso Lopez, aerospace marketing engineer at Teijin Carbon America, says, “The system that we’re talking about here is really very excellent for higher performance polymers, simply because they’re so difficult to handle. The quality of the tape manufactured in this particular method I think is really suitable and amenable to the quality that aerospace requires.”

Regarding non-powder/slurry impregnation, ter Steeg says, “Of course we are also looking into melt impregnation as an alternative to powder, but at the moment we do not have internal capacity with that technology. But we are watching this very closely.”

Following impregnation, the tape is passed through a dryer and then into a high-temperature oven, which does three things: melts the polymer to ensure homogenous polymer impregnation; helps minimize voids; and promotes proper crystallinity of the matrix. “With the oven we make sure we have the full impregnation of the molten polymer into the tape,” ter Steeg says, “and then of course we also handle the tape in such a way that we have the lowest possible amount of voids.”

Post-oven, the tape is trimmed to length — with offcuts collected and recycled as short fibers for injection molding — followed by laser-based width, thickness and areal weight measurement. “There is correlation of the width with the thickness, so we can basically predefine the fiber areal weight,” ter Steeg says. “And afterwards, we do measurements in the laboratory to ensure that we have the exact fiber areal weight and the exact resin content.” Plastics-recycling – Polyester-textiles

The tapes are then wound onto spools at the end of the line. “This is the 24-inch-wide roll,” ter Steeg says, pointing to a roll of tape at the end of the line. “We have 115 grams per square meter of PPS tape. Currently, this one is nearly 900 meters long without any [defect].” He adds that the line can produce tapes 2.5 kilometers long, without defect or interruption.

The speed of the lines cannot be revealed, but ter Steeg did claim that it can produce thermoplastic tapes at a rate greater than Teijin’s competitors. “The evaporation of volatiles from the slurry is the only limit on speed,” he notes. The total capacity of the line varies by the areal weight of the material being produced, but ter Steeg reports that the system, at maximum throughput and maximum areal weight, can produce up to 320 metric tons per annum.

In a control room adjacent to the tape line, Teijin technicians continuously monitor all manufacturing parameters, ultimately providing all of the production data needed for full material traceability. “This is critical of course for aerospace, as you know,” ter Steeg says, “to ensure that everything is traceable. So this is why we do have the continuous monitoring of all the essential data.”

In terms of overall product quality, Lopez says PEEK is the standard against which all other tapes are measured. PEEK crystallinity, he notes, is the most consistent of the three resins processed most frequently. “PEEK is the baseline because the crystallinity rate is so high that it really makes it amenable for welding and forming with a consistent degree of crystallinity, regardless of the rate at which you’re cooling,” he says. “That’s not necessarily the case with PEKK and low-melt PAEK, where you have to be more careful how you cool it. However, with the line that we have here, we can control the thermal history, so we can get materials off this line that have zero cold crystallization.”

The bottom line, ter Steeg says, is that the new line offers unprecedented process control options that produce highly consistent tape quality. “The length, width and speed at this quality is unique in the composites industry,” he says. “We are getting closer and closer to thermoset tape quality.” Plastics-recycling – Polyester-textiles

-Car maker Stellantis negotiating stake in Michelin hydrogen JV Symbio

Amsterdam-based group in exclusive negotiations over a “substantial stake” in hydrogen mobility company

Paris – Automotive giant Stellantis has started exclusive negotiations with Faurecia and Michelin to take over a “substantial stake” in their joint-venture hydrogen mobility company Symbio.

In a statement 23 Dec, Michelin said Symbio’s technical roadmap “perfectly matches” with Stellantis’ hydrogen roll-out plans in Europe and in the US.

The automotive group, which was formed in 2021 with the merger of Fiat Chrysler Automobiles and the French PSA Group, has been pursuing hydrogen mobility and launched its first “mid-size vans” in late 2021. Plastics-recycling – Polyester-textiles

As part of its ambitious “Dare Forward 2030” strategic plan, the car maker is expanding hydrogen offering to large vans as early as 2024 in Europe and 2025 in the US, while further exploring opportunities for heavy-duty trucks.

“This move will foster the speed of development to bring low emission products to our customers, beyond traditional electric vehicles,” said Stellantis CEO Calros Tavares.

Formed in 2019, the 50:50 Michelin-Faurecia joint venture aims to advance hydrogen fuel cells technology for vehicles.

In 2021, Symbio announced partnership with Stellantis to advance the group’s hydrogen fuel cell-powered commercial vehicles.

At the time, the Amsterdam-based automotive group said it planned to convert its commercial vehicles including the Peugeot Expert, Citroën Jumpy, and Opel Vivaro to hydrogen fuel.

-Colines shows 12 µm stretch film with up to 30% PCR at K

Innovative cast MDO-PE film-based pouches also shown at K

At the K2022 fair in October, Colines, which was also present at the Elite conference in Mumbai in September exhibited with live demonstrations one of its flat-head extrusion lines, the AllRollEX 3000 mm. We had an opportunity to meet Giuseppe Maddaluno at the company’s stand with the ongoing demonstration of the AllRollEx 3-meter wide cast line running daily from 11 am to 3 pm using its new Mastermind profile and line management system. In addition, Colines showed stand-up pouches produced using cast MDO-PE films produced using its latest generation MDO. Plastics-recycling – Polyester-textiles

The AllRollEX cast line shown at K was producing a 12 µm stretch film containing up to 30% PCR material obtained by chemical recycling from ExxonMobil. The stretch film was specified to be capable of over 400% ultimate strain and a 300% wrapping consistency. In test runs carried out at the fair on an Estl test machine, the ultimate strain values exceeded 400%, with a wrapping consistency better than 300%. In addition, Colines showed the new generation of its Allwrapper ‘any-bundle’ wrapper using stretch film in place of shrink film.

Colines handles recycled material for its cast and blown film lines, with the help of the Gneuss RSFgenius Melt Filtration system. This RSFgenius system is fully automated and can process up to 40% recycled content in the manufacture of 10 µm stretch film. The constant melt pressure offered by the RSFgenius system and its efficient self-cleaning function is a major benefit when using recycled materials. Gneuss also had its own stand at K.

Francesco Peccetti sales manager of Colines, at the Elite conference in Mumbai in September 2022 spoke about the new ‘Pure’ structure for barrier films and some of the company’s other innovations

As we learned at the Elite Conference in Mumbai in September, from Francesco Peccetti sales manager of Colines, the company is a pioneer in the engineering and manufacture of machine direction orientation (MDO) units that can add desirable properties on film lines. In his Elite presentation, Peccetti spoke about the company’s latest generation MDO that incorporates an IR heating unit. The company which manufactures a diverse range of plastic extrusion equipment has approximately fifty installations in India.

Colines’ expertise in cast extrusion or flat-head lines combined with MDO has evolved since its first stand-up pouches produced using an MDO-PE film obtained on a flat-head extrusion line. At K, the company showed stand-up pouches produced using a polyethylene-based film extruded with cast technology and its most recent generation MDO in line.

Seen as an alternative to MDO-PE films produced on blown film lines and also films based on PP and PET, the PE-based extruded film with cast technology is seen as an innovation that generated great interest at K. This is because an MDO-PE cast film is seen to have better optical properties and gloss values and is also much easier to both seal and to recycle with melting temperatures significantly lower than other polymers.

This MDO-PE cast film line was developed because an important end customer wanted an alternative to producing blown PE film with an inline MDO. Apparently, Colines announced a year ago, the successful development of a polyethylene-based cast MDO film featuring high mechanical and optical properties, and decorated using offset printing. The company says its next goal is to optimize the efficiency of its cast line to produce both MDO-PE film and the welding PE film that, in some cases, is necessary for the end products.

At K, where its stand was extremely busy with visitors often having to wait to enter for their appointments, Colines also presented its new Mastermind, a profile and line management system developed in cooperation with Elav, which became a subsidiary of the Gruppo Colines in 2006. The AllRollEX 3000 mm-wide cast extrusion line demonstrated at the stand was being manageed by the Mastermind automated electronic managment and control system. Plastics-recycling – Polyester-textiles

The impact, resilience, and growth of responsible packaging in a wide region are daily chronicled by Packaging South Asia.

A multi-channel B2B publication and digital platform such as Packaging South Asia.is always aware of the prospect of new beginnings and renewal. Its 16-year-old print monthly, based in New Delhi, India has demonstrated its commitment to progress and growth. The Indian and Asian packaging industries have shown resilience in the face of ongoing challenges over the past three years.

As we present our publishing plan for 2023, India’s real GDP growth for the financial year ending 31 March 2023 will reach 6.3%. Packaging industry growth has exceeded GDP growth even when allowing for inflation in the past three years.

The capacity for flexible film manufacturing in India increased by 33% over the past three years. With orders in place, we expect another 33% capacity addition from 2023 to 2025. Capacities in monocartons, corrugation, aseptic liquid packaging, and labels have grown similarly. The numbers are positive for most of the economies in the region – our platform increasingly reaches and influences these. Plastics-recycling – Polyester-textiles

Even given the disruptions of supply chains, raw material prices, and the challenge of responsible and sustainable packaging, packaging in all its creative forms and purposes has significant headroom to grow in India and Asia. Our context and coverage engulf the entire packaging supply chain – from concept to shelf and further – to waste collection and recycling. We target brand owners, product managers, raw material suppliers, packaging designers and converters, and recyclers.

Plastics-recycling – Polyester-textiles