Plastics rPET Nonwoven Hydrogen 19-10-2021 - Arhive

Plastics rPET Nonwoven Hydrogen

Crude Oil Prices Trend

-LATI Industria Termoplastici signs hemp plastics distribution agreement

Italy-based LATI Industria Termoplastici, a leader in self-extinguishing and high-performance thermoplastic compounds, and US-based sustainable hemp plastics provider The Hemp Plastic Company (THPC) have signed an agreement for the distribution of THPC’s line of ecological hemp blended plastics for use in packaging, automotive, furniture, toys and other sectors.

LATI has been committed to offering alternatives to plastics based solely on non-renewable sources, with a lower environmental impact. LATI’s range now includes sustainable products such as compounds based on polymers from mechanical or chemical recycling or from renewable sources. The themes of reuse and circularity have been in LATI’s remit since its foundation in 1945.

THPC CEO Glen Kayll said: “We are pleased to be working with LATI to bring our line of environmentally friendly hemp polymers to the European market. Hemp is one of nature’s greatest natural carbon absorbers, and together with a leader like LATI, we can accelerate our mutual customers’ transition to sustainable

-Shredding with a sustainable target

Multinational PET producer Indorama is investing in shredding to help it reach its sustainability and circular materials goals.

Thailand-based Indorama Ventures Public Co. Ltd. (IVL), a producer of polyethylene terephthalate plastic (PET) and other materials tied to the PET supply chain, has pursued a strategy of global growth that has included considerable investments in recycled-content PET (rPET) production.

The company’s global presence in rPET production may be unmatched, with the building of an rPET production and supply chain a high priority of IVL Chief Sustainability Officer Yashovardhan (Yash) Lohia. Yash is the son of IVL Group CEO Aloke Lohia.

The company’s investments in PET bottle recycling have spanned several continents, with this year marked in part by an increased presence in North America. This June, IVL announced and then completed the acquisition of a former CarbonLite PET bottle recycling plant in Texas.

In Europe, the company operates plants in France, Ireland, the Netherlands and Poland, while it also has rPET capacity in Latin America in Brazil and Mexico.

Asia also remains a target of IVL rPET investments, with the company announcing or completing new PET bottle recycling capacity in India and Indonesia this year alone. (A plant also is under construction in the Philippines.) The investments tie into an overall global goal of being able to recycle 50 billion PET bottles annually.

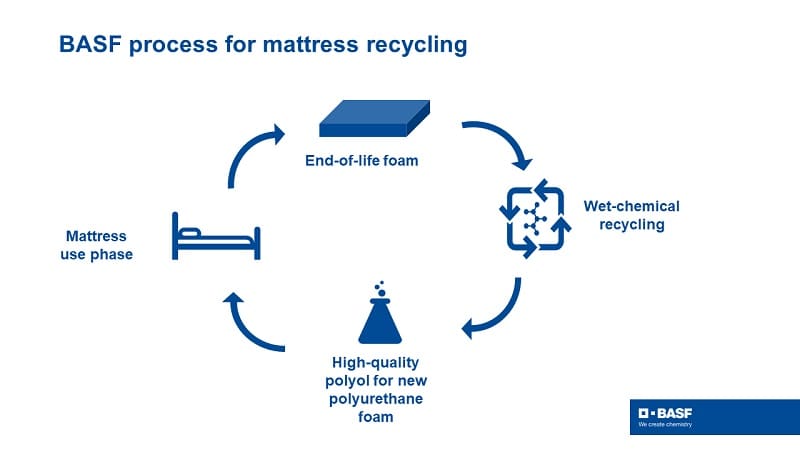

-Towards a circularity in recycling of mattresses

After an average of ten years most mattresses today are thrown away, thus squandering resources and creating high quantities of waste. At the same time, valuable raw materials are needed to manufacture new soft foam mattresses – above all crude oil. A circular economy solution for mattresses can therefore both reduce waste and save fossil resources.

At BASF, we are continuously looking at ways to reuse and re-enter waste into product lifecycles and to foster circular economy solutions. With the circular economy concept BASF aims to decouple economic growth from the use of finite resources and is accelerating the adoption of these principles into our day-to-day operations. BASF offers a solution to finally closing the loop for polyurethane soft foam with the chemical recycling of mattresses.

-Recycling through Pyrolysis: A Route with Great Promise for Circular Packaging

Carlos Ludlow Palafox, CEO of Enval Ltd. and the creator of a unique technology based on microwave-induced pyrolysis for flexible packaging including plastic laminates, shares his vision.

In the relentless global battle against the effects of the aggression towards the environment, diversity of perspectives is a constant source of controversy, but also of entrepreneurship and innovative technologies. This is the case of

Recycling through Pyrolysis: A Route with Great Promise for Circular Packaging

Carlos Ludlow Palafox, CEO of Enval Ltd. and the creator of a unique technology based on microwave-induced pyrolysis for flexible packaging including plastic laminates, shares his vision.

In the relentless global battle against the effects of the aggression towards the environment, diversity of perspectives is a constant source of controversy, but also of entrepreneurship and innovative technologies. This is the case of Enval Ltd., a company based at Huntingdon, United Kingdom. The absence of collaborative actions from different players within the production and consumption chains seems to stand in the way of achieving significant advancements in the mitigation or even revert their negative effects on our environment. Plastics rPET Nonwoven Hydrogen

However, urgency is manifest; and where most advancements towards the development of high-impact strategies in defense of the environment arise is in the efforts pushing the creation of innovative technologies to efficiently reuse materials and reincorporate them to the production chains.

With a critical yet realistic sense, Carlos Ludlow Palafox —who has developed a singular patented solution with microwave-induced pyrolysis for flexible plastic packaging,even laminates including aluminum, which recuperates materials from packaging waste into ready-to-use oils— drew, in a conversation with Mundo PMMI a clear picture of the possibilities currently opening worldwide through pyrolysis technologies.

., a company based at Huntingdon, United Kingdom. The absence of collaborative actions from different players within the production and consumption chains seems to stand in the way of achieving significant advancements in the mitigation or even revert their negative effects on our environment.

However, urgency is manifest; and where most advancements towards the development of high-impact strategies in defense of the environment arise is in the efforts pushing the creation of innovative technologies to efficiently reuse materials and reincorporate them to the production chains.

With a critical yet realistic sense, Carlos Ludlow Palafox —who has developed a singular patented solution with microwave-induced pyrolysis for flexible plastic packaging,even laminates including aluminum, which recuperates materials from packaging waste into ready-to-use oils— drew, in a conversation with Mundo PMMI a clear picture of the possibilities currently opening worldwide through pyrolysis technologies.

-Living nonwovens with Reicofil at INDEX

Reifenhauser Reicofil will exhibit at this week’s INDEX exhibition in Geneva (booth 2531) where, under the slogan Living Nonwovens, the nonwoven line specialist will showcase solutions for the production of sustainable nonwovens for a wide range of applications.

As Markus Müller, sales director at Reifenhauser Reicofil notes, sustainable nonwoven production starts with the amount of material used – the less raw material needed, the better. The Reicofil 5x line series specialises in this application and achieves fabric weights of 8 gsm (grams per square metre) or less through efficient downgauging, including on 1000 m/min composite lines containing three spunbond beams.

In addition, Reicofil customers can reduce the use of fossil raw materials on request by processing biobased raw materials as an ecological alternative – for example for diapers. The topsheet material, made of bulky, soft, and industrially compostable high-loft nonwovens, meets maximum hygiene requirements at the same time.

-Essar Oil plans to build USD1 billion low-carbon hydrogen plants in England

British refiner Essar Oil plans to build two low-carbon hydrogen plants at its Standlow refinery in northwest England at a cost of 750 million pounds (USD1 billion), according to Hydrocarbonprocessing.

The company has submitted planning applications for the project, it said in a statement.

If approved, construction of the two so-called “blue hydrogen” plants, where the fuel is produced from natural gas and carbon emissions from its production are captured and stored, will begin at the end of 2022 with output expected to begin from the mid-2020s.

As MRC informed earlier, in late September 2019, Essar resumed operations at its cracker in Stanlow, UK with the capacity of 45,000 mt/year of ethylene and 165,000 mt/year of propylene. It was shut on 11 September, 2019, due to the power outage at the site.

Ethylene and propylene are the main feedstocks for the production of polyethylene (PE) and polypropylene (PP), respectively. Plastics rPET Nonwoven Hydrogen

-Possible biotech solution to silkworm virus

Kraig Biocraft Laboratories, the biotechnology company focused on the development and commercialis ation of spider silk, is preparing to conduct challenge testing on two lines of immunity-enhanced silkworms. These silkworm lines were developed by Kraig Labs to combat one of the biggest challenges facing the global silk production industry.

It has been reported that as much as 50% of all losses in silk production result from a single widespread virus – a variant of nucleopolyhedrovirus, which is a baculovirus that selectivly and specifically targets Bombyx mori, the silkworm moth.

A 2020 paper cited that 75% of all silkworm raisers interviewed reported losses due to the disease. With no effective treatment, this virus results in countless millions of dollars of economic damage annually. Kraig Labs realised that the technologies it was developing for other applications could be used to significantly reduce these losses in the broader silk industry. The company has made rapid progress in the development of this new technology.

-innovations for interior design

After a challenging year 2020 for the Trevira CS business, in which the corona crisis put pressure on the markets for contract textiles, in particular the hotel and event sector as well as cruise shipping, positive signals are emerging on the market. Numerous new developments, especially from Trevira CS Club members, mark the way forward to the time “after Corona” and pick up on the trends intensified by the crisis.

Trevira will continue the successful Trevira CS Club concept in 2021. The Gold and Silver members of the year 2020 were transferred their status for the year 2021. The Trevira CS Club 2021 is made up of yarn producers, fabric manufacturers and textile publishers or wholesalers and unites members with gold status (such as.B. Gebrüder Munzert, Jab Anstoetz, Kvadrat) and silver status (such as.B. Delius, Sahco, Zimmer + Rohde).

Although the corona pandemic has clouded individual business areas, it also has the potential to open up new market opportunities for flame-retardant Trevira CS fabrics in the long term. Plastics rPET Nonwoven Hydrogen

The increased work from home as well as the longer and frequent stay in one’s own four walls has led to a change of perspective as far as the relevance of interior design is concerned. After Trevira CS has increasingly found its way into private living space in recent years, textiles for this area can also be found in the new collections.

The record high CO2 price also means that it would be cheaper to capture and store the emissions from steam methane reforming than to release it into the atmosphere, calculations show

The price of natural gas in Europe is currently so high that it would currently be cheaper to produce green hydrogen from renewable energy than grey or blue H2 from methane, according to new calculations. Plastics rPET Nonwoven Hydrogen

And the record high EU carbon price of €60 ($69) per tonne of CO2 means that grey hydrogen from unabated natural gas would currently be more expensive to produce than blue H2 (made in the same way but with carbon capture and storage) — although, of course, there is no blue hydrogen being produced in Europe yet.

Calculations by Australian maths-as-a-service company Keynumbers and the Energy Flux newsletter show that, under a realistic set of assumptions, the levelised cost of green hydrogen manufactured today would be €4.18 per kilogram, compared to €6.55/kg for grey H2 and €6.21/kg for blue.

-Polyamide Market Size Worth $53.32 Billion By 2028 | CAGR: 6.2%: Grand View Research, Inc.

The global polyamide market size is expected to reach USD 53.32 billion by 2028, according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 6.2% from 2021 to 2028.

Increasing adoption of polyamide in numerous industries, including automotive, electrical and electronics, consumer goods and appliances, packaging, and textiles is projected to fuel the market growth during the forecast period. Polyamides are widely used in the exterior parts of vehicles such as front-end grilles, fuel caps, wheel covers, doors, exterior mirrors, and tailgate handles.

Polyamide composites are expected to witness high demand from the automotive industry due to factors such as excellent mechanical properties, wear resistance, and the growing need for lightweight vehicles in order to improve fuel efficiency. Polyamide has been extensively used in the engine compartment to replace steel parts owing to the benefits derived from them such as lower weight and greater design flexibility as against traditional metals.

Key players in the market are continuously carrying out innovations and developing new versions of polyamide compatible with new polymer processing technologies.

Plastics rPET Nonwoven Hydrogen