PlasticsRecycling Petrochemicals BioPET 14-07-2021 - Arhive

PlasticsRecycling Petrochemicals BioPET

Crude Oil Prices Trend

-Teijin starts commercial production of carbon fiber products in Vietnam

Company initially will produce carbon fiber materials for sports and outdoor activities

Teijin Limited announced today that Teijin Carbon Vietnam Co., Ltd. (TCV) in Ha Nam, Vietnam, has started operating commercially to manufacture carbon fiber products including prepreg, a fiber sheet pre-impregnated with matrix resin as an intermediate material for composites. TCV initially will produce carbon fiber materials for sports and outdoor activities, including fishing, golf, bicycle and ice hockey goods, for markets in Southeast and South Asia and Asia-Pacific. Sales will be handled by TCV as well as carbon fiber sales affiliates of Teijin operating in these markets.

TCV, Teijin’s carbon fiber business base in Vietnam, was established in May 2019 to manufacture carbon fiber products, aiming to capitalize on the expanding demand for carbon fiber while strengthening Teijin’s global business capabilities. Teijin’s sales affiliates in Singapore, Shanghai and Taipei work to identify demand opportunities as well as provide customer services in Asia. Internal collaborations between these companies and TCV will strengthen Teijin’s presence in the upstream and downstream sectors of Asia’s fast-growing markets.

The United Nations Sustainable Development Goals (SDGs) of 2016 have been released by the European Commission.

The new EU climate law increases the emission reduction target from 40 percent to at least 55 percent by 2030 to meet the expectations of the November World Climate Summit in Glasgow. PlasticsRecycling Petrochemicals BioPET

TOMRA aims to help achieve the goals and take waste management to another level. A new study commissioned by TOMRA and conducted by EUNOMIA demonstrates the potential for an optimized waste management system regarding climate change. Overall, a reduction of 2.76 billion tonnes of CO2 per year is possible.

This reduction can be achieved using Holistic Resource Systems – the optimized combination of key waste management practices for collection, sorting and recycling to facilitate the transition toward a circular economy, which prevents resource depletion, reduces littering and contributes to a carbon neutral world.

-RECOUP receives funding for plastics recycling communications research

Innovate UK grant to help fund recycling education project in Kent.

RECOUP (Recycling of Used Plastics Ltd.,) Peterborough, U.K., has received a grant from Innovate UK to co-fund an industry-led communications and behavior change research project in Kent that brings together Kent Resource Partnership, Veolia, Viridor, Ocado, Ecosurety, British Plastics Federation, Plastics Europe and PPS Recovery Systems. PlasticsRecycling Petrochemicals BioPET

RECOUP’s Pledge2Recycle Plastics will connect with the 673,00 households across Kent over a 12-month period to gain citizen insights, deliver plastics recycling messages and evaluate the resulting tonnage and contamination data, the organization says.

The project will deliver and measure over time the impact recycling communications campaigns have on behavior change.

The nonprofit says it expects the insights collected will provide evidence to support future plastics recycling engagement strategies.

-Coperion: from PET flakes to granules without pre-drying

Polyethylene terephthalate (PET) is a high-value material that is on course to take over a key function in the plastics industry’s path toward a circular economy. PET flakes can now be processed without pre-drying into pellets using Coperion ZSK twin screw extruders. Next they are condensed in the SSP (Solid State Polycondensation) reactor, and reprocessed back into bottles again with the quality of virgin material.

PET recyclate manufactured using this innovative process has received approval from the United States Food and Drug Administration (FDA) for food-contact uses. Thanks to the highly efficient plastification within the ZSK extruder, Coperion systems for this bottle-to-bottle recycling process achieve throughput rates between 2 and 8 tons per hour, therefore recycling companies profit from very high product quality, reduced operating and logistic expenses as well as from energy cost savings up to 30% in comparison to conventional PET recycling methods. PlasticsRecycling Petrochemicals BioPET

Bottle-to-Bottle Recycling Now Clearly More Efficient

PET plays an ever more important role in recycling, due to the large volume of packaging materials in use today. PET is a very high-value material, possessing extremely good properties for reprocessing. Its continuously expanding use in single- and reusable bottles, as well as its recovery via deposit systems, add to its value. Correspondingly, it can be lucrative for companies to focus on PET recycling.

-POLYPLASTIC increases supplies of polymer compounds to Poland

R&P POLYPLASTIC, the largest Russian manufacturer of thermoplastic composite materials, has begun regular deliveries of Armamid PA6 SV 15-1E compound under the Export Fast and Furious progra, the company said.

The first batch of 10 tons was shipped in April, and in July the delivery volume was doubled and amounted to 20.5 tons. It is noted that the processing of the first batch of materials by SPE “POLYPLASTIC”, received in the spring, confirmed the high quality of the products, so the end client doubled the request. Parts of industrial equipment are produced from the Russian compound in Poland. Impact-resistant glass-filled Armamid PA6 SV 15-1E allows to manufacture products by injection molding. PlasticsRecycling Petrochemicals BioPET

The material is distinguished by increased values of mechanical properties, resistant to the action of hydrocarbons – for example, kerosene, gasoline, diesel fuel, etc., as well as mineral and synthetic oils, concentrated and weak alkalis, weak acids.

“Having established regular deliveries of Armamid PA6 SV 15-1E to Poland, we are not satisfied with what has already been achieved. Today the company is negotiating with partners to bring another material based on polyamide-6 to the Polish market, and they are moving forward quite successfully. that Russian compounds are quite competitive on the European market, “notes Pavel Kruglov, General Director of Trading House Polyplastic, an authorized commission agent of R&P POLYPLASTIC.

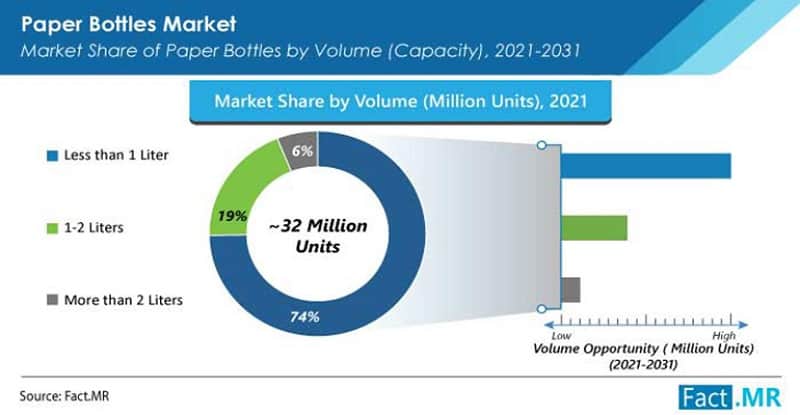

-Paper Bottle Market Driven by Sustainability

Valued at $25.2 million in 2020, the market for paper bottle packaging is forecast by a new report to expand at a CAGR of more than 6% over the next 10 years.

The standard grocery-store checkout question “plastic or paper?” is now spilling over into the bottle packaging market, according to a new report focused on an upstart format that’s gaining traction with brands: paper bottles. Brand owners’ commitment to improved sustainable practices through packaging choices is leading to increased adoption for this emerging option, according to the Paper Bottles Market, a just-published market study from Fact.MR. PlasticsRecycling Petrochemicals BioPET

Valued at $25.2 million in 2020, the increasing use of paper bottles in food and supplements, wine and spirits, personal care products, home-care products, and other categories is forecast to expand at a steady CAGR of more than 6% over the next 10 years.

Market giants such as L’Oreal, Coca-Cola, Carlsberg, PepsiCo, and others have collaborated with leading paper bottle manufacturers to provide them with innovative solutions in order to cut down on plastic consumption for bottle manufacturing. Such constructive collaborations have led to a surge in production and supply of paper bottles, driving global demand.

-New resin offers increased moisture barrier resin technology

Nova Chemcial’s next-generation Surpass HPs267-AB HDPE is designed for blown-film applications. PlasticsRecycling Petrochemicals BioPET

Nova Chemicals Corp. has introduced a new high-density polyethylene (HDPE) resin that it says offers significantly improved moisture barrier for multilayer flexible packaging and enables development of more recyclable polyethylene (PE) films.

Nova’s next-generation Surpass HPs267-AB resin offers stiffness and heat resistance that enable the acceleration of the plastics circular economy by allowing packaging engineers to design more recyclable PE film structures.

Designed for blown-film applications using Nova’s Advanced Sclairtech technology, HPs267-AB delivers up to a 20 per cent increase in water-vapor transmission performance in multilayer coextruded film structures compared to the company’s best-in-class Surpass HPs167-AB resin, officials with Calgary-based Nova said.

-PET bottle chip processing spread low, will plants massively shut down ?

PET bottle chip processing spread has been squeezed to near 600yuan/mt for a long while. Some plants begin to announce output cutback or shutdown plans.

According to CCFGroup statistics, so far, a total of 900kt/year PET resin capacity has been shut (excluding long-term shut plants previously and not fully run capacity). If future turnaround plans are implemented, like Sanfame to cut production by 30%, Wankai 250kt/year unit to turnaround mid-late Jul(though mainly producing PET fiber chip), Sinopec 150kt/year line to chop output in Jul-Aug, 900kt more output may be reduced in Q3. But since turnaround and output cut doesn’t concentrate in the same period of time, impact over industry operating rate is limited.

By then, PET bottle chip industry run may average down to slightly above 70% (80% based on designed capacity). In fact, compared with previous years, such a reduction in output is not too big. PlasticsRecycling Petrochemicals BioPET

Judging from the raw material market this year, polyester raw material prices are still on the low side most of the time, and the duration of the recent sharp rise is not too long, during which there are downward adjustments, so the pressure from the cost side is not very large. Even if some bottle chip factories have the idea of reducing production, not many have actually put it into action.

-VFSE: Continuous raw materials shortage affecting converters

Vinyl Films and Sheets Europe (VFSE) has expressed its concern at the continuation of force majeure declarations from European raw material suppliers.

VFSE: Continuous raw materials shortage affecting converters

The difficult situation in Europe is now also joined by similar problems in the US and other countries. PlasticsRecycling Petrochemicals BioPET

A press statement read: ‘This situation has led to a serious shortage of raw materials that puts the production of VFSE members at risk. The difficult situation in Europe is now also joined by similar problems in the US and other countries that make import operations of raw materials very difficult.’

The plastics converting sector is yet to fully recover from the ongoing pandemic. Furthermore, since the beginning of the year, converters are also struggling with the challenge of raw material shortages and price increase.

-Meeting the limits – reliable coloration of bioplastics

Thanks to the Colortherm-brand iron oxide pigments from LANXESS, which are proven to be almost completely free from heavy metals, the limits for biodegradable plastics can be reliably maintained, even with a high pigment content

Iron oxide pigments from LANXESS are not affecting biodegradation and compostability of bioplastics

Pigment analysis makes it easier to ensure compliance with heavy metal limits in formulations PlasticsRecycling Petrochemicals BioPET

LANXESS supports masterbatch producers in the process of formulating colored biodegradable plastics by offering pigment analyses. As a result, the Inorganic Pigments (IPG) business unit offers a unique service by providing its customers with recommendations regarding the maximum pigment concentration of iron oxide pigments of the Colortherm brand in so-called bioplastic formulations with a low heavy-metal content.

“Our Colortherm iron oxide pigments are ideally suited to the task of coloring compostable plastics. The decomposition of the polymer is not affected,” says Stefano Bartolucci, Global Market Segment Manager for Plastics at IPG. “Based on the recommended pigment dosing, masterbatch producers can instantly develop individual formulations for colored biodegradable plastics – no expensive pigment screening is required,” says Bartolucci. Thanks to the Colortherm-brand iron oxide pigments from LANXESS, which, unlike alternative products on the market, are proven to be almost completely free from heavy metals, the limits for biodegradable plastics can be reliably maintained, even with a high pigment content.

PlasticsRecycling Petrochemicals BioPET

PlasticsRecycling Petrochemicals EcoNy 13-07-2021