PlasticsRecycling Petrochemicals EcoNy 13-07-2021 - Arhive

PlasticsRecycling Petrochemicals EcoNy

Crude Oil Prices Trend

-India petrochemical demand may soon return to pre-pandemic levels – CPMA

India’s petrochemical demand should be able to return to pre-pandemic levels in the current fiscal year ending March 2022, an industry group executive said, citing moderate impact of the previous year’s sharp economic slowdown to the sector.

“Owing to end-market diversity and exposure to more resilient sectors, the impact of an economic recession on petrochemicals was moderate in the last one year as compared with other industries,” said Mahinder Singh, secretary general of India’s Chemicals and Petrochemicals Manufacturers’ Association (CPMA) told ICIS on Monday.

In the previous fiscal year ending March 2021, major commodity polymers – polypropylene (PP) and polyethylene (PE) – have performed well, he said.

“Demand (for PP and PE) remained at the same level as that in 2019-20,” Singh said.

“However, the demand for fibre intermediates got affected by around 20%, which has been rebounding to 2019 levels in the current financial year,” he said.

In late April and early May, at the height of the second wave of COVID-19 infections in India, run rates across most Indian polyester producers had dropped by nearly 30% to around 50%, according to media reports.

At the time, various forms of lockdowns had been in place across different states to stem the deadly contagion.

-China unveils new circular economy plan

China outlines next steps of its circular economy model within the remits of a new national five year plan to that effect.

China released its newest five-year plan (2021-2025) outlining goals for the adoption of a circular economy system on July 7PlasticsRecycling Petrochemicals EcoNy

The National Development and Reform Council (NDRC) intends to promote green design and clean production as well as establish a recycling system that extends to Chinese society as a whole. Major objectives are the gradual phasing out of fossil fuels in favour of renewable energy sources as well as the reduction of consumption and water use per unit GDP by 13,5 and 16 percent respectively by 2025.

In the agricultural sector, China is set to promote cleaner cultivation methods for livestock and aquatic products. Waste management is also a major concern, recycling being key here-China intends to improve the recycling proportion of electronic waste as well as that of energy saving lamps.

-New Bio-Gran Technology Processing Biodegradable Plastics

The new Bio-Gran technology by CMG Granulators was designed to handle small to large quantities of biodegradable polymer effectively and dependably, reportedly preserving all physical and mechanical characteristics of the polymer itself.

According to the company, conventional granulation equipment is not able handle biodegradable production rejects adequately.

As a result, those are not reintroduced in the production process and are given away for random recycling attempts. PlasticsRecycling Petrochemicals EcoNy

The Bio-Gran technology was designed to accomplish the objective of allowing recycling and reintroduction of biodegradable production rejects at the production site, by performing adequate size reduction and consequential storage/handling/processing so not to compromise the integrity of the polymer. The reject rate, predominantly deriving by post production finishing phases of the product, can be of a few percentage points up to tens of percentage points.

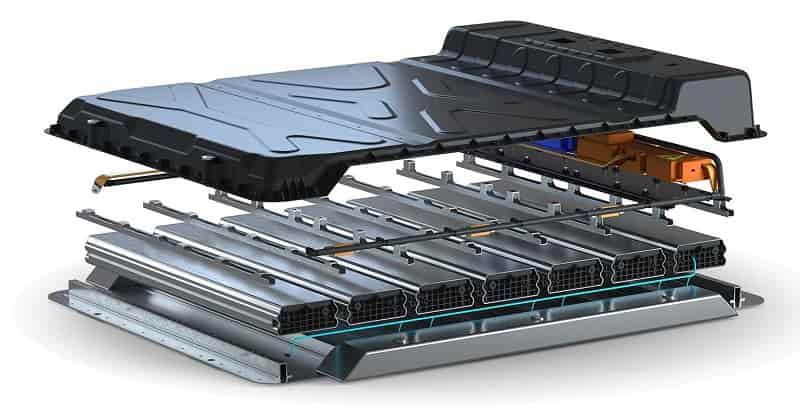

-Lightweight, Low-Cost Battery System Developed for E-Mobility Applications

A glass-fiber-reinforced epoxy SMC for the battery housing contributes to an overall 10% weight reduction without adversely affecting mechanical performance or safety.

Carmakers continue to make strides in extending the range of electric vehicles, a key factor in enticing consumers to make the switch from their gas guzzlers. This can be achieved through improved battery storage capacity and energy recovery technologies. Another means to that end is by lightweighting components and, thus, reducing the amount of energy the car consumes. That is the mission of a German consortium formed in 2019 that has developed a housing and battery concept for electric vehicles that meets all requirements for mechanical performance, manufacturability, and safety while reducing unit weight by about 10%.

Consortium members Lorenz Kunstofftechnik, Forward Engineering, Evonik, Lion Smart, Vestaro, and recent recruit Minth, a Chinese carmaker that joined this year, have developed a series-suitable battery concept in three energy configurations that, they claim, equals or surpasses batteries currently on the market in terms of energy density, safety, and cost. Proper material selection, as is often the case, was crucial to the success of the project. PlasticsRecycling Petrochemicals EcoNy

-Pinnacle Polymers Announces August US PP Price Increase

American Pinnacle Polymers, one of the main producers of polypropylene (PP) in the US, announced an increase in August prices for all grades of polypropylene (PP) in the US market, the company said in a letter to its customers.

Thus, an increase in PP prices in the amount of 5 cents per pound or USD110 per ton will come into effect on August 1, 2021 or under the terms of current contracts.

PP demand remains strong on the back of strong US GDP growth, mainly driven by increased demand for manufactured goods. PlasticsRecycling Petrochemicals EcoNy

On the supply side, declining supply of raw materials and some ongoing manufacturing problems are limiting the availability of PP in the market.

Earlier it was reported that Pinnacle Polymers in June raisedprices for all grades of polypropylene (PP) in the American market. Thus, an increase in PP prices of 3 cents per pound or USD66 per tonne will come into effect on June 1, 2021 or under the terms of current contracts.

Fortum Recycling and Waste have been granted 6 million SEK from the Swedish Energy Agency to carry out a feasibility study on chemical recycling of plastics. The study would define the technical requirements for the pre-treatment of plastics, quality control, and the sourcing of suitable materials. The feasibility study will test and evaluate which plastic waste streams and sorting methods are suitable for cost-effectively producing a CO2-neutral recycled raw material for the plastics industry.

– Waste will increasingly become new raw materials in all sectors. Significant proportions of plastics are today difficult to recycle. With the help of chemical recycling, the goal is to increase that proportion sharply and the feasibility study we now have been granted support to from the Swedish Energy Agency aims to produce CO2-neutral raw material for Boreali’s plastics recycling refinery, says Johanna d´Annibale, Manager Strategy Portfolio & Projects Fortum Recycling & Waste.

The feasibility study’s total budget is 12 million SEK, which means that the Swedish Energy Agency finances fifty percent. PlasticsRecycling Petrochemicals EcoNy

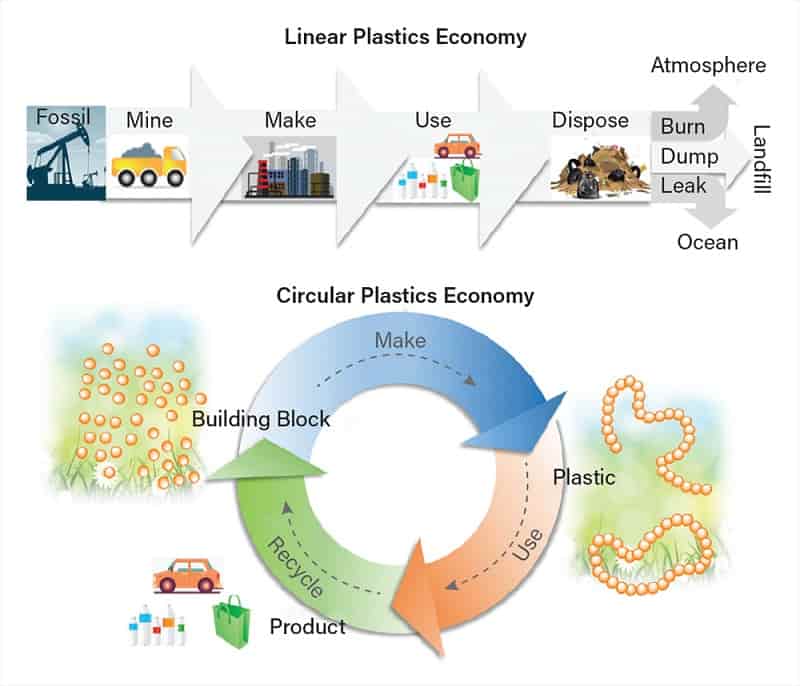

-Transforming the Science and Technology of Plastics Recycling

Finding solutions to the plastic waste problem will require public-private partnerships, innovation in deconstruction and upcycling technologies, and the invention of new recyclable-by-design materials. PlasticsRecycling Petrochemicals EcoNy

Plastics have revolutionized modern life, but our reliance on these inherently nondegradable materials is causing a global pollution crisis (1). Plastics manufacturing is predicted to account for 20% of global petroleum consumption in 2050, contributing substantially to greenhouse gas (GHG) emissions and carbon pollution (2). Of the nearly 5 billion m.t. of plastics that have been discarded across the globe in the past decades, only 600 million m.t. have been recycled. Research and development (R&D) into new technologies is required to mitigate this problem and protect the environment from further harm.

-IK interview: The insider perspective on plastic packaging

In the context of the ongoing debate about plastics packaging and sustainability, Elisabeth Skoda discusses recycling and recyclate goals and challenges, bioplastics, consumer behaviour and much more with Dr Isabell Schmidt, the managing director at IK, the German plastic packaging industry association.

ES: The European strategy for plastics has set a target to use 10 million tonnes of recycled plastics in the EU by 2025. This includes all plastic, not just packaging. In this context, IK has set the target to use 1 million tonnes of recyclate in plastic packaging by 2025. How far along is IK in this goal?

IS: Yes, 1 million tonnes of recyclates by 2025 is an ambitious target, starting from 400,000 tonnes in 2017. This is pretty much in line with the European Commission’s goal to use 10 million tonnes of recyclates in plastic products so it comes to approximately 22 per cent of the production volume. This year we have monitored our progress and the amount of recycled materials used has increased by 75,000 tonnes. At the same time, the use of virgin plastic material has decreased by about 2% so that’s a remarkable reversal of trends. PlasticsRecycling Petrochemicals EcoNy

-CEFLEX calls for amendments to EU’s Packaging Directive

CEFLEX argues that the EU’s Packaging Directive needs to define ‘recyclability’ with the flexible packaging industry in mind.

CEFLEX, the organisation dedicated towards establishing a circular economy model for flexible packaging, states that the EU Commission’s Packaging Directive has room for improvement. PlasticsRecycling Petrochemicals EcoNy

Officially known as the Packaging and Packaging Waste Directive (PPWD), said piece of legislation sets the universal recycling target for packaging at 95%. This means that for material to be recycled into high quality packaging, one needs to demonstrate that 95% of the source material already derives from packaging.

But plastic, especially in the food packaging industry, is not ‘one-size-fits-all’.

Manufacturers typically approach packaging with different needs in mind, ranging from airtightness to light-proofing, properties which to achieve require an amalgamation of different plastics within one package-for a mental picture, just consider the outside and inside of a regular chocolate bar wrapper. With the PPWD as it stands, most flexible packaging, which is prone to be made of hybrid plastics, do not stand a chance of being recycled and would have to be removed from the market over a three to five year period.

-Coveris unveils state-of-the-art-film science lab to support no waste strategy

Leading sustainable packaging manufacturer Coveris has unveiled a new Film Science Lab at its Winsford films facility in Cheshire, UK. Providing state-of-the-art technology and market leading expertise, the new scientific hub will support the accelerated R&D of innovative solutions across the manufacturer’s extensive product range and global customer base. PlasticsRecycling Petrochemicals EcoPolyamide

Supporting the Group’s vision of NO WASTE across its operations, packaging and the products it protects, the new Film Science Lab is a forward thinking initiative that sets out to minimise waste in all three areas, as well as offsetting this through inclusion in its own materials

Located at Europe’s largest co-extrusion facility, the lab supports the development, formulation and analysis of new and improved recyclable polyethylene (PE) films for food and non-food applications. Responsible for developing the sustainable films of the future, the lab targets material reduction through the delivery of best-in-class, downgauged films alongside the development of recyclable barrier and laminate replacement films with advanced functional performance up to 9-layers.

Meeting increased demand for recycled content, driven by the 2022 legislative UK Plastics Packaging Tax requirements, the lab supports food-safe recycled content application via mechanical sources, including its own reprocessing operations and closed-loop partnerships, as well as chemical recyclate options supported by its recent ISCC+ accreditation. PlasticsRecycling Petrochemicals EcoNy

PlasticsRecycling Petrochemicals EcoNy