PlasticsRWaste Petrochemicals CO2Fabric 16-07-2021 - Arhive

PlasticsRWaste Petrochemicals CO2Fabric

Crude Oil Prices Trend

-Versatile sorter targets bottle-to-bottle PET recyclers

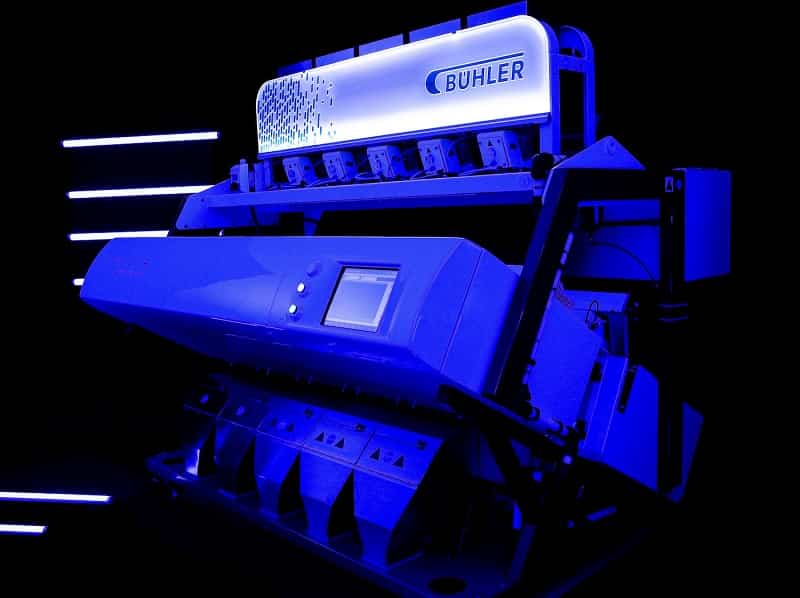

With increasing demand for bottle-to-bottle and food packaging applications, Bühler has launched what it is calling a ‘game-changing’ 4-in-1 optical sorter for PET recyclers.

The Sortex A GlowVision is a one-machine solution that includes a custom-built inspection system, double-sided cameras, and a flexible chute configuration.

Lawrence Kuhn, Bühler’s new head of segment for Plastics

“The solution can be used for simultaneous colour, polymer, foreign material and loose-label sorting,” explained Lawrence Kuhn, Bühler’s new head of segment for Plastics. “It’s the first Bühler optical sorter to feature integrated digital solutions from day one.”

The system also offers a simultaneous re-sort function, which delivers up to 40 per cent reject concentration, and is available in three to five chute models on a five-module frame.

“The Sortex A GlowVision will be of great interest to PET processors looking to reduce contamination levels on key colour and polymer defects, providing one of the most comprehensive solutions on the market today,” added Kuhn. “It deals effectively with opaque, white, and transparent coloured flakes, as well as on polymer defects including PVC, PC, PS, and PA, not to mention a superior performance on metals and significant reduction of loose labels.”

EcoBlue Ltd., Thailand’s first bottle-to-bottle recycler, has invested 25 million US Dollars to set up a new recycling facility for PET and polyolefins. A new Starlinger PET bottle-to-bottle recycling line is going to be part of the expansion.

“Our aim is to turn post-consumer and post-industrial waste materials into a sustainable substitute of virgin resin”, explains Pranay Jain, founder and Managing Director of EcoBlue Ltd. PlasticsRWaste Petrochemicals CO2Fabric

“In anticipation of the increased commitment of organisations towards sustainability, EcoBlue has invested in setting up a new world-class recycling facility with the very best technologies for PET and polyolefins recycling. By having Starlinger as a technology partner, we will ensure that we are able to provide consistent and high-quality bottle-grade rPET to our customers.”

-LanzaTech and lululemon partner to create the first fabric using recycled carbon emissions

Partnership includes India Glycols Limited and Far Eastern New Century

Biotechnology company LanzaTech today announced it has partnered with lululemon athletica inc. (NASDAQ:LULU), an athletic apparel company, to create the world’s first yarn and fabric using recycled carbon emissions that would otherwise be emitted to the atmosphere as pollution. LanzaTech uses nature-based solutions to produce ethanol from waste carbon sources and is working with partners India Glycols Limited (IGL) and Far Eastern New Century (FENC, TWSE: 1402) to convert ethanol to polyester. PlasticsRWaste Petrochemicals CO2Fabric

Recycling carbon is a fundamental element of the circular economy, which will keep fossil carbon in the ground, reducing pollution and fossil fuel usage when used to make polyester. With a lower carbon footprint, this innovation could transform lululemon’s products and the apparel industry.

Jennifer Holmgren, CEO, LanzaTech said, “We must radically change how we source, utilize and dispose of carbon. Carbon recycling enables companies like lululemon to continue to move away from virgin fossil resources, bring circularity to their products, and achieve their climate change goals around carbon reduction. We call this being ‘CarbonSmart.’”

-Rising oil price may speed shift to electric vehicles, says energy watchdog

IEA analysis offers hope for climate action but says inflated oil price may slow global economic recovery from Covid-19

Rising oil prices could help speed climate action by accelerating the shift to electric vehicles, but would come at the expense of the economic recovery from the Covid-19 pandemic, according to the global energy watchdog.

The world’s demand for crude surged by an average of 3.2m barrels a day (b/d) in June compared with the previous month but the return of oil production has failed to keep pace, triggering a steady rise in market prices. PlasticsRWaste Petrochemicals CO2Fabric

The International Energy Agency (IEA) warned that oil prices, which climbed by two-thirds this year to highs of $77 a barrel earlier this month, could climb higher and lead to market volatility unless big oil producers pump more barrels.

“While prices at these levels could increase the pace of electrification of the transport sector and help accelerate energy transitions, they could also put a drag on the economic recovery, particularly in emerging and developing countries,” the IEA said.

-Fluff Feeder Offers Higher Film-Scrap Capacity, Better Reclaim Efficiency

Feeds granulated film scrap into a stream of virgin material and delivers the mix to extruder.

Conair has redesigned its ScrapSaver fluff feeder to reportedly make high-volume film-scrap reclaim easier by feeding granulated film fluff into a stream of virgin material and delivering the mix to an extruder. Designed for use with in-line granulation systems, the feeder features an enlarged and strengthened main hopper and top plate for greater fluff surge capacity. The unit also has a beefed-up auger to deliver higher fluff-to-virgin ratios to the extruder, an integral control panel, and mounting adapters for varied extruder feed throats from 2 to 8 in. diam.

The special twin-chamber hopper of the redesigned ScrapSaver feeder holds granulated fluff in a large main chamber and virgin material in a smaller side chamber, keeping both separate until just before they are introduced into the screw flights. To prevent fluff from bridging and keep it flowing smoothly downward, the new unit employs a longer, stronger, one-piece auger, capable of driving higher fluff refeed ratios to the extruder throat. Virgin pellets feed in by gravity on one side at the base of the auger, maintaining a smoother infeed and a steady fluff-to-virgin ratio. PlasticsRWaste Petrochemicals CO2Fabric

-S Korea’s LG Chem to invest $8.7bn in new growth areas

LG Chem is investing won (W) 10 trillion ($8.7bn) through to 2025 in new business growth areas such as eco-friendly petrochemical products and battery materials, the South Korean producer said on ednesday.

The company will invest W3 trillion in “sustainability businesses” such as bio materials, recycling, and renewable energy materials, the company said in a statement.

LG Chem plans to start full-scale production of a “bio-balanced” superabsorbent polymer (SAP) this month with ISCC Plus certification and supply it to global customers such as those in the US and Europe, the company said.

Bio-balanced SAP is produced using a combination of bio-renewable raw materials, such as waste cooking oil, and fossil fuels.

ISCC Plus is an international certification for eco-friendly bio products.

LG Chem earlier in September 2019 said that it was reviewing the construction of a bio-SAP plant in North America after it agreed to work with US agribusiness firm Archer Daniels Midland (ADM) to develop bio-based acrylic acid (AA).

AA is used in the manufacture of SAP. PlasticsRWaste Petrochemicals CO2Fabric

What are said to be color-stable and cost-effectively processed eOrange nylon masterbatches for molded and extruded nylon components uses in E-mobility, have been jointly developed by Germany’s additives supplier Brüggeman and compounder Grafe. PlasticsRWaste Petrochemicals CO2Fabric

The striking pastel orange RAL2003 is increasingly being used to identify plastic-sheathed, high-voltage, current-carrying components in E-mobility to warn of the dangers associated with this new technology. eOrange is a color masterbatch for nylons, which even after 1,000 hours’ service at 130 C/266 F, reportedly still retain their warning effect without darkening. In comparison with preformulated compounds, eOrange offers processors considerable flexibility in meeting specific requirements and at the same time optimizes material consumption.

-Antimicrobial treatment for knits

Textile developer Livinguard has launched a new line of knitted garments, which integrate its patented antimicrobial treatment.

It comes after the company concluded third-party tests which demonstrated that the technology can kill bacteria at a >7 log10 rate (99.99999%).

“The COVID-19 pandemic has underscored the importance of hygiene technology in protecting the health of people across the world, and we continue to adapt our Livinguard technology to new consumer products, including shirts with permanent antiviral and bacteria-fighting properties,” said Sanjeev Swamy, Livinguard’s founder and CEO. PlasticsRWaste Petrochemicals CO2Fabric

Livinguard’s patented non-leaching formula captures and kills odour-causing bacteria, and has proven its efficacy in face masks applications.

The principle underlying the Livinguard Technology is the deactivation of microbes including bacteria and viruses. The technology applies a positive charge at the molecular level to textile surfaces, making them more powerful than the negative charge of microbes. Therefore, microbes are deactivated when they encounter textiles treated with Livinguard technology.

-Oceana Canada calls out plastic industry for deflecting blame onto consumers for plastic pollution

97 percent of Canadians say it is important that the government take responsibility for reducing the amount of plastic pollution in the ocean

During Plastic-Free July, Oceana Canada is calling on the federal government to put in place a strong ban on harmful single-use plastics that goes beyond the proposed six items. PlasticsRWaste Petrochemicals CO2Fabric

Ashley Wallis, plastics campaigner for Oceana Canada, says, “For more than half a century, the plastics industry has blamed individual consumers or “litter bugs” for plastic pollution, rather than investing in reuse systems or alternative plastic-free choices. Now is the time to demand that our government stand up to Big Plastic and cut this harmful pollutant off at the source. We need a strong ban on harmful single-use plastics in Canada that goes beyond the proposed six items, which represent only a fraction of one percent of the plastics we use.”

Recent Abacus Data polling commissioned by Oceana Canada reveals that 97 percent of Canadians believe that the government must take responsibility to reduce the amount of plastic pollution in the ocean.

-norda™ launches flagship product with DSM’s bio-based Dyneema® fiber

Royal DSM, a global science-based company in Nutrition, Health and Sustainable Living, today confirmed the introduction of the first seamless trail running shoe made with bio-based Dyneema® fiber by norda™, a Canadian shoe brand.

Designed for runners by runners, norda™ was founded under the mission to empower athletes to unlock their peak potential through innovation and cutting-edge technology. PlasticsRWaste Petrochemicals CO2Fabric

The brand’s flagship product, norda™001, utilizes bio-based Dyneema® fiber to enhance performance and sustainability in a lightweight construction.

The shoe upper is seamlessly constructed with Dyneema® fabric, which benefits from the intrinsic properties of Dyneema®, the world’s strongest fiber™. Dyneema® fiber is engineered at the molecular level to provide high strength, low weight, waterproof and breathable properties – fusing the technical performance of ultra-light materials with aesthetic design that does not sacrifice strength or durability.

PlasticsRWaste Petrochemicals CO2Fabric