Polyester-industrial-yarn – PDH – PP 24-08-2022 - Arhive

Polyester-industrial-yarn – PDH – PP

Crude Oil Prices Trend

-Japanese Resin Makers Collaborate to Market Biomass-Derived Polycarbonate

Mitsui Chemicals will supply biomass-derived BPA to Teijin, which will use it to produce biomass polycarbonate resin.

Mitsui Chemicals Inc. and Teijin Ltd. will become Japan’s first companies to develop and market biomass-derived bisphenol A (BPA) and polycarbonate (PC) resins to support efforts to achieve carbon neutrality by reducing greenhouse gas (GHG) emissions throughout a product’s life cycle.

The joint initiative follows Mitsui Chemicals’ receipt of ISCC PLUS certification from the International Sustainability and Carbon Certification (ISCC), based on which Mitsui Chemicals will begin supplying biomass BPA produced with the mass-balance approach. Teijin also will begin developing and producing biomass PC resin using the same BPA.

In May 2022, Mitsui Chemicals acquired ISCC PLUS certification for BPA raw materials used in PC resins. Mitsui Chemicals will now become the first Japanese company to produce commercial biomass-derived BPA offering the same physical characteristics as conventional petroleum-derived BPA.

Teijin will procure biomass-derived BPA from Mitsui Chemicals to produce biomass-derived PC resins possessing the same physical characteristics as the company’s existing petroleum-derived PC resins. The new biomass-derived versions will be used in commercial applications such as automotive headlamps and electronic components.

By expanding sales of products containing plastics produced through biomass conversion, the two companies aim to develop and produce more environmentally friendly products throughout their supply chains. Mitsui Chemicals, for example, is considering expanding its procurement network for bio-based hydrocarbons in order to provide stable supplies of related products to the market. Polyester-industrial-yarn – PDH – PP

The company, which is in the process of acquiring ISCC PLUS certification for biomass naphtha derivatives, has already received certification for phenol, acetone, BPA, and alpha-methyl styrene.

-Fed efforts to cut inflation to 2% set to trigger recession – US economists

US economists are not confident that the Federal Reserve will be able to bring inflation down to its 2% goal in the next two years without triggering a recession, according to findings in the latest Economic Policy Survey by the National Association for Business Economics (NABE) on Monday.

Also, about one-fifth of a panel of 198 NABE economists responding in the survey conducted from 1-9 August believes that the US is already in a recession.

Nearly half (47%) expect a recession to begin by the end of 2022 or Q1 2023.

Regarding the Inflation Reduction Act that became law last week, about two-thirds of economists in the NABE panel favour the act’s policies, including those that reduce the deficit, expand Medicare benefits, and address climate change.

FISCAL POLICY

Respondents’ views on fiscal policy are essentially unchanged from NABE’s March 2022 policy survey. Polyester-industrial-yarn – PDH – PP

Slightly more than half (50.5%) of survey respondents believe that current fiscal policy is too stimulative, while 44% find that current fiscal policy is “about right”.

On the Inflation Reduction Act, which was still being debated in the Senate while the survey was in the field, more than three-fourths of panelists (76%) support the $300bn deficit reduction goal, while 14% oppose the provision.

More than two-thirds of the panelists support the 15% minimum corporate tax – 69% in favour, 26% opposed.

Also, 63% of panelists support subsidies, rebates, and private-public investments to combat climate change, while 31% are opposed.

MONETARY POLICY

The economists view on monetary policies has shifted since NABE’s March survey.

Since then, the Federal Open Market Committee (FOMC) has approved four consecutive interest rate hikes.

As such, in the August survey 46% of panelists view monetary policy as “just right,” up from 22% in the March survey.

Nevertheless, 44% of panelists still view monetary policy as too stimulative. In March, 77% held that view.

Nearly three quarters (73%) of panelists in the current survey indicate they are “not very confident” or “not at all confident” that the Fed will reach its 2% inflation goal within the next two years without triggering a recession.

Only 27% feel confident, somewhat confident, or very confident that the Fed will achieve this outcome, known as a “soft landing”. Polyester-industrial-yarn – PDH – PP

-TAVIAN QUANG YEN PETROCHEMICAL

MoU for PP mega project in Vietnam / USD 1.5 bn investment

Together with the provincial government of Quang Ninh and management of the Bac Tien Phong industrial zone, Vietnamese multi-industry and multinational group Stavian (Hanoi; www.stavian.vn) has signed a memorandum of understanding (MoU) to build a USD 1.5 bn (EUR 1.47 bn) PP plant.

The new 600,000 t/y facility that would be operated under the name Stavian Quang Yen Petrochemical – a joint venture of Stavian Chemical and Yen Hung Liquid Port – is expected to start up by 2026 in the industrial zone located in north-eastern Vietnam, near the Chinese border.

A propane dehydrogenation (PDH) unit that presumably would have the same capacity is planned to be part of the project. The PDH technology will be supplied by Honeywell UOP, and the PP licence from LyondellBasell. Stavian boasts also that the facility will use high-quality equipment made in the EU and G7 countries with a closed, automated, environmentally friendly technology process that will reduce greenhouse gas emissions.

As a plastics producer, the privately held company operates plants in the Hung Yen and Hai Duong provinces in northern Vietnam, with a portfolio encompassing mainly standard thermoplastics in addition to a limited number of engineering grades.

Stavian is also regarded as Vietnam’s largest plastics distributor, a business that up to mid-2021 operated under the name Opec Plastics.

Besides having a significant position in Southeast Asia generally, the company also has offices in the US, Russia, China, India, South Korea, Singapore, Indonesia, and the Philippines. Polyester-industrial-yarn – PDH – PP

-North America’s First Integrated PDH/PP Plant

Canada’s Heartland Polymers is producing homopolymer PP with random copolymers slated for 2023.

Heartland Polymers is now offering a segment of its portfolio of PP products manufactured at North America’s first integrated propane dehydrogenation (PDH) and PP production facility, located near Edmonton, Alberta, in Western Canada. This strategic location is less prone to weather-related service disruptions than other plants. Moreover, the Heartland Petrochemical Complex (HPC) is connected to an extensive network of rail and storage facilities, ensuring reliable delivery of product to customers across North America and around the globe. Polyester-industrial-yarn – PDH – PP

Once commercial production is fully underway by end of third quarter, Heartland is expected to produce nearly 1.158 billion lb/yr of PP, filling approximately 18 rail cars per day, seven days a week. Heartland Polymers is initially producing homopolymer PP resins for extrusion thermoforming, extrusion blow molding, film, fiber, and molding grades for packaging, caps/closures, and consumer housewares.Plans to add random copolymers in 2023 are also underway.

HPC has been designed with sustainability built into every aspect of its operations to create one of the most sustainably produced PP resin in the world.

-Amcor Buys Scalable Flexible Packaging Plant in Central Europe

Amcor, a global leader in developing and producing responsible packaging solutions, today announced that it has closed the acquisition of a world-class flexible packaging plant located in the Czech Republic.

The strategic location of the site immediately increases Amcor’s ability to satisfy strong demand and customer growth across its flexible packaging network in Europe.

“With this acquisition, we are investing to accelerate the organic growth momentum of our flexibles business in Europe in attractive segments,” said Michael Zacka, President, Amcor Flexibles Europe, Middle East & Africa. “The scalable nature of the acquired site and its attractive location further bolsters our ability to service strong customer demand and generate strong returns for Amcor shareholders.”

The plant is a greenfield development commissioned by DG Pack in 2019 and features state-of-the-art specialized equipment for attractive segments including coffee and pet food. Polyester-industrial-yarn – PDH – PP

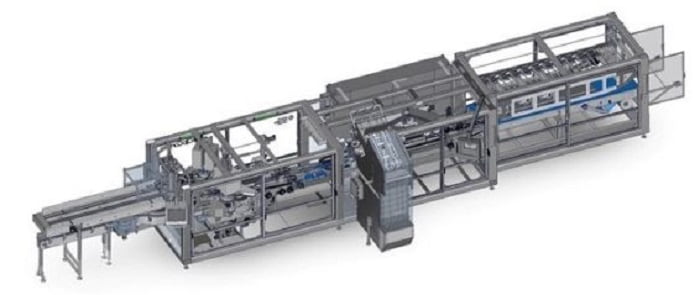

-Graphic Packaging to unveil ClipCombo packaging machinery system

Graphic Packaging International is launching a new modular machinery system.

ClipCombo offers producers the ability to run multiple fiber-based multipack styles across the same machine. Polyester-industrial-yarn – PDH – PP

Graphic Packaging said the concept will deliver value and flexibility, with options for cans or PET bottles, offering multiple combinations, including:

- KeelClip plus EnviroClip fiber-based clips for can multipacks

- GripClip plus EnviroClip fiber-based clips for can multipacks

- Cap-It plus EnviroClip fiber-based clips for PET bottle multipacks

The machine can achieve speeds up to 400 packs per minute (dependent on application) and rapid changeovers as part of an impressive list of benefits, ClipCombo enables customers to differentiate between brands and position premium or standard options.

The company also said it will lower capital investment for beverage packers, as the ability to deliver multiple pack styles with rapid changeover eliminates the need for several installs.

The machine will be unveiled at this Drinktec exhibition in Munich, Germany, 12-16 September.

Doug Hicks, vice president of the packaging machinery division at Graphic Packaging, looked ahead to the unveiling, saying, “We’re delighted to reveal the ClipCombo concept, a game-changing machinery philosophy that enables customers to select from a wide range of existing and new packaging options as well as container and configuration choices. Packers can combine products over a single machinery system, and be confident they have the options needed as the market evolves.

-Australian research centre to tackle global pollution with ‘green’ plastic

A new University of Queensland-led training centre is set to become a hub for world-leading research in ‘green’ plastic.

The $13 million Australian Research Council (ARC) Industrial Transformation Training Centre for Bioplastics and Biocomposites, based at UQ’s School of Chemical Engineering, aims to make large-scale plastic pollution a problem of the past.

Centre director, Associate Professor Steven Pratt said scientists will work toward developing bio-derived and bio-degradable plastics that have a minimal environmental impact.

“Every year it’s estimated more than 10 million tonnes of plastic leaks into oceans as part of the almost 400 million tonnes of plastic that’s destined for landfill,” said Dr Pratt.

“Urgent change is needed, and biodegradable bioplastics along with their natural fibre composites, will be pivotal. Polyester-industrial-yarn – PDH – PP

“It’s an exciting prospect to work toward manufacturing a commercially-available plastic with exceptional properties but without the legacy of accumulation in the environment.”

Dr Pratt said there was a rapidly growing local and international market for better bioplastics.

“But we need to consider their full life cycle, from the sustainable resources to make them right up to their end of life,” he said.

-Polyester industrial yarn price slumps after failed to break predicament

PIY market was greatly volatile in recent two months. Big PIY companies intensively raised yarn price to avert losses in late-Jun. The trading price of ordinary high-tenacity 1000D surged to 12,150yuan/mt from 10,500yuan/mt. However, trading failed to grow after price hiked. Therefore, PIY companies tried to curb price from reducing by scaling down output. Trading under low price successively emerged after shivering for around one month. The trading price of ordinary high-tenacity 1000D has been at 9,500-9,700yuan/mt now, near the cost line, but did not show signals to stop falling. Therefore, PIY producers could be described as failing to break the predicament. Polyester-industrial-yarn – PDH – PP

This failure was attributed to objective factors and subjective factors. In terms of objective factors, price of bright polyester fiber chip kept falling when PIY plants were firm in preventing price from diving. As downstream plants were under losses based on spot PIY price, some chose to consume PIY prepared before or scaled down production. Trading of PIY was lackluster. With inventory burden, price of PIY collapsed. If upstream feedstock price is rising and downstream speculative demand is moderate, PIY plants may be successful in curbing price from falling and turning to be profitable. As for the subjective factors, different companies saw various operation status. After curbing price from declining for around one month but with high stocks, some enterprises cut price for promotion, which dragged down the market price. However, the subjective factors were also impacted by the objective issue. Some PIY plants were forced to cut price for promotion with collapsing feedstock cost but high PIY price. Actually, the root was because the profit was hard to be high amid excessive capacity.

Polyester-industrial-yarn – PDH – PP