Polyesteryarn PETBottle Biopolymers 10-04-2021 - Arhive

Polyesteryarn PETBottle Biopolymers

-BMW Treads Sustainable Path with Recycled Fishing Nets

Sustainability has become a strategic priority for the automotive industry, with automotive organizations increasingly using sustainable materials, and 62% of them claiming to have a comprehensive sustainability strategy, according to Capgemini.

Since 2016, the BMW Group has used Econyl yarn, based on recycled polyamide (PA), to make the floors and floor mats for the BMW i3, BMW iX, and other models. Committed to sustainability and the process, Daniela Bohlinger, Head of Sustainability for BMW Group Design, visited Aquafil CEO Giulio Bonazzi in Ljubljana, Slovenia, where Econyl yarn is produced out of recycled fishing nets and other polyamide waste. Compared to petroleum-based PAs, manufacturing Econyl yarn from recycled materials reportedly results in an up to 90% reduction in global warming potential.

“At the BMW Group, we want to lead the automotive industry in the direction of sustainability.

From the very start, we consider the entire product lifecycle and increasingly use materials that can be recycled and then used for other purposes,” said Bohlinger.

“Since Econyl yarn features a wonderful range of colors, it is easy for us to design with. Of course, any product that is made from recycled materials must look flawless and provide outstanding quality.”

Avantium announces that it has signed a conditional offtake agreement with Resilux, an international rigid plastic packaging supplier, for the supply of PEF resin from the planned Avantium FDCA flagship plant. This brings the total of such offtake contracts to five. Polyesteryarn PETBottle Biopolymers

The planned FDCA flagship plant is set to produce 5 kilotonnes of FDCA (furandicarboxylic acid) per annum, the key building block for the 100% fossil-free, recyclable polymer PEF (polyethylene furanoate). Including an additional commitment from one of the previously announced offtake partners, the five conditional offtake agreements represent a total offtake volume of over 50% of the FDCA production capacity from the flagship plant. This marks an important step towards a positive Final Investment Decision (FID) for the construction of the world’s first commercial FDCA plant, which Avantium would plan to open in 2023.

Avantium previously announced that offtake contracts were signed with specialty chemical company Toyobo (Japan), specialty polyester film producer Terphane (US), the beverage bottling company Refresco (Netherlands), and an undisclosed major global food & beverage brand owner. Avantium is also collaborating with beer brewer Carlsberg in the development of PEF based packaging of beer, such as the Green Fibre Bottle. The offtake commitments are subject to a positive FID, financial closing, other customary approvals, and party-specific conditions.

-Plastics recyclers, end-markets must align to make circular economy a reality

Mechanical and chemical recyclers of plastics need to align with end markets to enable the circular economy to become a reality, panellists said during the 16th annual Plastics Recycling Conference and Trade Show, held virtually this year because of the pandemic. Polyesteryarn PETBottle Biopolymers

Major chemical companies have shown their commitments to reaching sustainability goals by investing in recycling operations and developing new and innovative products, and a panel comprised of plastic producers and recyclers shared their views on how the industry is working toward realising a circular economy.

Holli Alexander, strategic initiatives manager, global sustainability at Eastman Chemical, said that her company is working to improve the infrastructure in the recycling space.

“We recognise that in advanced recycling, or molecular recycling, there is an opportunity to be very compatible and complementary with mechanical recycling,” she said. “We all need more materials to recycle, so we are looking at what we can do collectively to work on infrastructure together to create the feed streams that work for all of us.”

-LyondellBasell to offer certified Circulen polymers

LyondellBasell is to offer mass balance certificates for its advanced (molecular) recycled and renewable-based Circulen polymers, after obtaining International Sustainability and Carbon Certification (ISCC) PLUS certification for its Wesseling, Germany, cracker and European polymer sites.

“In 2020, LyondellBasell announced our goal to produce and market two million tonnes of recycled and renewable-based polymers annually by 2030,” said Richard Roudeix, LyondellBasell’s senior vice president of olefins and polyolefins for Europe, Middle East, Africa and India. “This ISCC PLUS certification is another milestone on our path to becoming an industry leader in the production and marketing of recycled and renewable-based polymers.” Polyesteryarn PETBottle Biopolymers

The ISCC PLUS certification is recognised for its global certification of recycled and renewable-based materials and provides traceability along the supply chain. With the mass balance method, the company tracks how much advanced (molecular) recycled and renewable-based source material goes into the production process of its Circulen products and can attribute it to the final polymer via a Sustainability Declaration.

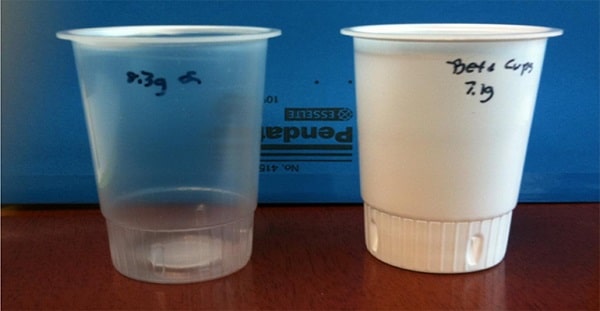

-Mayzo’s Beta Technology Helps Thermoformers Overcome Polypropylene Cost and Supply Challenges

As polypropylene resin prices continue to fluctuate, thermoforming plastics processors are looking for new cost-effective and sustainable solutions. Mayzo Inc., a provider of specialty chemical additive solutions based in Suwanee, GA, offers thermoformers the advantages of its proprietary Beta Technology, a beta nucleating masterbatch that enables processors to use less resin while producing more product faster. Polyesteryarn PETBottle Biopolymers

“Thermoforming customers are achieving two substantial advantages through the use of Mayzo’s Beta Technology,” said Philip Jacoby, an expert in polypropylene and retired VP of Technology at Mayzo. “First, they are achieving down-weighting of at least 15%. That means less polypropylene resin is required to produce the same amount of end product.

-Russia sees pandemic impact on crude oil demand to last until 2023-2024

Russia expects the fallout from the COVID-19 pandemic on the global consumption of oil and oil products may last until 2023-2024, a draft government document, seen by Reuters, showed.

The global oil and liquid fuels production dropped in 2020 to 94.25 million barrels per day (bpd) from 100.61 million bpd in 2019, amid the pandemic, which led to lockdowns, halting 80% of air traffic and a quarter of road traffic at its peak and denting fuel consumption. Polyesteryarn PETBottle Biopolymers

The Organization of the Petroleum Exporting Countries expects oil demand to grow by 5.6 million barrels per day this year under its base case scenario. Russian Deputy Energy Minister Alexander Novak has also projected similar growth.

The draft document, outlining oil industry developments until 2035, also showed that Russia could lose global oil market share due to curbs on oil production and exports.

It says global oil prices are likely to trade in the range of USD50-USD75 per barrel by 2025, while in the second half of 2020s prices are seen at USD50-USD60 per barrel and they are unlikely to fall significantly below USD50.

-Amcor: Edible oil in custom designed lightweight plastic bottle

Converting its traditional extra virgin olive oil bottle from glass to plastic allows Morixe Hnos to export its oil across Brazil to meet growing demand. The lightweight polyethylene terephthalate (PET) bottle, custom designed by Amcor, replicates the touch and feel of the incumbent glass container while reducing the overall costs associated with exports. Polyesteryarn PETBottle Biopolymers

In addition to being lightweight, the 500ml PET bottle delivers major manufacturing efficiencies, will not shatter, and offers greater sustainability advantages (1) than its glass predecessor, including:

- a 78% reduction in CO2 emissions which equates to 217 cars operating for a year (per million bottles).

- a 61% energy reduction during production which equates to 5190 household lights turned on annually (per million bottles).

- 15% higher line speeds, less breakage, and savings in secondary packaging.

- 60% more finished product per truck, thus substantially reducing transportation and logistics costs.

- 90% lighter in weight

-PureCycle Bullish on Ultra-Pure Recycled Polypropylene

When it comes to recycling, popularity is everything. Consider the plight of polypropylene (PP), a neglected polymer when compared to more highly recycled polymer brethren polyethylene terephthalate (PET) and high-density polyethylene (HDPE). A scant 1% of the 170 billion pounds of PP consumed last year was recycled versus almost 20% for polyethylene terephthalate (PET), according to the American Chemistry Council.

It’s an untapped resource for a circular economy model poised for development by forward-thinking companies like, for example, Procter & Gamble. P&G developed and patented a one-of-a-kind recycling technology that restores recycled PP (rPP) to virgin-like quality and licensed the rPP technology to PureCycle Technologies. Key facts about PureCycle’s process:

- It targets feedstock that traditionally ends up in a landfill.

- It’s a physical separation — not depolymerization — and purification doesn’t change the polymer molecules.

- It uses neither catalyst nor chemical reactions, and thus it saves energy versus depolymerization.

- It removes odor, color, and other contaminants that cannot be removed by traditional recycling methods, permitting the resin to be used in highly sensitive consumer applications. Polyesteryarn PETBottle Biopolymers

-Supply/Demand Equilibrium Remains Work in Progress

As the first quarter came to a close and many people started looking forward to a spring break — such as it is in pandemic times — spot plastics trading activity slowed a bit the week of March 29. Commodity resin prices were mixed, high-density polyethylene (PE) continued to climb while most of the other PE grades stayed steady, reports the PlasticsExchange in its Market Update. Polypropylene (PP) relinquished its early gains and then slid a couple cents by Friday. Completed volumes at the resin clearinghouse ran above its historic average, but fell short of the heightened levels seen during the first quarter of 2021.

Still, numerous company records were smashed in March and during this quarter, said the PlasticsExchange. Polyesteryarn PETBottle Biopolymers

The plastics industry has been recovering from a series of substantial production disruptions that began with the late August hurricanes and then continued to pile on in succession, culminating with the massive mid-February winter storm that hit the Houston/Louisiana region. The storm shut down the vast majority of US petrochemical and plastics production facilities, decimating PE supplies and driving PP resin inventories to record lows. After seeing virtually zero fresh railcar offers during the latter half of February, the recovery began and startup resin began to show up in the first half of March.

-Nova Chemicals debuts three PCR grades for film applications

The three resins are the first in a portfolio of PCR grades that the company is bringing to market.

Nova Chemicals Corp., Calgary, Alberta, has announced the availability of the first three grades of 100 percent postconsumer polyethylene resins that are suitable for a range of flexible film applications:

Natural recycled linear/low-density polyethylene (rLLDPE/LDPE) is collected from distribution centers and is suited for collation shrink, stretch wrap and e-commerce applications. Polyesteryarn PETBottle Biopolymers

Natural rLLDPE/LDPE is a recycled agricultural film that is ideal for reuse in agricultural films, heavy-duty shipping sacks, collation shrink and for e-commerce applications.

White rLLDPE is manufactured from closed-loop agricultural and irrigation film recyclate and is suitable for use in agricultural film, heavy-duty shipping sacks, collation shrink, trash bags and liners and e-commerce applications.

Polyesteryarn PETBottle Biopolymers