Polylactic Acid Corn Bioplastic 17-09-2021 - Arhive

Polylactic Acid Corn Bioplastic

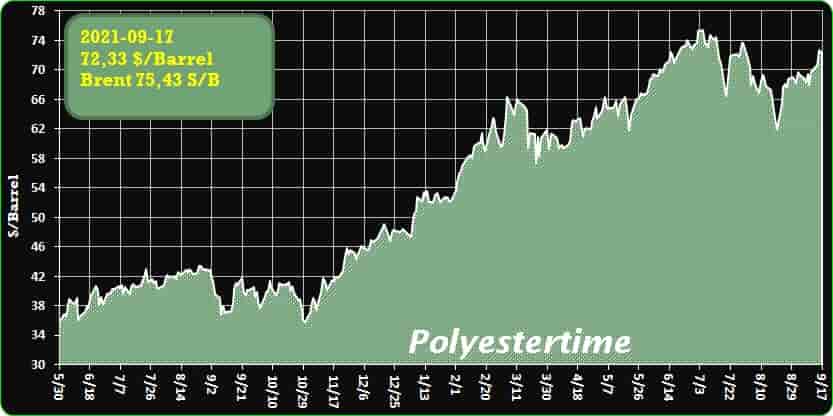

Crude Oil Prices Trend

Both companies to produce pure styrene from post-use polystyrene to be used as a virgin equivalent raw material to produce solution styrene-butadiene rubber (SSBR) for tires

Agilyx Corporation (AGLX), a wholly owned subsidiary of Agilyx AS (Euronext Growth (Oslo): “AGLX”) and a pioneer in the advanced recycling of post-use plastics and Kumho Petrochemical, a global leader in the manufacture of synthetic rubber, have announced a collaboration to explore the development and construction of a chemical recycling project in South Korea.

“We’re very interested in recycling of post-use plastics, while focusing on utilizing post-use polystyrene into the pure styrene,” stated Jong-Hoon Baek, CEO of Kumho Petrochemical. “Collaboration with Agilyx will give Kumho Petrochemical an opportunity of proposing new line of eco-SSBR products to most of our customers who prefer sustainable products.”

“We are pleased to partner with Kumho Petrochemical to explore this project and expand the market for post-use recycled polystyrene into new, high growth and technically demanding applications such as this,” stated Tim Stedman, CEO of Agilyx. “The potential to use waste plastic to create high performance SSBR for the manufacture of tires is a very exciting example of our technology’s ability to create a new life for plastic.”

-LG Chem, ADM to build JV in US to produce bioplastics made from corn

The deal is part of LG’s $8.7 billion plan to foster the battery material, renewable and bio businesses through 2025 Polylactic Acid Corn Bioplastic

South Korea’s LG Chem Ltd. said on Tuesday it is jointly building a corn-based bioplastic plant in the US with Archer Daniels Midland Co., a global grain processing company, as part of its efforts to pursue sustainable growth.

LG Chem, the chemical unit of LG Group, has signed a heads of agreement (HOA) with ADM, one of the world’s four major agricultural processing firms, to establish the joint venture by 2025 with an annual production capacity of 75,000 tons.

The JV, which will produce polylactic acid (PLA), a raw material used to make 100% biodegradable plastics, marks the first time for a Korean chemical company to build a PLA plant in America.

LG Chem said it expects to sign the definitive agreement with ADM in the first quarter of next year. The site of the factory hasn’t been decided yet.

-Finalist Interview: Inspecta BE from Piovan

In the most recent of our Sustainability Awards 2021 finalist interviews, Davide Cappellini, CTO at Piovan Group explains the company’s entry Inspecta Be, a finalist in the Machinery category, which helps to simplify the control of Benzene values in PET.

Congratulations on being selected by the international judging panel as a Sustainability Awards 2021 finalist! Would you please introduce your successful entry and what’s innovative about it? Polylactic Acid Corn Bioplastic

Inspecta is a family of analysers that takes the gas chromatography mass spectrometry (GC-MS) close to the production line of PET, thanks to its compactness, with testing times of 60 minutes maximum.

Inspecta Be (Benzene) was commercialised in 2020 for PET preforms only and in January 2021 extended the testable shapes to granules, sheet and bottles. It allows the complete tracking of production: from raw material acceptance to final product for Consumers and all its measurements can be saved into the database of Winfactory 4.0, the supervision software by Piovan, allowing traceability over time.

-Coca-Cola Germany is now selling drinks from its core brands in bottles made from 100% rPET

All non-returnable PET packaging up to and including 0.5 liters from Coca-Cola, Fanta, Sprite, mezzo mix and all non-returnable PET bottles from ViO, Fuze Tea and Powerade are now made from 100% recycled material

Start of campaign for consumers with OOH posters, digital content and influencer cooperations Polylactic Acid Corn Bioplastic

After Coca-Cola in Germany switched the non-returnable PET bottles of its brands ViO, Fuze Tea and Powerade to recycled material in the spring, the core brands Coca-Cola, Coca- Cola Zero, Coke light, Fanta, Sprite and mezzo mix their “On the Go” packaging (up to and including 0.5 liters) is now also being sold in bottles made from 100 percent recycled PET. With this measure, Coca-Cola in Germany is already exceeding its self-set goal of using at least 50 percent recycled material for the production of non-refillable PET bottles by 2023. In 2021 the company will save around 28,000 tons of new material by converting the above-mentioned packs to 100% rPET. This results in a CO2 saving of approx. 48,700 tons.

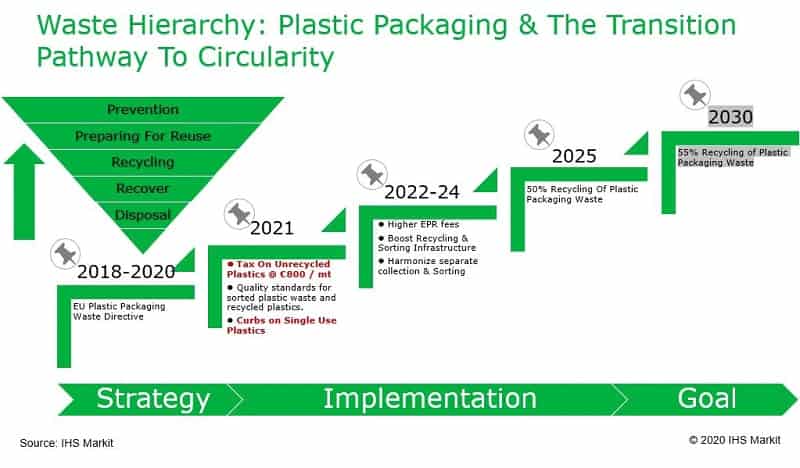

-Spain plans to tax plastics production

The Spanish Cabinet approved a draft law that introduces a new tax on plastic waste, among other environmental measures, said EsPlasticos.

The indirect levy will tax the manufacture, import or acquisition of non-reusable plastic packaging from other European Union countries for use in the Spanish market, according to the Spanish Ministry for Ecological Transition.

The ministry said that the proposed tax is similar to what other countries such as the United Kingdom and Italy are planning to introduce. It would require payment of EUR0.45 for every kilogram of plastic packaging, and is expected to bring in annual revenue of close to EUR724 million, based on 2017 figures.

The European Commission and international organizations such as the Organisation for Economic Cooperation and Development (OECD) and the International Monetary Fund (IMF) have been urging Spain for years to increase its green taxes and introduce greater penalties for the most contaminating activities.

On Tuesday, the ministry said that based on 2017 figures, revenue from green taxes represented 1.83% of Spain’s gross domestic product (GDP), compared with the EU average of 2.40%. Polylactic Acid Corn Bioplastic

“Spain has the fifth-lowest ratio of environmental revenue-to-GDP of the entire EU,” said the ministry in a release.

-Orca: World’s largest plant for direct CO₂ extraction from the atmosphere in operation

In Iceland, a plant now extracts 4000 tons of CO₂ from the atmosphere every year and stores it underground. How sustainable this is is controversial.

In Iceland, the world’slargestplant for climate-neutral CO 2 capture and storage directly from the air (DACCS) has gone into operation and is now to remove 4000 tons of CO2 from the atmosphere annually.

The power plant called Orca comes from the Swiss company Climeworks and is powered entirely by renewable electricity. Polylactic Acid Corn Bioplastic

The captured carbon dioxide is mixed with water and discharged into underground reservoirs where it mineralizes.

According to Climeworks, the technology used can easily be used at other locations to expand industrial CO2removal.

-SMI: Recycle – Regenerate – Reuse: This is the packaging of the future

The growing consumers’ awareness towards the problems of the ecosystem in which people live influence the activity of the companies that prefer the use of sustainable packaging, such as rPET and cutting-edge technical solutions, like those supplied by SMI, in order to save energy and reduce the production environmental impact.

Design of sustainable containers

Today all the main food and beverage manufacturers aim at promoting sustainable lifestyles in compliance with circular economy and support the importance of the responsible use of resources and recycle. Their commitment starts from the use of PET plastics: a 100% recyclable and regenerable material.

Thanks to an advanced CAD center for 3D design, SMI supports companies in the design and graphic realization of a wide range of 100% recyclable PET containers, featuring high quality and lightweight in order to save energy and material.

Green solutions for the primary packaging Polylactic Acid Corn Bioplastic

The wide range of SMI rotary stretch-blow moulders from EBS ERGON range is the ideal solution for manufacturing PET or rPET containers of different shapes and capacities from 0.10 L up to 10 L. The advantages of these machines are further enhanced in terms of space, energy and cost saving, when the blower is combined with a filler and a capper, which allows companies, actively involved in the environmental protection, to bottle their products in 100% recyclable, sustainable, light, unbreakable and safe containers with a high level of hygiene and suitable for the food and beverage storage.

UK recycling company Yes Recycling (Ashley Green; www.yesrecycling.org) said it is preparing to begin operations at a new facility in Glenrothes, Scotland that is to recycle 15,000 t/y of post-consumer hard-to-recycle plastic in a project supported with GBP 520,000 (EUR 609,000) of Scottish government funding. Scheduled to open in October 2021, the facility is designed to turn a range of low-grade plastic waste into pellets and flake, with the end result being a new generation of “Ecosheet”, an alternative to plywood being developed by the owners of Yes Recycling.

The plant has been backed by a range of business groups, including the Scottish government’s business agency Scottish Enterprise, Zero Waste Scotland, InvestFife and Ecosurety. Omer Kutluoglu, co-founder and director of Yes Recycling, said the new plant would create up to 60 jobs. Polylactic Acid Corn Bioplastic

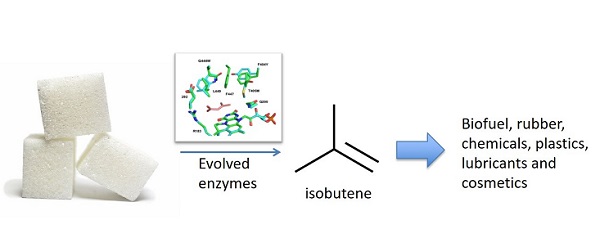

First time that a member of a widespread enzyme family has been repurposed to yield isobutene

A paper describing the results of collaborative work between Global Bioenergies and the team of Dr. David Leys at the University of Manchester has been published today in Nature Communications. Polylactic Acid Corn Bioplastic

This paper describes the evolution and mechanism of isobutene forming enzymes far superior to previously used catalysts. Isobutene, a gaseous hydrocarbon, is one of the major building blocks of the petrochemical industry: 15 million tons are produced every year and are turned into fuels, plastics, elastomers and cosmetic ingredients.

This is the first time a member of a widespread enzyme family that depends on an unusual vitamin B2 derivative has been repurposed to yield isobutene. This has been made possible through the extensive work performed on both sides of the Channel, with laboratory guided evolution carried out at Global Bioenergies, and detailed structure analysis of the the evolved enzymes at the University of Manchester.

-German market leader Wieland Electric switches to DOMAMID® 6LVGT85 for installation connectors

DOMAMID® a solution to all mechanical and flammability specifications

From February 2020, with the acquisition of the TECHNYL® brand, DOMO offers a complete and complementary range of solutions based both on PA6 and PA66

Domo Chemicals, a leading integrated solution provider, and PA6 and PA66 supplier, to the plastics processing industry, is driving materials development to meet evolving market needs and is working with customers to select the best base materials for specific applications. Polylactic Acid Corn Bioplastic

Recently, the German company, Wieland Electric, selected DOMAMID® 6LVGT85 for its installation connectors GST18i3 (3-pole) & GST18i5. These make up part of the gesis® pluggable electrical installation system for buildings, a flexible, future-oriented, and economic product range that meets all the requirements of modern energy distribution.

Polylactic Acid Corn Bioplastic