Polymers Petrochemicals Automotive additives 21-02-2019 - Arhive

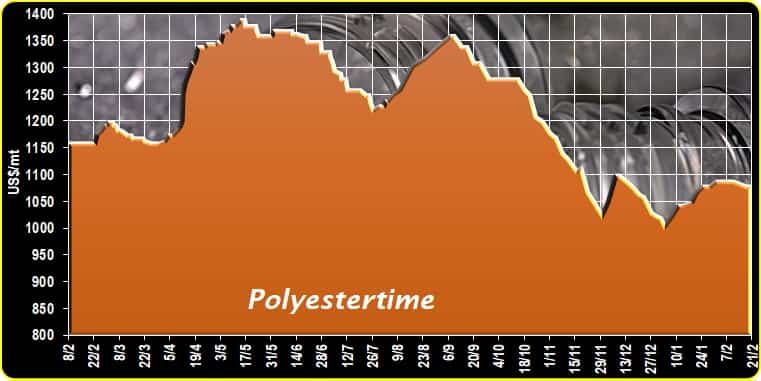

PET Resin bottle grade BGPET prices trend

China – Polyethylene Terephthalate

PET and its chain are steady.

- Polyamide 6 and its chain are steady.

PET Bottle grade export 1,040/1,080 $/ton – PET Bottle grade domestic market 8,250/8,350 yuan/ton – PET Filament grade SD domestic market 7,750/7,900 yuan/ton – PET Filament grade BR domestic market 7,750/7,850 yuan/ton

PTA Taiwan 850/860 $/ton – PTA domestic market 6,450/6,550 yuan/ton – MEG $ 605/615 $/ton – MEG domestic market 4,900/5,000 yuan/ton – PX Korea 1,085/1,095 $/ton

POY 150D/48F domestic market 8,400/8,550 yuan/ton – DTY 150D/48F domestic market 10,350/10,450 yuan/ton – PSF domestic market 8,800/8,900 yuan/ton

Crude Oil Prices Trend

Mass-production of Automotive Carbon Composite Parts Showcased at JEC World 2019

At this year’s JEC World, pultrusion specialist Thomas Technik & Innovation (TTI) is to showcase manufacturing technology that can produce affordable carbon fibre-reinforced plastic (CFRP) parts in high-enough volumes for the mainstream automotive industry.

Visitors to TTI’s stand and the Automotive Planet will see a CFRP bumper (fender), 100,000 of which could be manufactured each year using the company’s innovative Radius-Pultrusion process. TTI Sales Engineer Sebastian Mehrtens says, “There are not many CFRP manufacturing processes that can do these numbers.”

Uniquely, this process enables the manufacture of curved and coiled profiles. Mehrtens explains, “In the normal pultrusion process you have a mould that is stationary and two grippers or a caterpillar that pull the fibres through a heated mould. In our Radius-Pultrusion process, we move the mould.”

Azerbaijan is developing measures to reduce the use of polymer packaging, reports Sputnik Azerbaijan .

“The plan of measures to reduce the harmful effects of plastic packaging on the environment for 2019-2020” was approved by Azerbaijani President Ilham Aliyev. The main responsibilities in the process of refusing plastic bottles and plastic bags are assigned to the Ministry of Ecology and Natural Resources of AR (MENR).

The Ministry of Environment began to actively promote the harm of plastic and the policy of separate collection of garbage back in mid-2018. 135 special containers for collecting plastic containers appeared in the parks of Baku and district centers.

At Plástico Brasil 2019 from 25th to 29th March in São Paulo, Brazil, ENGEL, the injection moulding machine manufacturer and system expert headquartered in Austria will be demonstrating how their machines can make their customers more flexible, reliable and efficient with two sophisticated applications from the fields of packaging and technical moulding. It will be clearly demonstrated how digitalisation, and machine and system networking can unlock even more efficiency and quality potential.

Packaging: Thin-wall with IML in 2.2 seconds

Flexibility and high performance play the main roles in ENGEL’s packaging exhibition space at Plástico Brasil 2019. An ENGEL e-motion 440/160 will be used to produce polypropylene ice cream cups using thin-wall technology in a 4-cavity mould with a total shot weight of 14.8 grams. Thanks to in-mould labelling (IML), the cups are ready-to-fill when they leave the integrated production cell. The cycle time is 2.2 seconds.

Germany-based machine builder specializes in water-cooled and biax lines.

Reifenhäuser Group has announced the purchase of Plamex Maschinenbau GmbH, a Kelberg, Germany machine builder that specializes in blown film lines for water-cooled

and biaxially oriented films for the medical and food packaging industry. The company will operate under the name Reifenhäuser Blown Film Plamex GmbH & Co. KG.

The acquisition expands the Reifenhäuser Groups’ product range to include emerging technology for flexible film production. “The extremely efficient water cooling keeps the polymer in amorphous state and produces a particularly glossy and transparent film with remarkable puncture resistance and very good barrier properties. In our discussions with customers we can now provide even more differentiated advice and deliver the optimum solution for the particular application,” says Bernd Reifenhäuser, CEO of the Reifenhäuser Group.

Ineos Styrolution has today announced the completion of the acquisition of the polystyrene sites from Total S.A. following receipt of all applicable regulatory and legal approvals.

The transaction, which was agreed on August 21st, 2018, includes the purchase of the Foshan site in the Guangdong Province in South China and the Ningbo site in the Zhejiang Province in Eastern China and the two related sales offices in Guangzhou and Shanghai.

The transaction supports Ineos Styrolution’s Triple Shift growth strategy, as it will increase the company’s manufacturing footprint in Asia, and provides access to the domestic market in China with locally produced materials.

SustainabilityThe food and beverage segment led demand among end users in the global biopolymer films market in 2017, according to a new report from Global Market Insights (GMI; Selbyville, DE), Global Biopolymer Films Market.

Escalating demand for packaged food, particularly because of increasing per-capita income, along with a growing number of working populations across the world will boost demand.

Biopolymer films are used in the packaging of fresh food, tetra packs, dry snacks, bakery goods, juice bottles and meat trays along with coatings for beverage cups, films and card stock.

- Agreement between Bio-on and Innova Imagen for the production of Bioplastic in Mexico

- Bio-on and Innova Imagen (Himes Group) announce the signing of a new agreement to produce ultra-green PHA biopolymers in Mexico

- The two companies start the first collaboration in the central / north America, to exploit the Bio-on technologies for the industrial production of PHA bioplastics valorizing different local feedstock

- In the coming months Bio-on will work in exclusive with Innova Imagen to bring natural and biodegradable bioplastics for many market sectors into Mexico, with particular attention to the textile and fashion industry

Bio-on, listed on the AIM segment of the Italian Stock Market – Borsa Italiana and operating in the sector of high quality bioplastic, and Innova Imagen, a company of the Himes Group, with operations in the textile sector in Mexico and the United States with particular attention to eco-sustainable innovation, announce to have signed an exclusive agreement to design the realization of the first plant in Mexico for the production of 100% natural and biodegradable bioplastic, obtained from agro-industrial residues and by-products.

Sustainable plastic packaging solutions firm Paccor Group has produced its first 250,000t of eco-friendly materials using 100% recycled PET (rPET).

The company said that the achievement is the result of various investments totalling more than £10m in its UK operations in an effort to expand production.

Paccor Group UK managing director Ashley Jones said: “I am delighted that Paccor UK has achieved this excellent milestone of manufacturing out of fully recycled materials on a large scale.

“The lessons we have learned over the past decade are an important step for us to further support development in the market and to provide sustainable value for our clients and environmental benefits to the retailers and market.

The masterbatch industry is showing strong growth on the back of growing polymer demand and its ability to replace alternative methods of polymer modification, claims a report by AMI Consulting.

The global masterbatch industry continues to outperform both GDP and polymer demand growth and a growth rate in excess of 5 per cent per year is expected in the medium term. The more than 130,000 injection moulders around the world account for the largest customer group for masterbatches.

Mention food packaging and some people’s hackles rise over unnecessary layers of plastic or other wrappings.

However, scientists are working on several smart forms of sustainable packaging that can benefit consumers and help prevent food waste, according to Miranda Mirosa, Erin Young and Phil Bremer, of the department of food science at University of Otago.

They were part of a group of New Zealanders attending a packaging conference in China late last year, and have come back enthused about some of the emerging technologies and the different needs of the China market.