This content has been archived. It may no longer be relevant

- China – Polyethylene Terephthalate

PET is steady, while its chain is assessed mixed,but weak.

- Polyamide 6 and its chain are steady.

PET Bottle grade export 1,060/1,100 $/ton – PET Bottle grade domestic market 8,500/8,600 yuan/ton – PET Filament grade SD domestic market 7,700/7,800 yuan/ton – PET Filament grade BR domestic market 7,800/7,900 yuan/ton

PTA Taiwan 835/845 $/ton – PTA domestic market 6,500/6,600 yuan/ton – MEG $ 625/640 $/ton – MEG domestic market 4,950/5,050 yuan/ton – PX Korea 1,010/1,025 $/ton

POY 150D/48F domestic market 8,950/9,050 yuan/ton – DTY 150D/48F domestic market 10,550/10,650 yuan/ton – PSF domestic market 8,700/8,850 yuan/ton

Hydrosize Carbon from Michelman Helps Carbon Fiber Manufacturers Improve Quality and Performance of Composites

Michelman’s new Hydrosize® Carbon fiber sizing solutions allow customers to leverage carbon fiber’s unique benefits and produce higher quality composite parts. Part of Michelman’s Hydrosize® brand family of water-based sizing solutions, Hydrosize® Carbon allows carbon fiber manufacturers to optimize the interfacial adhesion between the polymers and the fibers by tailoring the surface chemistry of their reinforcement fibers to the chemistry of the matrix resin.

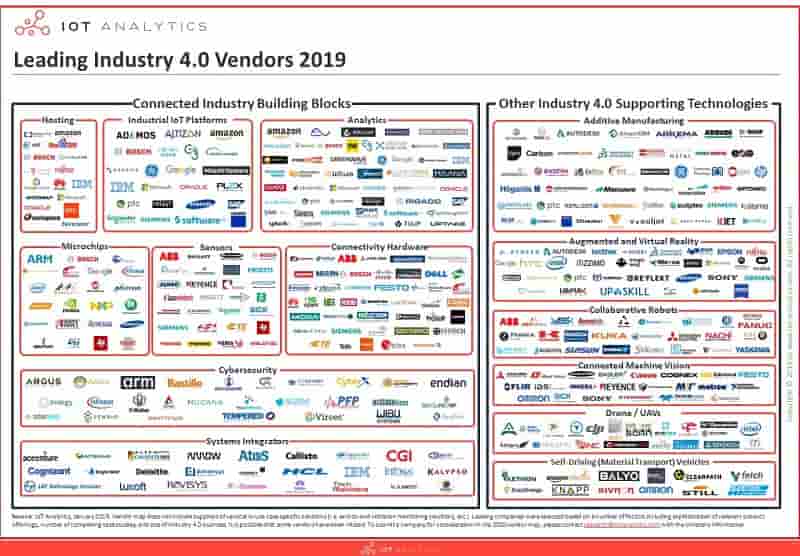

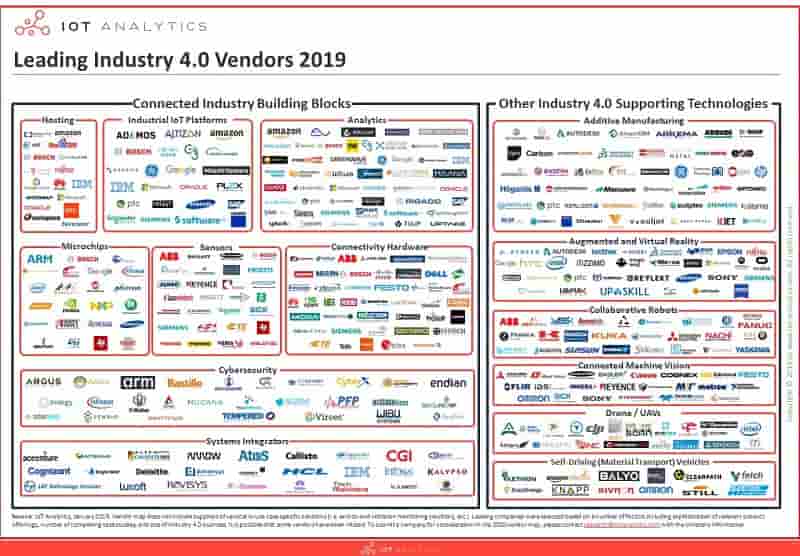

The Leading Industry 4.0 Companies 2019

Crude Oil Prices Trend

Tracking parts right back to the manufacturing data has taken another smart leap forward, with moulding machine specialist Sumitomo (SHI) Demag pioneering a fully automated In Mould Decorating (IMD) production cell.

Nigel Flowers, UK Managing Director, likens it to issuing each moulded component with its unique birth certificate, with all processing data held securely within the manufacturing executive system (MES).

Designed predominantly for automotive, medical device and aerospace manufacturing environments where quality control and traceability are critical, the advance is said to represent a change in how multiple components are individually issued with a unique identifier.

Mitsubishi has reportedly developed graphene-based MWIR sensors with extraordinarily high sensitivity.

Thanks to an internal graphene FET gain, the responsivity is said to be 10 times higher than that of quantum-type IR sensors with no internal amplification.

Mitsubishi uses graphene FET and leverages its high electron mobility.

High-performance materials from plants

Plants as sustainable raw material: Materials manufacturer Covestro and biotechnology company Genomatica have joined forces to research and develop high-performance materials based on renewable feedstocks.

With their collaboration announced on Wednesday, both partners are aiming to reduce the use of fossil-based resources such as crude oil.

Wind turbine blades for recycling at GFS.Wind turbines generate clean and renewable power, but when their blades reach end-of-life, the options – burning or landfilling – aren’t so green.

The wind power industry pulls at the heartstrings of environmentalists, but if the blades go into landfills, “that doesn’t exactly paint a real nice PR picture for the whole industry,” said Karl Englund. “We don’t want to see that happen.”

Englund is chief technology officer for Global Fiberglass Solutions (GFS), a Bothell, Wash.-based company that is hoping to make some of its own green by recycling the blades into pellets and boards. The company has developed – and is scaling up – a plant in Sweetwater, Texas to recycle fiberglass from wind turbine blades and other sources.

This development was made by a chemist in RUDN University. The new method synthesizes ‘yolk-shell’ nanoparticles on the basis of titanium dioxide and graphene.

Since the new particles have complex structure, scientists could carry out a selective oxidation for the production of aldehyde for many hours without the formation of any byproducts.

Although photocatalytic reactions are more eco-friendly, they are not selective enough.

The aldehydes produced by the process will start to oxidize and numerous byproducts will be formed.

The research team of this study came up with a solution to this problem, which is to use nanocatalysts with an unusual structure.

The first half of Article 53(b) of the European Patent Convention (“EPC”) states that essentially biological processes (“EBPs”) for the production of plants or animals are an exception to patent protection.

This small provision (which implements Art 4 of the Biotechnology Directive) has been the surprising source of conflict between the EU Commission and the Enlarged Board of the EPO about whether the products of EBPs are themselves patentable, as explained below:

Essentially biological processes

A process is an EBP “if it consists entirely of natural phenomena such as crossing or selection” (Rule 26(5) EPC).

EBPs do not, therefore, include genetic manipulation or the production of transgenic animals through chromosomal incorporation.

As we prepare for long-distance space travel and life on Mars, biotechnology could be the only possible solution to make spaceships no longer dependent on Earth’s constant supply.

“As human beings, we need a constant supply of oxygen.

We need constant access to nutritious food, clean water, and a safe and clean waste disposal system,” said Italian astronaut Samantha Cristoforetti during a live stream from the International Space Station (ISS).

A wafer-thin layer of glass on the inside wall of the PET bottle combines product protection with the option of full bottle-to-bottle recycling.

The public demand for more sustainability is growing stronger. As a result, the industry is increasingly concentrating on the recyclability of PET bottles.

However, this type of packaging often contains composite materials which considerably hinder simple,pure-grade recycling.

KHS’ FreshSafe PET technology offers the beverage and food industries a unique alternative.

Specialty materials company Eastman is set to introduce three recyclability solutions for shrink film allowing brand owners to select a resin that works best for them without sacrificing sustainability goals.

The newest members of the Eastman Embrace family of resins includes two new resins that enhance the recyclability of shrink-labeled PET packaging.

Embrace family of resins will allow to create 360-degree graphics and better designs for unique and highly contoured packaging.

The new resins include Embrace Encore copolyester, Embrace Float copolyester and Sun Chemical SunLam de-seaming adhesive.

At the VDI Congress ‘Plastics in Automotive Engineering’ (PIAE) on 3-4 April 3rd and 4th in Mannheim, Germany, Covestro will focus on a new priority topic: the car interior, with the motto ‘Designing Today for the Passengers of Tomorrow’.

Covestro

Polycarbonate and its blends will play an important role in car interiors

Polycarbonate and its blends will play an important role in car interiors but will also be a key material for future mobility solutions in general; for example, in the exterior shell and in the powertrain.

ENGEL de Mexico opened a second location in Mexico in San Pedro near Monterrey.

“We are thus shortening the distance to our customers in the very important industrial region in the north of the country,” emphasised Peter Auinger, Managing Director of ENGEL in Mexico.

ENGEL de Mexico SA de CV is headquartered in Querétaro near Mexico City “This is precisely why we decided to establish a permanent ENGEL team in the north,” says Auinger.

For Oerlikon Nonwoven, the IDEA, taking place in Miami Beach, FL, this week, kicked off with the signing of a contract. The customer, a renowned European meltblown specialist, invested in a two-beam, stand-alone meltblown system from the Neumünster-based plant manufacturer in order to meet its strongly increasing demand.

In the future, the system will be deployed to manufacture meltblown nonwovens for various application, especially from the filtration and wipes sector. The commercial production launch is scheduled for the first half of 2020.