Polymers Petrochemicals rPET Preforms 11-04-2019 - Arhive

- China – Polyethylene Terephthalate

- PET is steady ,while its chain is assessed mixed.

- Crude oil is always in good health.

- Polyamide 6 and its chain are steady.

PET Bottle grade export 1,080/1,130 $/ton – PET Bottle grade domestic market 8,650/8,750 yuan/ton – PET Filament grade SD domestic market 7,850/7,950 yuan/ton – PET Filament grade BR domestic market 7,950/8,050 yuan/ton

PTA Taiwan 850/860 $/ton – PTA domestic market 6,500/6,600 yuan/ton – MEG 595/605 $/ton – MEG domestic market 4,650/4,750 yuan/ton – PX Korea 1,040/1,045 $/ton

Polyester POY 150D/48F domestic market 9,250/9,350 yuan/ton – Polyester DTY 150D/48F domestic market 10,550/10,700 yuan/ton – Polyester Staple PSF domestic market 8,950/10,050 yuan/ton

Electricity harvested from the sun or wind can be used interchangeably with power from coal or petroleum sources.

Or sustainably produced electricity can be turned into something physical and useful.

Researchers in Arts & Sciences at Washington University in St. Louis have figured out how to feed electricity to microbes to grow truly green, biodegradable plastic, as reported in the Journal of Industrial Microbiology and Biotechnology.

“As our planet grapples with rampant, petroleum-based plastic use and plastic waste, finding sustainable ways to make bioplastics is becoming more and more important.

We have to find new solutions,” said Arpita Bose, assistant professor of biology in Arts & Sciences.

Crude Oil Prices Trend

Pilot seeks to find out if PEF from sugarcane could be more economical than PET at scale

Researchers in eastern Australia have started work on a three-month pilot plant to prove the economic viability of turning sugarcane waste into other compounds, including plastic drinks bottles.

The programme is being run by Darryn Rackemann, a senior research fellow at Queensland University of Technology’s Centre for Tropical Crops and Biocommodities, and will be carried out at Gladstone, north of Brisbane.

It is being undertaken in partnership with Mercurius Australia using a process patented by the start-up’s US-based parent Mercurius Biorefining. This has the potential to convert the fibre left over after sugarcane is pressed, known as bagasse, and other types of biomass into cost-effective biofuels and bio-chemicals. These include PEF, a material which many experts have touted as being a successor to PET.

At least 60 organizations are working to scale up depolymerization, pyrolysis and other emerging plastic processing methods. The North American market for the resulting products could top $100 billion annually.

Those statistics come from “Accelerating Circular Supply Chains for Plastics,” a market-landscape report released yesterday by Closed Loop Partners. It is the first comprehensive analysis of the range of approaches to plastics processing that are sometimes referred to as chemical recycling.

Such technologies have grabbed headlines over the past year, often framed as pathways to cut down on plastic pollution and offer solutions for the large quantities of material that are not making their way into established mechanical recycling systems.

New structure has carbon integrated into it that absorbs visible light and ‘feeds’ it to the metal oxide

Titanium dioxide is commonly used as an antibacterial surface, but not in areas like hospitals. This is owing to the UV light needed to activate the antibacterial properties of the surface, and the impracticality of this in a hospital setting.

The drive for this type of antibacterial is the need for cheaper coatings that can kill bacteria without contributing to the development of antibiotic resistance.

A new coating for stainless steel could be the solution to this, made of intricate titanium dioxide nanostructures, it kills bacteria under visible light without using antibiotics.

In this regard titanium dioxide is perfect, it kills by breaks down water vapour in the air to produce free radicals from oxygen that will attack whatever is touching it.

At an industry conference geared towards sustainable innovation in textile manufacturing, leaders from across the United Arab Emirates’ and Japan’s public and private sectors revealed plans to establish a plant in the city of Dubai that will leverage a solution developed to upcycle old clothes into raw material pellets.

Through initial investment of an estimated US$30 million, facilitated by a public-private-partnership, the new facility is seen as a way for textile manufacturers to shift their dependence from hydrocarbons-based pellets to more sustainable technologies such as that presented by JEPLAN (Japan Environmental Planning).

Evonik is expanding its production of transparent polyamides of the TROGAMID CX brand at the Marl Chemical Park (Germany).

With production expansion scheduled for completion in the first quarter of 2020, the project will double the specialty chemicals company’s capacity for its transparent, high-performance materials.

The company will be expanding its TROGAMID CX production in part through targeted debottlenecking efforts, in part through comprehensive optimisation initiatives undertaken by production management.

According to a report from the United Nations in 2018, a total of 13 million tonnes of plastic gets washed into the ocean every year. This includes many types of hard plastics and soft plastics as well that marine life mistake for food that often leads to their demise.

Aside from being responsible for endangering marine life, plastic is also largely responsible for greenhouse gas emissions during its production and when it is being disposed of.

However, plastic is somewhat important in the daily lives of people. This is the main reason for the popularity of plastic products.

The U.S.-Iran crude oil sanctions merry-go-round is starting to spin again with Asian crude buyers fretting over whether they will be allowed to continue imports from Tehran.

Against its desire to cut off Iran’s oil revenues, the administration of U.S. President Donald Trump must balance the potential impact of the loss of Iranian exports on the crude market, especially in Asia, home to top buyers India and China.

Global apparel company H&M used the equivalent of 325 million PET bottles in its recycled polyester last year, substantially up from the year before.

According to the company’s 2018 sustainability report, H&M is the sixth-largest consumer of recycled polyester in the world. Last year’s recycled PET (RPET) consumption was up from its use of the equivalent of 100 million PET bottles in 2017.

The report notes that several of the Sweden-headquartered company’s brands replaced conventional polyester and nylon with recycled alternatives last year. The Arket brand and H&M worked with a 100 percent recycled nylon fiber branded Econyl, which is produced by Italian company Aquafil. Plastics Recycling Update reported that Aquafil is further investing in its U.S. capacity to recover nylon from post-consumer carpet.

Runners in this month’s London Marathon will be the first to drink Lucozade Sport from 100 per cent recycled PET, after its UK-based producer unveiled a series of sustainability initiatives.

Lucozade Ribena Suntory’s (LRS) 380ml rPET bottles are made specifically for sampling at events and will prevent approximately 7.8 tonnes of new plastics being produced every year.

LRS will operate a closed-loop recycling initiative at London Marathon Events, where all bottles on the course will be collected and recycled back into new bottles.

The manufacturer will also give out 30,000 Lucozade Sport Ooho seaweed capsules. This will be the largest Ooho trial run by LRS at a mass-participation sporting event since the brand owner began using the material last year.

RadiciGroup, a leading developer of polyamide, chemical intermediates, synthetic fibres, and nonwovens, is showing solution dyed polyamide yarns used for carpets in five shades, along with Clariant ColorWorks at Fuori di Design. It is an exhibit promoted by Materioteca which is being held during the Milano Design Week from April 9-14, 2019, in Italy.

Now in its eighth edition, this year’s event features the five colours of “care-Less”, a social trend identified by Clariant ColorWorks.

RadiciGroup is showing along with this Swiss group, the creator of the guide ColorForward 2020, and the Treviso-based Brado, a supplier of solutions in the field of seating design.

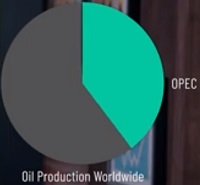

Venezuela is in chaos. Iran is grappling with US sanctions. And now there’s a surge of violence in Libya. Trouble in these three OPEC nations has helped send US oil prices climbing back above $64 a barrel.

The latest OPEC turmoil amplifies the supply constraints imposed by the cartel’s kingpin. Saudi Arabia has slashed production as well as exports to the United States in a bid to engineer higher prices and balance its budget.

Despite record-shattering US oil production, US oil prices have spiked 50% since plummeting to $42.53 a barrel on Christmas Eve. And gasoline prices are creeping higher just as the American economy grapples with a slowdown.

BARCELONA – Fashion for Good will once again host the ‘Pitch for our Planet’ textile innovation session at the forthcoming Planet Textiles event which takes place on 22nd June in Barcelona where it is being co-hosted alongside ITMA 2019.

Speakers at this special innovation session on new and emerging textile technology include Petri Alava, CEO of Infinited Fiber a company that turns textile, cardboard and agricultural waste into new fibres; along with Spencer Null, Director of Product Development at Natural Fiber Welding, which uses a closed loop platform to fuse fibres together without denaturing the natural polymers of the fibres.

Truetzschler Nonwovens will present production lines for green nonwovens at the Techtextil trade fair for technical textiles and nonwovens, which takes place from 14-17 May in Frankfurt.

“Since decades machine supplier answered requirements on enhanced product quality, better line efficiency and higher productivity with new concepts and innovative processes. Now we see a new dimension rising,” the company reports.

“As a supplier of complete production lines Truetzschler Nonwovens offers machinery, service and know-how out of one hand – everything from implementing product ideas to enabling new businesses.”

Last year, 45 producers reported selling plastic beverage containers to California consumers. Of those businesses, 13 said their bottles incorporated some amount of recycled plastic.

The California Department of Resources Recycling and Recovery (CalRecycle) recently published its 2018 Plastic Beverage Container Virgin and Post-Consumer Resin Reports, which are required by law. The requirement applies to producers of bottles subject to the California Redemption Value (CRV), a fee of 5 cents or 10 cents (depending on bottle size) paid by consumers but returned to them when they redeem containers.

For 2018, 66 companies submitted reports, but because some of them were distributors that don’t actually bottle drinks, only 45 respondents reporting using any type of plastic. This is the second year of required reporting. The 2017 report, released last year, included more respondents who did not report any plastic usage because they were distributors.

A team of Ohio State researchers have developed a material that could help reduce plastic pollution.

Until now, bioplastics made from renewable resources like sugar and cornstarch have historically been too brittle for wide industrial use. Post-doc researcher and lead author Xiaoying Zhao says she and her team have developed a new bioplastic that resembles conventional plastic, but has a smaller environmental footprint both in the way it’s made and in the fact it’s biodegradable.

“Our research was to improve its flexibility and toughness by blending it with natural rubber,” Zhao said

Get instant alerts when news breaks on your stocks. Claim your 2-week free trial to StreetInsider Premium here.

Tronox and Cristal, two of the largest suppliers of the white pigment chloride process titanium dioxide, have agreed to settle Federal Trade Commission charges by divesting Cristal’s North American titanium dioxide assets, thereby preserving competition in the market for this important and widely used compound.

The settlement comes after the FTC won key victories before a federal court and an Administrative Law Judge in its case to block the transaction. Chloride process titanium dioxide (TiO2) is used in a wide variety of products, including paint, industrial coatings, plastic, and paper. Under the settlement, Tronox and Cristal will sell the divested assets to Ineos, a multinational chemical manufacturer, no later than 30 days from the close of the acquisition.

Ube Industries, Ltd. (Ube; Tokyo, Japan; www.ube-ind.co.jp) announced that its consolidated subsidiary, UBE Corporation Europe S.A.U. (UCE), has decided to acquire Spanish compound manufacturer Repol S.L. and has entered into an agreement for the transfer of shares. Details of the majority share participation are outlined below.

Repol operates a compound business in Europe using nylon 6, nylon 66, polypropylene, polyacetal and other resin raw materials. These products are mainly used for automobiles but are also broadly used in industrial materials and for the electrical and electronics industries.