Polymers Petrochemicals sustainability biodegradable 23-02-2019 - Arhive

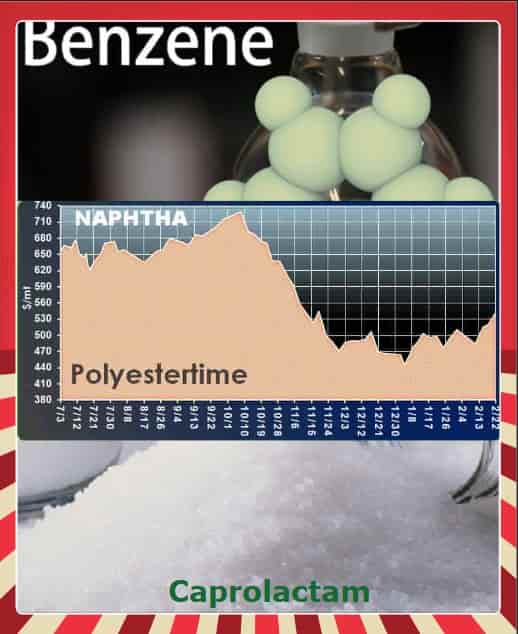

China : Naphtha $ prices

New lactam wastewater recovery plant at RadiciFil: setting new targets on energy savings and emission reduction

Enhanced environmental performance and improved polymer and, hence, yarn quality: these are the main objectives set for the new lactam wastewater recovery plant installed at the RadiciFil production site in Casnigo (Bergamo) during the course of 2018. The production facility specializes in polyamide 6 polymerization and BCF yarn production, the core business of the RadiciGroup Performance Yarn Business Area.

The new plant, which has recently undergone a test run, recovers the wastewater from the polymerization process with a caprolactam concentration of 8-12%. Using falling film and mechanical vapour recompression technologies, the plant processes the water, so as to raise the caprolactam concentration in the output up to 80%, thus making the recovered caprolactam suitable for reuse in continuous cycle polymer production.

“This investment has taken advantage of some of the benefits provided by Industry Plan 4.0”, said Nicola Agnoli, CEO of the RadiciGroup Performance Yarn Business Area, “and is part of the company production plan.

According to the American Chemistry Council (ACC), the U.S. Chemical Production Regional Index (U.S. CPRI) rose by 0.3 percent in January, following a 0.6 percent gain in December and a 0.2 percent gain in November.

During January, chemical output rose across all regions, with the largest gains in the Gulf Coast region.

Chemical production was mixed over the three-month period. There were gains in the production three-month moving average output trend in inorganic chemicals, plastic resins, synthetic dyes & pigments, and other specialty chemicals.

These gains were offset by declines in the output of fertilizers synthetic rubber, consumer products, manufactured fibers, adhesives, pesticides and coatings.

Prime Minister of Ireland Leo Varadkar TD has announced the GW Plastics is expanding its advanced manufacturing operations in Sligo.

GW Plastics established its first European location with the purchase of Avenue Mould Solutions in 2017 and is growing its operation in response to increased customer demand in its medical device and drug delivery business.

The project is supported by the Irish Government through IDA Ireland.

GW Plastics plans to invest in excess of €6 million to grow their product development, precision tooling, thermoplastic and silicone injection moulding, and contract assembly capabilities in Europe.

The company plans to expand its moulding operations into a scalable 28,000 square foot site in Sligo.

A team of researchers at NYU have presented a new chemical reactor type that synthesizes a precursor for nylon production through electrosynthesis, rather than a thermal based reaction.

The need for chemical products accounts for about a quarter of the world’s energy demand.

With most of that energy turned into heat for thermochemical reactions, researchers from New York University’s Tandon School of Engineering have developed a new type of reactor that uses renewable energy to generate electrosynthesis reactions.

Battenfeld Cincinnati China The market for polyethylene in China is strong, but U.S.-based suppliers may be hamstrung in exporting there because of an ongoing trade war.

For most North American commodity resins, 2018 was a good year.

U.S./Canadian high and linear low density PE sales reported major growth in 2018, according to the American Chemistry Council, resulting from larger amounts of new capacity being sold into the export markets as well as domestic sales that have grown at strong rates.

HDPE sales in the region were up 12 percent for the year, according to ACC, with domestic growth of more than 5 percent amplified by export sales growth of more than 42 percent. Domestic HDPE growth for 2018 was led by the pipe and conduit market, where sales surged 14 percent.

Color masterbatches are combinations of pigments and additives that are used in various applications, for instance, roofing, storage containers, cables, electronics, cosmetic objects, toys, belts, silage sheets, pipes etc.

They have numerous benefits owing to which several synthetic fiber and plastic producers use color masterbatches – they come in form of pellets which makes it easier to apply, store or move as compared to powdered pigments, it is easier to handle and feed the color concentrates during manufacturing where color masterbatches are used, binding agent used in the masterbatches can be easily matched to the polymer which is used for enhanced melt processing, they offer good control on transparency as well as opacity of colored objects and special effects can be added to enhance color thus distinguishing between different objects.

NatureWorks’ Blair, Nebraska, production facilityThe recent initiative at Nature Works targets that by 2020, 100 percent of the agricultural feedstock for Ingeo biopolymers and Vercet performance chemicals will be certified by the International Sustainability & Carbon Certification System (ISCC) to the ISCC PLUS standard of best practices in agricultural production.

In 2012, Nature Works became the first biopolymers manufacturer to become certified to the new ISCC PLUS standard. Looking at the current scenario, more than 40 percent of its agricultural feedstock stands certified. However, it is expected that around 90 farms will be involved in this program by 2020.

Construction could resume in May at the M&G plant in Corpus Christi. The bankrupt company was sold last year to Corpus Christi Polymers LLC, which signed a year-long lease this week with the Port of Corpus Christi for a laydown yard used to store construction materials and equipment. The agreement allows for an extension of one year if needed.

Corpus Christi Polymers is a consortium of its former vendors: Alpek S.A.B. de C.V., a Mexican chemical manufacturing company; Indorama Ventures Holding LP, a subsidiary of Indorama Ventures Limited; and Far Eastern Investment Holding Limited of Taiwan. It was formed to purchase the plant, which is under construction, and put it into operation.