Polymer-plants – Biobased-Nylon 46 01-07-2022 - Arhive

Polymer-plants – Biobased-Nylon 46

Crude Oil Prices Trend

-Biobased, High-Performance Aliphatic Nylon 46

DSM’s Stanyl B-MB 100% biobased version of the company’s flagship Stanyl 46 and said to be an ‘industry-first launch’ of a biobased high-temperature nylon.

A new 100% biobased content high-performance aliphatic nylon 46 has been added to the Stanyl nylon 46 portfolio of DSM Engineering Materials.

Designated Stanyl B-MB (Biobased Mass Balanced), this more sustainable version of the company’s flagship material, reportedly offers the same high performance offered by its virgin counterpart. Polyurethane-recycling – Loop-battery-recycling

Its excellent high-temperature mechanics (melting temperature of 554 F/290 C), superior flow and processing, and distinguished wear and friction resistance make it ideal for high-temperature applications in automotive, electronics, electrical, and consumer goods industries, such as USB connectors, automotive and industrial actuator gears, powertrain timing chains, bearing cages, and food contact conveyors.

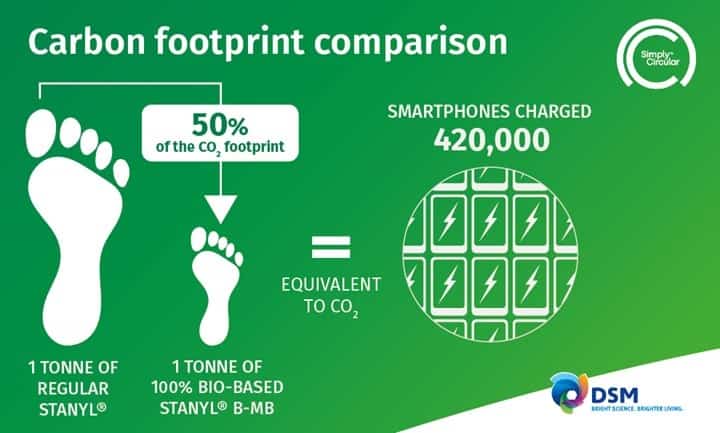

Using the maximum possible levels of biomass-waste feedstock, it enables DSM to halve the carbon footprint of this product line and, in turn, of the Stanyl B-MB-based products of its customers. This ‘industry-first launch’ of a 100% biobased high-temperature nylon underlines the company’s ongoing commitment to helping customers fulfil their sustainability ambitions by making planet-positive choices and supporting the transition to a circular and biobased economy. Polyurethane-recycling – Loop-battery-recycling

Avient Corporation, a premier provider of specialized and sustainable material solutions and services, today introduced its breakthrough PCR Color Prediction Service for polyolefins and polyethylene terephthalate (PET) resins, and the company’s new polyolefin antioxidants, Cesa™ Nox A4R Additives for Recycling. Polymer-plants – Biobased-Nylon 46

These sustainability solutions are specifically designed to improve the customer experience of working with post-consumer recycled (PCR) content for materials used in packaging. Both align with the eight ways Avient helps customers be more sustainable.

“Avient is fully committed to increasing opportunities to expand the use of recycled polymers, addressing any barriers that arise either during the recycling process or when customers want to incorporate PCR content into existing or new applications,” said Norbert Merklein, vice president and general manager for the Europe, Middle East and Africa regions of Color, Additives and Inks at Avient. “Our Cesa Nox A4R Additives for Recycling, together with the PCR Color Prediction Service, help overcome these roadblocks. These are two new ways Avient is contributing to the circular economy and empowering customers to meet their sustainability goals.” Polyurethane-recycling – Loop-battery-recycling

Calculating the Color Gamut

The PCR Color Prediction Service, helps brand owners understand what colors are achievable based on the amount of PCR used. It uses sophisticated technology to determine – through prior color matching – if colors are feasible in a new application that incorporates PCR content. A first of its kind for the plastics industry, this internally developed solution also calculates how much PCR content can be added to an existing application without affecting its signature color. Polymer-plants – Biobased-Nylon 46

Using proprietary software, Avient experts measure resin characteristics to identify the gamut of colors that can be successfully reproduced in a specific PCR-based material.

-thyssenkrupp to build three major polymer plants for Merions in Turkey

thyssenkrupp Industrial Solutions’ subsidiary Uhde Inventa-Fischer signed a contract to build new world-scale polymer plants for MERINOS HALI SANAYI VE TICARET A.S., Turkey, said Hydrocarbonprocessing.

The plant will use Uhde Inventa-Fischer’s proprietary patented MTR (Melt-to-Resin) technology to produce 330,000 tpy of resin for the production of PET bottles as well as bright chips for textile applications.

Ali Erdemoglu, Chairman of Merinos Hali San. Ve Tic. A.S.: “The foundations of the companies and brands of Erdemoglu Holding, which have become a giant company by adding new ones to its achievements day by day, were laid in 1970. Merinos Hali, one the major group of companies of Erdemoglu Holding, will secure his international quality standard and global leadership in the carpet industry with its state-of-the-art production facilities.Polymer-plants – Biobased-Nylon 46

It is an honor to cooperate with UIF for our growth strategy.”

Werner Steinauer, CEO of Uhde Inventa-Fischer: “We are very proud that Merinos chose us to build a MTR plant for bottle grade and textile application. Scope of delivery for all plants includes basic and detail engineering, delivery of all necessary components, technical services regarding plant erection as well as supervision of erection and commissioning.”

MTR – a cost-effective solution for producing high-quality PET resin The MTR process eliminates the SSP (solid-state polycondensation) and leads to substantial energy savings. It reduces investment, operating and maintenance costs, has a higher raw material yield and results in products of superior quality. The MTR process is based on Uhde Inventa-Fischer’s proprietary 2-Reactor technology which uses the patented ESPREE and DISCAGE reactors to obtain the desired high melt viscosities.

As per MRC, Thyssenkrupp suspended its 2021/22 forecast for free cash flow before mergers and acquisitions for due to the Ukraine crisis and said it was unclear if it would still be able to spin off its steel division, said the company.

Although the group’s sales from Russia and Ukraine are negligible at significantly less than one percent of total sales, the Executive Board estimates that the group’s business performance will be impacted by the far-reaching macroeconomic and geopolitical consequences of the war in Ukraine. Polymer-plants – Biobased-Nylon 46

-Covestro says investments boost polyurethane recycling

European company establishes partnerships to close loops for tarps, mattress foam and other products.

German-based polymers producer Covestro AG says it is working to “align itself comprehensively with circularity and help make it the global guiding principle” as it develops technologies to reuse plastics and return them to the value cycle, “often in close cooperation with partners.”

The goal of one new collaboration, with Switzerland-based backpack and messenger bag producer Freitag, is “the unlimited recycling of truck tarps, based on thermoplastic polyurethanes (TPUs),” Covestro says. At the end of their useful life, the tarps are to be recycled via a chemical recycling process and used for new tarps or other products, the firm says. Polymer-plants – Biobased-Nylon 46

Covestro says its focus to date has been on proven mechanical recycling to obtain materials. More recently, it sees chemical recycling processes, in which polymer molecules are broken down chemically, as a way forward.

Calling mechanical recycling “particularly suitable for polycarbonates,” Covestro says numerous corresponding products from Covestro are already on the market, including polycarbonate blends for IT applications with up to 75 percent recycled material.

“In addition, new plastic products are designed from the outset to be easier to recycle at the end of their useful life,” the company says.

A consortium of industrial partners in the Circular Foam project is researching processes for the chemical recycling of rigid polyurethane foam, according to Covestro, which says it is guiding that effort.

-Can closed loop battery recycling and geothermal lithium help solve the supply crunch?

Analysts warn that a lithium supply chain crunch could come as soon as 2023 — and put a potential damper on U.S. vehicle electrification goals.

Five- to tenfold growth is expected in the global lithium battery market over the next decade as people shift to electric vehicles (EVs), but already lithium supplies are tight.

“Big companies probably feel like there’s a lot of lithium in the world right now, and I’m going to get access to it,” Venkat Srinivasan, director of the Argonne Collaborative Center for Energy Storage Science and deputy director of the Joint Center for Energy Storage Research, told GreenBiz. “But for everybody else, if you don’t have that long-term contract, what do you do?”Polymer-plants – Biobased-Nylon 46

Companies that use lithium outside of the EV market are especially feeling the pain, he told GreenBiz. Some can’t get anyone to answer their calls.

President Joe Biden invoked the Defense Production Act in March to encourage domestic production of minerals for lithium batteries. But with China, Australia and Chile producing most of the world’s lithium, and China manufacturing roughly 70 percent of the world’s EV batteries, the U.S. has a lot of catching up to do.

Nevertheless, Srinivasan is optimistic that the U.S. will solve its supply chain crunch. A lot of people are “throwing ideas at the wall,” he said, and that means something has to stick. Plus, he’s excited that many companies finally have market funding in the $100 million range. “People like me who are feeding the R&D pipeline have companies that are now looking at these solutions very carefully because they have the funding to scale,” he said.

Here’s what looks promising in the near-to-medium term:

A closed loop lithium-ion battery economy

A handful of companies have cracked the challenges of lithium battery recycling and are commercializing a promising new technology for recovering lithium, cobalt and nickel from spent batteries. Investors are pouring in hundreds of millions to the industry, while the Biden administration earmarked $3.16 billion toward it.

A lithium battery recycling industry could provide a new source of lithium within the next few years, and without the environmental and community impacts from mining new materials

Ascend Elements of Westborough, Massachusetts, is a pioneer of this technology. It shreds batteries, extracts the impurities and leaves behind valuable lithium, cobalt and nickel in a “black mass.” It then converts the black mass into battery cathodes in a closed loop system that produces minimal waste. The technology is a vast improvement over smelting or burning batteries, a simple but inefficient process that produces waste and toxic air emissions. Polymer-plants – Biobased-Nylon 46

Faerch Group, a manufacturer of rigid food packaging and integrated recycler, recently announced the renaming of its subsidiary 4PET Recycling to “Cirrec”. The new name therefore reflects the company’s commitment to circular recycling of food packaging. By ordering additional capacity, “Cirrec” aims to expand tray-to-tray recycling to countries across Europe and is driving the development of the establishment of food-grade tray RPET, regenerated from pots, tubs and trays, as a new commodity on the market.

The new name “Cirrec” underlines the company’s focus on “CIRcular RECycling”. In contrast to downcycling, circular recycling returns products to their original use without loss of quality and food safety. Functional properties such as food quality, color, impact resistance, etc. are retained or completely recovered.Polymer-plants – Biobased-Nylon 46

According to a presee information, “Cirrec” already processes industrial quantities and recycles the equivalent of 1.2 billion food trays per year. This should roughly correspond to the entire Dutch market for sorted rigid PET food packaging for the household or alternatively to the total amount of sorted PET pots, cups and trays in Scandinavia.

According to the information, “Cirrec” has begun to expand its shell recycling capacities to other countries in Europe. The next two tray washers have already been ordered, which is expected to quadruple production capacity to more than five billion food trays per year by 2025.

-Caprolactam drops below supporting line, may continue bottoming

In the past two weeks, due to the impact of the Fed’s interest rate hike, the global market has generally declined. In nylon industry, in addition to the impact of the decline in crude oil, the aromatic market was quickly giving up previous surge, and these had all accelerated this round of downward adjustment in CPL and nylon 6 market.

From June 13th to June 23rd, the price of CPL RMB spot plunged. In nine working days, it quickly dropped from 15,300yuan/mt to 14,000yuan/mt, with a cumulative drop of 1,300yuan/mt. As Brent crude rebounded, CPL fell to 13,900yuan/mt on June 27 after a two-day brief adjustment. During the same period, nylon 6 chip market also fell chaotically. Polymer-plants – Biobased-Nylon 46

In terms of industry fundamentals, CPL and nylon 6 chip are still facing the extreme pull from cost and demand. But it is not enough to give a clear direction only from the consideration of the long and short factors of the macro and the nylon industrial chain alone.

Let’s talk about the conclusion first, considering the performance of crude oil, commodity index, bulk chemical indexes and related products, CPL market may continue bottoming downward. Here we just talk about two most related aromatic products, benzene and styrene.

-The world’s first CO2 battery for long-duration energy storage is being commercialized

Italian startup Energy Dome has now begun to commercialize the world’s first CO2 Battery, which was launched earlier this month in Sardinia, Italy. The battery uses carbon dioxide to store renewable energy on the grid, and Energy Dome says the technology can be quickly deployed anywhere in the world.

June 28 update: Energy Dome today announced that it has secured $11 million in bridge funding, which will enable it to buy equipment for a 20-megawatt/200-megawatt-hour/10-hour duration facility for Italian utility A2A, with which it has a memorandum of understanding. Polymer-plants – Biobased-Nylon 46

The Evolution Fund of asset management company CDP Venture Capital Sgr, together with existing investor Barclays, led the convertible funding. Swiss family office Novum Capital Partners, an existing shareholder in Energy Dome, also joined the round.

With the closing of this latest convertible round, Energy Dome has now raised a total of nearly $25 million since the company emerged from stealth mode in February 2020. Its series B round is planned for later in 2022

World’s first CO2 Battery

Energy Dome sited the CO2 Battery in Sardinia to favor speed to market and ease of execution, as it’s in an industrial area with an existing electrical connection. Further, Sardinia currently uses coal, but the fossil fuel will be phased out by 2025. The battery can be paired with both wind and solar.

Energy Dome began its operations in February 2020 and has progressed from a concept to full testing at multimegawatt scale in just over two years.

Energy Dome Founder and CEO Claudio Spadacini said:

The CO2 Battery is now commercially available to make cost-effective renewable energy dispatchable on a global scale.

Energy Dome asserted that its CO2 Battery facility in Sardinia uses off-the-shelf equipment available from a globally established supply chain, and said that rapid global deployment of the CO2 Battery is now possible without bottlenecks.

The company has secured multiple commercial agreements, including one with Italian utility A2A for the construction of the first 20 MW-5h facility. Earlier this year, Energy Dome also signed a nonexclusive license agreement with Ansaldo Energia, a power generation plant and component provider, to build long-duration energy storage projects in Italy, Germany, the Middle East, and Africa.

Energy Dome’s plan is backed by investors that include European deep tech venture capital firm 360 Capital, Barclays, Novum Capital Partners, and Third Derivative.

How the CO2 Battery works

CO2 is one of the few gases that can be condensed and stored as a liquid under pressure at ambient temperature, so, as Energy Dome states on its website, it’s the perfect fluid to store energy cost-effectively in a closed thermodynamic process. It allows for high-density energy storage without the need to go to extremely low temperatures.

Spadacini explained how it works to Bloomberg in May:

To charge the battery, we take CO2 at near atmospheric temperature and pressure and we compress it. The heat that is generated during compression is stored. When we exchange the thermal energy with the atmosphere, the CO2 gas becomes liquid.

To generate and dispatch electricity, the liquid CO2 is heated up and converted back into a gas that powers a turbine, which generates power. The CO2 gas is always contained and the entire system is sealed.Polymer-plants – Biobased-Nylon 46

We don’t use any exotic materials. The technology uses steel, CO2 and water. So there is no dependency on rare earth materials like cobalt or lithium. This makes our technology geopolitically independent. It can be produced everywhere and it can be used everywhere.

Polymer-plants – Biobased-Nylon 46