Pyrolysis-technology – Petrochemicals 16-01-2023 - Arhive

Pyrolysis-technology – Petrochemicals

-Petrochemicals – PET-Bottles – MEG

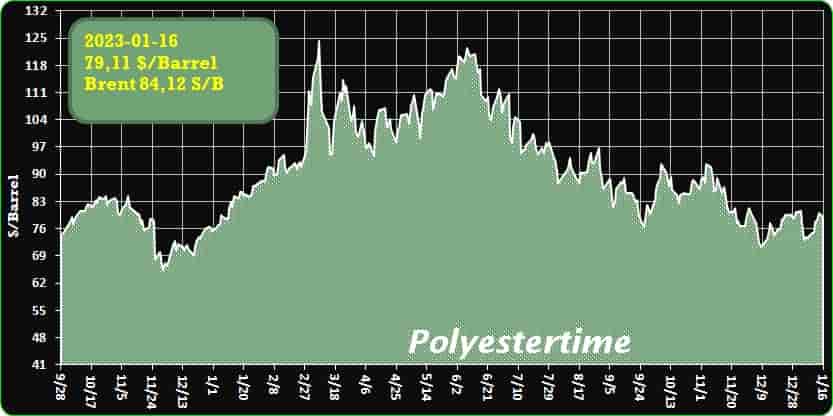

Crude Oil Prices Trend

Crude Oil Prices Trend Polyestertime

-SK Geo Centric opts for Plastic Energy’s pyrolysis technology

At the recent CES 2023, SK Innovation subsidiary SK Geo Centric signed a contract with British chemical recycling company Plastic Energy under which Plastic Energy will supply the pyrolysis technology to be used for the third chemical recycling plant SK Geo Centric is planning to build in the new plastic recycling complex in Ulsan (South Korea). Na Kyung-soo, CEO of SK Geo Centric, Bruno Guillon, Chief Commercial Officer of Plastic Energy, and others attended the signing ceremony.

SK Geo Centric will start construction of the pyrolysis plant this year. The plant, with a capacity of some 66,000 tonnes of end-of-life plastic waste, will be the largest in Asia. SK Geo Centric also plans to build a pyrolysis oil post-treatment plant based on proprietary technologies designed to improve the quality of the pyrolysis oil produced.

The two companies also signed an MOU to establish a strategic partnership aimed at promoting the development of advanced recycling, following the construction of the plant in Ulsan, in selected countries across Asia. To that end, they propose to create a joint venture to fast-track the construction of new advanced recycling facilities in China, Japan and other key markets. Pyrolysis-technology – Petrochemicals

Plastic Energy’s patented TAC process enables currently unrecyclable plastics to be converted into a feedstock called Tacoil. This can be used to create virgin-quality plastics that are suitable for use in numerous consumer packaging products, including food and cosmetics applications.

The official name of the Ulsan plastic recycling complex – the world’s first such complex – was announced at the signing. Called the Ulsan Advanced Recycling Cluster (ARC), it will boast three advanced chemical recycling plants based on different technologies at a single site. In that context, SK Geo Centric has partnered with global companies such as PCT (US), Loop (Canada), and now, Plastic Energy (UK) to achieve this.

SK Geo Centric is cooperating with PureCycle Technologies in the US to implement the Ultra PP supercritical extraction technology developed by that company. The technology makes it possible to remove pollutants from waste plastics. SK has signed a contract to create a joint venture following an equity investment of 55 million dollars. It has also secured exclusive sales rights in Korea and the rights to conduct business in China and Southeast Asia.

With Loop Industries, the company has formed a partnership to make use of that company’s depolymerisation technology, which allows previously unrecyclable PET plastic and polyester fibre waste to be broken down into their base building blocks, dimethyl terephthalate (DMT) and monoethylene glycol (MEG), using low heat and no added pressure. These DMT and MEG monomers are then purified and polymerised (or re-combined) into Loop™ branded PET plastic and polyester fibre. The end product is made from 100% recycled content.SK Geo Centric has made an equity investment of 10% and holds exclusive rights to conduct business in Asia. Pyrolysis-technology – Petrochemicals

-Kolon Industries exhibits in ‘DOMOTEX Hannover 2023’, the world’s leading trade fair for carpets and flooring

Actively targets the European carpet backing market with the newly launched eco-friendly product line-up

Obtained international green certifications for the first time in Korea by the eco-friendly PET spunbond textile from recycled plastic bottles

Strengthens global network through the eco-friendly product line-up with the brand name “FINON ECO”

Kolon Industries Inc. (KRX: 120110), top chemical materials and textile maker in South Korea, exhibits its polyester spunbond textile (brand name: FINON) at ‘DOMOTEX Hannover 2023’ in Germany from 12-15 January (local time). The company plans to speed up the implementation of global marketing strategy in the European market through this world wide opportunity. Pyrolysis-technology – Petrochemicals

‘Domotex Hannover 2023’ is a world leading trade fair for carpets and floor coverings. Exhibitors and trade show attendees introduce and exchange information about the latest trends in the global flooring industry. It has been held every year since it was first held in Hannover, Germany in 1989 and more than 730 exhibitors from 50 nations are participating this year.

The South Korean textile maker has been exhibiting in DOMOTEX Hannover every year since 2011. This time, the company is focusing on groundbreaking networks and enhancing partnerships with customers by presenting the newly launched eco-friendly PET spunbond line-up, the brand name “FINON ECO”. In particular, the company was the only non-woven textiles company to participate in ‘THE GREEN COLLECTION’, a special eco-friendly product exhibition of DOMOTEX Hannover. “FINON ECO” has been proven to be effective in sustainability by obtaining the GRS (Global Recycle Standard) and EPD (Environmental Product Declaration) certificates.

“Participating in DOMOTEX Hannover has always been a definite must for us. Our goal is to enhance global partnerships and show our differentiated technology in the global market through this world wide platform”, explains Hyeonjun Choi, Director of the company’s non-woven business. Pyrolysis-technology – Petrochemicals

Polyester spunbond is a non-woven fabric that is bonded after being spun in the form of filaments. It is widely used as carpet backing, media filters, construction, civil engineering materials and more. Kolon Industries Inc. was the first synthetic textiles manufacturing company in South Korea and started the spunbond business in 1985. It has developed its own technologies to supply high quality products with excellent mechanical properties and durability to customers worldwide.

About Kolon Industries Inc.

Kolon Industries is a South Korean chemical and textile manufacturing company. It was founded in 1957 as Korea Nylon Inc., the first nylon manufacturer in Korea. It has since expanded to a global comprehensive chemical company focusing on four major businesses: industrial materials, chemical, film/electronic materials and fashion. It is actively creating sustainable values through development of eco-friendly materials for biodegradable plastics, representative materials of hydrogen fuel cell, and upcycling fashion brands. Pyrolysis-technology – Petrochemicals

-Michelin Partners with DHL to Trial Airless Puncture-Proof Tire

First-ever pilot on Singapore roads will see prototype tires fitted to nearly 50 DHL delivery vehicles in Singapore by the end of 2023.

Nearly 50 DHL Express vans will begin running on Michelin Uptis airless tires to make last-mile deliveries in Singapore by the end of 2023.

The pilot program began with the first vehicles making delivery trips from Jan. 10 of this year. One year ahead of schedule, the very first Michelin Uptis tires are now marketed in real-world conditions. Pyrolysis-technology – Petrochemicals

The Michelin Uptis prototype is a puncture-proof tire and wheel assembly with no compressed air and is intended for cars and light vans. The air has been replaced by a revolutionary structure capable of supporting the vehicle. This ensures the wheel’s robustness and guarantees driving comfort and safety. It was designed as a plug-and-play solution that allows users to drive conveniently and not worry about road hazards impacting the tires. It also limits the number of tires scrapped due to punctures.

With the Michelin Uptis tire, DHL can optimize its fleet’s productivity and ensure business continuity, as tire pressure issues and punctures are eliminated. This will lower the frequency of tire replacement, leading to less wastage.

“Michelin Uptis is a major breakthrough innovation in the tire field. This is a result of some fifty patents linked to the tire’s structure and high-tech materials,” said Bruno De Feraudy, Director of OEM activities for the Michelin Group. “It demonstrates Michelin’s capacity for innovation in favor of safer mobility that is better for the environment. We are delighted that DHL is trusting Michelin to equip its fleet with the very first Michelin Uptis tires, marketed one year ahead of schedule.”

According to a patent filed by Michelin, “Spoke Edge Geometry for a Non-Pneumatic Tire,” the spokes in the airless tire can be made from “liquid polyurethane in a mold.” It is contemplated that “other thermosetting or thermoplastic materials could be used.” Another patent describes a “continuous loop reinforcement assembly or yarn with a higher melt temperature material and lower melt temperature material configured in a core/sheath arrangement combined with a polyurethane matrix material.”

“As a pioneer in green logistics, we are excited to partner with Michelin to trial its airless tires on our vehicles in Singapore,” said Christopher Ong, Managing Director at DHL Express Singapore. “To drive sustainability efforts here, we have since converted 80 vehicles in our ground fleet to electric vans. This collaboration marks another milestone for us as we set out to green our last-mile operations and achieve net-zero carbon emissions across the DHL network globally.” Pyrolysis-technology – Petrochemicals

Airless technology is the key to Michelin’s vision of a fully sustainable tire by 2050. Today, 20% of tires are scrapped prematurely due to flats and blowouts (12%) or irregular wear and tear caused by poor tire pressure (8%). Based on internal research, Michelin projects that Uptis airless technology could prevent premature scrapping of up to 200 million tires a year worldwide or 2 million tonnes of material — a material savings roughly equivalent to the weight of 200 Eiffel Towers.

-Nexeo Plastics and Teknor Apex announce strategic partnership

Nexeo Plastics announced an expansion of its relationship with Teknor Apex. Nexeo Plastics will become a key distributor for Teknor Apex in Europe of its portfolio of thermoplastic elastomers (TPEs) under the Sarlink and Monprene brands, said the company.

This partnership provides Nexeo Plastics customers with a broad portfolio of TPE technologies, including styrenic block copolymer (SBC or TPS), thermoplastic vulcanizate (TPV) and specialty adhesion-modified grades for multi-shot molding onto a wide variety of engineering resins. The Teknor Apex TPE portfolio encompasses several product lines developed over time to meet specific industry requirements: Sarlink TPVsare ideal for sealing applications that require superior elasticity and long-term performance that well serve the automotive, industrial, consumer, and building & construction markets. Sarlink® styrenic-based TPEs provide automotive OEMs with more design flexibility and superior colorability for interior applications. Pyrolysis-technology – Petrochemicals

Monprene® TPEs are extremely versatile with a wide hardness range and broad thermal performance. These materials are ideal for consumer products, industrial applications and packaging, and include grades formulated for food-contact applications.

“This partnership with Teknor Apex enlarges our portfolio of high-value TPEs and complements the solutions we offer key industries, such as automotive, packaging, consumer, industrial and building and construction,” said Joost d’ Hooghe, Vice President EMEA at Nexeo Plastics.

“Nexeo Plastics and Teknor Apex complement each other well with our highly customer centric approach and similar broad customer base and market coverage. The European market is well served by our partnership; providing real value with our state-of-the-art systems and high level of technical support capabilities,” said Stef Hordijk, Director of Sales and Marketing for the TPE Division in the Europe. “Their extensive distribution in Europe significantly expands our reach in important target markets.”

Nexeo Plastics is accepting orders for Teknor’s TPE products beginning Jan. 1, 2023.

MRC earlier said, Nexeo Univar Inc., announced that it has completed the acquisition of Nexeo Solutions, creating a leading global chemical and ingredients solutions provider. The combined company will conduct business as Univar Solutions, reflecting a commitment to combining the ‘best of the best’ from each legacy organization.

Nexeo Plastics is a leading global thermoplastic resins distributor, representing quality products from world-class suppliers, and serving a diverse customer base across North America, Latin America, Europe, Middle East, Africa and Asia. From material selection assistance to identifying supply chain and inventory solutions, we go beyond traditional logistics to provide value-added services across many industries, including automotive, healthcare, packaging, wire and cable.

-China Deflation Pressure Worsens as Economy Slumps, Survey Shows

Chemours (Wilmington, Delaware) has announced a USD200-million investment to increase capacity for its Nafion fluoropolymer copolymer ion exchange materials at its manufacturing facility in Villers-Saint-Paul, France, said the company.

The ion exchange materials are used for water electrolyzers, energy storage in flow batteries, and hydrogen conversion to power fuel cell vehicles to help support the clean hydrogen economy. Pyrolysis-technology – Petrochemicals

Chemours has an existing robust and reliable ion exchange material capacity in the US to help support the hydrogen supply chain and this new expansion will contribute to Europe’s energy transition as well as expand the Villers-Saint-Paul site’s capabilities to be able support and advance technological progress for the worldwide hydrogen economy, Chemours says.

“Chemours has chosen France for this investment in the hydrogen economy because of the strong alignment between our sustainable growth vision, the French government’s goal to create a reliable and strong hydrogen economy, and the European Union’s ambition to deliver a clean energy transition based on the objectives set in the EU Climate Law,” Mark Newman, Chemours’ president and CEO, says.

Despite robust growth in green hydrogen technologies, more urgent scaling-up of the hydrogen supply chain capacity remains critical in meeting clean hydrogen potential and escalating demand, Chemours says. The proton exchange membrane (PEM) technology is an advancement for its faster start-up; reliance on fewer components; and its smaller footprint, simpler maintenance, and zero emissions when used coupled with renewable energy, the company says.

We remind, Chemours Company (Wilmington, Del.) announced that it will be expanding its Chemours Opteon YF (HFO-1234yf) capacity to help meet customer needs as they continue transitioning to lower GWP refrigerants. The Opteon YF and YF blends refrigerants are now used in millions of vehicles and thousands of retail stores around the world, with zero ozone depletion potential (ODP) and global warming potential (GWP) that is significantly lower than the legacy refrigerants. Pyrolysis-technology – Petrochemicals

Chemours is committed to leadership in responsible manufacturing, and this capacity investment will contribute to its goal of shifting the company’s product portfolio to offerings that contribute to achieving the United Nations Sustainable Development Goals (UN SDGs). Chemours is evaluating potential locations in the United States and Europe for the investment in accordance with applicable regulatory frameworks and is particularly interested in supporting the local communities where they operate.

Xi Jinping : President of the People’s Republic of China

-Borealis gains controlling stake in Renasci

Borealis has announced that it has acquired a majority shareholding in Renasci, the pioneering Belgian recycling company behind the creation of the Smart Chain Processing (SCP) concept. Pyrolysis-technology – Petrochemicals

The acquisition follows an initial 10% investment in the company announced by Borealis in July 2021. The present acquisition boosts that holding to 50.01%

Renasci’s SCP concept is a proprietary method of maximising material recovery in order to achieve zero waste. The concept combines multiple compatible waste-treatment technologies, enabling an exceptionally high valorisation of waste. Diverse waste streams – plastics, metals, biomass – are sorted and processed all under the same roof using different recycling technologies. For plastic waste, these technologies are first mechanical recycled, after which any remaining material is chemically recycled into circular pyrolysis oil and lighter product fractions, which are used to fuel the process. According to the recycler, only 5% of the original waste remains as residual material in the end, which is then used as filler in construction materials. Because of this extremely efficient way of processing, the overall CO2 footprint of these waste streams is greatly reduced.

Renasci and its SCP concept are perfectly aligned to Borealis’ circular cascade model, noted Lucrèce Foufopoulos, Borealis Executive Vice President of Polyolefins, Circular Economy Solutions and Innovation & Technology. That model is ‘at the heart of our ambition to become circular in plastic and in carbon’, she added.

The present strategic investment will provide Borealis with an additional supply of the chemically recycled feedstock it requires to produce its Borcycle C portfolio of mass-balanced virgin-level grade recycled products, as well as access to key circular technologies. Pyrolysis-technology – Petrochemicals

Borealis has committed to achieving an ambitious six-fold increase in the volume of circular products and solutions – to 600 kilotonnes – by 2025, rising to 1.8 million tonnes by 2030.

The investment marks another milestone towards the realisation of Borealis’ Strategy 2030 goals, according to CEO Thomas Gangl.

“Our acquisition of a controlling stake in Renasci has the potential to unlock significant progress on circularity for our entire industry and is proof of the EverMinds spirit in action,” he said.

For Renasci, the investment is a signal of Borealis’ ongoing confidence in the Smart Chain Processing concept to drive circularity.

Borealis is ideally placed to develop and implement the SCP concept, as well as to leverage our combined technological capabilities to unlock further circular progress, said Gert Vanderseypen, general manager of Renasci.

-What is Microban Technology? A Comprehensive Guide to Its Benefits, Uses, and Safety

Introduction

Microban technology is a type of antimicrobial protection that helps to reduce or prevent the growth of bacteria, mold, and mildew on surfaces. It works by creating an invisible barrier that prevents these organisms from colonizing and growing on the surface. The technology has been used for many years in a variety of industries, including medical, food processing, and consumer products. With its ability to inhibit the growth of harmful microbes, microban technology can help to keep surfaces cleaner and safer for longer periods of time. Pyrolysis-technology – Petrochemicals

Benefits of Using Microban Technology

The main benefit of using microban technology is that it helps to reduce the spread of bacteria, mold, and mildew on surfaces. This protection can help keep surfaces cleaner and free of potentially harmful microbes. Additionally, microban technology can help to extend the life of products, as it helps to prevent wear and tear caused by microbial growth. According to a study by the American Cleaning Institute, “products with antimicrobial product protection can last up to three times longer than those without.”

How Microban Technology Works

Microban technology works by creating an invisible barrier on surfaces that inhibits the growth of bacteria, mold, and mildew. The technology works by creating a reaction between the surface and the antimicrobial agent. The reaction creates an environment on the surface that is hostile to microbial growth, which helps to prevent the colonization and growth of these organisms.

Overview of the Process

The process of applying microban technology begins with the application of an antimicrobial agent to the surface. This agent is designed to react with the surface and create an environment that is hostile to microbial growth. Once applied, the agent will begin to form an invisible barrier that will help to inhibit the growth of bacteria, mold, and mildew on the surface. This barrier will remain active for the life of the product, helping to keep it clean and safe from potentially harmful microbes. Pyrolysis-technology – Petrochemicals

Detailed Explanation

The antimicrobial agent used in microban technology is typically composed of two components: an active ingredient and a carrier. The active ingredient is the component that reacts with the surface and creates an environment that is hostile to microbial growth. The carrier is the component that helps to deliver the active ingredient to the surface. When the two components mix, they create a bond that forms an invisible barrier on the surface. This barrier helps to prevent the colonization and growth of bacteria, mold, and mildew on the surface.

History of Microban Technology

The development of microban technology dates back to the late 1970s when the first antimicrobial agents were developed. Since then, the technology has continued to evolve and is now used in a variety of industries. Today, microban technology is used in a range of products, from medical devices to consumer products.

When Was It Developed?

Microban technology was first developed in the late 1970s and has since evolved into one of the most widely used antimicrobial technologies today. The technology was initially developed for use in medical applications and has since been adapted for use in other industries such as food processing and consumer products.

Who Developed Microban Technology?

The development of microban technology was led by a team of researchers at the University of Rochester in New York. Pyrolysis-technology – Petrochemicals

The team was led by Dr. Richard L. Clements and included scientists from various disciplines, including chemistry and microbiology. Together, they developed the first antimicrobial agents that were used in microban technology.

Comparing Different Types of Microban Technology

Today, there are several different types of microban technology available, each with its own unique properties. Each type has its own set of advantages and disadvantages, so it is important to understand the differences between them before choosing which type to use. Some of the most common types of microban technology include silver-based, copper-based, and quaternary ammonium compounds (QACs).

What Makes Each Type Unique?

Silver-based microban technology relies on silver ions to create an environment that is hostile to microbial growth.

Copper-based technology uses copper ions to create a similar effect. QACs are organic compounds that are effective against a wide range of bacteria, fungi, and viruses. Each type has its own unique properties, so it is important to understand the differences between them before deciding which type to use. Pyrolysis-technology – Petrochemicals

Pros and Cons of Different Types

Silver-based microban technology is effective against a wide range of bacteria, but it can be expensive. Copper-based technology is effective against both bacteria and fungi, but it can be corrosive. QACs are effective against a wide range of bacteria, fungi, and viruses, but they can be toxic if not used correctly. Each type has its own set of pros and cons, so it is important to consider all of them before making a decision.

Common Uses of Microban Technology

Microban technology is used in a variety of industries, from medical to consumer products. In the medical industry, it is used to protect medical devices from microbial contamination. In the food processing industry, it is used to keep food products safe from microbial contamination. In the consumer products industry, it is used to protect products from microbial contamination and extend their life span.

Microban technology is also used in a variety of other industries, such as textiles and plastics. Pyrolysis-technology – Petrochemicals

Examples of Industries Utilizing Microban Technology

Medical: Medical devices, such as catheters and prosthetics, often use microban technology to protect against microbial contamination. Food processing: Food processors use microban technology to help keep food products safe from microbial contamination. Consumer products: Microban technology is used in a variety of consumer products, from kitchenware to clothing, to help protect them from microbial contamination and extend their life span. Textiles: Microban technology is used in textiles, such as carpets and upholstery, to help protect them from microbial contamination.

Products That Use Microban Technology

A wide range of products use microban technology, including medical devices, kitchenware, clothing, carpets, upholstery, and more. Some of the most common examples include cutting boards, baby bottles, children’s toys, bedding, and footwear.

Examining the Safety of Microban Technology

Microban technology is generally considered safe, as it is designed to inhibit the growth of bacteria, mold, and mildew on surfaces. However, it is important to ensure that the technology is being used properly and according to the manufacturer’s instructions. Additionally, it is important to follow any applicable regulatory standards when using microban technology. Pyrolysis-technology – Petrochemicals

Evaluating Risks and Benefits

Before using microban technology, it is important to carefully evaluate the risks and benefits. On one hand, the technology can help to reduce the spread of potentially harmful microbes on surfaces, thereby helping to keep them cleaner and safer for longer periods of time. On the other hand, it is important to ensure that the technology is being used properly and according to the manufacturer’s instructions. Additionally, it is important to follow any applicable regulatory standards when using microban technology.

Regulatory Standards

It is important to ensure that any microban technology used meets the applicable regulatory standards. In the United States, the Environmental Protection Agency (EPA) oversees the registration and regulation of antimicrobial products. Companies must register their products with the EPA and adhere to the agency’s guidelines in order to legally use microban technology.

Case Studies: Success Stories of Using Microban Technology

There are numerous success stories of companies that have benefited from using microban technology. For example, a medical device company used microban technology to protect its products from microbial contamination, resulting in fewer product recalls and improved customer satisfaction. Pyrolysis-technology – Petrochemicals

Another company used microban technology to protect its textiles from microbial contamination, resulting in increased product life span and cost savings.

Examples of Companies That Have Benefited from Using Microban Technology

Medical device company: A medical device company used microban technology to protect its products from microbial contamination, resulting in fewer product recalls and improved customer satisfaction. Textile company: A textile company used microban technology to protect its textiles from microbial contamination, resulting in increased product life span and cost savings.

Discussion of Results

The results of these case studies show that microban technology can provide significant benefits to companies that use it. By reducing the risk of microbial contamination, companies can reduce product recalls and improve customer satisfaction. Additionally, companies can save money by extending the life span of their products with the help of microban technology. Pyrolysis-technology – Petrochemicals

Conclusion

Microban technology is a type of antimicrobial protection that helps to reduce or prevent the growth of bacteria, mold, and mildew on surfaces. It works by creating an invisible barrier that prevents these organisms from colonizing and growing on the surface. The technology has been used for many years in a variety of industries, including medical, food processing, and consumer products. With its ability to inhibit the growth of harmful microbes, microban technology can help to keep surfaces cleaner and safer for longer periods of time.

The main benefit of using microban technology is that it helps to reduce the spread of bacteria, mold, and mildew on surfaces. Additionally, it can help to extend the life of products, as it helps to prevent wear and tear caused by microbial growth. There are numerous success stories of companies that have benefited from using microban technology, showing that it can provide significant benefits to companies that use it.

Pyrolysis-technology – Petrochemicals