Recycle-packaging-waste – Cellulose-fiber 02-06-2022 - Arhive

Recycle-packaging-waste – Cellulose-fiber

-LanzaTech demonstrates MEG production from carbon emissions

A new route to the production of monoethylene glycol, a key monomer in the production of polyethylene terephthalate (PET), has been discovered, Illinois-based biotech company LanzaTech has announced, as per Sustainableplastics.

The method builds on the carbon capture technology previously developed by the company. That technology is based on a microbial gas fermentation process that initially could convert carbon monoxide into ethanol, but today provides a sustainable pathway to produce a range of platform chemicals. Gas streams from multiple sources are used, including industrial off-gases from steel and alloy mills; petroleum refineries, petrochemical complexes and gas processing facilities; syngas generated from municipal solid waste, organic industrial waste, agricultural waste; and reformed biogas.

To produce MEG, LanzaTech uses carbon emissions from steel mills or gasified waste biomass and a proprietary engineered bacterium to convert carbon emissions directly into MEG through fermentation. This bypasses the need for an ethanol intermediate, and simplifies the MEG supply chain as it eliminates the multiple processing steps required to convert ethanol into ethylene, then ethylene oxide and then to MEG.

The direct production of MEG was proven at laboratory scale and the presence of MEG was confirmed by two external laboratories.

The discovery is a breakthrough in the production of sustainable PET that has vast potential to reduce the overall environmental impact of the process, said Dr. Jennifer Holmgren, CEO of LanzaTech. Recycle-packaging-waste – Cellulose-fiber

The Consortium for Waste Circularity and the Flexible Packaging Association (FPA) have announced a collaboration with the Packaging Engineering programme at the University of Florida, with the aim of developing the Regenerative Robust Gasification process that converts difficult-to-recycle packaging materials into methanol for use as feedstock in further plastics production via mass balance.

According to the involved organisations, packaging industry stakeholders have been running trials through the University of Florida for several months. The testing programme is apparently now being expanded to all packaging industry stakeholders, targeting difficult-to-recycle but functionally valuable packaging materials.

The organisations claim that, to date, multi-layer materials, metallized films, barrier films containing PVDC, and cross-linked photopolymer flexographic plates have been successfully converted into synthesis gas, also known as syngas.

The Consortium for Waste Circularity says it is promoting a system where mixed complex waste is converted to syngas, and then syngas is converted into so-called “waste-derived” Eco-Methanol. Recycle-packaging-waste – Cellulose-fiber

According to the consortium, Eco-Methanol is key to achieving circularity for carbon-based packaging waste. This is because methanol is a primary feedstock chemical for the manufacture of many products and plastics.

-Why is plastic so resistant to decomposition when it comes from nature?

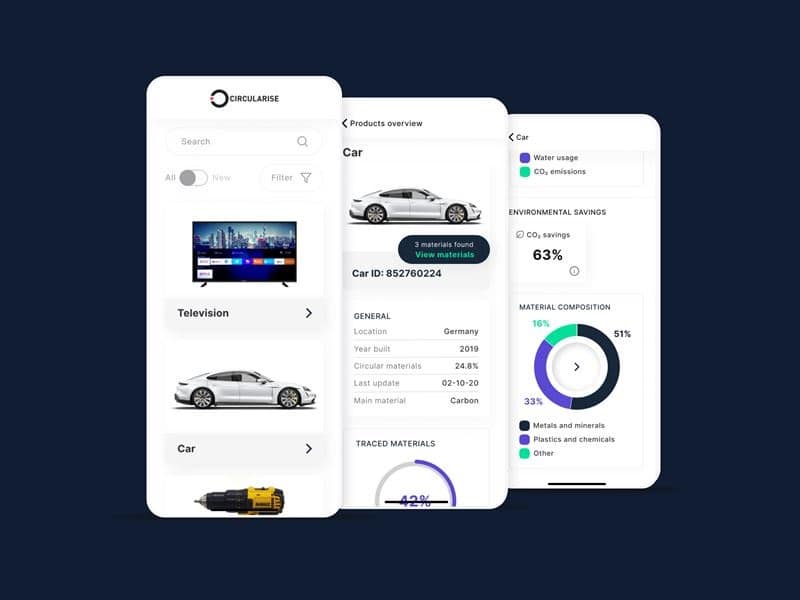

Neste and Netherlands-based startup Circularise have announced a partnership to bring Circularise’s traceability software into circular polymers and chemicals supply chains. The companies are collaborating in establishing digital solutions to trace renewable and recycled material flows, providing increased transparency along the value chain.

The companies will use Circularise’s blockchain-based supply chain traceability software, which creates a digital twin for the physical material. The twin stores information on the used materials throughout the value chain, enabling all value chain parties to keep track of the material. This allows them to verify where materials come from and how and where they were processed. The digital twin can also provide information on sustainability data such as the carbon footprint of the materials or products made from them. Recycle-packaging-waste – Cellulose-fiber

Data-based supply chain visibility can strengthen trust in sustainable solutions

Solutions to increase visibility into supply chains become particularly valuable in the polymers and chemicals industry as materials undergo several processing steps and often get blended and co-processed with other materials. Especially in the ramp-up phase of more sustainable and circular value chains, renewable or recycled materials may be processed together with fossil materials – making it difficult to verifiably link end products with a much lower carbon footprint and the renewable or recycled materials they were produced with. As long as there is a mix of raw materials, a large share of renewable or recycled products will rely on a mass balancing allocation method as a way to link the end products to their raw materials.

With a digital supply chain tracking system, Neste and Circularise intend to enable value chain players to still make verifiable claims about such products. At the same time, it will allow parties along the value chain to better understand their supply chains, leading to improved transparency when it comes to life cycle emissions of products or other sustainability factors such as biodiversity and human rights.

“It’s usually very easy to claim sustainability, but very often, it’s not easy at all to back these claims,” says Isabella Tonaco, Vice President Strategy Execution & Marketing at Neste Renewable Polymers and Chemicals. “Yet, trust and credibility are crucial factors when it comes to sustainability. Being able to track and trace all the materials going into a product provides a solid basis for gaining that trust and credibility. We are looking forward to working with Circularise to provide the polymers and chemicals industry with a traceability solution to bring the necessary transparency into the value chains.”

While the purpose of the collaboration is increasing visibility and trust, Circularise also puts priority on confidentiality. Using a public blockchain-based infrastructure and Circularise’s proprietary Smart Questioning technology allows combining these two targets into one solution, enabling the sharing of trustworthy data and information between parties along the value chain without compromising on intellectual property or privacy. Recycle-packaging-waste – Cellulose-fiber

-China cellulose fiber companies report strong revenue growth in 2021

In 2021, market participants generally had high expectation for economic recovery with the alleviation of panic over the COVID-19 pandemic. China as the country with the fastest recovery of supply chain in the world benefited a lot. Compared with 2020, the operating conditions of most cellulose fiber enterprises have improved significantly, according to the annual reports disclosed by Chinese listed companies.

Aoyang Health Industry: Funing Aoyang Technology Co., Ltd, a subsidiary that operates the chemical fiber sector, has a revenue of 1.048 billion yuan and a net profit of -1.068 billion yuan (-420 million in 2020). The huge losses are mainly caused by asset impairment losses, asset disposal losses and disposal costs of related employees. In terms of operating data, the annual output is 85,386 tons, a year-on-year decrease of 36.26%. The sales volume is 89,965 tons, a year-on-year decrease of 36.84%. The inventory is 500 tons, a year-on-year decrease of 90.67%. The significant year-on-year decrease in production, sales and inventory is mainly due to the company’s divestiture of viscose business. On Apr 9, 2021, the company announced that it planned to sell viscose business, and the counterparty is Sateri China Investment Co., Ltd. The proposal was approved by the general meeting of shareholders on Jul 23. After that, Aoyang Health Industry will focus on the big health business. Recycle-packaging-waste – Cellulose-fiber

Jilin Chemical Fiber: the disclosure of the annual report was previously delayed by the impact of COVID-19. The company’s main business is viscose filament yarn and viscose staple fiber. During the reporting period, the company transformed to carbon fiber. According to the operating data, the revenue of viscose filament yarn is 2.206 billion yuan, an increase of 29.7% year-on-year, and the revenue of viscose staple fiber is 1.197 billion yuan, an increase of 72.52% year-on-year. The production and sales of viscose filament yarn is 67,259 tons and 70,723 tons respectively, and the production and sales of viscose staple fiber is 106,052 tons and 103,797 tons respectively.

-Textile recycling and processes for the future

From 2025, used clothing and other textiles will be collected separately throughout Europe to facilitate reuse and recycling.

What industrial recycling solutions for textiles are already available?

Lukasz Debicki (LD): Nowadays, used clothing textiles are either reused as second-hand goods or in the form of, for example, cleaning rags. In addition, there are various recycling processes. Clothing or home textiles are often mechanically recycled and processed into insulation or filling materials. The textiles are torn, which dissolves the fabrics down to the individual fiber. These can then be further processed into said nonwovens or – if the fibers are of sufficient length – into staple fiber yarns. Mixed materials can also be recycled this way. Furthermore, a lot of textile waste is also incinerated or landfilled. Recycle-packaging-waste – Cellulose-fiber

Amrei Becker (AB): Mono-material industrial waste, such as fibers made of polyester or polyamide, which are produced during the ramp-up of the melt spinning plant, can be regranulated and a small percentage of it can be returned to the process. Recycling of waste is also possible in yarn production from natural fibers. Furthermore, there is a Chinese company that already carries out the chemical recycling of worn polyester uniforms. The textiles are made of 100% PET and are specifically collected for recycling.

-BENEO Acquires Meatless B.V. to Further Expand its Portfolio of Plant-based Solutions

BENEO, one of the leading manufacturers of functional ingredients, has today announced the acquisition of Dutch company, Meatless B.V., ensuring it becomes a major player in the field of plant-based texturising solutions for meat and fish alternatives.

The move comes amid a huge rise in demand for plant-based products, with figures showing that the market for fish and meat alternatives is expected to grow by more than 10% CAGR over the next five years. The acquisition of Meatless B.V. allows BENEO to broaden its portfolio and offer customers a versatile selection of plant-based solutions that serve as texturisers for meat and fish alternatives. BENEO sees great prospects for the new range of solutions in Europe as a focus market in the first instance, with plans to further expand globally.

Commenting on the announcement, Andreas Herber, Member of the Executive Board at BENEO states: “Following the recently announced investment into our new faba bean processing plant, the acquisition of Meatless B.V. is the next logical step to reaffirm BENEO’s commitment to strengthening its business with solutions for plant-based alternatives.” Recycle-packaging-waste – Cellulose-fiber

Meatless B.V, founded in 2005 and located in Goes, The Netherlands, is a supplier of textured plant-based ingredients with a unique portfolio of solutions derived from different raw materials (i.e., rice, faba beans, wheat, pea, lupin and quinoa). This range fully complements BENEO’s ingredients portfolio and allows for exciting new combinations. As a result, BENEO’s customers will benefit from a much broader variety and greater flexibility that supports the development of meat and fish alternatives.

Recycle-packaging-waste – Cellulose-fiber