Recycled-ABS – Bio-Polyolefin 23-05-2022 - Arhive

Recycled-ABS – Bio-Polyolefin

-Ineos, Barnes Partner to Optimize Molding of Recycled ABS

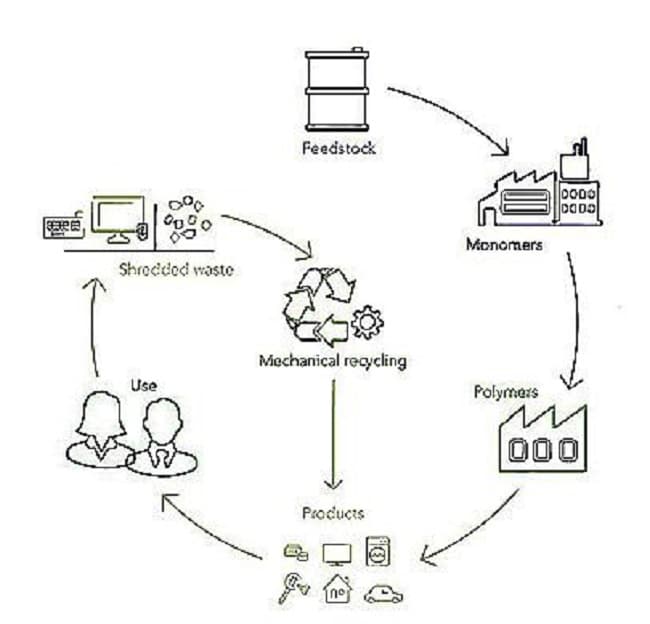

Ineos collaborates with the Molding Solutions business of Barnes Group to develop optimal molding parameters for its new grades of mechanically recycled ABS.

Two new grades of mechanically recycled ABS, featuring either 50% or 70% recycled content, promise to match the properties of prime materials and are the focus of a partnership intent on optimal molding of the materials.

The grades — Terluran ECO GP-22 MR50 and MR70 — from Germany’s Ineos Styrolution are based on post-consumer waste electrical and electronic equipment and will be available in black. The materials are aligned with the company’s pledge to incorporate at least 325 kilotons a year of recycled materials into its products.

“We are convinced that our Terluran ECO is the best mechanically recycled ABS in the world,” said Yohann Bach, Product Director ABS Standard EMEA for Ineos Styrolution. “It offers identical properties to the respective native material.”

Terluran ECO materials are expected to match the mechanical properties of their respective prime Terluran grades, the company said, with no need for downcycling. They are intended to be used in the same applications as prime Terluran GP-22, including household applications and housings for electronic devices. ECO materials compare favorably in performance with prime GP-22, per the company’s data sheets. For instance, the tensile modulus of GP-22 is 2300 MPa vs. 2100 for both ECO variants.

Ineos will collaborate with Molding Solutions, a business unit within the Barnes Group, to explore how best to mold these sustainable materials.

-The contract price of paraxylene in May increased by EUR75 per ton in Europe

MOSCOW (MRC) — The contract price of paraxylene rose by EUR75 per tonne in Europe in May compared to April, reaching a new all-time high since February 2013, ICIS reported.

Thus, the May contract price of paraxylene was agreed at EUR1,240 per tonne, FD NWE. Recycled-ABS – Bio-Polyolefin

Demand for paraxylene in Europe should continue to grow in the near future as markets for purified terephthalic acid (TPA) and polyethylene terephthalate (PET) enter the peak season.

Rana was informed that the participants in the negotiation process to agree on the May contract prices of paraxylene in Asia could not reach an agreement for the current month. Approval of the monthly contract price for the material is achieved when it is agreed by at least two suppliers and two buyers. This is the fifth month in a row this year that the contract price of paraxylene remains uncoordinated.

Paraxylene is a raw material for the synthesis of terephthalic acid, an intermediate for the production of polyethylene terephthalate (PET).

-Milliken prepares to launch major clarifier plant

New S.C. plant set to boost Millad® NX® 8000 capacity by more than 50 percent

Milliken & Company will begin production at its new clarifier plant soon in Blacksburg, S.C. This significant additional capacity will address strong worldwide demand for clarified plastic products. The company, a global manufacturer with plastic additives and colorants expertise, says this new, world-class facility will increase production capacity of its market-leading Millad® NX® 8000 polypropylene clarifier by more than 50 percent. Recycled-ABS – Bio-Polyolefin

“This represents the largest clarifier plant investment in Milliken history,” said Cindy Boiter, president of Milliken’s Chemicals Business. “Engineering is complete, and we are in the process of commissioning the plant. When we launch production in the fall, it will allow us to address both current market needs and increasing demand for these products well into the future.”

“Global demand for Millad NX 8000 clarifier has grown at an 11 percent compounded annual growth rate (CAGR) for each of the past nine years,” added Boiter. “Global clarifier demand grew by 16 percent in just the past two years,” outstripping the growth rates for global polypropylene (PP) resin. “All regions have contributed to the growth of clarified PP, with Asia leading the way.”

A number of factors are driving this demand. Milliken’s own customer research underscores the importance of being able to clearly see the products they are buying. Millad NX 8000 provides close to glass-like clarity in PP packaging, which improves customer confidence during their buying process, especially for food products. This clarity enables brand owners to replace PET, polystyrene, polycarbonate, and more with PP — shown by studies to be a more sustainable option.

The current soaring energy prices, meanwhile, have also spiked interest in any resins or additives like this one, which can help converters to save energy during processing. As a result of these certified savings, brand owners using PP clarified with Millad NX 8000 ECO can display a UL Environmental Claim Validation label on their injection molded parts.

Polypropylene is not only lightweight and durable; it also is one of the least energy-intensive polymers to make and recycle compared to other clear polymers.

-Contract prices of extrusion PC in Europe increased by EUR60 per ton

Contract prices for extrusion polycarbonate (PC) in Europe rose by EUR60 per tonne in May amid high production costs and despite demand showing signs of decline, ICIS said. Recycled-ABS – Bio-Polyolefin

Manufacturers have demanded further price increases as they argue that production costs remain high, production margins are shrinking, and the cost of raw benzene is rising.

The increase in prices occurs despite a decrease in demand due to difficulties in supply in sales markets and the reluctance of buyers to accept the current high prices of PCs.

Buyers are reducing their orders as a sharp decline in demand allows them to live off their inventory and wait one or two months to buy at a potentially lower price.

This decline is due to macroeconomic problems that hinder the European economy and reduce the costs of end consumers.

Earlier it was reported that the May contract price of benzene in Europe rose to the level of EUR1,175 per ton, which is EUR45 per ton more than in April. The price of the May contract was agreed in US dollars at USD1,232 per tonne and converted to euro at the agreed exchange rate EUR1= USD1,049.

-Bio-Polyolefin Market Set to Grow as Fast as Sugar Cane

Market leader Braskem is being joined by a multitude of new sources, as suppliers, brand owners, and nations pursue sustainability targets.

Sugar cane can grow to a height of 10 feet in 12 months. Independent research by plastic market and technology expert MLT Analytics (MLTA) indicates that usage of polyethylene and polypropylene derived from renewable resources such as sugar cane, non-edible plants, and biogenic fats and oils has the potential to grow equally fast. Recycled-ABS – Bio-Polyolefin

Bio-polyethylene market leader Braskem exported almost 150,000 tonnes of bio-PE in 2021, headed by bio-HDPE and bio-LDPDE grades, according to MLTA analysis. Further, with mass balance–based production picking up in Europe and Japan, the global bio-PE market will soon surpass 200,000 tonnes annually.

“Bio-based polyolefins are emerging as key enablers for plastics suppliers and brand owners alike to reach their sustainability goals,” notes MLTA CEO Stephen Moore. Regulatory pressure is also evident. Case in point: Japan’s Green Growth Strategy Through Achieving Carbon Neutrality in 2050 targets two million tonnes of biomass plastics in 2030. “Leading Japanese polyolefin suppliers are already gearing up to meet these targets,” says Moore. For example, “Prime Polymer shipped its first bio-PP shipment in March this year using bio-based hydrocarbons from Neste, while parent company Mitsui Chemicals is also developing its own process technology to polymerize PP from bio-isopropanol.”

While low-density PE, particularly for coating of paperboard containers, and high-density PE, mainly for packaging and bags, currently dominate the marketplace, bio-linear-low-density PE and bio-EVA are also emerging sustainable options, as is bio-PP. “A key differentiator in the market going forward will be whether these offerings are indeed 100% bio-based resins or marketed using a mass balance approach,” says Moore.

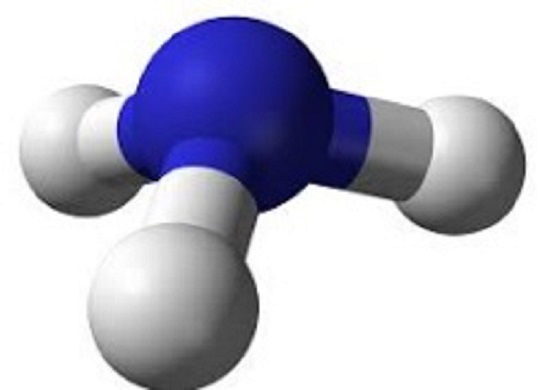

-Canada AmmPower announces that demonstration unit produces first green ammonia

Canadian firm AmmPower announced that their independent ammonia making machine (IAMM) demonstration unit, which is capable of 50 kg/day of green ammonia production, is now operational and made its first ammonia on 16 May.

The company said the technology used in this demonstration unit will be scaled up for use in their 4 tonne/day IAMM unit, which is also being designed in-house.

The target market for the full-scale units will be the independent distributors and retailers of anhydrous ammonia used for fertilizer with Q1 of 2023 the target date for first deliveries. Recycled-ABS – Bio-Polyolefin

Previously the company said while pricing has not been finalised it is expected to cost between $3m-3.5m per unit.

AmmPower said their production team have begun patent submissions around the IAMM process of green ammonia production as they designed the novel ammonia synthesis reactor and performed months of catalyst research.

The goal was to develop the techniques used to create scalable, safe, and economically viable green ammonia solutions, which the company said is applicable for farming, fuel, and the cracking of hydrogen for a variety of purposes.

“The IAMM unit is something that has been missing in the agricultural world. Allowing for ammonia production, on location, providing fertilizer for dealers and growers, is something that has rarely been seen before in modern farming history,” said Eric Kelley, AmmPower Head of Agriculture.

Recycled-ABS – Bio-Polyolefin