Recycled batteries- Carbon cycle 27-02-2023 - Arhive

Recycled batteries– carbon cycle

-Petrochemicals – Recycled-POY – CPL

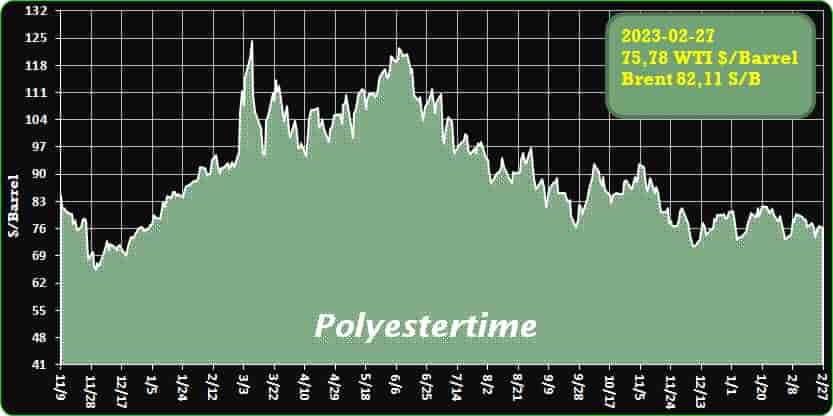

Crude Oil Prices Trend

Crude Oil Prices Trend Polyestertime

-Project STOP Pasuruan Hands Over to Local Government

Project STOP celebrates a milestone this week: the handover of its second city partnership in the Pasuruan Regency of East Java, Indonesia. The local government and community will take sole management of its work to reduce waste and plastics leakage and to support circularity of materials. Recycled batteries– carbon cycle

The handover marks a coming-of-age for Project STOP Pasuruan, which provides waste collection to more than 132,000 people in Lekok and Nguling Municipality, East Java. It has created 120 new jobs in the community, and collected over 5,000 tonnes of waste – including over 700 tonnes of plastic – since the programme started in 2019.

Launched in 2017 by Borealis and Systemiq, Project STOP is based on public-private partnership. It works with cities in Indonesia to create effective, circular waste management systems. Supported by industry and government partners, it aims to achieve zero leakage of waste into the environment, recycle more plastics, build economically sustainable programs, and create economic and health benefits for local communities.

-Plastic upcycling to close the carbon cycle

A new PNNL-developed process produces fuel quickly at mild temperature, with few by-products.

There’s a lot of potentially useful raw materials bound up in used face masks, grocery bags and food wrap. But it has been much cheaper to keep making more of these single-use plastics than to recover and recycle them. Recycled batteries– carbon cycle

Now, an international research team led by the Department of Energy’s Pacific Northwest National Laboratory has cracked the code that stymied previous attempts to break down these persistent plastics. They reported their discovery in today’s issue of Science.

Low temperature and reaction control

Typically, recycling plastics requires ‘cracking’ or splitting apart the tough and stable bonds that also make them so persistent in the environment. This cracking step requires high temperatures, making it expensive and energy intensive.

The novelty here is combining the cracking step with a second reaction step that immediately completes the conversion to a liquid gasoline-like fuel without unwanted by-products. The second reaction step deploys what are known as alkylation catalysts. These catalysts provide a chemical reaction currently deployed by the petroleum industry to improve the octane rating of petrol. Recycled batteries– carbon cycle

-Aqua Metals produces high-purity lithium hydroxide directly from recycled lithium-ion batteries

Process recovers lithium in the form suited for battery manufacturing

Aqua Metals, Inc. has recovered high-purity lithium hydroxide from lithium-ion battery black mass at the company’s Li AquaRefining recycling facility located at the Tahoe-Reno Industrial Center (TRIC).

The production and availability of recycled lithium hydroxide at scale will help close the supply chain loop for critical battery metals in the U.S., paving the way for a more sustainable, efficient battery manufacturing industry. The immediate recovery of lithium hydroxide also improves the economics of recycling advanced battery chemistries like lithium iron phosphate (LFP), where lithium makes up most of the valuable material, unlike current nickel and cobalt-based batteries. Recycled batteries– carbon cycle

“We believe this new capability can have a profound impact on the lithium battery industry in North America,” says Steve Cotton, CEO and president of Aqua Metals. “Our sustainably recycled lithium can help ensure a robust supply of critical metals to meet the Inflation Reduction Act’s ambitious goals for domestic content and enables us to share samples and advance our discussions with prospective partners in battery and cathode manufacturing.”

-Toppan and Polymateria release Biotransformed packaging

Toppan and Polymateria release ‘Biotransformed’ packaging that can return to nature harmlessly in just 176 days – a new speed record! – Polymateria and Toppan Specialty Films have released packaging which fully biodegrades leaving no microplastic and toxins behind. – Data released today shows that biotransformed packaging can return to nature in record time – 176 days. Recycled batteries– carbon cycle

The revolutionary technology does not affect the mechanical or aesthetic qualities and allows plastic to be recycled for a pre-determined amount of time via a time-set feature. – Biotransformation technology will help push boundaries in the plastics industry, propelling the switch to more sustainable materials across the value chain in India.

A new breakthrough by sustainable plastic innovator Polymateria in partnership with Indian plastic manufacturer Toppan Specialty Films (TSP), has seen plastics commonly used in the packaging industry biotransform in under 4 months and return to nature in just 176 days, leaving no microplastics or toxins behind. It’s the fastest-ever full biodegradation of biaxially oriented (flexible) polypropylene which is used in food and cosmetic packaging. Recycled batteries– carbon cycle

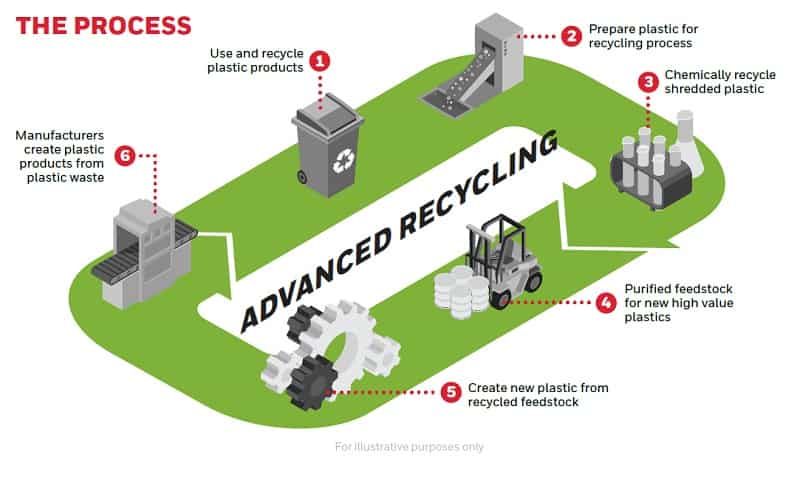

-Complimentary Recycling Strengthens Circular Plastics Economy

The head of Honeywell’s Plastics Circularity Business points to a dual mechanical/advanced recycling pathway to optimize packaging sustainability.

Governments are getting serious about tackling the environmental risks posed by plastics that enter the waste stream, spurring exploration into achieving true plastics circularity.

However, developments in advanced recycling technology are just one part of the equation. We must close the loop between recycling infrastructure owners and operators, plastics manufacturers, and consumer goods manufacturers to further improve the recycling rate. According to the Organisation for Economic Co-operation and Development, globally, only 9% of plastic waste is recycled. Recycled batteries– carbon cycle

Of all the plastic manufactured between 1950 and 2017, 7 billion tonnes have become waste and that amount continues to grow. Today, the world produces twice as much plastic as two decades ago, and 8 million tons a year end up in oceans. By 2050, there could be more plastic in the sea than fish, according to the World Wildlife Fund.

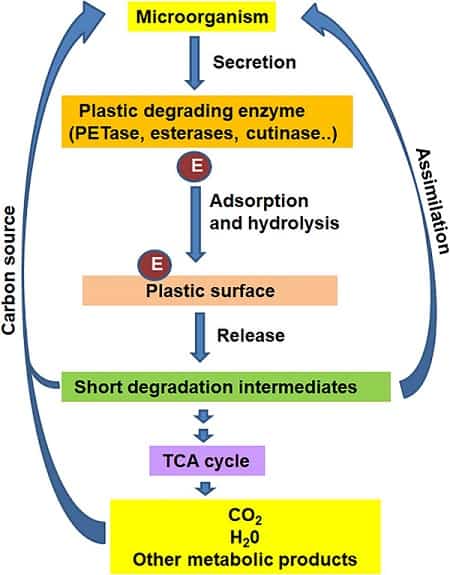

-Microbial Enzyme Applied to Plastic Depolymerization

The accumulation of synthetic plastic waste in the environment has become a global concern. Microbial enzymes (purified or as whole-cell biocatalysts) represent emerging biotechnological tools for waste circularity; they can depolymerize materials into reusable building blocks, but their contribution must be considered within the context of present waste management practices. Recycled batteries– carbon cycle

- Introduction

Biotechnology tools have been employed for more than 20 years to depolymerize complex biomass waste into organic building blocks that, in turn, can be converted into useful intermediate feedstocks. These processes are typical applications of the circular (bio)economy concept.

One of the most interesting examples is the conversion of lignocellulosic materials contained in plant waste from farming activities into bioethanol [1][2]. More recently, biotechnology strategies based on the use of microbial enzymes have been applied also to the degradation of petroleum-based plastics with the aim of providing greener alternatives to the traditional methods of recycling. Recycled batteries– carbon cycle

Various enzymes are used by bacterial or fungal organisms to fragment polymers into units of about 10–50 carbon atoms, which are used as carbon sources [3]. The catalytic capacity of highly purified stocks of enzymes (produced at an industrial level) can be exploited in biochemical processes performed under mild conditions (e.g., water solution in the 20–80 °C range) because they are biocatalysts evolved to act under conditions compatible with life.

This allows for lowering of the economic and environmental costs of traditional processes, which usually require high temperatures and pressures [4]. The wide diversity in the metabolism of living organisms allowed for the discovery of biocatalysts suitable for many chemical reactions, including those responsible for plastic degradation, although consortia of whole organisms may also be required in some cases [5]. Recycled batteries– carbon cycle

The enzymatic or microbial recycling of plastic materials is divided into three main steps: (i) the production of the biocatalysts, (ii) the depolymerization reaction of the polymer into monomers, and (iii) the purification and reuse of the monomers for resynthesis of the original material (closed-loop processes) or their bioconversion into different products (open-loop processes) Recycled batteries– carbon cycle