Recycled-PET – Polymers-demand 21-06-2022 - Arhive

Recycled-PET – Polymers-demand

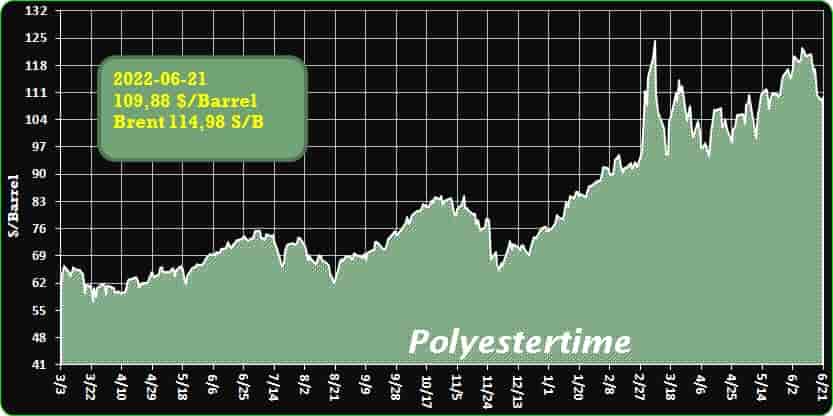

Crude Oil Prices Trend

-RadiciGroup at Techtextil with innovative textile solutions

Target markets: automotive, furnishings, sports and technical apparel. New product entry: radipeople® line of personal protective equipment.

RadiciGroup is at Techtextil 2022, the leading European trade fair for technical textiles, taking place in Frankfurt am Main, Germany, from 21 to 24 June. On display in the RadiciGroup exhibition area (Hall 9.1 – Stand D50) are the Group’s latest products for the automotive, furnishings and apparel markets: from nylon and polyester yarn, including biosource and recycled lines, to nonwovens and the new radipeople® line of personal protective equipment (PPE). Recycled-PET – Polymers-demand

“Our focus at the trade fair is on technical applications,” noted Marco De Silvestri, sales & marketing manager of the Apparel and Technical Business Line of RadiciGroup Advanced Textile Solutions. “These sectors have always been the centre of attention at RadiciGroup: outdoors, workwear, automotive and sports, to mention just a few of the target sectors where RadiciGroup high performance products are used. In addition to our traditional range, we are presenting our sustainable offering. In recent years, we have expanded our line of solutions developed according to the principles of sustainability and the circular economy, with the awareness that this approach needs to move forward beyond theory and be put into practice. Thanks to our in-depth knowledge of materials, we offer to partner with our customers in designing and realizing innovative and environmentally friendly proposals.”

Indeed, at Techtextil, RadiciGroup is showcasing RENYCLE®, a yarn obtained from recycled nylon; REPETABLE®, a polyester yarn from post-consumer recycled plastic bottles; RESPUNSIBLE®, a nonwoven fabric from recycled polypropylene; and BIOFEEL®, a brand identifying a yarn line obtained from renewable sources of both nylon and polyester. Recycled-PET – Polymers-demand

Care for the environment and the protection of people. In fact, at the fair RadiciGroup is also presenting radipeople®, a new line dedicated to personal protective equipment for the medical and industrial sectors: coveralls, gowns and accessories with different levels of protection, depending on the intended use, for a variety of industries, such as construction, agriculture, oil and gas, chemicals, pharmaceuticals and food.

-Klöckner Pentaplast awarded gold rating by EcoVadis

Klöckner Pentaplast, a leading global manufacturer of high barrier protective packaging solutions with industry-leading use of recycled content, has been awarded a gold rating for the second consecutive year by EcoVadis, the independent provider of global sustainability ratings for environmental, social, and ethical performance.

The gold rating ranks kp in the top 3% of plastic product manufacturers assessed by EcoVadis, with each company being rated on the material sustainability risks and issues for their size, locations and industry. Recycled-PET – Polymers-demand

The evidence-based assessment covers policies, actions and results across the key sustainability and ESG dimensions of environment, labour and human rights, business ethics and sustainable procurement.

“EcoVadis is an important rating that is widely recognised by our customers and stakeholders and we are very proud to have been awarded gold rating for the second consecutive year. The rating reflects our on-going commitment to our sustainability strategy “Investing in Better”, which continues to be well recognized by the industry broadly for our work toward the most sustainable future.”, said Yui Kamikawa, kp’s Vice President of Sustainability.

-SKGC and partners to build recycled PET facility in Europe

The joint venture plant will produce fully recycled polyethylene terephthalate (PET) plastic and polyester fibre.

South Korean chemical company SK Geo Centric (SKGC) has partnered with SUEZ and Loop Industries to build a recycled polyethylene terephthalate (PET) facility in Europe.

Under the partnership, SKGC will become an equal partner in the previously announced joint venture (JV) formed by Loop and SUEZ, which is developing what they claim to be Europe’s first Infinite Loop manufacturing facility.

The JV plant will produce 70,000 million tonnes of virgin quality, fully recycled PET plastic and polyester fibre for the European market. Recycled-PET – Polymers-demand

SKGC will provide petrochemical manufacturing experience while SUEZ and Loop will offer their resource management expertise and proprietary technology respectively.

The Infinite Loop facility is intended to help consumer goods companies increase the amount of recycled content in their products and/or packaging, as well as meet the growing demand for recycled PET resin and polyester fibre.

SK Geo Centric CEO Na Kyung-Soo said: “We are thrilled to participate in (the) Infinite Loop™ Europe project together with SUEZ, leading French environmental service and LOOP, which possesses an advanced recycling technology.

“This collaboration will be the first step for SK Geo Centric to move beyond Asia to be a global eco-friendly chemical company.”

Loop Industries is a Canadian plastic recycling company that manufactures fully recycled PET plastic and polyester, while SUEZ supports local communities and industrial companies in managing services such as water, waste and air quality. Recycled-PET – Polymers-demand

The partners will review the feasibility of the project and choose the best location to support European consumer brands’ 2025 target for recycled content.

-Food crisis in 2023 may represent major threat to developing-world polymers demand

As the developing world confronts a major food crisis, expected to reach a critical point next year, polymers demand is of course hardly the most important issue. But the purpose of the blog is to support planning by chemicals and polymers companies – and the buyers of chemicals and polymers. Recycled-PET – Polymers-demand

A crucial factor in successfully navigating the multiple crises we face is making the right production and sales decisions, based on demand scenarios. The right decisions will make or save you many millions of dollars.

To this end – combining the knowledge of the ICIS fertilizer team, which points toward the food crisis getting worse next year, with the ICIS Supply & Demand Database – the blog has drawn-up a scenario where –

Instead of high-density polyethylene (HDPE) demand in the developing world growing by 800,000 tonnes in 2023, the ICIS base case, it contracts by 300,000 tonnes.

This would result in next year’s global demand growth for HDPE being at 2% rather than 4%.

These alternative outcomes are for demonstration purposes only, as they don’t involve the essential deep dive into country-by-country complexities.

-RCS Plastics receives ”Grüner Engel” recoginition

The North Rhine-Westphalian family company RCS Plastics in Werne practices exemplary resource and environmental protection with its heart of the system, the VACUNITE bottle-to-bottle technology. For this, the progressive company was honored with the medium-sized company prize in the category “Innovative technology solution for recycling” at the bvse trade fair evening. Recycled-PET – Polymers-demand

“Know-how and innovative ideas paired with high-quality recycling technology is the combination that distinguishes the successful medium-sized companies in the industry. With this recipe for success and its innovative process for the production of food-grade regranulates of the highest quality, the sustainability-oriented company RCS Plastics impressively convinced the jury in the competition for “DIE GRÜNEN ENGEL 2022”, bvse CEO Eric Rehbock and Florian Lankes, managing director of “DIE GRÜNEN ENGEL – treatment center in Nuremberg, at the presentation of the award ceremony at the bvse trade fair evening. “With its groundbreaking technical solution, RCS is also an important part of the implementation of the new provisions of the Packaging Act that came into force in January 2019,”

“The accumulated experience in the extraction of secondary raw materials from commercial waste from 4 decades has already motivated us 10 years ago to invest in the field of plastics recycling and to develop it further,” said Managing Director Adelheid Hauschopp-Francke, explaining the development of the RCS Group’s youngest division Werne on the lip.

Quality expectations exceeded – high added value for environmental and resource protection

The company has been recycling PET bottles into sorted PET flakes since 2011. In the summer of 2020, the next important step towards sustainability was taken: With the help of the VACUNITE® bottle-to-bottle recycling system developed by the manufacturer EREMA, which was further optimized in cooperation with RCS, RCS-Plastics is now processing the previously produced PET flakes in a highly efficient process to regranulate for the food industry. Recycled-PET – Polymers-demand

-Nylon filament yarn plants to cut operation under deeper split with upstream

In May 2022, as upstream CPL RMB spot chased up benzene cost actively, the price increased by 7.2% to 14,900yuan/mt by May 25, and nylon 6 HS chip prices also followed up with a month-to-date increase of 4.1% to 16,240yuan/mt. However, the lift in nylon 6 textile filaments is only around 1.5-3%. Recycled-PET – Polymers-demand

With such gap in price movement, NFY plants are suffering increasing losses in the month. However, NFY plants’ operating rate has been nailed at around 72.5% in May. Why are NFY plants struggling in holding the relatively high run rate under deficits?

Since late April, benzene market kept strengthening continuously. CPL plant operating rate was below 70% in most time of the month and thus formed a balance between supply and demand. Due to heavy deficits, CPL plants actively raised their offers.

At the same time, nylon 6 semi-dull HS chip market was in tight balance and trading focused on contract, the spot offers for HS chip had lifted with CPL as well, and the increment was just a bit narrower than CPL.

The supply and demand pattern was basically healthy for both CPL and nylon 6 chip market, thus the price increase had been relatively smooth.

Smooth increase from benzene to CPL and chip stopped in filament sector. With rising frequency of raw material price lift, nylon 6 textile filament plants also raised offers appropriately. But what waited for them was not the active follow-up of fabric mills, but disregard. Trading for textile filament was more difficult with downstream resistance enhanced.

The May contract settlement for CPL jumped by 800yuan/mt month-on-month, and some specifications of nylon filament increased by 300-500yuan/mt or slightly more, but it was also common to see some other sources dropped 500-1,000yuan/mt even. DTY market suffered heaviest burden and the low-price competition was mostly seen.

The price increase was blocked in the link of nylon textile filament, thus filament plants suffered heavily expanded losses in the month. Recycled-PET – Polymers-demand

-Recycled PET prices to remain firm

Recently, international oil price trend is firm overall, leading to higher polyester feedstock costs, and polyester product prices climb up obviously. Driven by the bullish sentiment, recycled chemical fiber and recycled PET product prices also move upward. Though PX price has fallen somewhat, and PET bottle chip and PET fiber chip prices edge lower, recycled PET flakes and popcorn prices remain firm.

For the support of recycled market: first, recycling volumes of bottles reduce this year as consumption of beverages decreases impacted by the multiple outbreaks of epidemic. In the meantime, with the long-time lockdown measures in some key areas, the consumption has reduced significantly directly. Though the lockdown is lifted recently, the daily recycling volumes only recover to about 10-20% of the volumes in the same period of previous years. The reduction of recycling volumes is the main reason for the supply tightness of re-PET. Recycled-PET – Polymers-demand

Second, the large rise of PET fiber chip and PET bottle chip has shown the price edge of recycled PET flakes in sheet field. With the larger price spread between PET fiber chip/PET bottle chip and recycled PET flakes, the cost edge of recycled PET flakes for sheet plants expands further. Take 3A-grade white flakes as an example. Bright PET fiber chip prices are at around 7,500yuan/mt in early May, and 3A-grade white flakes are at 7,400yuan/mt, so it has no advantages. Prices of hot washed blue and white flakes for HC re-PSF are around 5,800yuan/mt. The quality of flakes used for sheet is slightly better than that of flakes for HC re-PSF. On Jun 15, the price spread between bright PET fiber chip and 3A-grade white flakes has expanded to 800-1,000yuan/mt, and prices of blue and white flakes for HC re-PSF are around 6,100-6,200yuan/mt. So sheet plants have more choice on feedstock, so the supply to recycled chemical fibers reduces.

-Movers & Shakers – June 2022: Techtextil, Frankfurt news

In the dynamic and global textile fiber industry with its various manufacturing processes and end-uses, news and information is breaking on a daily basis.

International Fiber Journal is tracking stories relevant to our industry from manmade to natural to bio-based fibers, innovations in nonwoven, woven, braided and technical textiles, technologies for additives, bonding, coatings and polymers, and applications from apparel to hygiene to transportation, and more. Recycled-PET – Polymers-demand

Here we will post news stories relevant to textile fibers and their downstream applications on an ongoing basis. Please check back for regular updates.

Retech to present godet roll at Techtextil

Retech will address demand for technical yarns with maximum strength with a newly launched godet roll at Techtextil, Germany later this month. The roll has an ideal length of 420 mm to process 8-12 threads at a time. Its extended diameter of 250 mm allows a significantly increased speed with the same dwell time. Additionally, the higher motor torque guarantees the very best results in yarn tenacity. Further technical parameters are speeds that can be ramped up to 6500 m/min and the temperature reaches 250°C with an excellent temperature profile of +/- 1.5 °C. Recycled-PET – Polymers-demand

High-temperature godet rolls are used for high-performance fibers. High-performance fibers require temperature at extremely high levels, since fibers such as para-aramids have high glass transition temperatures nearing 370 °C. Retech high-temperature godet rolls have a heating power of up to 400 °C. They also offer outstanding performance in terms of precision within 0.5°C – guaranteed by the established Retech temperature controller – and repeat accuracy from 1 to 100 godets.

Recycled-PET – Polymers-demand