Recycled Plastic Production Capacity 05-10-2021 - Arhive

Recycled Plastic Production Capacity

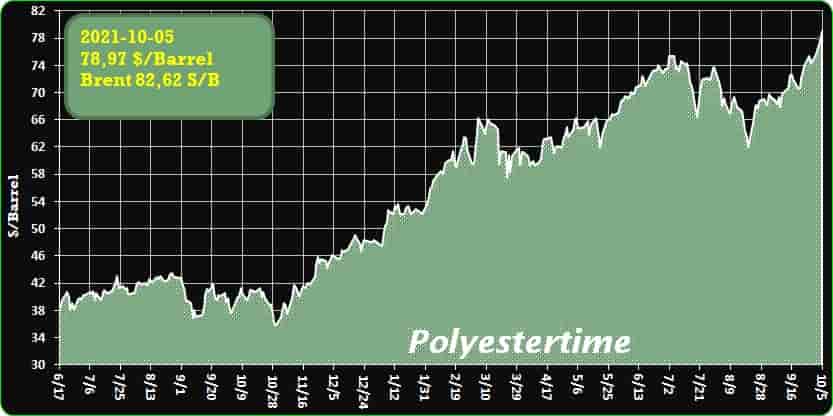

Crude Oil Prices Trend

-How CO2 becomes a valuable resource

Scientists from the University of Tübingen involved: International research center works on technologies that can convert carbon dioxide into new raw materials

Tübingen environmental biotechnologist Lars Angenent and his team are involved in a new research center that will develop technologies for the capture, storage and reprocessing of carbon dioxide (CO2). The interdisciplinary center will be funded by the Danish “Novo Nordisk” foundation with 84.7 million euros in the coming years.

Located at the University of Aarhus in Denmark, the center will cooperate with Angenent’s team in Tübingen and other research institutions from the USA, Norway, the Netherlands and Denmark. Partnerships with industry are also intended to ensure the rapid implementation of basic research into practice.

CO2 in the atmosphere is one of the main causes of climate change. In order to curb the rise in temperatures worldwide, not only CO2 emissions must be reduced. This would also require carbon dioxide to be removed from the atmosphere and reused in products that are currently based on carbon, i.e. obtained from fossil fuels such as oil and coal.

In the new center, teams from chemistry, life sciences and systems analysis are jointly researching technologies that can be used to recycle CO2 from the atmosphere as well as from industrial plants and power plants. For example, carbon dioxide, water and electrons could be converted into raw materials for new plastics with the help of bacteria and electrochemistry. The subject of research is also a plant that uses microorganisms to convert carbon dioxide into fuel, thus replacing the use of fossil fuels such as coal, crude oil and natural gas.

-TotalEnergies Doubles its Recycled Plastic Production Capacity in France

TotalEnergies has inaugurated the extension of Synova in Normandy, the French leader in recycled polypropylene production. TotalEnergies is therefore doubling its mechanical recycling production capacity for recycled polymers, to meet growing demand for sustainable polymers from customers, such as Automotive Manufacturer (Auto OEM) and the construction industry. Recycled Plastic Production Capacity

Moving the circular economy forward

Plastics are essential to everyday life because of their many properties, including lightness, which allows the automotive industry, for example, to reduce the weight of vehicles and hence also fuel consumption and CO(2) emissions. But plastics’ end-of-life is a crucial topic, which is why TotalEnergies is actively involved in plastics recycling as part of its circular economy approach.

In order to increase its mechanical recycling capacity, TotalEnergies acquired in 2019 Synova, the French leader in the production of recycled polypropylene derived from industrial waste plastics, household waste and car parts such as bumpers.

-China traditional Q4 petchems demand increase unlikely because of economic rebalancing

The cliché “paradigm shift” is so overused it can often be meaningless.

Not in this case, though. There is no doubt that China is undergoing a profound paradigm shift where changes in government policies mean real estate will no longer by as big an economic driver. Recycled Plastic Production Capacity

A new study finds that no other economy is or has been as dependent on real estate as China’s. The property sector is worth 29% of Chinese GDP.

This shift in real-estate policies, combined with decarbonisation, has HUGE implications for the global petrochemicals industry.

Just focusing on the short-term implications for polyethylene (PE) in today’s post, do not expect the traditional Q4 improvement in demand.

Total Chinese PE demand was already heading for a 1.6m tonnes reduction over 2020, even before the accelerating Evergrande crisis and the firmer government emphasis on “common prosperity”.

And PE imports were already heading for a 3.4m tonnes reduction – again before the policy shifts.

Outcomes for PE demand and imports in 2021 could now be even worse.

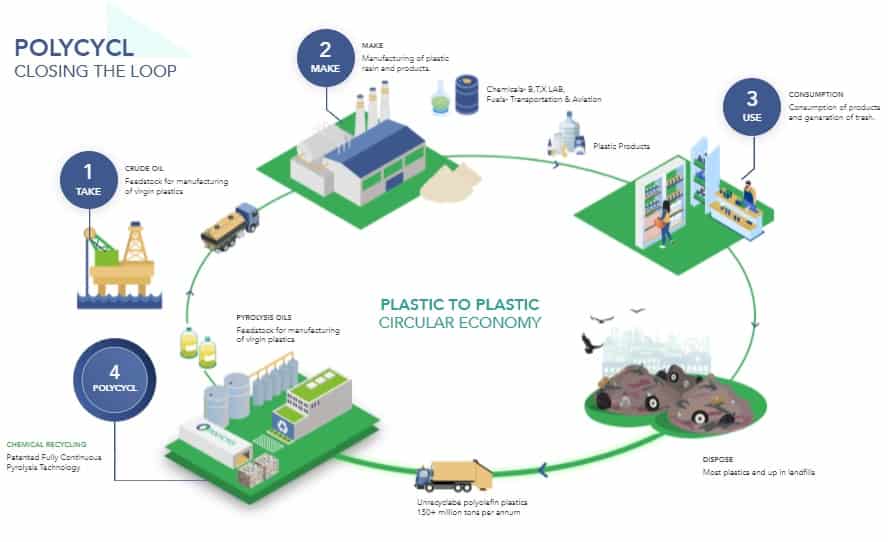

-A circular economy for plastics

ADVANCE RECYCLING OF LANDFILL PLASTICS

Conversion of waste plastics extracted from landfills and legacy waste heapsto high-value hydrocarbon oils

The company has developed a specially designed and configured pre-treatment system that extracts hard-to-recycle polyolefin plastics from landfills and legacy waste heaps. Recycled Plastic Production Capacity

The segregation process removes organics, textile, paper, fibres and metals while also dropping mud and dirt using non-wetting methods.The end result is a polyolefin rich stream which is processor ready for advance recycling.

CONTIFLOW CRACKERTM

PolyCycl’s flagship technology enables an endless plastic-to-plastic recycling loop, whereby used plastics such as flexible grocery bags and discarded ketchup bottles can be upcycled to make virgin ‘food-grade’ plastics.

-Evolon certified to the highest standards

Freudenberg’s Evolon fabrics are known for combining high performance technical properties with numerous ecological benefits in many durable applications. According to the independent Oeko-Tex institute, they also meet the most stringent requirements in terms of sustainability and health and safety.

Freudenberg in Colmar, France, recently received the STeP by Oeko-Tex label for Evolon along with the Made in Green label. Recycled Plastic Production Capacity

Certificates awarded by the independent institute are highly trusted by the textile industry because they are 100% transparent and independent. For manufacturers, they are confirmation of ecologically and socially responsible production and products – a quality characteristic that plays a growing role in the purchasing decisions of companies.

By awarding the STeP (Sustainable Leather and Textile Production) label, the Oeko-Tex institute certified environmentally friendly production processes, a high level of health and safety and socially responsible working conditions at the Freudenberg site in Colmar. The company scored top marks and reached the highest grade of certification, Level 3, for “exemplary implementation of best practices”.

-Flint Group debuts coating products to improve shrink sleeve recyclability

The Evolution Deinking Primer and Evolution Caustic Resistant Over Print Varnish aim to increase the yield of material in the recycling process.

Flint Group Narrow Web, Rogers, Minnesota, has released two UV-flexo coating products to improve the recyclability for shrink sleeves and pressure-sensitive labels. Flint Group’s new coating products are available in North America and will soon be available in Europe and other regions. Recycled Plastic Production Capacity

Flint Group’s Evolution Deinking Primer for shrink sleeves and the Evolution Caustic Resistant Over Print Varnish (OPV) for self-adhesive labels are designed to increase the yield of material in the recycling process. The company says both of these new coatings have been recognized by the Washington-based Association of Plastic Recyclers (APR) to comply with the critical guidance for polyethylene terephthalate (PET) packaging.

According to Flint Group, the new Evolution Deinking Primer coating for shrink sleeve materials makes the ink release in the caustic bath of the recycling process. When used with crystallizable polyester shrink sleeve material (CPET), the primer keeps the ink anchored to the substrate through the usable life of the sleeve but releases it in the caustic bath. The ink is removed from the sleeve material without contaminating the bottle flake. The materials are rinsed and pelletized into recycled polyester for reuse.

The company says the Evolution Deinking Primer is applied by the conventional UV-flexo process and works with Flint Group’s EkoCure XS flexo inks that are designed for shrink sleeves.

-Sabic to market petchem products of Petro Rabigh

Sabic, a global leader in diversified chemicals, announced that beginning October 1, 2021, it will begin marketing petrochemical products of Rabigh Refining & Petrochemical Company (Petro Rabigh).

This aligns with the strategic positioning of Sabic as the chemicals arm of Aramco, while the realignment of marketing responsibilities relates to a range of liquids and polymers, which include mono ethylene glycol (MEG), polyethylene (PE), polypropylene (PP), poly methyl methacrylate (PMMA) and polyamide (PA) products.

By marketing Petro Rabigh products, Sabic will strengthen its combined product and services offering, and maintain its competitive preference in the global chemicals industry. As a result, Sabic’s customers will benefit from an enhanced product range and availability, ordering and points of sale, and after-market services and solutions. With these latest changes, the company also expects to drive further supply chain efficiencies. Recycled Plastic Production Capacity

-Colombia’s Ecopetrol eyes 18 hydrogen projects

State-controlled Ecopetrol is evaluating 18 possible hydrogen projects, including pilot projects for its Cartagena and Barrancabermeja refineries, that would require about $200mn-$300mn in investment, as part of Colombia’s goal of developing hydrogen energy options. Recycled Plastic Production Capacity

Ecopetrol is one of the eight companies in Colombia, including Grupo de Energia de Bogota, that signed a letter committing to develop hydrogen projects. Colombia officially launched the government’s 30-year hydrogen roadmap yesterday.

Ecopetrol plans to import a small electrolyzer from Spain in the first quarter of 2022 to test the production and application of the emerging fuel at its 165,000 b/d Cartagena refinery, on the Caribbean coast, chief executive Felipe Bayon said at a press conference.

-Fakuma: New LSR Dosing System and All-Electric Cold Runner

Elmet is introducing the new SMARTmix TOP 7000 Pro dosing system and all-electric SMARTshot E cold runner system at the show in Friedrichshafen.

LSR injection molding technology supplier Elmet will introduce the new SMARTmix TOP 7000 Pro dosing system and all-electric SMARTshot E cold runner system at Fakuma (Oct. 12-16; Friedrichshafen, Germany; hall A5, booth A5-5306).

Elmet describes the new SMARTmix TOP 7000 Pro dosing system as an all-round update of its predecessor, the TOP 5000 P. The new dosing system has a footprint of just 45 by 31 in, while still being able feed material from 200 liter (53-gal) drums. The completely revamped pump unit now has fewer components, and despite being capable of operating at pressures of up to 210 bar (3045 psi) the new unit’s slimmer design is significantly more compact. Elmet says this means that a smaller volume of LSR is present in the system, which increases process reliability and reduces purging volume. Recycled Plastic Production Capacity

Recycled Plastic Production Capacity