Recycling PET Bottles Petrochemicals 14-06-2021 - Arhive

Recycling PET Bottles Petrochemicals

Petrochemicals PETBottles Ethylene Trend

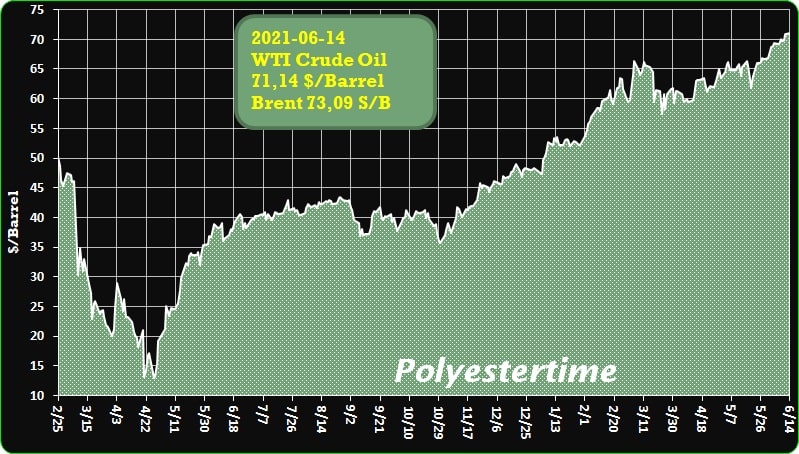

Crude Oil Prices Trend

-Strong PET demand will eventually find its supply

PET (polyethylene terephthalate) is designated #1 in the plastics recycling code. It is the most common plastic used for bottles, jars, food containers and packaging. PET is a clear, strong, and lightweight material used for bottled water, carbonated soda, teas, sports drinks and other beverages. PET is also the most recycled plastic in the U.S., so the market dynamics affecting it eventually are realized in the recycled PET market.

PET containers are lighter in weight than alternative materials, such as glass. This difference makes PET containers easier to stack and ship, more efficient to transport, and has resulted in some companies switching to PET containers from other materials, according to the most recent Plastics Market Watch report.

Despite the fundamental strengths of PET, COVID-19 introduced unforeseen volatility to consumer behaviour across the economy. Production of common consumer goods responded accordingly. By extension, this disruption impacted PET resin demand-supply dynamics, the adjustments of which are ongoing and are be expected to continue into the near future.

-ZoltekPetrochemicals PETBottles Ethylene Trend Mexico expands carbon fiber production

Guadalajara, Mexico facility to increase production capacity of PX35 carbon fiber to 13,000 metric tons annually, for a total of 28,000 metric tons globally.

It was announced on June 10 that Zoltek Companies Inc. (Zoltek, St., Louis, Miss., U.S.) a Toray Group that develops and manufactures low-cost industrial grade carbon fiber, is expanding its carbon fiber production capacity at the facility located in Guadalajara, Mexico.

By expanding operations, Zoltek says the facility’s carbon fiber production capacity will increase to 13,000 metric tons annually, and will increase Zoltek’s global production capacity of its PX35 carbon fiber to a total of 28,000 metric tons.

Zoltek says it is continuing its mission to commercialize carbon fiber, and increase its position as a global leader in industrial-grade carbon fiber. Zoltek’s PX35 50K carbon fiber, which is produced in Hungary and Mexico, is said to be the established standard for large-scale industrial applications such as wind energy and automotive.

-America’s Flor completes ten years of area rugs with Aquafil’s Econyl

Flor, a rug brand for homes, offices, and every space in between, is celebrating ten years of area rugs featuring Aquafil’s Econyl regenerated nylon that blend beautiful design, smart functionality, and environmental responsibility into all the spaces people live. The brand was the first flooring company that started using recycled nylon in its products.

Today, Econyl regenerated nylon, a sought-after responsible solution for well-known fashion and interiors brands, is featured in most Flor area rugs, rather than brand-new nylon that uses new resources. Econyl is made from 100 per cent waste, fishing nets, textile scraps, old carpet, that would otherwise pollute the Earth. The regenerated nylon performs the same as virgin nylon and can be recycled, recreated, and remoulded infinitely. Not only a waste solution, Econyl reduces the global impact of nylon by up to 90 per cent compared with the material produced from oil, Flor said in a media statement.

Flor’s use of regenerated nylon in its carpet tile is a key part of its efforts to lower the carbon footprint of its products. Recently, the company introduced its new backing, CQuest, which is made of post-consumer recycled content from carpet tiles, bio-based additives, and pre-consumer recycled materials, which are net carbon negative. With its combined new backing and yarn made from regenerated nylon, Flor offers area rugs that look beautiful while being good for the planet.

-Zhejiang Saintyear opts for second Andritz spunlace line

International technology Group Andritz has received a repeat order from Zhejiang Saintyear Textile Co., Ltd., based in China, to supply a second, complete neXline spunlace line for the production of premium-quality nonwoven roll goods. The line is scheduled for start-up during the third quarter of 2022.

The order comes just nine months after the company placed a first order for a complete high-speed spunlace line, with Zhejiang Saintyear Textile deciding to rely on Andritz once again by purchasing another complete line dedicated to the production of first-class wipes. The production capacity will be up to 2,800 kg/h for lightweight fabrics.

Andritz will provide a full line – from web forming to drying. The scope of supply includes the precise opening and blending machinery from Laroche – newly acquired by the Andritz Group, two inline TT cards, a proven JetlaceEssentiel unit for hydroentanglement, and the efficient neXdry through-air dryer.

-Towards the circularity of plastics

Researchers at the Department of Chemistry are developing technologies to make recycling plastics easy, clean and affordable – promoting a truly ‘circular economy’ for the material.

Our modern world is addicted to plastics. Cheap, light, durable and very flexible they have largely replaced traditional materials such as metal and wood. Used for everything from food packaging and medical equipment to parts for consumer goods, plastics have made our lives easier and better in many ways.

But plastic waste is now one of the most urgent environmental issues of our time.

Disposal is difficult because of the huge volume of waste generated and its extreme durability. More than 30% is sent to landfill where it takes hundreds of years to decompose; even more is simply thrown away and accumulates around land, rivers, and oceans.

Although it is possible to recycle plastic waste, current methods are expensive and often polluting. Around 40% is incinerated to produce energy, while only 30% percent is recycled into new products. Astonishingly, less than 10% of the 8 billion tons ever produced worldwide has been recycled.

-Exporting Plastic Waste for Recycling

The export of plastic waste materials for recycling, particularly to developing countries, is sometimes seen as a questionable practice. However, the UK remains dependent upon export markets to achieve its plastic recycling targets because we do not currently have capacity to recycle all our plastic waste.

Why do we currently export some of our plastic waste for recycling?

The UK currently exports plastic because there is not enough capacity within the UK to recycle it. In 2019, the UK exported 61% of its plastic packaging for recycling.

When export takes place, this needs to be without a detrimental effect on the quality of material and making sure that the exported plastic waste is managed in an environmentally sound manner once it reaches its end destination. It is vital that waste exporters adhere to national and international legislation governing waste exports and robust checks are in place to prevent fraud.

-Are Oil Prices Headed toward $100 a Barrel?

On June 1, 2021, Jeremy Schwartz, Global Head of Research at WisdomTree and regular host of the Behind the Markets podcast, was joined by Mobeen Tahir, Associate Director of Research at WisdomTree, to host Erik Gilje, professor of finance at the University of Pennsylvania’s Wharton School of Business. The topic was oil, and the focus was on Erik’s bullish view on the commodity stemming from structural supply issues in the U.S. amid an improving demand outlook.

Professor Gilje outlined that over the last decade, almost all new supply of oil has come from North America—i.e., either Canada or the U.S.—while the Organization of the Petroleum Exporting Countries and its partners (OPEC+) have lost market share. The group was forced by the COVID-19 pandemic to reduce 9.7 million barrels of supply in what can be characterized as a dramatic and unprecedented policy coordination.

But OPEC+ may not necessarily be fixated on quickly bringing this supply back online. This is because the group is possibly less worried about losing further market share to U.S. shale producers now than in the past. This marks a major shift in the dynamic between the two and could be the key force that drives oil markets higher.

-Fuel cell vehicle progress at Grupo Antolin

New nanofibres with excellent electrical conductivity, corrosion resistance and specific surface area.

Grupo Antolin – the manufacturer of one in every four car headliners made worldwide – is studying the potential of carbon nanofibres to improve the efficiency, durability and cost of critical components for next-generation hydrogen fuel cells.

The company, headquartered in Burgos, Spain, says it aims to make a solid contribution to the development of a key technology to make electric mobility more cost-effective efficient, and accessible,

Hydrogen fuel cell vehicles cause no exhaust emissions, only high purity water, allow refuelling as quickly as petrol-fuelled cars and can achieve similar range levels, Grupo Antolin points out.

It has been working for a number of years on the development of processes for producing carbon nanofibres with optimised properties for different industrial applications in various sectors. The result has been new nanofibres with excellent electrical conductivity, corrosion resistance and specific surface area, making them ideal for application in the electrodes of the electrochemical cells that constitute the hydrogen fuel cell systems.

-The Problem with PET Thermoforms

PET thermoform packaging—such as those used for fruits, vegetables, muffins, eggs and more—is technically recyclable with PET bottles. In fact, many PET reclaimers accept thermoforms in bottle bales, as long as auto-sort systems and best practices are in place.

However, only 9 percent of them ever make it to recycling bins.

In this week’s blog post, we will go over the obstacles reclaimers face in recycling PET thermoforms and what the plastics industry has planned to work past them.

A New Law

On September 24th, 2020, Governor of California Gavin Newsom signed a bill made by California Assembly member Phil Tang, requiring manufacturers to include recycled materials when making plastic bottles, and, by extension, plastic thermoform parts.

AB 793 is designed to bolster the market for recycled polyethylene terephthalate in the state. Manufacturers must meet a number of deadlines for recycled content, achieving 15 percent by 2022, 25 percent by 2025 and 50 percent by 2030.

Recycling PET Bottles Petrochemicals