Recycling Polyester Yarn Petrochemicals 12-06-2021 - Arhive

Recycling Polyester Yarn Petrochemicals

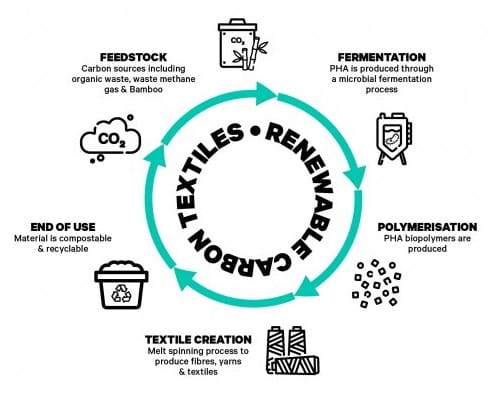

-Consortium plans PHA fibres for fashion

Amsterdam-based Fashion for Good is launching the Renewable Carbon Textiles Project, bringing together a powerful consortium to accelerate the development of polyhydroxyalkanoates or PHA polymer fibres – a promising biosynthetic alternative to fossil based fibres with the potential to reduce carbon emissions in the fashion supply chain.

With catalytic funding provided by Laudes Foundation, collaborating partners include Bestseller, Norrøna, PVH Corp. and the Fabrics Division of WL Gore providing industry expertise and financial support.

Participating innovators Bio Craft Innovation (formerly Biomize), Full Cycle Bioplastics and Newlight Technologies will contribute their solutions, providing insights to scale the industry in the long term.

“There is an urgent need to find replacements for the predominantly fossil-based fibres in the fashion industry through solutions such as biosynthetics from renewable sources,” said Katrin Ley, managing director of Fashion for Good. “PHA polymers represent an exciting, yet challenging solution for reducing carbon emissions in the fashion industry, and this project aims to drive further innovation in this space to bring them to scale.”

-FCC Medio Ambiente coordinates the LIFE4FILM Project

EASME (Executive Agency for Small and Medium Enterprises), the Executive Agency that runs the LIFE programme, has approved LIFE4FILM project coordinated by FCC Medio Ambiente Recycling Polyester Yarn Petrochemicals

The main objective of LIF4FILM Post-Consumption Film Plastic Recycling From Municipal Solid Waste) project is to prevent landfilling or waste to energy valorisation for film plastics (LDPE) separated from the municipal solid waste by means of the implementation of an innovating recycling process at semi-industrial scale 10,000 t/y pilot line in Granada (Spain) that will include equipment from ROLBATCH and STADLER. This plant will be operated by FCC with the aim of demonstrating its profitability and replicability at an European context.

The project develops a new low carbon recycling technology thus obtaining more sustainable process. This new technology will increase the resources efficiency, valorising the LDPE by the production of industrial accepted products (validated by the Tech Centre AIMPLAS and the University of Granada), thus fostering the implementation of the circular economy.

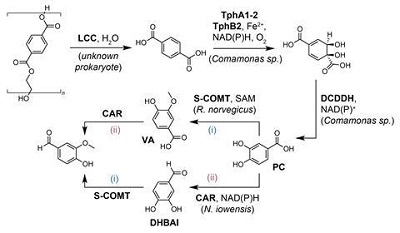

-Genetically engineered microbes convert waste plastic into vanillin

Scientists in the UK have genetically engineered Escherichia coli to transform plastic waste into vanillin. Recycling Polyester Yarn Petrochemicals

‘Instead of simply recycling plastic waste into more plastic, what our system demonstrates for the first time is that you can use plastic as a feedstock for microbial cells and transform it into something with higher value and more industrial utility,’ says Stephen Wallace from the University of Edinburgh.

The biotransformation ‘isn’t just replacing a current chemical process, it’s actually achieving something that can’t be done using modern synthetic methods.’

Polyethylene terephthalate (PET) is one of the most widely used types of plastic.

Most existing recycling technologies degrade PET into its substituent monomers, ethylene glycol and terephthalic acid, then repurpose them in second-generation plastic materials.

Wallace and Joanna Sadler, also at the University of Edinburgh, want to upcycle these monomers into alternative products.

-Borouge partnered recycling firm Plaspulp Union

Borouge has partnered with Singapore-based recycling firm Plaspulp Union to further develop and commercialize new packaging applications using recycled materials, said the UAE-based company.

The Memorandum of Understanding (MoU) marks Borouge’s first foray into the recycling market in Southeast Asia, the company said in a statement. “Borouge is expected to develop more partnerships with other processing companies in the coming months,” it said. Recycling Polyester Yarn Petrochemicals

Borouge has already successfully tested the use of Plaspulp Union recycled materials in flexible packaging such as laminate and shipping packaging.

The MOU with Plaspulp Union will add to the existing partnerships Borouge has established with two other recycling companies in China to increase the volume of recycled materials in its portfolio and jointly develop innovative new solutions for packaging applications.

-Thailand chemical firm IVL reports Q1 FY21 revenue of $3.24 bn

Indorama Ventures Public Company Limited (IVL), a global chemical producer, has reported 10 per cent year-over-year (YoY) revenue increase to $3.24 billion in its first quarter (Q1) for fiscal 2021 compared to revenue of $2.94 billion in the corresponding quarter of previous fiscal. The company’s EBITDA rose to $369 million (Q1 FY20: $304 million). Recycling Polyester Yarn Petrochemicals

“Last quarter I stated that 2020 brought no structural damage to the industries IVL plays in and the first quarter of 2021 has further solidified this thesis. Our advantaged portfolio and experienced management, supported by our transformation programs, will yield superior returns for shareholders in line with our 2023 targets,” Aloke Lohia, group CEO of Indorama Ventures, said in a press release.

The company’s total expenses for Q1 FY21 was $2.94 billion, while profit for the period jumped to $215 million ($17 million).

According to the company, the fibres segment made a positive start to 2021 with strong volumes and demand across all three verticals due to recovery in polyester fibre demand, increase in light vehicles sales driven by China and continued strong demand for hygiene fibres, achieving an increased overall average operating rate of 86 per cent. Combined PET segment achieved core EBITDA of $260 million, growing 35 per cent YoY, driven primarily by demand growth and higher integrated industry spreads on top of the sharp rise in crude oil prices.

-Sinopec-SK Wuhan to start up new HDPE plant in China

China’s Sinopec-SK Wuhan Petrochemical, a joint venture between one of the world’s largest energy and chemical companies and the largest oil refinery in Asia – Sinopec – and South Korea’s SK Global Chemical, plans to begin test production at its new high denisty polyethylene (HDPE) plant in Wuhan, China in July, according to CommoPlast.

This new plant with the production capacity of 300,000 mt/year of HDPE is part of the second phase of the petrochemical complex in Wuhan.

The company already operates the first HDPE plant of a similar capacity at the same site. Recycling Polyester Yarn Petrochemicals

As MRC reported earlier, the company conducted a scheduled turnaround at this HDPE plant from 16 October to 23 December 2020.

Sinopec-SK Wuhan Petrochemical also received commercial production at a new plant with the capacity of 300,000 mt/year of polypropylene (PP) in Wuhan on 21 May, 2021.

According to MRC’s ScanPlast, April estimated HDPE consumption in Russia slumped to 70,420 tonnes from 132,340 tonnes a month earlier. Domestic producers raised their exports, while some producers’ output decreased. Overall HDPE shipments into the Russian market totalled 422,370 tonnes in the first four months of 2021, up by 5% year on year. Production increased, whereas imports fell by 39%.

-Plastic Waste Chemical Recycling Study

French collaborative research group to study status of chemical recycling of plastic waste in economic and environmental terms.

French collaborative research network, RECORD, launched a research project on the status of chemical recycling of plastics. Recycling Polyester Yarn Petrochemicals

The project aims at understanding the different existing technologies for chemical and biochemical recycling of plastic waste. Mechanical plastic waste recycling does not produce high quality recycled materials. The study would therefore look into the status of the more promising chemical recycling of plastic waste. Currently, little information is available to compare the different processes and to evaluate their performance in economic or environmental terms. The uncertainties related to these new technologies are also high given their current stage of development.

Thus, this study aims to provide an overview of the different chemical and biochemical recycling technologies through a literature review and to shed light on the outstanding issues with the help of expert opinions.

-Borealis commits to scale-up of Project STOP in Indonesia

Borealis has announced a significant financial commitment to expand Project STOP, an initiative it co-founded with SYSTEMIQ in 2017 to prevent plastic waste from entering the world’s oceans. The announcement came on 8 June, World Oceans Day.

The support will enable the project to continue to scale up efforts to create effective circular waste management systems in high-need areas of Southeast Asia.

“We at Borealis want to showcase together with our partners how to end the plastic waste issue,” said Borealis CEO Thomas Gangl. “Plastics are key for prosperity and a modern life. Recycling Polyester Yarn Petrochemicals

We need to implement waste management solutions to avoid any negative impact to the environment from those valuable materials. As Project STOP continues to grow, we look forward to welcoming new strategic partners, whose skills and resources will be crucial to addressing this significant global challenge together.”

Project STOP works together with city governments, providing support with technical expertise to achieve zero-leakage of waste, increase recycling and to build economically sustainable programs, creating new jobs and reducing the harmful impact of mismanaged waste on public health, tourism and fisheries. The first city partnership was established in 2018 in Muncar, located in the Regency of Banyuwangi, East Java. Project STOP also operates two additional city partnerships, in Pasuruan, also in Java, and Jembrana, on the northwest coast of Bali.

-China-based Xtep launches environment-friendly polylactic acid t-shirt

Xtep Group, a Chinese enterprise of shoes and clothing, has launched new environment-friendly polylactic acid (PLA) t-shirt. Clothes made of PLA fibre have a low environmental impact as when buried in a specific environment, they can degrade naturally within one year. PLA is extracted from crops that contain starch and is turned into fibre after spinning. Recycling Polyester Yarn Petrochemicals

Xtep had launched its first PLA windbreaker on June 5, 2020. At that time, PLA accounted for 19 per cent of the trench coat fabric. One year later, the proportion of PLA t-shirts has risen sharply to 60 per cent.

The company also plans to increase the PLA content of knitted sweaters scheduled to go on sale in the second quarter of 2022 by 67 per cent, and in the third quarter of the same year, 100 per cent pure PLA trench coats will be on the market. In the future, Xtep will gradually achieve layers of breakthroughs in the application of PLA products and strive to achieve more than one million pieces of PLA products in a single season before 2023, Xtep said in a press release.

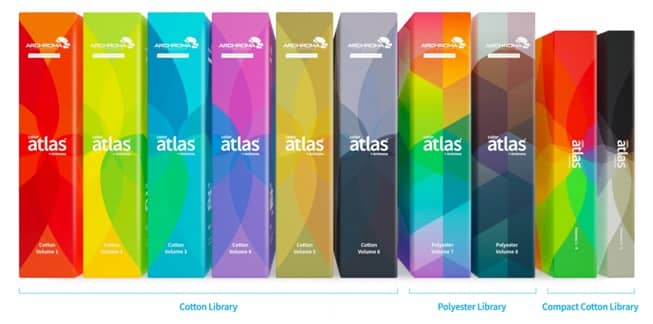

Archroma, a global leader in specialty chemicals towards sustainable solutions, today announces the launch of its new Color Atlas by Archroma® Polyester Library, with 1’440 colors for sportswear, athleisure, swimwear, children’s clothing, shoes, fashion and home textiles.

A library of 1’440 off-the-shelf color standards, adding to the already available 4’320 colors of the ‘Color Atlas’ for cotton Recycling Polyester Yarn Petrochemicals

Online and physical library of colors allowing increased speed-to market for sportswear and fashion designers, brands, retailers and manufacturers.

In 2016, Archroma launched the Color Atlas by Archroma®, a unique tool dedicated to providing fashion designers and stylists with off-the-shelf color inspiration for cotton that can be implemented in production with just a few clicks.

This original Color Atlas Cotton Library today contains 4’320 colors, almost double compared to similar tools available to textile and fashion specialists, with options for purer ingredients and lighter resource usage for brands exploring more sustainable collections.

Recycling Polyester Yarn Petrochemicals