Recycling Sustainability Oil Chemicals 18-11-2021 - Arhive

Recycling Sustainability Oil Chemicals

Crude Oil Prices Trend

Polyplastics Group has announced the introduction of two new RENATUS (R) polyethylene terephthalate (PET) grades which deliver superior mechanical properties, appearance, and weather resistance for automotive exterior components, reaffirming Polyplastics’ strong commitment to PET as a key pillar of its extensive resin business portfolio.

The two new glass-reinforced grades, RH030 (30% glass-filled) and RH045 (45% glass-filled), maintain their jet blackness and reduce whitening on the surface of molded articles in outdoor environments, making them ideally suited for applications such as automotive side mirrors and rear wiper arms/blades. Since PET parts are not painted, weathering degradation can occur over time. The glass filler can start to float and the jet blackness can decrease. Accelerated weather-resistance testing demonstrates that Polyplastics’ new PET materials maintain lower index values than their competing products, thus indicating that whitening is being reduced.

Plastic resins that are reinforced with glass fiber are typically made stronger but glass fillers can also have a negative effect on the surface appearance of molded articles. RENATUS (R) RH030 and RH045 PET are glass fiber-reinforced grades, but they can still produce molded articles with good surface appearance because of their superior mold transferability during molding.

Recent company testing shows that when compared to standard grade PBT-GF30, RH045 (PET-GF45) exhibits higher surface gloss even though it has a large amount of glass fiber added to the formulation.

In terms of mechanical performance, PET typically has superior properties compared to PBT. At similar glass loadings, RH030 and RH045 PET grades have higher mechanical properties including greater tensile strength, flexural modulus, and deflection temperature under load compared to PBT grades.

-Recycling innovator receives cash injection

Ellesmere Port recycling innovator BIG ATOM has received a £350,000 grant from Innovate UK.

The funding will be viewed as a major breakthrough in the firm’s attempt to revolutionise the tyre recycling process. Recycling Sustainability Oil Chemicals

The Oil Sites Road based clean-tech recycling company has been given the cash injection to develop its patented chemical reactor technology.

This will convert old waste tyres into new materials.

Alexander Guslisty, company founder, said that the grant would enable the business to develop the concept of a novel pyrolysis reactor.

It would have improved temperature control and efficiencies to create an even more sustainable regeneration process for polymers.

Guslisty said: “We already recycle tyres and have just processed our one millionth, but this Innovate UK grant will accelerate our tech development and bring us closer to create circular economy for polymers – thus ending the concept of polymer waste.”

“It is a huge breakthrough and will open up new opportunities that will accelerate our IP and pathway to commercialisation. What’s more, the process will be good for the environment and support our ultimate goal of bringing an end to waste materials.”

“We will be able to generate higher yields of valuable products compared to existing reactors and ultimately, we’ll be able to produce a more stable and desirable product for refineries to use as their feed.”

Berry’s access to recycled plastic grows to over 600 million pounds per year by 2025

–Berry Global Group, Inc. announced today an agreement with PureCycle that will provide Berry with PureCycle’s Ultra-Pure Recycled (UPR) advanced recycled resin. This agreement is the latest in a growing list of advanced recycling material sourcing announcements from Berry and is the Company’s second based in North America.

North American consumer interest in package sustainability rises

If given the option to buy products with recyclable or compostable packaging, 47% of Americans opt for recyclable products as their first choice, and 20% prefer compostable products. (Ipsos, Aug. 2021)

77% of Americans are concerned about the environmental impact of products they buy, and 78% are more likely to purchase a product that is clearly labeled as environmentally friendly. (Greenprint, April 2021) Recycling Sustainability Oil Chemicals

64% of consumers say that buying sustainable products makes them feel happy about their purchases (this reaches 72% in the 25-35 age group). (Capgemini Research Institute, July 2020)

As demand for sustainable products grows, customers look to Berry for access to recycled material and packaging design expertise to maintain their brand image and package performance. As a result, Berry continues its leadership position in the converter market for access to recycled plastic material – over 600 million pounds per year by 2025. In addition to its material access, Berry understands the specific design requirements of brands’ products – combining material expertise with product specification needs creates a range of opportunities for advanced recycling technology to be used in the marketplace.

-Kelheim retains leading position in Canopy report

Bavarian viscose speciality fibre manufacturer Kelheim Fibres has once again secured a leading position in Canopy’s Hot Button Ranking system.

With an increase of 2.5 points in the 2021 evaluation, Kelheim tied for third place out of around 40 viscose fibre manufacturers worldwide and a dark green/green shirt for the second year running. Recycling Sustainability Oil Chemicals

As well as responsible raw material sourcing, the Hot Button Report is also regarded as an overall sustainability indicator for viscose fibre producers.

In the areas of transparency and procurement, the NGO Canopy, which is committed to the preservation of ancient and endangered forests, awarded Kelheim Fibres top points; Kelheim is the only EMAS-certified viscose fibre manufacturer worldwide and publishes all environmentally relevant data publicly.

Kelheim Fibres also gained points in the area of “Next Generation Solutions” – the use of alternative raw materials in fibre production. Together with the Swedish textile recycling company Renewcell, the fibre experts are planning to realise the large-scale production of high-quality viscose fibres from up to 10,000 tonnes of the 100% textile recyclate Circulose per year.

“As a manufacturing company, we take our responsibility towards the environment very seriously,” said Matthew North, Commercial Director at Kelheim Fibres. “Sustainable action must begin with the raw materials on which our products are based.

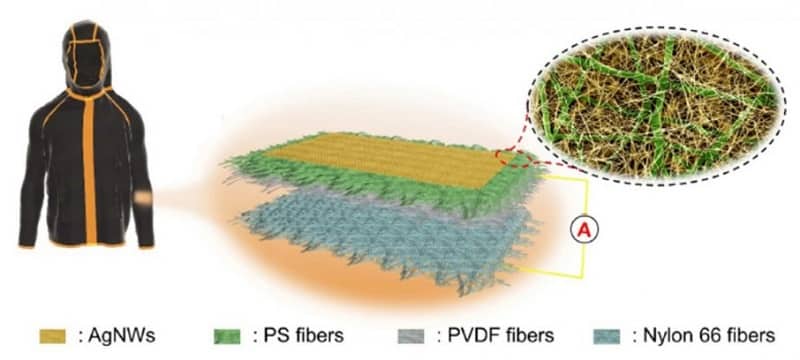

-Breathable fabric can power small electronic devices

Electrospun AF-TENG triboelectric nanogenerator retains its surface charge density over time.

Scientists at the University of Fukui in Japan and Nanjing University in China have succeeded in creating a new triboelectric fabric that generates electricity from the movement of the body while remaining flexible and breathable.

Using the movement of a body to charge electronic devices such as phones may soon become a reality, thanks to the work being done on triboelectric nanogenerators (TENGs), but most current TENGs are not breathable, making them uncomfortable to wear.

The new multilayered TENG – made from electrospun fibres, silver nanowires and a polystyrene charge storage layer – not only has a high electrical performance, but also superior wearability. Recycling Sustainability Oil Chemicals

The triboelectric effect is a phenomenon where a charge is generated on two dissimilar materials when the materials are moved apart after being in contact with each other. TENGs use this effect to convert mechanical motion into electrical energy. The compactness of TENGs allows them to be used as wearable devices that can harness the motion of the body to power electronics.

-INEOS Styrolution’s Novodur® 550 selected by THACO Plastics Components for rear spoiler application

Novodur® 550 selected for use in the range of car models manufactured by THACO Plastics Component

Combination of high heat resistance, good process-ability and high impact strength, making it an ideal polymer for rear spoiler application

Hanoi, Vietnam – November 16, 2021 – INEOS Styrolution, the global leader in styrenics, announced today that its Novodur 550 has been selected by THACO Plastics Component (TPC), one of the leading OEMs producing key automotive parts for global brands in Vietnam, to be used for rear spoiler application.

Novodur® is INEOS Styrolution’s brand of specialty acrylonitrile butadiene styrene (ABS) copolymers. The product line contains grades with a well-balanced mix of properties, including good impact strength, dimensional stability and heat resistance. It is easy to process and gives a high aesthetic colourful surface appearance. This versatile product line is also available pre-coloured and contains products with many unique features to fit the most demanding applications across industries including automotive, household, electronics, medical and construction. Recycling Sustainability Oil Chemicals

Mr. Nguyen Hoang Huy, Managing Director, P-CARE Vietnam Group[1], comments “As a supplier to one of most successful automotive manufacturers in Vietnam, it is imperative for us to partner with world class and innovative material suppliers like INEOS Styrolution to provide the right solutions for our customers. The high quality and consistency of INEOS Styrolution’s products enable OEMs like TPC to meet the global standards required by well-known car brands. Novodur 550 is the material of choice as it offers high heat resistance, high impact strength, good process-ability and is suitable to be coated with premium paint, offering a luxurious appearance for THACO’s cars.”

-OPEC Vs The United States: Who will win the oil war?

Just when you thought Donald Trump’s exit would mean OPEC could enjoy their carte blanche management of the oil markets, Joe Biden, just like every other US President, has found himself in a squabble with the oil cartel over the global prices of oil.

With gasoline prices higher than last seen in 2008, a game of chess has ensued between the United States and the Organization of Petroleum Exporting Countries.

Joe Biden has called for OPEC+ to increase global oil supply so as to bring prices down but OPEC+ indirectly has shrugged off each request as it continues its current approach of “managing supply in line with global demand.” Recycling Sustainability Oil Chemicals

Historically, higher oil prices lead to higher gasoline prices and the prices at the pump are beginning to affect the lives of American citizens.

The President of the United States knows it is his prerogative to find different ways to bring gasoline prices down. But given the correlation between oil prices and gasoline, Joe Biden has to target bringing down oil prices by forcing OPEC’s hand to increase supply.

Biden recently said they “have tools they can use” to sway OPEC+.

We analyse some of the ‘tools’ the president of the united states might consider using;

A coordinated SPR release with a U.S export ban

Issuing export waivers to Iran and Venezuela to flood the oil market despite sanctions.

Severe diplomatic ties with Saudi Arabia by withdrawing military aid.

U-turn on domestic production and drilling. Boost shale.

Push and consent to NOPEC bill to Congress

Collude with financial funds to short oil prices – speculator frenzy.

The direction from the White House is pointing to an SPR release and a possible US export ban.

An SPR is a Strategic Petroleum Reserve. Most countries have stockpiles of oil they reserve in case of emergencies, war, or extreme weather conditions. The US currently has about 613 million barrels stacked in its SPR. There is talk that the US will issue millions of barrels to bring down oil prices, but outside an emergency – an SPR release is limited to 30 million barrels.

To make the kind of impact on prices Joe Biden will want, he would have to ensure other countries release out of their own SPR. China did that during the year in their battle with high oil prices by “downplaying their demand” for oil and picking out of their SPR but prices still went up over time.

-US infrastructure bill to boost spending on chemicals and plastics by $45.8bn

The $1tr US infrastructure bill signed by President Joe Biden into law on Monday will boost spending on chemicals and plastics by around $45.8bn over the next decade, while also giving a boost to decarbonisation and clean hydrogen development.

“The infrastructure bill provides for higher spending on many traditional infrastructure projects – roads, bridges, ports, airports, etc. It also includes spending on a host of other projects and programs, including energy efficiency, R&D and environmental clean-up. Much of this spending will generate additional sales of chemical products,” said Kevin Swift, senior economist at ICIS. Recycling Sustainability Oil Chemicals

“Federal spending on electric buses, for example, will generate chemistry sales in the form of plastic components, battery materials and chemistry, coatings, wire insulation, polyurethane (PU) foam seating, seat covers, styrene butadiene rubber (SBR) and other elastomers, and many specialty chemicals,” he added.

While the infrastructure bill provides funding through five years, from 2022-2026, the actual impact on spending will be drawn out further to around 10 years, noted the economist.

The additional spending of an average of around $4.6bn/year over 10 years will be lower at first and then ramp up in the mid-to-late years, providing a long-term tailwind for the US chemicals industry, Swift pointed out.

His analysis breaks down spending on chemicals and plastics by infrastructure category, and adjusts for non-physical spending such as engineering studies and program administration.

A number of programs also include cost-sharing elements such as grants and loans, so the amount of Federal spending is multiplied through additional funding from state and local governments, along with private sector sources.

Recycling Sustainability Oil Chemicals