Regenerated-nylon -Polymer-business 20-04-2022 - Arhive

Regenerated-nylon -Polymer-business

Crude Oil Prices Trend

-ECONYL® Makes a Difference This Earth Day + Beyond

The following post is brought to you by ECONYL®. Our partners are hand-picked by the Design Milk team because they represent the best in design.

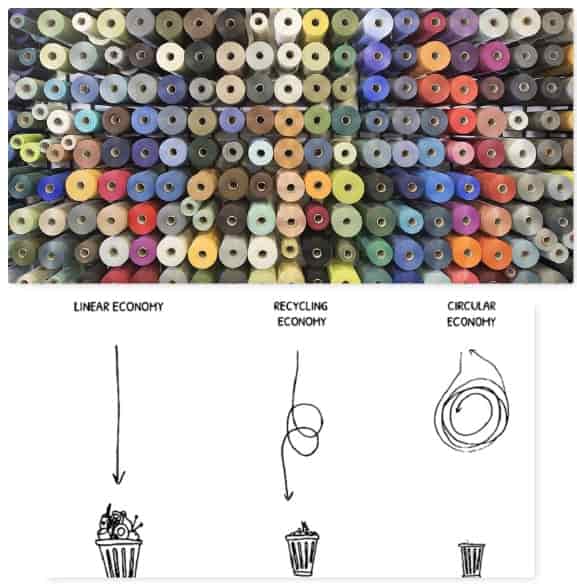

With Earth Day coming up this Friday, April 22, running a circular economy and taking the best possible care of our one and only planet is top of mind. That sentence brings along a lot of questions with it: What is the circular economy? Why is it important? How do we achieve it? What role do designers play in a circular economy?

A circular economy is a systemic approach to economic development that’s designed to benefit businesses, society, and the environment. Regenerated-nylon -Polymer-business

It’s the opposite of a linear model that creates waste in a throwaway society. Instead, a circular economy is regenerative and aims to separate the ideas of growth and consumption from one another. It minimizes the use of virgin resources, doesn’t add to pollution, and protects our health. A circular economy is the keystone to creating a sustainable society. And one of the biggest keys to creating one lies in the products we choose to purchase and use in our daily lives.

Last year we introduced you to ECONYL®, a versatile, innovative nylon that can be recycled and regenerated infinitely without reducing quality. Resource extraction, and the waste created by the process itself, are big contributors to environmental damage and climate change. ECONYL® yarn uses 100% waste materials in its manufacturing process, saving 70,000 barrels of crude oil and avoiding roughly 65,100 tons of CO2 eq. emissions for every 10,000 tons of raw material produced in comparison with standard nylon.

ECONYL® nylon is currently used by more than 2,000 brands worldwide, proving that beauty and quality are not exclusive of sustainability. And as renewable, carbon-free energy gains in popularity, a growing number of manufacturers are sourcing what were once seen as throwaway materials and using them to create new products. This not only reduces waste and energy, it makes the circular economy that much stronger. Aquafil, manufacturer of ECONYL® regenerated nylon, is a leader in this push forward. Regenerated-nylon -Polymer-business

-Angelini Industries Takes Full Ownership of Fameccanica

P&G gives up ownership stake in hygiene machinery specialist

Angelini Industries, a multi-business Italian industrial group which operates in 26 countries with 5700 employees, has signed an agreement with Procter & Gamble to buy 50% of Fameccanica, which until now was a 50/50 joint venture between the two companies. The deal will give Angelini Industries 100% ownership of the international company which specializes in automation and robotics for the consumer goods industry. Regenerated-nylon -Polymer-business

The closing of the operation is subject to approval by the Antitrust Authority and is expected during June 2022.

The agreement aims to consolidate Angelini Industries’ pursuit of growth and diversification as it becomes increasingly active in the field of industrial technology, thanks to the skills and know-how of Fameccanica, which will keep its leadership unchanged under the guidance of Alessandro Bulfon.

“We are taking an important step,” says Sergio Marullo di Condojanni, CEO of Angelini Industries,”in the diversification and internationalisation of Angelini Industries. With the acquisition of Fameccanica we wish to further invest in a sector which has great growth potential and in which Italy has extraordinary resources. We are convinced that automation, innovation and robotics will be increasingly at the heart of profound change in industrial processes and will therefore represent a great growth opportunity for our Group.”

“The operation opens up a new stage in the history of Fameccanica,” comments Alessandro Bulfon, general Mmanager at Fameccanica –which will see the strengthening of our strategy of growth and leadership in the sector of single-use hygiene products, our historic stronghold, at the same time providing further drive to our diversification plans. I wish to thank P&G, which has participated in the growth and development of Fameccanica and will remain one of our key clients on all the main markets.” Regenerated-nylon -Polymer-business

With over 1200 lines of machinery delivered worldwide, over 600 active patents and 700 employees in three production facilities in Italy (San Giovanni Teatino, in the province of Chieti), China (Shanghai) and the U.S. (West Chester, OH), Fameccanica designs and develops technologies, robotics and services for the industrial production of fast-moving consumer goods, sustainable packaging, handling and automated recognition for logistics and digital services dedicated to process optimisation, with constant attention to sustainability and continuous innovation.

–ECONYL® Makes a Difference This Earth-Day + Beyond

–Angelini-Industries Takes Full Ownership of Fameccanica

–LyondellBasell sells Australia-polymer-business

–Technip-Energies & Alterra-Energy jointly developing sustainable-plastics-projects

-Exports of PTA-from-China increased by almost a third in February

–Evrnu Is Driving The Apparel-Sector To Embrace The Circular-Economy

–PP futures in China fell 1.5% amid weak demand and falling crude-oil-futures

–Dow plans to raise PE-prices in the US and Canada-in-May

Regenerated-nylon -Polymer-business