rPET-trays – Chemical-recycling-technology 07-06-2022 - Arhive

rPET-trays – Chemical-recycling-technology

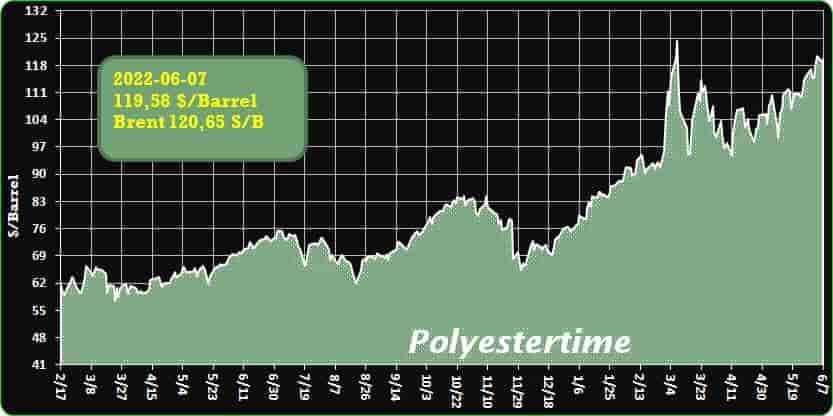

Crude Oil Prices Trend

The now-established phrase ‘From niche to must-have’ describes how plastics recycling has evolved in recent years. Faerch, as a Denmark-based plastic packaging manufacturer and EREMA customer, has contributed to this by becoming the first company in the world to successfully integrate the recycling of European post-consumer PET household pots, tubs and tray packaging into its own production process. rPET-trays – Chemical-recycling-technology

Faerch is recognised as a leading manufacturer of food packaging, largely made from PET thermoforming film well suited to many applications, especially in the food sector. Faerch produces trays for ready meals, fresh meat, takeaway meals and packaging for dairy products for well-known food producers and trading companies around the world. The packaging must meet the highest quality standards for direct contact with food, and must meet special functional criteria.

A closed loop for food trays

The trays Faerch produces are fully recyclable and, depending on the PET type (CPET, MAPET or APET), are made of up to 100 per cent recycled post-consumer PET (rPET). This is because in comparison to bottle-to-bottle recycling, where the circular economy has been established, closing the material loop of PET trays has lagged behind.

Christoph Wöss, Business Development Manager at EREMA Group GmbH, said: “For us it was clear that with purpose-specific modification of our flexible VACUREMA technology, tray-to-tray recycling could become just as much of a success story. Faerch was our first customer to be as convinced of this as we were.”

At Faerch’s Netherlands-based recycling plant 4PET, PET bales obtained from collection and sorting companies throughout Europe are sorted, washed and recycled. Both post-consumer rPET flakes and pellets are supplied to packaging manufacturers and reused in the company’s own production, making Faerch the only integrated recycler in the world capable of recycling used household PET packaging on an industrial scale and turning them back into new trays, according to Thomas Bak Thellesen, Senior Director Group Sustainability and External Affairs: “Trays from all over Europe are recycled to make 1.2 billion PCR PET trays per year.

The aim is to quadruple the recycling capacity within the coming years.

Without any compromises in terms of food contact compliance and functional properties, quality and sustainability must go hand in hand for us, because this is the only way we can offer our customers circular packaging solutions and drive the change necessary to establish an infrastructure needed to achieve a real circular economy.” rPET-trays – Chemical-recycling-technology

-Italy – Redundancy fund at Novamont di Terni

The company has decided to temporarily reduce the activity of the Polymer production center, where it produces bioplastics. The ordinary CIG has been requested since 1 July.

The Italian bioplastics producer Novamont has decided to temporarily reduce the production activity of the Polymer production center in Terni, placing workers on ordinary layoffs starting from next 1 July 2022 for a period that could last up to 13 weeks. rPET-trays – Chemical-recycling-technology

The company motivates the decision with the “persistence of a situation of strong uncertainty in the reference market and, despite the interventions implemented by the company to cope with the increase in the costs of raw materials and energy, the effects of war in Ukraine and the increasingly unsustainable situation of the site’s economic conditions “.

Going into more detail on the market difficulties, Novamont emphasizes the competition from fossil-based products with a high environmental impact, from Asia, sold “at prices that clearly suggest dumping actions” and the widespread illegality in the shopper and clothing market. products subject to the implementation in Italy of the SUP directive on disposable plastic products.

Novamont headquarters 400 The Novarese company also reports the perverse effect of the costs for the purchase of CO2 credits, which weigh on Novamont production, despite the fact that in 2021 the incidence of renewable raw materials reached 58% of production, with development of products whose significant contribution to decarbonisation is not considered for the purposes of calculating overall CO2 emissions. Especially considering that products of fossil origin from Asia do not have to pay any CO2 costs. rPET-trays – Chemical-recycling-technology

Finally, to worsen the situation, the situation of uncertainty is indicated for the entire bioindustries sector for the circular bioeconomy, “lacking a formal recognition that allows to identify the origin and economic and environmental value generated by the entire Italian supply chain”.

The Polymer site in Terni is Novamont’s main production center: it employs 124 people and produces biodegradable and compostable plastics Mater-Bi and Origo-Bi. Plants are also in operation in Bottrighe (RO) and Patrica (FR), while research laboratories are present in Novara, Terni and Piana di Monte Verna (CE). The Novara company also operates in Porto Torres through Matrìca, a 50/50 joint venture with Versalis (ENI).

–Italy – Redundancy fund at Novamont di Terni

-We can sort-plastic-waste, but when it comes to recycling…

–Germany’s chemicals hit hard by China lockdowns, automotive sentiment improves – Ifo

–World-Environment-Day: How are plastic-pet-bottles-recycled into clothing?

–Smart-coatings that perform innovative functions

–Caprolactam: upstream or downstream, long or short?

–Teijin-Frontier develops new chemical-recycling-technology for polyester-fibers

rPET-trays – Chemical-recycling-technology