Sustainability – Carbon Nanotubes -11-03-2023 - Arhive

Sustainability – Carbon Nanotubes

-STF America announces the sale of what will be the first PET bottle washing plant in the Dominican Republic

STF Group of Germany and Zimmer America Corp. announce the sale of an STF PET bottle washing plant in the Dominican Republic, the first of its kind in the country. The line will be installed at Cilpen Global Business s.r.l., a major waste and plastic recycler on the island.

The line has a capacity of 2.5 metric tons/hour (5,500 lbs/hr) output of PET flakes and features STF machinery manufactured in Germany, such as the screening trommel, label scraper, star screen, grinder, washing, drying, and flake separation machinery, as well as a complete water re-circulation system.

Installation of the line will begin in the first quarter of 2024.

STF Group is a leading manufacturer for plastic recycling and washing machinery, with more than 150 turnkey plants and many single recycling machines delivered worldwide. Furthermore, STF is the largest PET-recycler in Europe with more than 180,000 metric tons per year of in-house PET recycling.

-The hard work of balancing growth, sustainability

Plastics and chemicals firms are looking for ways to be sustainable while growing their businesses.

“Everyone wants to achieve sustainability goals and lower emissions,” David Yankovitz said March 1 at the Plastics News Executive Forum in Clearwater Beach. “They’re trying to figure out what part of the ecosystem they can control and what they can do to act on it.”

Yankovitz is a principal and U.S. chemicals market leader with consulting firm Deloitte Consulting LLP. He was joined at the event by Deloitte specialist executive Robert Kumpf.

“Chemicals are on the pathway to decarbonize and reduce dependence on fossil fuels,” Yankovitz said. “They’re critical to build a sustainable economy and reduce carbon while fueling growth.” Sustainability – Carbon Nanotubes

Kumpf cited market data that showed that consumer goods were the biggest end market for sustainable chemical solutions, with 31 percent of the market. Transportation was the second largest end market for those products at 21 percent, followed by construction at 15 percent.

“Suppliers need sustainable products and solutions in their portfolio,” said Kumpf, whose industry experience includes more than 20 years with Bayer MaterialScience, now Covestro. “Sustainability is already affecting material selection.”

He added that customers are looking at total emissions, recycling rates and how materials fit into the entire ecosystem. For example, in comparing polypropylene vs. polyurethane for rigid construction and insulation, PU performs better but under-performs in sustainability. As a result, suppliers have introduced new lower carbon PU grades and circular PP grades. Sustainability – Carbon Nanotubes

-Big gap exists between recycled plastic demand and supply – Dow CEO

An enormous gap exists between the amount of post-consumer recycled plastic that companies want to incorporate into their products and the amount that can be supplied by the market, the CEO of Dow said on Tuesday.

The owners of many valuable consumer brands want to incorporate 30% of post-consumer recycled plastic into their products by 2030, said Jim Fitterling, Dow CEO. He made his comments during the CERAWeek by S&P Global energy conference.

The market can provide 2-5% of that demand, he said.

That gap between demand and supply is causing an influx of money into waste management, municipal recycling centres, curbside collection and technology for sorting waste, Fitterling said. Sustainability – Carbon Nanotubes

Dow itself could build a chemical recycling plant with Mura in Bohlen, Germany, that will rely on hydrolysis to break down plastic into monomers, which can then be re-polymerised. They could make a final investment decision in 2023.

The demand for products made of recycled and renewable plastic has caused them to command high premiums over their petroleum-derived equivalents, Fitterling said. In some cases, these premiums could be $1,000/tonne.

Customers are willing to pay such premiums on a smaller scale but not in the broader market, Fitterling said. For example, most consumers will not pay a 100% premium to own a net-zero automobile, he said.

If policy makers want to speed up the transition towards more sustainable products, then Fitterling said they should consider establishing a price on carbon. This would allow companies to recover the operating costs and capital costs involved in developing sustainable products while the markets for such materials develop and while demand grows. Sustainability – Carbon Nanotubes

Given how much companies are willing to pay and how much is at stake, Fitterling stressed the need for third-party certification and verification. Companies that own valuable consumer brands do not want to face accusations of greenwashing if they end up with materials that were not made from recycled or renewable plastics or chemicals.

-Carbon Nanotubes, Polyimide Combine in High-Modulus Carbon-Fiber Reinforcement

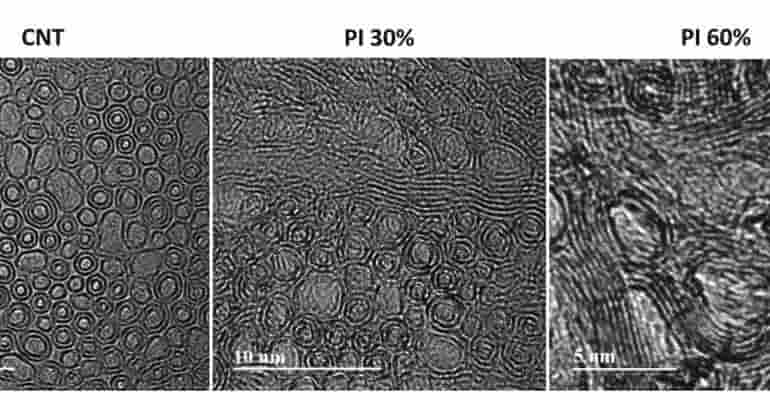

Korean researchers have developed a low-cost fabrication technology for carbon-nanotube-based composite carbon fibers with high modulus and tensile strength.

Carbon nanotubes (CNTs) are novel materials boasting 100-times the strength of steel at 75% less weight. Further, conductivity can be as high as that of copper. If fibers could be made using these CNTs, they theoretically could exceed the performance of existing carbon fibers, making carbon-nanotube-based fibers a novel material of interest for the aerospace, military, and mobility sectors. However, maintaining the outstanding properties of CNTs in fibers is very challenging and commercialization would be difficult because of the extremely high cost of carbon nanotubes. That may change thanks to research coming out of Korea. Sustainability – Carbon Nanotubes

A low-cost fabrication technology for CNT-based composite carbon fibers with high tensile strength and modulus has been developed by a research team led by Dr. Bon-Cheol Ku of the Korea Institute of Science and Technology (KIST) Jeonbuk Institute of Advanced Composite Materials in collaboration with researchers led by Professor Han Gi Chae from the Ulsan National Institute of Science and Technology (UNIST). The study was published in the journal Composites Part B: Engineering.

Carbon fibers are conventionally carbonized from polyacrylonitrile (PAN) polymer or pitch derived from pyrolyzed fuel oil. The researchers developed a technology that greatly improved the modulus while maintaining high strength by utilizing carbon nanotubes in conjunction with polyimide (PI) resin.

The Korean team successfully fabricated fibers with high modulus (528 GPa) and high strength (6.2 GPa) by initially creating a CNT-PI composite fiber using a continuous wet spinning process. Chlorosulfonic acid (CSA) is used as a solvent, and high-temperature heat treatment is applied during the process.

The modulus obtained was 1.65-times greater than that of commercially available fibers, which normally rate at around 320 GPa. Sustainability – Carbon Nanotubes

-BASF announces 2,600 jobs losses as it cuts costs in Europe

BASF has announced that it is taking additional cost cutting measures in Europe, primarily at its Ludwigshafen integrated chemical complex, which will lead to a net loss of 2,600 jobs.

This comes on top of previous plans BASF outlined in October to “permanently” cut costs in Europe to protect the company from weakening chemical market conditions in the region.

The company expects high levels of uncertainty that arose last year to continue due to factors including high raw materials and energy prices and the conflict in Ukraine. It also expects that the impacts of Covid-19 will continue to have an effect. To counteract the resulting negative impact on global demand it said it must make “concrete cost savings measures”. Sustainability – Carbon Nanotubes

Cost-cutting programme

Overall, the company plans to save €500m/y (US$528.8m/y) through a cost-saving programme in Europe – particularly in Germany – that it will implement from 2023 to 2024. In 2022 the continent accounted for 84% of a €3.2bn increase in energy costs, most of which was due to the vast integrated Ludwigshafen chemicals site. Higher natural gas costs accounted for 69% of the overall increase in energy costs, again primarily due to Europe and Ludwigshafen.

Changes include bundling services into hubs to simplify structures in divisional management, reducing business services, and increasing efficiency of research and development. The expected net loss of 2,600 jobs includes the creation of new positions in “particular hubs”, BASF said. Sustainability – Carbon Nanotubes

-NextChem further expands technological portfolio with strategic acquisitions

Buys majority stakes in Conser, Biorenova

Through its subsidiary NextChem Holding, Maire Tecnimont S.p.A. has acquired a majority interest in Conser, a technology licensor and process engineering design company based in Rome, Italy.

Upon closing, NextChem Holding will hold 83.5% of the shares in Conser and, under the terms of the agreement, also has an option to retain the remaining 16.5% within the next 3 years.

The closing, which is subject to customary conditions, is expected to take place by April 15, 2023. The terms of the transaction were not disclosed.

The transaction is a strategic one, enabling Maire Tecnimont to expand into the market for bio-based technologies and products. Conser has a portfolio of patented technologies for maleic anhydride, butanediol and dimethyl succinate, the building blocks for producing biodegradable plastics such as polybutylene succinate (PBS) and polybutylene adipate co-terephthalate (PBAT). Sustainability – Carbon Nanotubes

PBS and PBAT have excellent biodegradation properties, and their relevant consolidated markets show very promising outlooks driven by a growing demand, especially in Asia, where Conser has licensed more than half of the plants in the region in the last year for several leading global players.

Conser’s portfolio also includes technologies for liquid organic hydrogen carriers, specialties for lithium-based batteries production and bio-based (vegetable glycerine) derivatives.

-RECOUP launches LCA service and unveils new lab to test materials

Plastics resource efficiency and recycling charity RECOUP is to introduce a lifecycle assessment (LCA) service and its own state-of-the-art laboratory.

The move is designed to complement its RecyClass certification service and facilities. RECOUP said that the use of LCA can offer evidence-based decisions on product development. The aim is to improve environmental outcomes and challenge greenwash.

Katherine Fleet, head of sustainability and circularity said: “RECOUP has been working on building LCA capability to assist members and the wider industry to better inform decision making related to product design in order that decisions are based on environmentally sound evidence rather than emotion.” Sustainability – Carbon Nanotubes

The addition of the lab will allow RECOUP to further enhance its testing of plastic samples and material identification. In addition, the lab uses near-infrared and Fourier transform infrared spectroscopy to identify the constituent components of a pack and help determine recyclability.