Sustainability Microfiber Automotive Spandex 23-10-2021 - Arhive

Sustainability Microfiber Automotive Spandex

-Coca-Cola unveils prototype bottle made from 100% plant-based sources

The Coca-Cola Company today revealed its first prototype bottle made from 100% plant-based plastic (bPET), produced using technologies that the company says are now ready to be commercially scaled across the industry.

This builds on Coca-Cola and UPM’s technological breakthrough announced earlier this week for the first planned commercialization of technologies to convert second-generation biomass to plant-based monoethylene glycol (bMEG), one of two molecules necessary to create bPET. The other molecule used is PTA, comprised of bPTA and Virent’s bPX.

The new prototype announced today (barring its label and lid) exclusively uses materials from renewable, plant-based sources, removing all petroleum-based content from the bottle. According to the company, it represents a significant technological step forward in the reduction of virgin oil-based PET across commercially produced bottles.

A limited run of approximately 900 of the prototype bottles has been produced. Coca-Cola says that the pack is recyclable and can be recycled bottle-to-bottle within existing recycling infrastructures, alongside PET from oil-based sources.

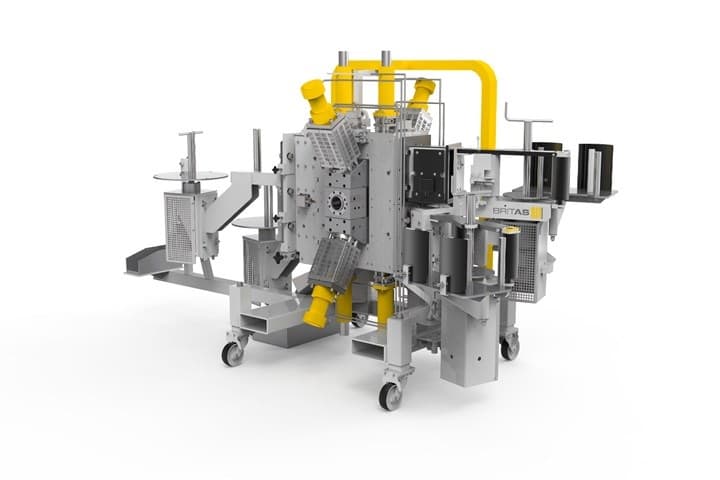

-Fakuma: BritAS Introduced New Melt Filter for Contaminated PET

The technology is suitable for post-consumer plastic waste, focused on PET as well as PET-similar materials.

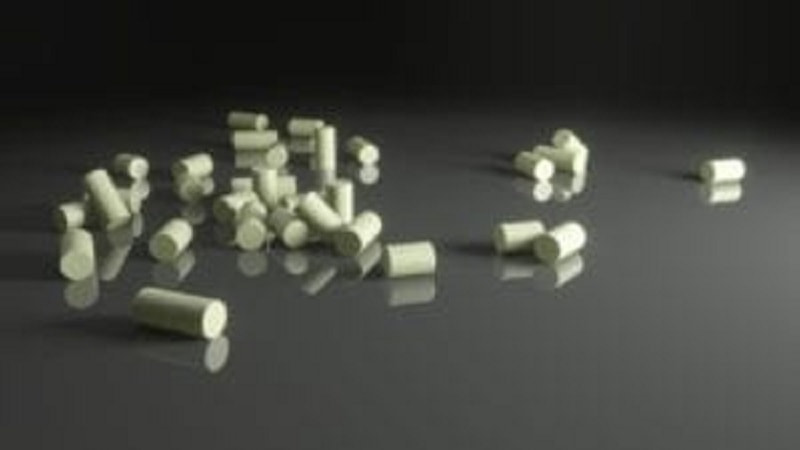

During Fakuma 2021, BritAS introduced its new ABMF PET-C, a melt filter for contaminated PET. The ABMF PET-C relies on the established BritAS basic technology and is equipped with special features while also being technically optimized. The filter is especially suitable for underwater as well as strand pelletizing, the company stated.

In order to filter contamination out of plastic waste effectively and efficiently, during each filter change, a clean screen mesh is inserted automatically and without production stop. Up to three screen belts can simultaneously be inserted, which reportedly allows an exact adjustment of different filter fineness. This keeps the quality of the re-granulate constantly high and the contamination is removed out of the machine with a very low melt loss. It features a filter fineness of up to 20 μm and melt loss of <1.0 %.

The technology is suitable for post-consumer plastic waste, focused on PET as well as PET-similar materials. Sustainability Microfiber Automotive Spandex

In combination, the filter mechanics and control offer a fully-automatic, practical operation in double-cavity mode, which does not require any temporary storage of the melt. During the screen movement, the extruder is not stopped and ensures process safety.

-NEXTLOOPP unveils results of tracer-based sorting trials

NEXTLOOP, the PP recycling project led by Nextek Limited, has announced that its trial to sort food-grade plastic packaging waste using a label marker achieved 99.9% sorting purity at maximum production speed.

The trial, which took place at the Germany-based TOMRA test centre in September 2021, is part of NEXTLOOPP’s programme to develop new recycling initiatives for food-grade polypropylene (FGPP). NEXTLOOPP’s PolyPrism ‘plug-and-play’ marker system was used on TOMRA’s sorting equipment for commercial purposes, enabling it to be validated at the test site.

The PolyPrism technology is intended to differentiate food packaging from non-food packaging to meet standards required by the Food Standards Authorities in the UK and EU. This is achieved using an invisible marker on the label, which can apparently be identified by optical detectors and sorted at high speeds with air jets.

According to NEXTLOOPP, the technology can identify variations – such as between a milk bottle and a bleach bottle – in plastic packaging at a maximum production speed of more than two tonnes per hour.

Ralph Uepping, technical director at TOMRA, comments: “During recent trials held at our TOMRA Test Centre, we achieved very promising results on all polypropylene 3D samples in all test runs with state-of-the-art NIR/VIS technology.

“We exceeded the required 95% purity for food-grade in each test run.”

For the First Pass, 99.3% purity of sorted packs was achieved, while the Second Pass gave the 99.9% figure.

Uepping addS: “The next important milestones will be a field demonstration as well as demonstrating chemical compliance with food-grade regulation.”

NEXTLOOPP adds that the next step in its goal of creating a low carbon, circular economy for plastics is its patented decontamination process, PPristine, which should enable sorted and recycled plastics to be reintroduced to food packaging streams.

-Lithuania’s life sciences sector is on the rise

Why do large companies and start-ups choose the Baltic country for their R&D?

During the past couple of decades, the Baltic States have transformed their economies significantly, shifting towards innovative, high value-added industries and increasingly focusing on technologies, information and science sectors. One of the most striking examples of that is the rise of Lithuania’s life sciences industry, which is gaining a lot of momentum and attracting more and more attention internationally.

Fast growing hub of innovation

In 2020, Lithuania’s biotechnology sector grew by almost 87% in terms of revenues, while the country’s life sciences sector grew by an annual average of 22.1% between 2011 and 2016. In 2019, the World Economic Forum recognised Lithuania as the best place for R&D in Central and Eastern Europe, and the capital Vilnius is one of the fastest growing innovation hubs in Europe. Sustainability Microfiber Automotive Spandex

Today Vilnius hosts biotech giants, such as Thermo Fisher Scientific and Biogen, as well as an expanding number of life sciences start-ups, such as Biomatter Designs, Droplet Genomics and Diagnolita. These companies (and their investors) value the opportunity to collaborate with Lithuania’s strong life sciences research centres and access its distinctive modern research infrastructure, in which more than €400 million has been invested in the past few years alone. Overall, Lithuania’s life sciences sector today is comprised of more than 400 companies and 5,000 people working in such areas as molecular biology, biophysics, genomics, bioinformatics and biomedicine.

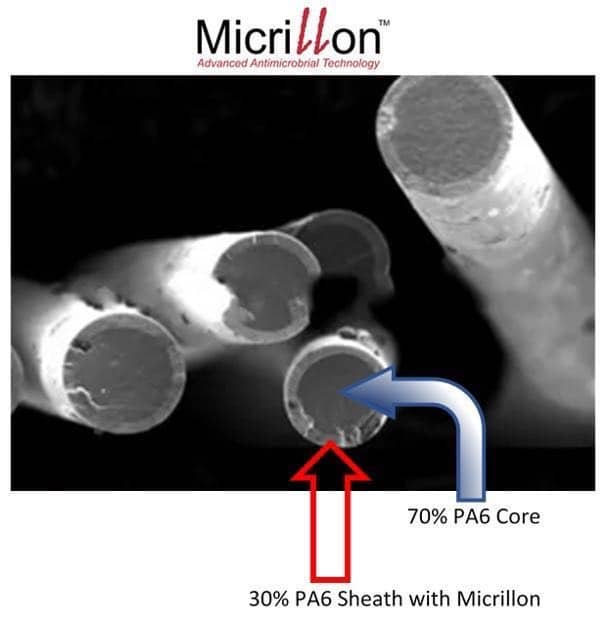

-UMF Corp Micrillon® Microfiber Eliminates Recontamination Risk

UMF Corporation ‘s Micrillon® microfiber, made in the USA, is setting a new standard as the first hospital-grade microfiber that can be converted into a wide range of long-lasting, reusable products, including: towels; cubicle curtains; socks; gloves; walk-off mats; reusable N95 rated face masks; and color-coded microfiber cleaning products. Leading manufacturers are using these high performance microfiber yarns to develop a new standard for materials targeting infection prevention in hospitals, hotels, cruise lines, long term care, and many other industries, according to a news release.

“The introduction of Micrillon microfiber puts an end, once and for all, to any question about recontamination related to reusable products,” said UMF Corporation CEO George Clarke. “Some manufacturers and distributors of disposable products – including cubicle curtains, microfiber mops, and wipers – have generated controversy around the risk of reusable products, such as microfiber wipers, recontaminating a patient room, even after being laundered. This illusive thinking ignores the fact that after laundering, wipers used in hospitals are immersed in an EPA-registered disinfectant before use – effectively killing bacteria and inactivating viruses.” Sustainability Microfiber Automotive Spandex

Micrillon Microfiber Yarns

Micrillon is a rechargeable polymer additive that can be incorporated into manmade fibers, films, and plastics and then charged with chlorine molecules. The Micrillon chemistry recharges for the life of the product, and will not leach into the environment. When microbes come into contact with a Micrillon surface, they are eliminated; viruses are inactivated.

UMF’s series of high-performance Micrillon yarns, including sheath and core, bicomponent segmented pie, and hollow core segmented pie, demonstrate significant antiviral properties against Human Coronavirus, which causes COVID-19, and Human Influenza A H1N1 virus in just minutes. Micrillon also demonstrates 100 percent antibacterial elimination of Staphylococcus aureus (MRSA) and E. coli 0157:H7, according to the release.

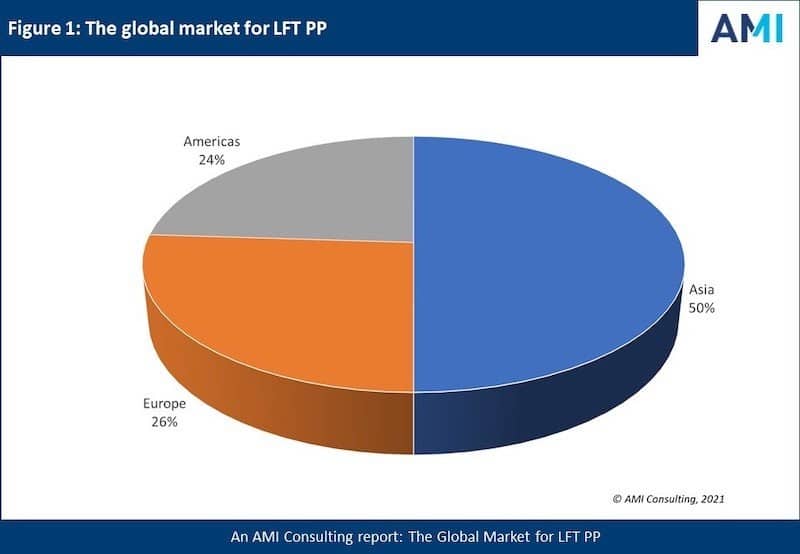

-AMI Consulting: Automotive LFT PP demand rising

According to a report published by industry experts AMI Consulting, market penetration for Long Fibre Polypropylene (LFT PP) is rising.

The new report quantifies the use of both granule LFT PP (LFT-G) and direct in-line compounding LFT PP (LFT-D) tracking its use around the world. The result is a comprehensive analysis of LFT PP by application, OEM, producer and geographical region. The key metric in the report is kg/vehicle which allows the disaggregation of volatile car production numbers from underlying usage trends.

LFT PP is used widely in automotive front-end carriers, instrument-panel carriers, door-panels, consoles, pedals, under-body shields and many other applications. A feature of many of these applications is that LFT PP replaces steel and thereby reduces weight or replaces more expensive engineering plastics.

AMI Consulting is forecasting strong growth of LFT PP through to 2025. Some applications are growing much faster than others and some OEMs are adopting LFT PP more rapidly than others. Sustainability Microfiber Automotive Spandex

One of the fastest growing adopters since the last edition of this report in 2017 has been Fiat-Chrysler, which now is part of Stellantis, since merging with PSA earlier this year. The company is at an early stage of bringing together its engineering and materials expertise.

One of the fastest growing applications is liftgates where designs range from extensive use of metal to virtually no metal at all. In the metal-free designs LFT PP is used to provide structural strength and is complemented with high performance PP to provide the paintable exterior skin. In the most demanding applications, the structural interior LFT PP elements are neither covered nor painted so good is the aesthetic finish. Plastic liftgates are particularly valuable to EVs as a new way of saving weight.

-DOST-PTRI researchers develop greener bamboo textiles

Bamboo textiles have become increasingly popular as part of a sustainable and eco-friendly solution to textile materials and manufacturing.

It is along this line that the DOST, through its Philippine Textile Research Institute (DOST-PTRI), develops sustainable technologies to create greener bamboo textile materials.

The DOST-PTRI bamboo fiber extraction technology, already applied for intellectual property protection with the Intellectual Property Office of the Philippines (IPOPhil), was first developed in 2015.

It includes the mechanical, chemical, and biological processes to liberate the fibers from the bamboo culm. The extracted bamboo textile fiber is treated to obtain highly cellulosic textile fibers while preserving the inherent properties of bamboo such as antimicrobial and UV-blocking properties.

The technology, applied to natural extraction of different Bamboo species in the Philippines such as kawayan tinik (Bambusa blumeana), bolo (Gigantochloa levis), yellow bamboo (Bambusa vulgaris), and giant bamboo (Dendrocalamus asper), produces strong and fine bamboo fibers.

The considerably mild and eco-friendly technology coupled with the simplicity of the extraction and treatment technique makes it highly suitable for textile fiber processing in remote bamboo-rich local areas leading to economic gains for the bamboo textile industry.

-Clariant Catalysts & Lummus Technology expand CATOFIN® footprint with India’s first PDH plant

- GAIL (India) Limited to build the country’s first propane dehydrogenation (PDH) plant with CATOFIN technology

- CATOFIN catalysts and technology are quickly becoming a popular choice for PDH globally

- Benefits include significantly higher productivity, reliability, and return on investment

Clariant Catalysts and its process partner, Lummus Technology, continue to expand their presence in the PDH market with a major contract award in India. GAIL (India) Ltd. has chosen Lummus Technology’s CATOFIN process and Clariant’s tailor-made catalysts for India’s first PDH plant. Its upcoming 500 kiloton per annum propane dehydrogenation facility in Usar, Maharashtra, will be integrated with a downstream polypropylene (PP) unit. The US$1.2 billion PDH-PP project is expected to start operations by 2024.

Since 2017, CATOFIN Technology has now been selected for a majority of new PDH awards globally, representing 32 new PDH plants, or more than 22 million metric tons of propylene annually. Sustainability Microfiber Automotive Spandex

Stefan Heuser, Senior Vice President and General Manager of Clariant Catalysts, stated, “We are extremely proud of the ever-increasing global demand for CATOFIN – and we couldn’t have achieved this without our long-time partner, Lummus Technology. Thanks to our collaboration, we are able to offer GAIL (India) Ltd excellent performance and profitability by combining the best of PDH expertise with catalyst innovation.”

-Spandex market witnesses stabilizing price & improving sales after Dual Control

Prices of raw materials of textiles and apparels advanced obviously impacted by the Dual Control of energy consumption. Price of polyester, nylon, cotton and cotton yarn hiked since late-Sep, with increment at 4.1%-28%. Price of mainstream spandex 40D soared as high as 106% in Jan-Aug and hit 13-year high but shivered at high level in end-Q3 and early-Q4. However, sales of spandex improved before and after the National Day holiday (Oct 1-7) impacted by the regulation of energy consumption.

Price of mainstream spandex was largely stable amid the regulation of energy consumption and some sellers discounted price for promotion with high stocks. Most downstream buyers showed higher rigid demand for spandex. Some large customers slightly increased replenishing. Price of spandex stopped falling and stabilized recently. Sales of spandex improved in the first half of Oct but slightly slowed down from this week.

Firstly, from the perspective of supply, impacted by the regulation of energy consumption, the production of spandex and the launch of new spandex units will have uncertainty.

The Dual Control of energy consumption affects most major spandex production bases, covering near 80% of spandex capacity in China.

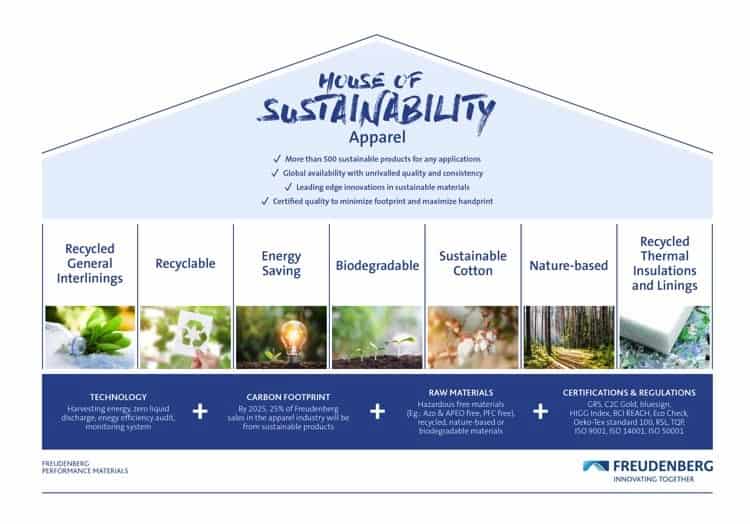

-Freudenberg unveils House of Sustainability

Freudenberg Performance Materials Apparel has launched its House of Sustainability, a new initiative designed to assist customers in enhancing the sustainability of their products. Sustainability Microfiber Automotive Spandex

With this initiative, Freudenberg says it is making its entire portfolio of sustainable solutions visible and transparent with customers able to find more than 500 sustainable and innovative solutions for a comprehensive range of applications in the apparel industry.

“Sustainability is a mission and driving force for us,” said John McNabb, chief technology officer, Freudenberg Performance Materials. “We initiate sustainable programs at global and regional level and are constantly innovating globally available sustainable solutions. Many examples bear witness to our forward-looking efforts. To name just a few highlights, we are, for example, pioneers in recycling PET bottles, and commissioned our first recycling plant back in 1991. We developed the first biodegradable nonwoven interlinings in 1995. And today, we recycle more than 2.5 billion post-consumer PET bottles per year.”

The foundation for the Freudenberg House of Sustainability is made up of four elements: Certifications & Regulations, Raw Materials, Technology and Carbon Footprint along with support for seven pillars

The 4 elements making up the foundation are

Certifications & Regulations – Freudenberg is certified to definitive standards. These include the following: BCI, bluesign, C2C Gold, ECO-CHECK, Global Recycled Standard, Higg Index, ISO 14001, ISO 50001, ISO 9001, Standard 100 by OEKO-TEX, REACH and Restricted Substances List.

Raw Materials – Freudenberg uses sustainable raw materials to develop solutions. These materials are, for example, free from environmentally harmful substances (Azo & APEO, PFC), recycled, natural-based or biodegradable.

Sustainability Microfiber Automotive Spandex