Sustainability Plastic Recycling PETG 04-11-2021 - Arhive

Sustainability Plastic Recycling PETG

Crude Oil Prices Trend

-Emerson to Provide Advanced Automation Technologies for Revolutionary Plastics Recycling Plant

ReNew ELP, a UK-based advanced recycling company, has selected Emerson as its digital automation partner for its new plastics recycling plant in Teesside, north-east England. Emerson’s advanced automation technology and software will help achieve safe, efficient operation of an innovative hydrothermal process to convert end-of-life plastics back into their original feedstock to produce new plastic products, reducing waste and pollution.

Currently, many post-consumer plastics, including flexible and multi-layer plastic packaging items, such as films, pots, tubs and trays, are considered ‘unrecyclable’ via traditional mechanical recycling methods and are instead sent to landfill or incinerated. After a short first-use cycle, 95% of plastic packaging material value, or $80-120 billion annually, is lost to the economy, according to the World Economic Forum.

“By converting end-of-life plastics into fossil-replacement feedstocks, ReNew ELP has the potential to eliminate unnecessary single-use plastic and make the raw ingredients for a circular plastics economy, creating value instead of waste,” said Richard Daley, managing director, ReNew ELP. “Pivotal to achieving these goals is the construction of this first commercial-scale plant using a unique hydrothermal platform, and in Emerson we have found a valuable, long-term partner to create an advanced automation model for further plants planned across Europe.”

-SABC group announces XAF5 bln investment to boost its glass producing capacity

Société anonyme des brasseries du Cameroun (SABC) announces that it is planning to invest an estimated XAF5 billion to renovate its furnace n°1 (on line 11) and acquire a third PET preform line for glass factory Socaver (Société camerounaise de verrerie).

According to the SABC, the investment aims to boost Socaver’s production capacity. Meanwhile, the weighbridge being installed will help improve “internal circulation given the production load that has been growing over time.” Sustainability Plastic Recycling PETG

As per SABC’s estimates, the furnace n° 1 should become operational by late 2023 while the third PET preform line will start operations by April 2022. Without revealing details about the additional production volume to be gained by Socaver thanks to the investments, SABC stresses that the projects are launched in a bid to meet commercial partners’ ever-growing demand, which is now up by 15,000 tons.

-SK Chemicals Mass-produces PETG from Chemically Recycled Material

South Korean chemical company SK Chemicals Co. said Tuesday it had launched the mass production of ECOTRIA CR, a polyethylene terephthalate glycol (PETG) copolyester product that is made from chemically recycled material, for the first time in the world.

The company started mass-producing ECOTRIA CR at its Ulsan plant using the materials derived from chemically recycled waste plastics.

The company will be supplied with 20,000 tons of such materials per year from Chinese company Shuye Environmental Technology Co.

SK Chemicals plans to churn out more than 10,000 tons of ECOTRIA CR by next year and supply it to major cosmetics brands in and outside of Korea.

Chemical recycling refers to the process in which waste plastics are decomposed into their pure material state and then used for the production of high polymer plastics.

Compared to physical recycling methods, in which waste plastics are pulverized and processed, this method prevents the deterioration of product quality while enabling recycling in a repeated manner. Sustainability Plastic Recycling PETG

-China and Russia revive push to lift UN sanctions on North Korea

China and Russia are pushing the United Nations Security Council to ease sanctions on North Korea, reviving a similar previous attempt that had flailed in 2019.

The two countries filed a reworked draft resolution, seen by Reuters on Monday, that proposes removing a ban on Pyongyang’s exports of statues, seafood and textiles, as well as lifting a cap on refined petroleum imports.

China and Russia want the 15-member council to remove those sanctions “with the intent of enhancing the livelihood of the civilian population” in the isolated Asian state, according to the resolution. Sustainability Plastic Recycling PETG

North Korea has been subject to UN sanctions since 2006 over its nuclear and ballistic missile programs.

The draft resolution also includes other measures first proposed by Russia and China nearly two years ago, including lifting a ban on North Koreans working abroad and exempting inter-Korean rail and road cooperation projects from sanctions.

Several UN diplomats, speaking on condition of anonymity, said the refreshed draft resolution would find little support. In 2019 Russia and China held two informal rounds of talks on the draft resolution, but never formally tabled it for a vote.

Diplomats said on Monday that China and Russia have not yet scheduled any talks on their new draft resolution. A resolution needs nine votes in favor and no vetoes by the United States, France, Britain, Russia or China to pass.

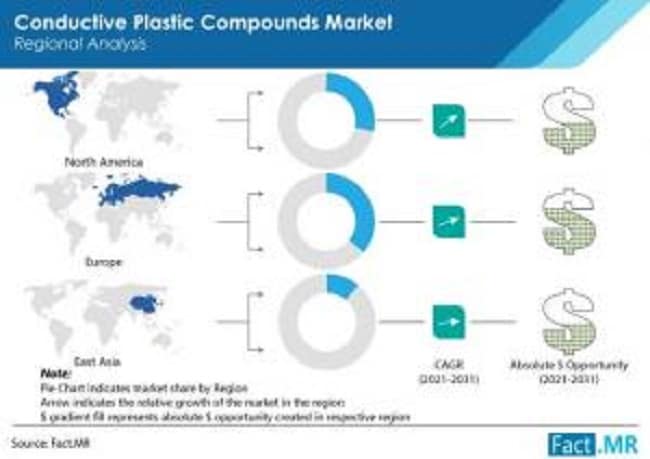

Demand for conductive plastic compounds to surge across regions. Fact.MR explores key trends in moderate- and high-growth markets.

As per the report published by Fact.MR, the conductive plastic compounds market is anticipated to surpass US$ 20.5 billion by the end of 2031, and is poised to expand at a CAGR of around 11% over the next ten years.

Conductive plastic compounds having properties such as electrostatic discharge and electromagnetic shielding have elevated the sales of during the past half-decade and is expected to rise during the assessment period.

Medical industry is rapidly growing and new advanced devices are being introduced continuously. As the use of conductive plastic compounds particularly which are made from carbon nanotubes fillers has seen an increase in recent years and is set to showcase promising growth owing to mounting healthcare industry.

Sales of conductive plastic compounds in electric & electronics industry is seeing fastest growth compared to other industries due to their unique product attributes. These compounds are finding use in many electrical components and electronic devices, the compounds are also used as covers for electric components. Electric & electronics industry is expected to grow at substantial rate which in turn will provide influential boost to the sales of conductive plastic compounds. Sustainability Plastic Recycling PETG

-Ahlstrom-Munksjö expands Reliance brand

Ahlstrom-Munksjö has expanded its Reliance portfolio to now include its historical Dextex range of wetlaid nonwoven sterilization wraps.

Ahlstrom-Munksjö’s sterile barrier systems are designed to offer excellent bacterial barrier thanks to cellulosic fibres that create a tortuous path for excellent sterility maintenance of surgical instruments up to the point of use. The high-performance sterilization wraps also play a key role in the prevention of hospital-acquired infections, protecting patients’ health.

Dextex wetlaid sterilization wraps have a long history of use in the sterilization industry and are well recognized throughout the globe for their reliable performance. In an effort to facilitate its customers and help their businesses succeed, Ahlstrom-Munksjö has now decided to harmonize the portfolio in the United States under its globally recognized Reliance brand. The move will see a name change for its sheeted wetlaid sterilization wrap products manufactured at the Medical business plant in Windsor Locks and sold in the United States to Reliance Dextex.

In addition to sterilization wraps for terminally sterilized medical devices, the Reliance Dextex brand includes overwrap for single use Custom Procedure Trays (CPT) and tray liners for moisture absorption and protection of the tray.

“The Dextex brand joins our current Reliance Solo and Tandem brand of SMS sterilization wraps and reflects one of the most technologically diverse portfolios of sterile barrier systems in the industry.

-NAPCOR 2020 PET recycling report shows decline in fiber end market

The amount of recycled PET for end-market use increased by 800 million pounds from 2010 to 2020, according to the report.

The National Association for PET Container Resources (NAPCOR), Charlotte, North Carolina, has released its “2020 PET Recycling Report,” which marks its 26th edition of the annual report.

According to the report, the amount of recycled polyethylene terephthalate (rPET) used by end markets in the U.S. and Canada increased by 10 percent, signaling strong support of postconsumer content in brand packaging.

RPET use by the Food/Beverage and Non-Food/Beverage Bottle categories grew by 32 percent in total, surpassing fiber for the first time as the primary user of postconsumer PET bottles. Sustainability Plastic Recycling PETG

Additionally, from 2010 through 2020, rPET consumption in U.S. and Canadian markets has grown from 1 billion pounds to 1.8 billion pounds.

“This continued increase of postconsumer rPET usage in bottles and jars is encouraging and points to a commitment toward a circular economy by brand owners,” says Tom Busard, NAPCOR chairman and chief procurement officer for Plastipak Packaging Inc. of Plymouth, Michigan, and president of Clean Tech, Plastipak’s recycling affiliate.

NAPCOR says its analysis shows the higher market demand outpaced collection, which drove PET reclaimers to rely more heavily on imports after depleting their existing inventories.

Thanks to enhanced performance, Sidel’s Super Combi Compact complete water line opened the door for more business opportunities for Zulal Water Factory, in Sharjah, UAE (Zulal). Running at up to 45,000 bottles per hour (bph), the line not only delivers increased productivity by 280%, but also helps the company save 56% on energy costs, when compared with their existing PET line. In addition, with the new, lighter PET bottle and optimisation of utilities, there has been a considerable reduction in the overall carbon footprint.

Zulal was established by H.H. Sheikh Dr. Sultan Bin Mohammed Al Qasimi, Supreme Court Member, and Ruler of Sharjah, which is part of SEWA (Sharjah Electricity and Water and Gas Authority) in the UAE. The company’s vision is to provide clean, pure drinking water for all people in the region. In 1995, Zulal was the first government organisation to address this requirement. It is the only water enterprise that provides 100% pure groundwater directly from the Hamdah wells in Sharjah. The water is certified by international standards and packed according to the highest international standards for packaging drinking water.

The connection between Zulal and Sidel can be dated back to the late 1990s, when Zulal first installed a Sidel blower. In 2019, the company reached out to Sidel again for a new high-speed line to meet market demand. As a complete line solution provider, Sidel consulted the customer on packaging design and line capacity, as well as line design and layout to enhance the overall performance.

-UniteChem expands its portfolio of high-performance light stabilizers

Dusseldorf, Germany, November 3, 2021 – UniteChem Group, the world’s leading supplier of light stabilizers for plastics in a broad range of high-end industrial applications, has recently started full-scale production of advanced high-performance light stabilizers UniteChem LS2020 and LS119 in its newly commissioned production facilities.

“UniteChem Group began producing industry-standard light stabilizers such as UniteChem LS944 in 1997 and has been continuously expanding its polymer additives portfolio ever since”, says Junyi Lin, CEO of UniteChem Group. “Today, we are proud to be among the world’s largest-capacity suppliers of light stabilizers and other plastic additives, offering over 40’000 tons of finished products. Our full backward integration with a production capacity of over 80’000 tons of intermediates provides extensive production flexibility, high reliability, and maximum quality control. Current production, located in two state-of-the-art production facilities in Jiangsu province, is now in process of being complimented with two new major production facilities in Jiangsu and Sichuan provinces, with completion in 2022/23.” Sustainability Plastic Recycling PETG

UniteChem LS2020 is a modern HALS (hindered amine light stabilizer) offering excellent anti-aging properties in applications such as cross-linked polyethylene, olefin copolymers and other polymer materials. UniteChem LS119 is especially suited for use in polyethylene greenhouse film applications, polypropylene fibers, TPO automotive parts as well as other polymers such as EVA, EPDM, PA, PET and PMMA. With these product additions, UniteChem Group further enhances its commitment to offer customers the most up-to-date and value-added product portfolio.

Sustainability Plastic Recycling PETG