Sustainable-textile – Carbon-neutral-H2 14-01-2023 - Arhive

Sustainable-textile – Carbon-neutral-H2

-MEG prices rise in Asia amid ongoing supply cuts

Spot prices for monoethylene glycol (MEG) in Asia rose above USD500 a tonne on Tuesday for the first time in three months as major producers continued to reduce production load amid persistently low margins, ICIS said.

The deals were concluded at a price of USD500-505 per ton, CFR (cost and freight) CMP (china’s main ports), market sources said. Since October 11, 2022, meg has been trading below USD500 per tonne amid rising supply and weak demand in China.

In the futures market, MEG rose more than 2% on Tuesday as some Chinese MEG producers considered switching to ethylene oxide production due to low profitability.

A major producer from Northeast Asia has no plans to reopen its two MEG production lines in the near future if profitability remains low. Sustainable-textile – Carbon-neutral-H2

Meanwhile, the recent strengthening of the Chinese yuan against the U.S. dollar has also boosted buying sentiment towards MEGs, market sources said.

However, most market participants are concerned that the uptrend may not continue due to a slowdown in demand ahead of the week-long lunar New Year celebrations on January 21-27.

Earlier it was reported that the January contract price of monoethylene glycol (MEG) in Europe was agreed at the level of EUR790 per ton, which is EUR60 per ton less than in December. The price was agreed on the terms of free shipping (FD) in Northwest Europe (NWE). The December contract price of MEGs in Europe was agreed at EUR20 per tonne lower compared to November.

According to the ScanPlast review, in January-November 2022, the estimated consumption of PET in Russia amounted to 758.69 thousand tons, which corresponds to consumption for the same period a year earlier.

Compared with November 2021, total estimated consumption increased by 4% and amounted to 78.77 thousand tons against 75.44 thousand tons last year.

-Germany’s Heimtextil 2023 explores sustainable textile innovations

The ongoing Heimtextil 2023, which will continue until January 13, 2023, offers a global stage where textile sustainability is holistically mapped—with products that are both scalable and sustainable innovations. The international trade fair for home and contract textiles features 2,400 exhibitors, an exhibitor internationality level of 94 per cent, and participants from more than 120 countries.

“Over the next four days, Heimtextil is the place where supply chains are rethought, circular approaches are experienced, and green innovations are condensed. This shows that trade shows are a business model with impact for global partnerships and the environment,” said Detlef Braun, member of the executive board of Messe Frankfurt, in his opening speech. Sustainable-textile – Carbon-neutral-H2

Panelists Caroline Till, director and co-founder FranklinTill Studio; Professor Dr. Anabel Ternès von Hattburg, futurologist and executive director of the International Institute for Sustainability Management; and Olaf Schmidt, vice president for textiles and textile technologies of Messe Frankfurt, discussed the transformation towards sustainability from several perspectives under the moderation of Alexandra Bohn, style content director of Frankfurter Allgemeine Zeitung Quarterly.

The panel on materials, supply chains, and social responsibility highlighted how sustainability can be experienced holistically as a cross-cutting theme at Heimtextil.

Are entire collections produced in an environmentally compatible way? Do sustainability strategies include social responsibility? The one-hour Green Tours provide answers to these questions and enable an intensive exchange between visitors and exhibitors—led by independent sustainability expert Bernd Müller on behalf of Consulting Service International Ltd.

Heimtextil exhibitors are also increasingly focusing on transformation strategies that take into account multiple Sustainable Development Goals (SDGs). These include innovative sustainable product designs—from fibres made of PET to linen in combination with other natural fibres such as hemp to bed linen made of cotton coated with cork.

Heimtextil Trends 2023 ‘Textiles Matter’ by Franklin Till brings four ways of circular economy to life and gives the market impulses for sustainable development. In the panel talk, Caroline Till, member of the Heimtextil Trend Council, showed how the foundation for circular economy is laid during product development. This, she said, requires conscious decisions at the beginning of the design process and looking at waste as a resource. She also stressed the importance of collaborations between experts and keeping an open ear for different disciplines—from young designers to material engineers.

Heimtextil 2023 covers the entire range of home and contract textiles: from coupon business to retail volumes to high-volume orders. Buyers—including retailers and wholesalers, furnishing houses, interior decorators, designers, architects, or hotel decision-makers—can find new business contacts, redefine supply chains together with suppliers, and experience a bundled holistic market overview of textile trends over the four days of the fair. Sustainable-textile – Carbon-neutral-H2

In 2023, the leading international trade fair for home and contract textiles is responding even more strongly to the growing demand in the field of fibres and yarns by offering a dedicated section for the first time—including new suppliers who are expanding the global range of upholstery and decorative fabrics as well as leather and imitation leather, said the event’s organiser Messe Frankfurt.

In addition, Heimtextil is once again covering a wide range of functional contract textiles, such as those that are water-repellent, flame-retardant, recyclable, antimicrobial, or thermoregulating, with the “Interior.Architecture.Hospitality” programme aimed at interior designers, architects, planners, and furnishers. For textile professionals hungry for knowledge, there will be numerous Lectures, special presentations, and guided tours. This includes a new edition of the Interior.Architecture.Hospitality Library: a curated selection of exhibitor products that feature special functional properties. Expert talks, selected exhibitor products, and exchanges with the industry combine the new Interior.Architecture.Hospitality Talks & Tours.

In addition to sustainability, the focus will be on design topics. Another highlight is the continuation of the Heimtextil Conference Sleep & More. Leading speakers will talk about the prerequisites for good sleep, sustainable solutions in the retail sector, and digital gadgets. Due to the positive response to the Green Tours, the Sleep tours on smart bedding innovations will be launched and led by sleep expert Markus Kamps of Schlafkampagne. Sustainable-textile – Carbon-neutral-H2

The Green Village—the platform for seal providers and certifiers—has been expanded from this year to include exhibitors who are fully committed to sustainability. Under the motto ‘Textiles Matter,’ visitors can experience decisive approaches to the circular economy.

The construction of the entire trend area is based on the Heimtextil Material Manifesto: only local, environmentally friendly or borrowed materials should be used for stand design. The green offering at Heimtextil is mapped by the Green Directory, which identifies sustainable exhibitors and their certified products online and at the booth. The one-hour Green Tours bring trade visitors together with selected exhibitors and enable exchange on sustainable developments—guided by an external expert. Independence sets the Green Tours apart and brings an important outside perspective.

The special denim show Tones of Freedom by the Frankfurt School of Clothing and Fashion is presenting a young collection by students of the School of Design at Heimtextil 2023. The creations deal with the diverse aspects of denim and jeans in a cultural context. Ten models in collaboration with Heimtextil exhibitors will show visions of body positivity in the special presentation titled ‘Embrace new horizons’. Sustainable-textile – Carbon-neutral-H2

-Halogen-free Flame-Retardant Additive Introduced for PC Film

Ultra-thin polycarbonate (PC) film containing a low dosage of the additive achieves UL 94 V-0 certification.

CAI Performance Additives has introduced a halogen-free flame retardant for polycarbonate (PC) film or sheet. With the addition of ST-SR487, 0.25-mm-thick PC film can achieve UL 94 V-0 certification, according to CAI.

The safety of halogen-based flame-retardant (FR) materials has come under increased scrutiny from consumers and regulators. “Halogen-based FR solutions can contain bromine, iodine, even chlorine; all chemicals of concern nowadays,” said CAI CEO Richard Marshall. “I’m proud to say we are offering a safer alternative to our customers in ST-SR487, our first FR additive that is entirely halogen-free.”

The additive also provides resistance to yellowing and other forms of weathering as well as hydrolysis protection for water-contact end products. Sustainable-textile – Carbon-neutral-H2

Headquartered in Boston, CAI Performance Additives LLC operates facilities in Massachusetts and offers logistics across North America to customers processing virgin and recycled engineering thermoplastics.

-Ultra-Compact PET Machine For 12 L in Two Cavities

New size of all-electric reheat stretch-blow machine for large PET bottles debuted from 1Blow at K 2022. It retains the company’s signature small footprint and energy-sparing features.

At the recent K 2022 show, 1Blow of France introduced a model of its very compact all-electric reheat stretch-blow machines for bottles up to 12 liters (3 gal). The new 2XL machine is the company’s first two-cavity system for bottles of this size, while retaining a small footprint of only 6.5 x 8 ft. (Previous models could mold a single container of 12 L or even up to 30 L.) It handles neck finishes up to 53 mm and outputs up to 3800 bph for 0.5 L, 9-g bottles. Sustainable-textile – Carbon-neutral-H2

Optional technology kits include preferential and offset neck heating, neck orientation, heat-set/hot-fill and Sure Grip molded-in handle.

In keeping with the overall “green” theme of K 2022, 1Blow emphasized the low energy consumption of its reheat stretch-blow machines under the new label “GreenBlow.”

Among the energy-saving features of this all-servo design are recovery of braking energy on the five servomotors to power the next motion; recovery of high-pressure blowing air to furnish 100% of the machine’s low-pressure air requirement; and “SuperVenting” mold technology (supplied by a moldmaking partner) that allows bottles to be blown with a little as 300 psi vs. the conventional 600 psi, reportedly saving 30-40% in energy. These features were highlighted at the show on a new 2XL model for two-cavity production of up to 12 L bottles.

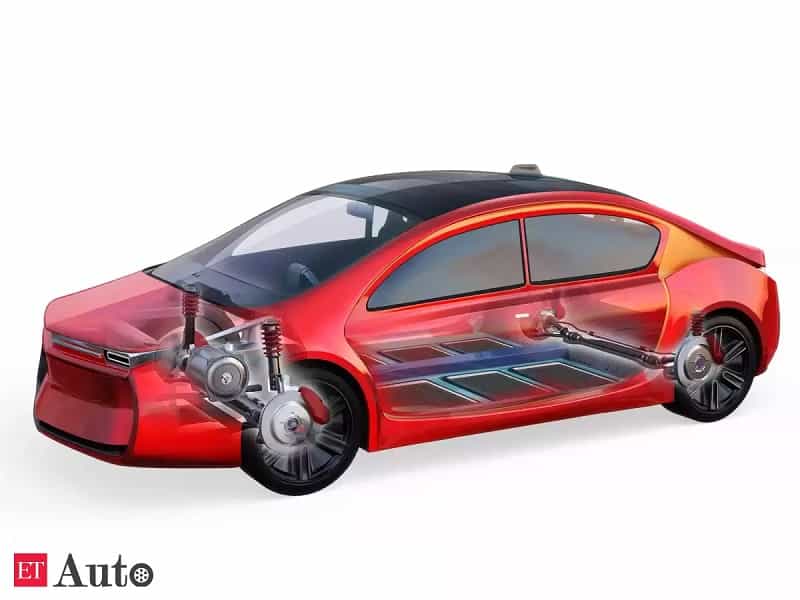

-Electric vehicles’ mobility to drive engineering plastics industry in India

India’s commitment to driving the world for a greener future has accelerated demand for electric vehicles (EV) and their accessories that are backed by efficient technologies for the smooth adoption of environment-friendly personal and public transport. Sound technology-backed engineering plastics find their place in the midst of the growth trajectory with a projection of almost similar to the increase in EV mobility.

Data compiled by India’s Union Ministry of Transport showed 1.4 million EVs plying on Indian roads as on August 2022. The demand for EVs (including passenger and personal cars, two-wheelers, buses, etc.) increased rapidly with the resurgence in post-pandemic economic recovery. India’s Union Ministry of Transport estimates total EV demand in the country to rise to 45-50 million by 2030. Sustainable-textile – Carbon-neutral-H2

India’s automotive industry size is estimated to be worth around US$222 billion as of today, of which the EV market is projected to be worth a mere US$2 billion by 2023 and US$7.09 billion by 2025. Growing at a compounded annual growth rate (CAGR) of 49 percent from its low base, India’s EV market is anticipated to record phenomenal growth going forward. Between April 2000 and March 2022, this sector attracted equity inflows as Foreign Director Investment (FDI) to the tune of US$32.84 billion or 6 percent of the total FDI attracted in equities during that time.

EV’s link with engineering plastics

Normally, polycarbonate (PC), polyamide (PA), polymethyl methacrylate (PMMA), polyacetal/polyoxymethylene (POM), polyethylene terephthalate (PET), polybutylene terephthalate (PBT), among a host of other innovative raw materials are used to manufacture EV components such as dashboard, bumpers, lighting, interior/exterior trims, electric motor and powertrain, battery pack, connectors, and cable, to name a few. The increasing mobility of electric vehicles has multiplied demand for components made of engineering plastics and eventually their raw materials.

All these raw materials and finished products are manufactured with an extremely high degree of efficiency to equip EVs with the most modern safety features. In EVs, however, the industry has increased the use of lightweight engineering plastics without compromising the quality of vehicles. This helps in reducing the application of metals to the maximum possible extent and also improves the vehicles’ efficiency, speed, and control. Sustainable-textile – Carbon-neutral-H2

Ankur Betai, Director of Autotech Sirmax India Pvt Ltd, said, “EVs are going to increase demand for engineering plastics not only in India but all across the world. There are a lot of projects the industry is presently working on which enable shifting from metals to plastics. Going forward, the volume of engineering plastics per vehicle will increase, but how much only time will tell. In terms of cost also, the cost of engineering plastics could be lower than that of metals. Hence, the overall cost of the vehicles per unit is also going to decline.”

He further added, “Presently, original equipment manufacturers (OEMs) are spending a huge amount on technological innovations, either procuring from others or developing on their own. Hence, the overall unit cost of EVs will also depend upon the use of technology. In the long run, the cost of EVs is going to be lower than the current price levels of EVs. However, it is still left to be seen if the price can match or be lower than internal combustion engines (ICE) due to the advancement of technology. Only time will tell that.”

Trend in the engineering plastics market

The overall global electric vehicles engineering plastics market size is estimated at 12.5 billion in 2021 and is projected to surpass US$106 billion by 2030 with a compounded annual growth rate of 27 percent. The companies engaged in manufacturing engineering plastics for application in EVs have been leveraging the growth opportunities in this sector with a series of incentives being offered by governments across the world.

Although the growth of this sector was slowed due to several waves of coronavirus (Covid-19) outbreak, demand for EVs picked up steadily with the post-pandemic economic recovery. Sustainable-textile – Carbon-neutral-H2

According to a study, the innovation of glass fiber-reinforced polyamide 6, which is being publicized for its insulation and flame-resistance properties, is set to become a game changer for the engineering plastics industry for electric vehicle mobility. This material is full of features like the lightweight and simplified assembly of EV batteries. Due to stringent mechanical and chemical properties requirements for electric vehicle components, manufacturers are increasing R&D in glass-fiber-reinforced polyamide 6 which is easy to process and enables the integration of complex functions required for housing components.

Since the mobility industry is transitioning towards an all-electric future, manufacturers in the electric vehicles engineering plastic market are bolstering R&D in thermoplastic-based solutions. Manufacturers in the electric vehicle engineering plastics market are taking cues from such innovations to develop a plastic-intensive EV battery pack using a systems-engineering approach, which holds potential for lightweight plastic components.

Future growth drivers

With an aim to promote green energy, the government of India has taken all possible steps to incentivize manufacturers of EVs and their components. Thus, many conventional automotive players and oil companies are investing heavily to boost EV demand to reach the aspirational goal. To name a few, Skoda revealed its plan to produce EVs locally in India in 2021, and Indian Oil Corporation announced to the creation of 22,000 EV charging stations over three-five years. Sustainable-textile – Carbon-neutral-H2

Almost all automakers and also large corporate houses forayed into this segment to take part in the growth of the EV industry. As late as today, Jindal Mobilitric (JM), a subsidiary of Jindal Worldwide, announced the setting up of an electric 2-wheeler manufacturing plant with a production capacity of 250,000 vehicles annually in Ahmedabad. Additionally, the Indian government has also been implementing programmes to encourage the growth of electric mobility, including 100 percent foreign direct investment (FDI) through the automotive route in the EV space, incubator programmes, shared facilities for prototyping and small-scale manufacturing, financial support, tax breaks, and subsidies for consumers. Also, India’s central government announced a production-linked incentive (PLI) scheme to attract investment in this sector. Sustainable-textile – Carbon-neutral-H2

-PKN ORLEN closes acquisition of petrochemical assets

PKN ORLEN has closed the transaction to acquire a part of the business of Poland’s largest plastics manufacturer Basell Orlen Polyolefins, in which the Company holds an equity interest. The business involves the production and marketing of LDPE, as well as customer service in the Polish market. The transaction was cleared by the Polish and Dutch antitrust regulators. The acquired production capacity is 100 thousand tonnes per year, which means that PKN ORLEN, as Poland’s only producer of LDPE, will single-handedly cover about a third of the country’s overall demand for the plastic.

Low density polyethylene, or LDPE, is a fully recyclable product playing an important role in advancing the circular economy.

It is a polymer commonly used to make consumer and industrial products, found in plastic films, bags, canisters, food packaging, as well as components of electronic devices, such as wires and cables. Sustainable-textile – Carbon-neutral-H2

“Keeping a close eye on the market environment, we can see that demand for petrochemical products is growing strongly across the globe. According to forecasts, the value of the petrochemicals and base plastics market is expected to double by 2030. This is a big chance for our Company. We want to capture the largest possible share of that promising business in order to drive fast profit growth. The acquisition we have just completed is opening up such opportunities. We are also looking into a project that would allow us to add another petrochemical product to our portfolio, solidifying our position as a leading producer in Europe. It is this business segment that is expected to generate half of our future profits from oil processing,” says Daniel Obajtek, CEO and President of the Management Board of PKN ORLEN.

Poland is the largest consumer of LDPE in Central Europe, forecast to account for nearly 35% of regional demand by 2025. At present, annual demand on the Polish market is about 300 thousand tonnes, compared with close to 800 thousand tonnes in Central Europe. The combined capacities of regional producers are estimated at 520 thousand tonnes. According to forecasts, by 2025 the LDPE market in Central Europe and in Poland will grow to about 890 thousand tonnes and 312 thousand tonnes, respectively, in which PKN ORLEN is bound to have a significant share. Sustainable-textile – Carbon-neutral-H2

In July 2022, PKN ORLEN signed a preliminary agreement to acquire a part of the assets of Basell Orlen Polyolefins. Once all antitrust approvals had been secured in Poland and the Netherlands, it was possible to close the transaction. Basell Orlen Polyolefins is a joint venture in which PKN ORLEN and LyondellBasell Industries each hold a 50% stake. After the spin-off of the LDPE production business from Basell Orlen Polyolefins, the company will focus on developing the PP technology, used to produce polypropylene and HDPE, high density polyethylene.

In response to steadily growing market demand, PKN ORLEN has undertaken conceptual work to expand the LDPE unit at the Płock Production Plant. PKN ORLEN has signed a licence and front-end engineering design agreement with the world leader in polymer technology LyondellBasell.

-Topsoe and Fidelis New Energy partner to produce carbon-neutral hydrogen

Topsoe and Fidelis New Energy have entered into a global alliance for technology used for producing carbon-neutral hydrogen. The alliance pairs Topsoe’s hydrogen process portfolio with FidelisH2 technology for reduction of lifecycle carbon emissions in hydrogen production. Combined, the alliance solution enables the production of hydrogen from natural gas with a lifecycle carbon intensity of 0 kgCO2e / kgH2.

Fidelis and Topsoe will jointly and exclusively license FidelisH2 alongside Topsoe’s blue hydrogen technology portfolio. Topsoe will lead engagement with potential licensees interested in utilizing FidelisH2 to produce carbon-neutral hydrogen at world scale using proven technologies. Sustainable-textile – Carbon-neutral-H2

Topsoe’s hydrogen process portfolio includes both steam methane reforming and SynCOR autothermal reforming solutions to produce hydrogen with integrated carbon capture. FidelisH2 is a proprietary solution for incorporation of renewable energy into reforming processes to achieve clean hydrogen production.

The novel integration of these proven technologies offered through the alliance provides a scalable solution well suited for generating climate and environmental incentives such as the Section 45V tax credits provided in the “Inflation Reduction Act” of 2022.

Sustainable-textile – Carbon-neutral-H2