Textile-sector – Recycled-Bottles 02-08-2022 - Arhive

Textile-sector – Recycled-Bottles

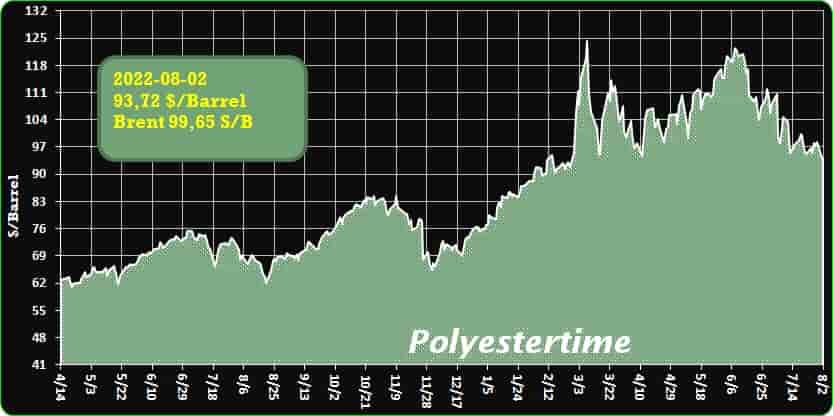

Crude Oil Prices Trend

-TMR Study: Recycled PET Bottles Market to Reach US$ 4.3 Bn by 2031

Continuing global shift of packaging businesses and their customers toward sustainability pivots the adoption of recyclable materials, thereby underpinning streams of revenue of rPET bottles market. Abundant use of plastics in packaging of myriad food & beverage products presents vast lucrative opportunities in key market segments in rPET bottles. According to a study by Transparency Market Research Inc. the rPET bottles market is forecast to advance at a CAGR of 9.6% from 2022 to 2031.

Food-grade rPET bottles held a major share of the global market—a whopping 92.2%—in 2021. The segment also is expected to present largest opportunity for rPET) bottles market during the forecast period. Textile-sector – Recycled-Bottles

The material is characterised with chemical and biological inertness, resistance to microorganisms, and stability, thus spurring the incorporation of these in beverage bottles and food trays.

Globally prominent beverages brands in particular are keen on using bottles made with 100% rPET plastic. This stridently will enrich the future market outlook for recycled PET bottles. Companies are ramping up their efforts to bolster PET bottles recycling infrastructure and increasing their research spending on developing technologically advanced systems, thus extending the horizon of the rPET bottles market.

Key Findings of rPET Bottles Market Study:

Massive Demand for Sustainable Plastics in F&B Industries to Generate Sizable Opportunities: Recycled PET resins are gaining preference over glass and aluminium in the packaging industries. In particular, the prevalent use of plastics packaging in the food & beverages industry presents a massive avenue for companies in the rPET bottles market. The adoption of the products has enabled them to lower carbon footprint. F&B brands are increasingly emphasising on minimising PET waste being sent to landfill.

Rise in Adoption of Food Grade rPET Bottles: Growing trend of strengthening recycling operations for post-consumer products is spurring lucrative opportunities in rPET bottles market. Of note, developed regions of the world such as Europe have witnessed bottle-to-bottle recycling for food-grade PET gaining momentum. This has led to the availability of high-quality rPET resins for the packaging manufacturers to cater to the requirements of both food as well as non-food products.

Recycled PET Bottles Market: Key Drivers:

The growing role of adopting recyclable plastics in supporting circular economy is a key driver of the rPET bottles market. Several forward-looking organisations around the world are inclined toward making circular economy transition, which has led them to shun single-use plastic materials. Textile-sector – Recycled-Bottles

Abundant use of plastics in the food & beverage industry for storage, handling, and transport of the products has driven the evolution of the rPET bottles market

-China : PP plant operating rate returns to low

Recently, more and more plants shut for maintenance, some shut on schedule, and some shut accidentally. The overall operating rate of PP once again dropped to a low level, currently close to 80%, and it is not difficult to find that it is already a low point of the year. Meanwhile, the overall operating rate of PP in 2022 is generally lower than that of the same period last year, which is closely related to the production cut of petrochemical plants under high cost pressure. Textile-sector – Recycled-Bottles

It can be seen that since July, there are only few sets of PP plants restarted, while more and more plants shut for maintenance. PP plant operating rate declines.

Some plants are scheduled to shut for maintenance in July. For example, Shaanxi Yanchang plans to shut for maintenance since mid Jul for around one-and-a-half-month, and Zhongan Lianhe plans to shut for maintenance in late Jul for around 45days. But the actual implementation of maintenance still needs to be tracked. In addition, in recent years, it is frequent that plants shut accidentally, which also needs timely attention.

In addition to the operating rate, the production ratio of homo PP raffia has also dropped to an all-time low of nearly 20% recently. On the one hand, some plants such as Qinghai Yanhu, Haiguolongyou, Hebei Haiwei and so on mainly produce homo PP raffia, the shutdown of these plants has a significant impact on the loss of homo PP raffia output. On the other hand, some plants have switched their production from homo PP raffia to others, such as Yangtz River Petrochemical, Zhongan Lianhe, Sinochem Quanzhou II, etc.

-Eni confident it will replace Russian gas by 2025

Italian energy group Eni believes it will be able to completely replace Russian gas imports by 2025 as uncertainty over Moscow’s energy supplies to Europe forces countries to seek alternative sources, said Reuters. Textile-sector – Recycled-Bottles

After signing new gas supply agreements with Algeria, Egypt and Congo earlier this year, Eni sees additional opportunities arising in other countries including Libya, Angola, Mozambique, and Indonesia, as well as in its home country.

The initiatives are designed to secure up to an equivalent of 100% of Russia’s 20 Bcm3 of annual gas exports to the Italian market by 2025, the group said on Friday.

Under the plan, Algeria is expected to provide up to 6 Bcm3 of additional gas by 2023, reaching up to 9 Bcm3 by 2024, Eni said in a post-result presentation. “Recently we discovered gas in Algeria … we are also working very well, with good coordination, with (Algeria’s)Sonatrach, so it could be possible to accelerate and increase,” Eni’s CEO said during a conference call with analysts.

Eni, whose main shareholder is the Italian state, is one of the biggest wholesale buyers of Russian gas. Since mid-June Russia’s Gazprom has been supplying less gas than requested to Eni, and European countries fear it could completely halt its supplies in the coming months.

Eni is confident its global gas & LNG portfolio division (GGP) will be at least free-cashflow positive in 2022 even if Moscow shuts off its gas supplies from this winter, GGP Director Cristian Signoretto said after the group reported Q2 results above expectations.

We remind, Gazprom has told customers in Europe it cannot guarantee gas supplies because of ‘extraordinary’ circumstances, upping the ante in an economic tit-for-tat with the West over Moscow’s invasion of Ukraine. Textile-sector – Recycled-Bottles

-Registration now open for BPF Chemical Recycling webinar

Registration has now opened for the British Plastics Federation’s half-day online event looking at the latest developments in chemical recycling scheduled to run from 13.00 to 17.00 on 11 October. Those booking before 31 August will receive a 20% discount on ticket prices. Textile-sector – Recycled-Bottles

The BPF is organising the webinar in collaboration with Plastics Europe. The programme features a lineup of 8 speakers from organisations including Unilever, Dow and the Food and Drink Federation, while delegates will also be given access to four pre-recorded sessions by academics, looking at key innovations.

The first live session will feature Global Petrochemical Analyst at S&P Global Commodity Insights Joshua Forber, who will speak about developments and investment in chemical recycling across the globe. He will explore both current and future global capacities and the effect this is likely to have on the polymer market.

President and CEO of Plastics Energy Carlos Monreal will then discuss forecasts of the future of chemical recycling in Europe, as well as how legislation may impact the sector. This session will be followed by Unilever’s Home Beauty and Personal Care Packaging Director Colin Kerr, who will provide a brand owner’s perspective on using chemical recyclate. Delegates will also hear about challenges Unilever have faced in using chemical recycling as well as its future plans.

Dow’s Global Market Manager Mark van den Biggelaar will explain Dow’s progress and experiences in scaling up chemical recycling technologies. ISCC Systems’ Principal Inna Knelsen will then explore mass balance, how it works and how it might be used to certify products, looking at the legislative landscape across Europe and the rest of the world. A panel discussion about legislation will then take place, featuring representatives from Plastics Energy, Plastics Europe and the BPF. Textile-sector – Recycled-Bottles

The final live presentation will feature David Bellamy, senior environment policy manager at the Food and Drink Federation, who will present his thoughts on how chemical recycling can play a role in overcoming barriers to using recyclate in food contact applications.

-A New Solution for Plastic Recycling

What has the plastic waste crisis taught us about recycling innovation? UK-based company Greenback Recycling Technologies Ltd. – in partnership with chemical recycling company Enval – presents a microwave-induced pyrolysis solution for dealing with low-density plastic waste. A specialist article by the company:

It is estimated that eight billion tons of plastic have been produced since the 1950s. Of that total figure, only 10 percent, at best, has ever been recycled. Plastic recycling has taken place for decades and there is no denying that mechanical recycling works well for rigid plastics such as PET and mono materials. Currently, however, most plastic waste still ends up being dumped, burned or sent to landfills. The reasons for this are manifold. Some plastic substrates are manufactured from multiple polymers – laminated or coextruded. This makes them difficult to recycle as the various materials cannot be easily separated and sent to the relevant waste channels. Other forms of plastic are too expensive to collect and sort so it is not economic to recycle them. This applies to most plastic films. Moreover, in the main, plastic contaminated with food cannot be recycled either. Textile-sector – Recycled-Bottles

As a result, plastic waste has become a runaway global problem and it is only set to get worse. According to the United Nations Environment Programme, the world produces three hundred million tons of plastic waste each year. In contrast, the world’s plastic recycling capacity is estimated to be forty-six million tons a year according to the Organisation for Economic Co-operation and Development (OECD). Meanwhile, plastic production is projected to double by 2040. By the same year, the amount of plastic waste finding its way into the oceans is expected to triple to 29 million tons.

-Dornbirn-GFC 2022: Centre stage for new cellulosics

Over 100 lectures will be held in three parallel sessions across the three-day conference.

Cellulosic fibres can’t help but take centre stage at the forthcoming Dornbirn Global Fiber Congress (Dornbirn-GFC) from September 14-16 this year, given the many exciting new developments based on sustainable fibres that are underway – and especially those rapidly being developed in the Nordic region. Textile-sector – Recycled-Bottles

Among notable keynote speakers at the conference will be Gittan Schiöld, CEO of Paper Bottle Company (Paboco), which was founded in 2019 to drive the ongoing Fibre Bottle project first initiated by Danish innovation company EcoXpac in 2010, and joined by Carlsberg in 2015.

Via an innovation community and platform bringing together some of the world’s leading experts in materials, design and technology, Paboco’s aim is to completely transform the bottling industry.

Fibre Bottle

In the past few weeks, Carlsberg has supplied some 8,000 samples of its Generation 2.0 Fibre Bottle to select festivals and flagship events across West Europe, in order to more widely gauge the reaction of consumers to the bio-based and fully recyclable innovation.

A significant milestone is its plant-based PEF polymer lining, which has been developed by Amsterdam-headquartered Avantium, a leading expert in renewable chemistry. PEF is made entirely from natural raw materials, is compatible with plastic recycling systems and can degrade into nature should it end up outside national recycling systems.

The outer shell of the bottle, produced by Paboco, consists of sustainably-sourced wood fibre and is also bio-based. It has the added benefit of insulative properties which can help keep beer colder for longer compared to cans or glass bottles.

New business models

At this year’s Dornbirn-GFC, Paboco’s Gittan Schiöld will also take part in a panel discussion with other keynote speakers including Uday Gill, CEO of Indorama Ventures (IVL), Yogi Dandapure of Lululemon and Lenzing’s COO Robert van de Kerkhoff, who has previously emphasised the need for new business models for the fibres and textiles supply chain. Lenzing is one of the main sponsors of the conference and is extremely active in driving a sustainable agenda for the fibres industry. Textile-sector – Recycled-Bottles

-Türkiye textile sector eyes $1bn in US exports in 2022

The Istanbul Textile and Raw Materials Exporters Association (İTHİB) expects textile revenues for US-bound exports to go above US$1bn by the end of this year, according to reports. Textile-sector – Recycled-Bottles

The head of ITHİB, Ahmet Öksüz, explained the US is an important market for Türkiye’s textile sector with sales in 2021 already reaching US$850m, according to a news report by local publication Hurriyet Daily News.

The Istanbul Apparel Exporters’ Association (IHKIB) tells Just Style exclusively: “US imports of both textile and apparel from Türkiye has increased in recent years. The industry’s argument is as Türkiyeis the second biggest supplier of the EU, why not have a similar positioning in the US market?”

IHKIB also suggests the sustainability agenda values the long-life of Turkish textile and apparel products, as well as their quality and other competitive features, and believes Türkiye has the potential to change the perceptions of buyers, brands and US consumers on fast fashion and apparel business partnerships.

It also explains the figures quoted by Öksüz are specifically for fabrics and yarns as the apparel sector already had an export value of US$1.3bn in 2021 and has a target of US$5bin for no more than five years’ time. Textile-sector – Recycled-Bottles

-Vietnam firm to build USD1.5 bln polypropylene plant

Stavian Quang Yen Petrochemical Joint Stock Company, Quang Ninh Provincial People’s Committee and Bac Tien Phong Industrial Park Joint Stock Company have just signed a Memorandum of Understanding on Investment Cooperation (MoU) at the Quang Ninh Investment Promotion Conference in 2022, officially kicked off the project of Stavian Quang Yen petrochemical plant, said Vietnam postsen.

The project has an estimated investment capital of up to 1.5 billion USD, with a production scale of 600,000 tons of polypropylene/year.

It is known that Polypropylene is an important input material for many manufacturing and manufacturing industries such as household appliances, automobiles, electronics, packaging production, packaging, supplies, medical equipment. … Therefore, when the factory comes into operation, it will attract and motivate investors in the manufacturing sector to invest in the locality later. Textile-sector – Recycled-Bottles

To ensure that the petrochemical plant operates safely, efficiently with high reliability and produces the best quality Polypropylene products, the project has selected the most advanced patented technologies in the field of Polypropylene production. currently include PDH technology from Honeywell UOP (USA) and PP technology from LyondellBasell (Italy).

In addition, the project also uses high-quality equipment from EU and G7 countries with a closed, automated, environmentally friendly technological process and reduces greenhouse gas emissions. Stavian Quang Yen Petrochemical Factory was built on an area of ??30ha in Bac Tien Phong Industrial Park, Tien Phong Commune, Quang Yen Town. The plant’s commercial operation is expected to begin in the fourth quarter of 2026.

Textile-sector – Recycled-Bottles