For summer 2019 Wolford launches stockings in regenerated nylon from fishing nets and other materials recovered at sea.

Sustainability has different faces.

women underwear

Polyestertime publishes news on polymers, automotive, events, crude oil, textile, bioplastics, mechanical and chemical recycling etc.

China – Polyethylene Terephthalate

PET and its chain continue to be weak.

Crude oil is steady.

Polyamide 6 and its chain are very weak.

PET Bottle grade export 860/915 $/ton – PET Bottle grade domestic market 6,800/6,950 yuan/ton – PET Filament grade SD domestic market 6,300/6,450 yuan/ton – PET Filament grade BR domestic market 6,400/6,550 yuan/ton

PTA Taiwan 740/750 $/ton – PTA domestic market 5,350/5,450 yuan/ton – MEG 525/535 $/ton – MEG domestic market 4,150/4,300 yuan/ton – PX Korea 815/825 $/ton

Polyester POY 150D/48F domestic market 7,300/7,400 yuan/ton – Polyester DTY 150D/48F domestic market 9,050/9,150 yuan/ton – Polyester Staple PSF domestic market 7,150/7,300 yuan/ton

-Crude Oil Prices Trend Thermoplastics Petrochemicals Bioplastics

women underwear

-TOMRA offers a circular solution to the world’s plastic problem Thermoplastics Petrochemicals Bioplastics

With global recycling rates for plastic disastrously low compared with other materials, it’s up to technology-led companies to create a circular economy through sustainable collection, sorting and recycling

In recent years, there has been a huge shift in attitudes towards waste and recycling, with new regulations and targets being set by policymakers and governments alike. At the heart of these discussions is the need to create a circular economy – one that ensures countries handle resources in a sustainable and effective way. This is particularly true of plastic, which, despite being the workhorse of the global economy, is often produced and disposed of unsustainably.

The sheer amount of plastic used around the world each year is staggering: since plastic production entered the mainstream in the 1950s, more than 8.3 billion tonnes have been produced, 6.3 billion tonnes of which is now regarded as plastic waste.

-Canada to host the 2020 World Circular Economy Forum Français

Canadians know that we need to find new ways to reduce our waste and use our resources more efficiently. When we don’t properly recycle and reuse materials, letting them become landfill instead, it is economic value we are throwing away.

The Minister of Environment and Climate Change, Catherine McKenna, and the Minister of Innovation, Science and Economic Development, Navdeep Bains, today announced that Canada will host the 2020 World Circular Economy Forum (WCEF2020), in partnership with Finnish Innovation Fund, Sitra. Canada has already started building a circular economy that benefits people, the economy and the environment.

-Aquafil acquires O’Mara for US40.5 million

Aquafil is a pioneer in the circular economy with its Econyl regeneration system. © Aquafil Aquafil, a leading Italy-based specialist in the production of Polyamide 6 (nylon 6), has finalised the acquisition of 100% of O’Mara for a total of US$ 40.5 million. The deal was completed through the Group’s US subsidiary, Aquafil USA.

O’Mara, founded in 1970, produces nylon, polypropylene and polyester fibres mainly in solution-dyed colours in its plant based in Rutherford College, NC. In 2018, O’Mara reported a turnover of $US 40.1 million, with margins in line with those of Aquafil Group.

“O’Mara’s identity and market positioning are fully consistent with those of Aquafil Group,” the company reports. “This compatibility accelerates the globalisation process of the textiles business, with positive consequences for Econyl and Dryarn products as well.” O’Mara will provide access to a broader product range, thereby driving further development of the US market in the sectors of athletic apparel, hosiery, fashion and accessories. Thermoplastics Petrochemicals Bioplastics

As a result of the production activity in the USA, the Group will also benefit from the trade agreements between the US federal government and certain Central and South American countries (CAFTA), which allow for exemptions from US tariffs on apparel produced in the latter countries using yarns of US origin.

-BBC covers biodegradable bioplastics made from cactus juice.

“My idea is to produce a plastic from natural ingredients and substitute it for some of the plastics we use today.”

The BBC has shone a spotlight on a Mexican researcher who has discovered a way to produce biodegradable bioplastic from cactus juice.

Sandra Pascoe, who is based at the Mexican University of the Valley of Atemajac (Univa [@SistemaUNIVA]), used the most common variety of edible nopal cactus to make the bioplastic.

The plastic is made out of the sugars (monosaccharides and polysaccharides) of nopal juice. The sugars, pectin and organic acids in the juice give it a very viscous consistency. Thanks to the viscosity, a solid and flexible material can be produced.

Toray Industries, Inc. announced that using a proprietary composite spinning technology called NANODESIGN®, Toray Industries has created a new nylon textile, one that delivers high water repellency despite using a DWR treatment with a lower environmental cost.

The textile’s structure has microscopic slits running lengthwise on the yarn. Water repelling treatments fill these slits below the outside diameter of the yarn, also making the treatment more abrasion-resistant. This results in two benefits:

The construction enables the textile to use C6 water repellents, which are normally insufficient for outdoor sports and

The textile provides more resistance to abrasion, which is a leading contributor to diminishing DWR performance. Thermoplastics Petrochemicals Bioplastics

-How much Indorama paid for a U.S. PET processor

Earlier this year, global plastics producer Indorama Ventures acquired reclaimer Custom Polymers PET. Financial filings show the deal was worth $30 million.

A recent filing from Indorama, a publicly traded company headquartered in Bangkok, shows the business paid 954.7 million Thai baht, which is worth nearly $30.5 million today, to acquire Custom Polymers PET.

With a plant in Athens, Ala., Custom Polymers PET is capable of producing up to 68 million pounds of RPET flake and food-grade pellets per year. It’s Indorama’s first bale-to-flake plant in the U.S., and it’s located close to one of Indorama’s nine U.S. production facilities.

-LyondellBasell and Braskem end merger talks

Petrochemical firms LyondellBasell and Braskem have jointly ended talks over a potential merger, with the former insisting that its appetite for growth and investment remains strong.

Braskem’s controlling shareholder Odebrecht is looking to offload the company, which is valued at around $13 billion, and LyondellBasell seemed keen to establish a manufacturing stronghold in Brazil, where Braskem dominates.

Analysts suggest that there were a number of complications in the deal, not least that Braskem failed to a file a 2017 annual report with the US Securities and Exchange Commission, and was subsequently delisted from the New York Stock Exchange. The Brazilian firm was embroiled in a corruption scandal in 2017 that also involved state-owned Petrobras. There are also suggestions that Braskem may be culpable for environmental and geological damage caused by its salt mining operations in Brazil, which could lead to substantial costs. Thermoplastics Petrochemicals Bioplastics

-Rare earths battle looms as U.S. aims to counter China threat

In this December 30, 2010, file photo, workers use machinery to dig at a rare earth mine in Ganxian county in central China’s Jiangxi province.

The US and China are heading for a standoff over critical minerals used in everything from washing machines to military hardware.

The US Commerce Department on Tuesday promised “unprecedented action” to ensure that the US won’t be cut off from supplies of rare earths, a group of 17 obscure but vital elements whose production is dominated by China. The Department’s release of a report outlining steps to ensure supply came hours after the Asian nation’s top state economic planning body said it’s studying proposals to establish export controls on the materials.

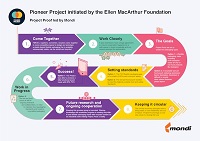

-Mondi boosts recycled flexible packaging project

Mondi Group has created a proof-of-concept prototype flexible plastic pouch incorporating a minimum of 20 per cent PCP originating from mixed household waste.

Mondi accelerates efforts to create flexible packaging from post-consumer recycled plastic.

As part of the Mondi-led ‘Project Proof’ facilitated by the Ellen MacArthur Foundation, the company’s commitment to the Ellen MacArthur New Plastics Economy Initiative focuses on designing products in line with circular economy principles.

Mondi will now develop the prototype further to ensure it can be rolled out as a commercially viable product for its multinational FMCG customers. This will support Mondi’s work as a signatory of the New Plastics Economy Commitment to ensure a minimum of 25 per cent of post-consumer waste is incorporated across all its flexible plastic packaging where food contact regulations allow by 2025.

-Unilever Launches New Pigment For Polyethylene Bottles

Unilever has launched the new black pigment for high-density polyethylene (HDPE) bottles that will make them detectable by recycling plant scanners and sorting machinery. The new pigment will be launched by TRESemmé and Lynx and will allow the sorting and recycling of an extra 2,500 tonnes of plastic bottles. The company has mentioned that apart from launching the bottles, it will also introduce at least 30 percent recycled content into TRESemmé and Lynx packaging. Conventional black plastic bottles that are reinforced with carbon black pigments are difficult to detect with the help of sorting machines in recycling plants as they tend to absorb the near infra-red (NIR) light used for sorting.