Waste textiles – Tire-Pyrolysis – PHA 23-03-2023 - Arhive

Waste textiles – Tire-Pyrolysis – PHA

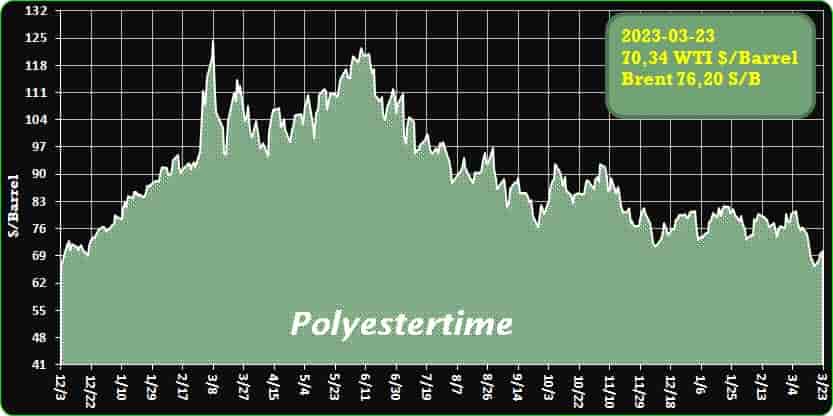

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

-Emissions from waste textiles could be cut with chemical sorting process

A process that separates polyester from other textiles known as “chemical sorting” could help to cut the huge carbon emissions associated with the clothes industry, researchers have said.

The sector currently accounts for around 10 per cent of global carbon emissions and almost 90 per cent of post-consumer fibre waste is disposed of through incineration or in landfills.

Among these forms of waste, synthetic fibre has become a major threat to the environment and human health because, like other plastics, it is not biodegradable in nature. Waste textiles – Tire-Pyrolysis – PHA

Owing to its low cost and durability, polyester is the most widely used synthetic fibre on the planet, accounting for more than half of all fabrics annually produced.

Now, a research team from the Korea Research Institute of Chemical Technology (KRICT) has developed a “chemical sorting” process that separates polyester from waste textiles that are disposed of in a mixed and contaminated form.

-Equate announces April contract price for MEG shipments to India

Kuwait’s Equate Petrochemical Co., one of the world’s largest companies producing polymers and other petrochemical products, has announced the contract price of monoethylene glycol (MEG) for shipments to India at USD2023 per tonne, a company source told ICIS.

Thus, the April bid price was USD515 per ton lower than the March bid.

On March 23, spot prices for MEGs were at USD20-495 per ton, CFR China Main Ports (CMP).

Earlier it was reported that Equate Petrochemical Co., one of the world’s largest companies for the production of polymers and other petrochemical products, announced the contract price of monoethylene glycol (MEG) for March 505 for supplies to India at the level of USD2023 per ton. Thus, the March bid price was USD538 per ton lower than the February bid. Waste textiles – Tire-Pyrolysis – PHA

MEG, along with terephthalic acid (TPA), is one of the main raw materials for the production of polyethylene terephthalate (PET).

-Bluepha launches commercial PHA portfolio

After six years of development and research work, China-based biotech company Bluepha, a China-based biotech company, celebrated the launch of its first portfolio of marine degradable biopolymers at a festive 1 March event. At the event, the company presented its Bluepha PHA, together with information about its properties and applications. As well, the company discussed the production processes developed, the facilities constructed and its innovative ‘Biohybrid’ technology. Waste textiles – Tire-Pyrolysis – PHA

PHA is a natural polymer occurring in the cells of a wide range of microorganisms, where it serves as a storage of carbon and energy. Microorganisms produce PHA using biomass as fermentation feedstock. Bluepha has developed an industrial process for its mass production. The company markets its PHA under the Bluepha name, or 蓝晶™ in Chinese.

Bluepha built and commissioned its first industrial-scale production facility, called BioFAB1, in 2022 in Yancheng. With this first 5000 tonne/year unit, which is staffed by a team with international experience in biomanufacturing, a solid basis could be laid for the stable supply of PHA.

-Overview of a Fully Continuous Tire Pyrolysis Plant

Exactly what is pyrolysis? This term describes the simultaneous chemical and physical reactions that exist in organic substances when they’re in contact with very high temperatures.

Exactly what is pyrolysis? This term describes the simultaneous chemical and physical reactions that exist in organic substances when they’re in contact with very high temperatures. Generally, a completely continuous tire pyrolysis plant is a specially made tire recycling equipment that implements the pyrolysis technology to recycle waste tires into various products including fuel oil and carbon black.

With these machines, you may create fuel oil from all kinds of waste plastics. Remember, this can be all performed in an eco-friendly way. That also means these are essential in handling the waste plastic disposal issue. Waste textiles – Tire-Pyrolysis – PHA

Typically, a completely continuous pyrolysis machine implements an entirely automatic procedure that might be remotely controlled using a Programmable Logic Controller system or even a computer. As a result of continuous or automated feeding and discharge system, this machine can constantly retain the optimum performance of your pyrolysis system.

Please read on and learn about the working process of this continuous pyrolysis machine, and a few of the benefits it offers.

The Working Process

– The method begins by shredding the available plastic materials into fine plastic granules by using a plastic crusher. Afterward, these granules are fed into this fully continuous tire pyrolysis machine through the machine’s feeding door. Waste textiles – Tire-Pyrolysis – PHA

Source : .Chemical Engineering World

-New Energy Security Scenarios explore how the world could evolve

Shell plc has today published its latest scenarios: the Energy Security Scenarios. The two new scenarios explore how the world could evolve following Russia’s invasion of Ukraine. Specifically, they look into the possible energy and climate outcomes that could result from a world that has security as its dominant concern.

Shell Scenarios are not predictions or expectations of what will happen, or what will probably happen. They are not expressions of Shell’s strategy, and they are not Shell’s business plan; they are one of the many inputs used by Shell to stretch thinking whilst making decisions. Waste textiles – Tire-Pyrolysis – PHA

The first scenario, called Archipelagos, follows how today’s pressures could play out to the end of the century. National interest remains key and renewables are mainly seen as a way to improve energy security. By 2100, net-zero emissions is within sight, but the world has failed to meet the goal of the Paris Agreement. This scenario is “exploratory”: it seeks to plot a course from where the world stood in 2022.

The second scenario, called Sky 2050, shows just how fast the world must move to meet the goal of the Paris Agreement. Global climate security becomes the primary concern. Nations race to switch to cleaner energy and a competitive landscape emerges for technology, minerals and manufacturing capacity. Competition drives rapid change and the world reaches net-zero emissions in 2050. This scenario is “normative” and extremely challenging: it set goals of net-zero emissions by 2050 and warming restricted to below 1.5°C by 2100, and then worked back to the realities of 2022 to explore how these end points could be reached. Waste textiles – Tire-Pyrolysis – PHA

Key points from the Energy Security Scenarios include:

- Fossil fuels lose market share. The energy system is decarbonising, the questions is: how fast?

- There is no realistic path to an instant and steep drop in emissions.

- The average temperature rise is highly likely to breach 1.5°C.

- The future of energy is electricity, although hydrogen and bioenergy have significant roles to play.

- Bringing the temperature rise back down below 1.5°C will require large-scale carbon removal and storage.

Scenarios are informed by data, constructed using models and contain insights from leading experts in the relevant fields. Ultimately, for all readers, scenarios are intended as an aid to making better decisions. They stretch minds, broaden horizons and explore assumptions.

Explore the Energy Security Scenarios, including a summary, at www.shell.com/scenarios to find out more. Waste textiles – Tire-Pyrolysis – PHA

-Smart surface supports the next-gen automotive user interfaces

To support the next generation of automotive user interfaces and experiences, TouchNetix now provides its aXiom technology which helps smart surfaces.

This unique user interface chip technology seamlessly and cost-efficiently integrates underneath materials and fabrics. The market-leading SNR assists features including touch, force-sensing, haptic feedback, 3D proximity and hover sensing, even when an air gap separates the sensor and the user area. This technology can be implemented through all kinds of plastic, wood, glass, fabric, and even in combination.

Car manufacturers increasingly want to redefine automotive user experiences by offering intuitive, safer, and more modern user interfaces at smaller costs.

Backlit icons directly behind the dashboard fabric may be activated upon power-up or by using the aXiom 3D proximity-sensing gesture technology. Together with its patented touch and force-sensing technology allows for a modern and low-cost implementation of key functions directly on the dashboard. The single-chip technology supports curved shapes, finger guides, sliders, and buttons, directly on the dashboard fabric or on a touch display or pad. Waste textiles – Tire-Pyrolysis – PHA

-The Rise of Biodegradable Plastics & New Recycling Technology

Biodegradable plastics have emerged as a potential solution to the severe environmental problem caused by the production and disposal of traditional plastic. These plastics can be made from natural sources like plant-based materials and micro-organisms such as bacteria that can be used in a variety of industries such as packaging, construction, and healthcare. While plastic pollution remains a significant issue, biodegradable plastics and enzymatic plastic recycling offer promising alternatives.

For every human on this planet, there are 21 000 pieces of plastic in the ocean. If a legally binding global plastic treaty doesn’t come to fruition, plastic in the oceans will almost triple by 2040. And most of those pieces are tiny, and can’t be recycled. Humans produce over 300 million tons of plastic waste every year, with only 9% of it being recycled and about 19% incinerated to generate energy, according to the Organization for Economic Cooperation & Development.

Traditional plastics are non-biodegradable, meaning they do not decompose naturally in the environment. Instead, they break down into microplastics that pollute our ecosystems and pose a risk to human health. Waste textiles – Tire-Pyrolysis – PHA

As a result, plastic waste has found its way into our oceans, forming massive garbage gyres and causing harm to marine life. The Great Pacific Garbage Patch, the largest accumulation of ocean plastic, is estimated to be twice the size of Texas. Fortunately, scientists, entrepreneurs, and companies are developing biodegradable plastics and recycling technology (using pyrolysis and enzymes) to help mitigate the plastic pollution problem.

The Promise of Plant-Based Plastics

Biodegradable plastics, also known as bioplastics, are made from renewable resources such as plant-based materials, and they can break down naturally in an industrial composting facility. They offer a more sustainable alternative to traditional plastics, reducing the amount of plastic waste that ends up in landfills or pollutes our oceans.

There are different types of bioplastics, each with its unique properties and applications. For instance, polyhydroxyalkanoates (PHAs) are produced by microorganisms such as bacteria and can be used for packaging, agriculture, and medical devices.

Polylactic acid (PLA) is another common bioplastic made from renewable sources like corn starch, which can be used for food packaging, 3D printing, and textiles.

Waste textiles – Tire-Pyrolysis – PHA