Biodegradable-plastic – Sustainable-tire 07-01-2023 - Arhive

Biodegradable-plastic – Sustainable-tire

-Researchers develop new biodegradable plastic with thermoplastic properties similar to polyethylene

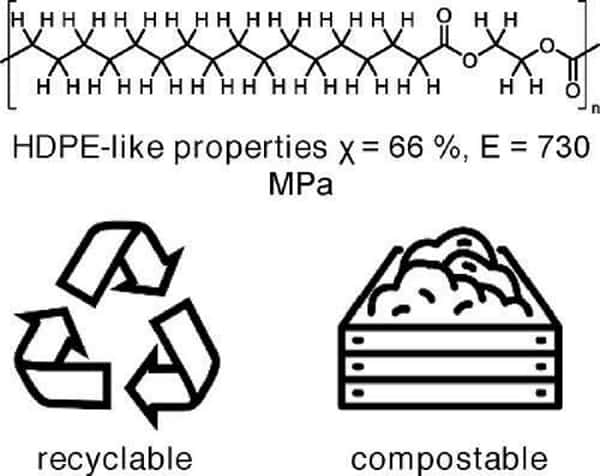

Polyethylene has a number of advantageous properties, but biodegradability is not one of them. A team of researchers has now developed a plastic which has similar thermoplastic properties to polyethylene but is also biodegradable. The material in question is a semicrystalline polyester that breaks down fully to its starting materials using mild chemical or biological processes, as the team explain in their study published in the journal Angewandte Chemie International Edition.

High-density polyethylene (HDPE) is a particularly strong and durable material. It owes its thermoplastic properties to the internal structure of its molecular chains, which are arranged in a crystalline manner with added attraction due to van der Waals forces. The molecular chains are also pure hydrocarbons. The combination of crystallinity and hydrocarbon content means microorganisms, which might be able to degrade the plastic, cannot access the chains to break them up. Biodegradable-plastic – Sustainable-tire

The research group of Stefan Mecking and colleagues, at the University of Konstanz, Germany, have now developed a polyester that has similar crystallinity to HDPE and also retains its beneficial mechanical properties. Unlike polyethylene, polyesters also contain functional groups that could theoretically be degraded chemically or enzymatically. However, under normal circumstances, the more crystalline a polyester is (i.e., the more similar to HDPE), the less readily it can be biodegraded.

The team was therefore understandably surprised by how quickly their crystalline polyester degraded when exposed to enzymes. “We tested degradation with naturally occurring enzymes, and it was an order of magnitude faster than with our reference material,” Mecking explains. It wasn’t just enzymatic solutions which degraded the material: soil microorganisms were also able to completely compost the polyester.

But what is it that makes this polyester so exceptionally biodegradable? The team were able to identify the significant contribution of ethylene glycol, one of the building blocks of the polyester. Mecking adds: “This building block is actually really common in polyesters. It gives you a high melting point, but it also increases degradability in these polyethylene-like materials.” Biodegradable-plastic – Sustainable-tire

Because of its good chemical and biological degradability, together with its mechanical properties, the new polyester could find applications as a recyclable thermoplastic material with minimal environmental impact. The end goal is closed-loop chemical recycling to break the plastic down into its raw materials and produce new plastics, Mecking adds. The added benefit of the team’s plastic is that, if any materials do get into the environment despite this closed loop, they can biodegrade and leave no lasting impact.

-Germany’s inflation rate estimated at 8.6% in December 2022: Destatis

The inflation rate for Germany is expected to be at 8.6 per cent in December 2022, compared to the corresponding period of the previous year, according to the provisional data by Federal Statistical Office (Destatis). Due to immediate assistance, the inflation rate in December is estimated to be significantly lower than in the previous months, with 10 per cent in November and 10.4 per cent in October.

Based on the results available so far, consumer prices are expected to decline by 0.8 per cent compared with November 2022. The annual average inflation rate is expected to stand at 7.9 per cent in 2022, as per Destatis. Biodegradable-plastic – Sustainable-tire

Energy and food prices, in particular, increased considerably since the war started in Ukraine and had a substantial impact on the inflation rate. However, the federal one-off payment in December 2022 to cover the monthly instalment for gas and heat had a downward effect on prices.

-Braskem Acquires Filament Supplier Taulman3D

The acquisition expands Braskem’s portfolio of 3D polyolefin-based filaments to nylon, recycled PETG and PET.

Braskem has acquired taulman3D, a leading 3D filament supplier of nylon, recycled PETG, and PET filaments to aerospace, automotive, healthcare, industrial, government and higher education professionals. Biodegradable-plastic – Sustainable-tire

The acquisition of the Linton, Ind., company is reportedly a perfect complement to Braskem’s existing portfolio of next-generation 3D printing filaments (PE, PP, carbon fiber, glass fiber & recycled polymers). Braskem offers solutions across technologies such as Fused Filament Fabrication (FFF), Selective Laser Sintering (SLS), and high-speed pellet extrusion. The taulman3D filament and polymer offerings include:

▪ Carbon fiber alloy nylon 3D printer filament

▪ Glass fiber alloy nylon 3D printer filament

▪ Alloy 920 3D printer filamen

▪ Alloy 910 high-heat 3D Printer Filamen

▪ PCTPE 3D printer filament

▪ Tech-G 3D printer filament

▪ T-Glase 3D printer filament

▪ Bridge nylon, nylon 230, nylon 645 & nylon 680 (FDA material)

▪ PA cast plate nylon 3D printer filament

▪ SAC1060 – support material for nylon

▪ Guideline 3D printer filament (Medical Grade)

▪ Enviro 100% recycled PETG 3D printer filament

Said Jason Vagnozzi, Braskem’s global commercial director of additive manufacturing, “Braskem’s acquisition of taulman3D brings a high-quality 3D filament producer with a globally diversified client list and a highly complementary product portfolio. With projections for the 3D printing industry expected to grow from $15 billion today to $78 billion by 2030 – growing at an estimated 20% CAGR – we see enhanced opportunities to serve this rapidly growing demand. Biodegradable-plastic – Sustainable-tire

Today’s acquisition doubles Braskem’s market share in the additive manufacturing market and further accelerates our growth strategy.”

-Goodyear develops 70% sustainable-material tire with industry-leading innovations

he company has made significant progress toward its goal of a 100% sustainable-material tire by 2030.

Today, The Goodyear Tire & Rubber Company announced the release of a demonstration tire with 70% sustainable-material content, including industry-leading innovations.

“We set an ambitious goal in 2020 to create a tire made 100% from sustainable materials in 10 years, and our scientists and engineers have made great progress toward that goal,” said Chris Helsel, senior vice president, global operations and chief technology officer. “This is an exciting achievement that demonstrates our commitment to increasing the use of sustainable materials in our tires.” Biodegradable-plastic – Sustainable-tire

The 70% sustainable-material tire includes 13 featured ingredients across nine different tire components, including those described below. Company performance indicators have shown the component properties to deliver strong overall tire performance.

- Carbon black is included in tires for compound reinforcement and to help increase their life and has traditionally been made by burning various types of petroleum products. Goodyear’s new tire features three different carbon blacks that are produced from methane, carbon dioxide, and plant-based oil. Initial life cycle assessments demonstrate either reduced carbon emissions compared with current methods of carbon black production or the use of bio-based or waste feedstock sources.

- The use of soybean oil in tires is a significant Goodyear innovation that helps keep a tire’s rubber compound pliable in changing temperatures. Soybean oil is a bio-based resource that reduces Goodyear’s use of petroleum-based products. While nearly 100% of soy protein is used in food/animal feed applications, a significant surplus of oil is left over and available for use in industrial applications.

- Silica is an ingredient often used in tires to help improve grip and reduce fuel consumption. Goodyear’s new tire contains a unique variety of silica produced from rice husk ash, a byproduct of rice processing that is often discarded and put into landfills. A high-quality silica has been produced from this waste ash.

- Polyester is recycled from plastic bottles and other plastic waste by reverting the polyester into its base chemicals and reforming them into technical grade polyester feasible for tire cords. Biodegradable-plastic – Sustainable-tire

The 70% sustainable-material tire has been produced as a demonstration tire.

-India’s Nayara Energy to start up new PP unit in end-2023

India’s Nayara Energy expects to begin operations at its greenfield 450,000 tonne/year polypropylene (PP) plant between October and December 2023.

The new PP plant has been built at a site adjacent to the company’s existing refinery complex at Vadinar in the western Gujarat state, with a capital outlay of around $750m.

“The PP plant is part of the company’s vision of revamping and revitalising its Vadinar refinery into a world-class integrated refinery petrochemical complex,” Nayara Energy said in a statement on 30 December. Biodegradable-plastic – Sustainable-tire

The petrochemical complex is being developed in phases. The PP line, a propylene recovery unit, along with upgrades to an existing fludized catalytic cracking (FCC) unit form Phase 1 of Nayara’s petrochemical complex.

“Phase-1 project development has achieved over 85% progress,” it said.

The revamped FCC unit was commissioned on 20 December 2022 and the company expects to begin pre-commissioning activities at the propylene recovery unit in February, it added.

“With completion of the FCC revamp, we have made significant progress on our petrochemical entry,” Nayara Energy CEO Alois Virag said.

In the second phase, the company expects to set up an integrated petrochemical complex, he added. Biodegradable-plastic – Sustainable-tire

Nayara Energy’s refinery in Vadinar, Gujarat is the second largest in India. It has an annual capacity of 20m tonnes which constitutes about 8% of India’s overall refinery capacity.

-Packaging and waste recycling, Italy’s primacy in the EU

The recycling rate of packaging and waste in Italy has been growing steadily for 25 years and is confirmed to be at the top of the European ranking. The data comes from the Report ‘Recycling in Italy 2022’, presented on 16.12.22 by the Foundation for Sustainable Development at the National Conference of the Recycling Industry. (1)

Edo Ronchi – president of the Foundation for Sustainable Development as well as ‘father’ of the waste management reform, as the Minister of the Environment who launched it – indicates some useful measures to improve the demand for recycled products (MPS, secondary raw materials) . Biodegradable-plastic – Sustainable-tire

1) Waste recycling, the Italian revolution

In 25 years, thanks to the reform launched with the legislative decree 22/1997, Italy has gone from the waste emergency to excellence in recycling:

- in 1997 only 9,4% of urban waste and 21% of industrial waste were subject to separate collection and recycling. While 80% and 33%, respectively, ended up in landfill,

- in 2020 separate collection and recycling have reached 63% of municipal waste and 70% of industrial waste, while landfill disposal has dropped to 20% and 6%.

The Italian recycling industry is today a strategic sector of the national production system with 4.800 companies, 236.365 employees, a production of over 25 million tons of recycled materials (+13,3%, between 2014 and 2020) and an added value of 10,5 billion ( +31% in the period 2010-2020).

2) Recycling, the Italian record in the EU

The Italian primacy in the EU in the recycling of waste and packaging waste is remarkable:

- 72% the average recycling rate of all urban and special-industrial waste in Italy, compared to an average of 53% in the EU and 55% in Germany, its leading industrial power,

- 21,6% the rate of use of recycled materials out of the total consumed materials, compared to 12,8% in the EU and 13,4% in Germany (2020 data),

- 73,3% the recycling rate of packaging waste (10,5 million tonnes in 2021), already higher not only than the European target for 2025 (65%) but also the one set for 2030 (70%), 9 years in advance. Biodegradable-plastic – Sustainable-tire

3) The needs of the sector

‘The recycling sector, a fundamental pillar of a circular economy. it is strategic in order not to waste precious resources, not to fill the country with landfills, to recover materials useful for the economy and reduce greenhouse gas emissions. In a moment of negative economic situation, therefore, the following are needed:

- incisive measures to strengthen the demand for MPS, the secondary raw materials produced with recycling, e

- structural interventions to address the sharp increase in energy costs which for the recycling industry constitute the largest share of production costs’ (Edo Ronchi, president of the Foundation for Sustainable Development).

3.1) Strengthen the demand for recycled materials

Measures proposals to strengthen the demand for recycled materials (MPS, secondary raw materials) are:

- introduce a reduced VAT rate on recycled material, to be compensated with an increase in the levy on waste disposed of in landfills or incinerators,

- provide for the obligation to acquire set minimum quantities of recycled material in green public procurement (Green Public Procurement, GPP) and related Minimum Environmental Criteria (CAM),

- increase the use of recycled material in the production sectors through specific sector agreements. Biodegradable-plastic – Sustainable-tire

3.2) Structural interventions to mitigate energy costs

Structural interventions to reduce the sector’s exposure to energy costs they should, according to the Foundation for Sustainable Development:

promote research and innovation aimed at improving the efficiency and saving of electricity and heat,

simplify the procedures for the ‘thermal valorisation’ of the residues of the recycling processes. A delicate issue, given the risks of environmental pollution and public health.

4) Italy, updated data on the 19 recycling chains

The report ‘Recycling in Italy 2022’ means the performance for each of the 19 recycling chains, where Italy stands out in most cases with record numbers at European and global level. Biodegradable-plastic – Sustainable-tire

Paper and glass, high recycling

The recycling rate of paper packaging in 2021 reached 85% and for glass 77% and have exceeded the European target for 2030.

in 2021 63% of paper and cardboard and 61,6% of glass produced in Italy are derived from recycling.

Plastic packaging, progress and challenges

Al 2021 the recycling rate of plastic packaging waste reached 56%, +14% compared to 2016, exceeding the EU target for 2030 (55%).

The new European method measurement of the targets will also reduce the indicated value. It will therefore be necessary to increase separate collection and/or the development of new recycling technologies. Biodegradable-plastic – Sustainable-tire

Aluminum and steel, good levels of recycling

The quote recycling of packaging released for consumption in 2021 reached 68% for aluminum and 72% for steel. Italy is the European leader in the recycling of scrap iron.

Wood recycling, Italian excellence in chipboard panels

In 2021 the percentage of recycling of wood packaging released for consumption has reached 65%, almost double the EU average (32,4%).

97% of the wood material recycled in Italy is transformed into chipboard panels, a sector where Italy is a world leader. Biodegradable-plastic – Sustainable-tire

Bioplastics, the Italian case

1,6 million tons of bioplastics compostable were produced in Italy in 2021, +25% compared to 2020. Also due to the national derogation – of dubious legitimacy, as seen – the prohibitions and limits imposed by the UAS directive (Single-Use Plastics).

According to estimates sector, following the recognition of the Biorepack Consortium, the organic recycling of these materials will be able to reach 51,6 thousand tons in 2024. An ‘Italian case’, where politics has encouraged an innovative industrial sector without sparing, literally, the expense . Biodegradable-plastic – Sustainable-tire

Organic fraction, recycling is growing

7,2 million tons (Mt) of organic waste were sent for recycling in 2020, obtaining approximately 2,2 Mt of compost and approximately 130 million m3 of biomethane.

One need remains the improvement of plants to produce quality compost and biomethane is a priority.

Worn tyres, numbers still low

in 2020, over 442 thousand tons of ELTs (end of life tires) were managed in Italy. In 2021, 52% of ELTs were destined for energy recovery, 48% for material recovery.

To deal with possible limitations of the use of ELT rubber infills in synthetic fields, the ministerial decree is awaited for the use of powder for modified asphalts.

WEEE, growing collection but far from EU target

385.000 t of WEEE (waste from electrical and electronic equipment) were sent for treatment in 2021. +5,3% compared to 2020 but still little compared to the EU target of 65% for 2019, all the more considering the growth rates of sector sales ( +16,6% in 2021). Biodegradable-plastic – Sustainable-tire

Batteries and Accumulators, collection down

in 2021 10.200 t of exhausted portable batteries and accumulators were collected, a decrease compared to 2020 (-7,4%) and equal to 32% of the input in the last three years, still far from the European target of 45% set since 2016.

Waste mineral oils, the collection is growing

77.000 tons of vegetable and animal oils and fats have been sent for recycling, +5% compared to 2020. 98% of the harvest has been regenerated.

Discontinued vehicles, not online yet

1,2 Mt of vehicles were treated in 2020, down (-5,8%) compared to the previous year. The supply chain records a recycling and reuse rate of 84,7% of the average weight of the vehicle, in line with the target established in the EU in 2015 (85%) but not yet the current one of 95%, due to the lack of plants . Biodegradable-plastic – Sustainable-tire

Textile waste, expected growth

Separate collection mandatory for textile products was introduced in Italy at the beginning of 2022, three years ahead of the deadline established in the EU.

The quantities of textile waste collected and sent for recycling (143.300 tons in 2020, decreased by 9% compared to 2019) should therefore grow considerably in the coming years.

Inert waste, a critical phase

inert waste from construction and demolition started in Italy in 2020 to the recovery of materials were 39,1 Mt, equal to 77,9% of those produced, well beyond the European target (70%).

The DM End of waste, in force since 4.11.22, could decrease these performances in prescribing quality requirements of the aggregates that require new investments.

Waste from street sweeping, collection grows

Between 2016 and 2020 street sweeping waste collection doubled, from 215 to 422 kt. However, a still significant portion of these materials is still sent to landfills, without any type of pre-treatment. Biodegradable-plastic – Sustainable-tire

Sewage sludge, boost recovery

in 2020 the management of sludge from urban waste water treatment involved over 3,4 Mt. 53,5% was sent to disposal operations, 44,1% to recovery operations. The Italian disaster goes on.

Mineral oils, high recovery rate

The oil supply chain lubricants in Italy holds a record of European excellence. The recovery rate of used oil exceeds 46% (41% EU average) and the regeneration of collected oil has for some years been established at 98% (61% in EU).

Solvents, mostly recycled

in 2021 77% of wastewater with solvents was recycled, 21% disposed of and 2% sent for energy recovery.

5) (Op)positions to the Proposal for a Regulation on Packaging and Packaging Waste (PPWR)

The Italian industries of recycling and bioplastics claim to maintain a leading role in the circular economy, regardless of its own paradigm, the hierarchy of waste or Lansink scale.

The (op)positions expressed at the proposed regulation on waste and packaging waste (PPWR, Packaging and Packaging Waste Regulation) thus tend to favor recycling compared to:

material reduction. The first objective of the circular economy has already been betrayed in Italy, where the continuation of the use of disposable plastic objects is allowed when made of bioplastic. Biodegradable-plastic – Sustainable-tire

And the industries of the sector, ça va sans dire, claim to continue in this direction which is already contrary to EU rules, as well as logic,

reuse of materials. The recycling sector also asserts primacy over reuse and consequently also opposes the deposit system (Deposit Return System, DRS). (2) Without any consideration, it goes without saying, of the very different environmental impact of reuse compared to producing new materials and disposing of others, perhaps in incinerators.

Biodegradable-plastic – Sustainable-tire