Carbon dioxide upcycling – MIT has unveiled a groundbreaking development: supercapacitor concrete infused with carbon black 13-09-2023 - Arhive

Carbon dioxide upcycling

Stellantis’ E-fuel Initiative Preserves Internal Combustion Engines Until 2050

Stellantis has unveiled a game-changing strategy to ensure the longevity of endothermic vehicles until 2050, effectively sidestepping the European Union’s “Fit for 55” regulations. This remarkable effort by the automotive powerhouse, formed through the merger of FCA and PSA, hinges on the use of e-fuels.

In a significant development, Stellantis has charted a path to safeguard internal combustion engines. This global automotive conglomerate, boasting an impressive portfolio of brands including FIAT, Lancia, Alfa Romeo, Abarth, Jeep, Maserati, Dodge, Chrysler, Ram, Peugeot, Citroen, DS Automobiles, Opel, and Vauxhall, has devised a solution that ensures the continued operation of its vehicles until 2050, effectively bypassing the European Union’s “Fit for 55” plan slated for enforcement from 2035.

Stellantis has conducted extensive trials, revealing that e-fuels demonstrate compatibility with the group’s current Euro 6 vehicles. Carbon dioxide upcycling

These experiments, conducted in collaboration with Aramco, mark a significant stride toward achieving the ambitious goal of making e-fuels accessible at affordable prices to the mass market. Such a development would extend the lifespan of internal combustion engines on the roads for an additional 15 years beyond 2035.

It is worth noting that the “Fit for 55” provisions exclusively pertain to new vehicles. Consequently, combustion engine cars purchased between now and 2034 will retain the ability to operate even beyond the 2035 regulatory deadline. Carbon dioxide upcycling

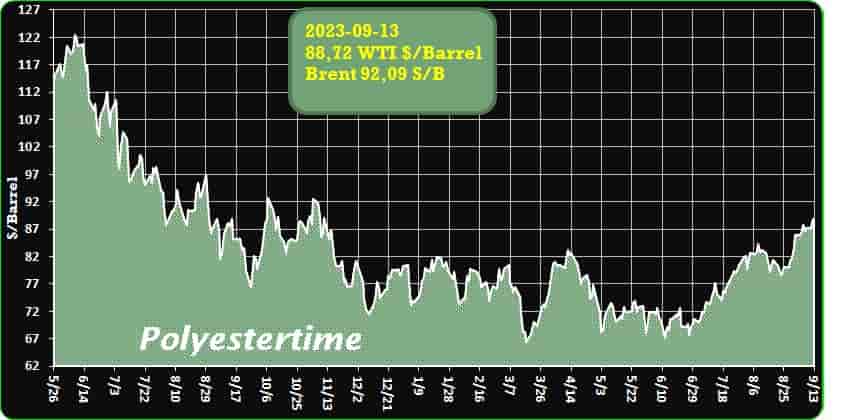

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

Techtextil India 2023: Unveiling Cutting-Edge Innovations and Business Opportunities in the World of Technical Textiles

The grand inauguration of the 9th edition of Techtextil India has taken place at the prestigious Jio World Convention Centre (JWCC) in Mumbai. This momentous event has brought together over 160 prominent industry players, each showcasing more than 200 esteemed brands. Techtextil India 2023 is not just an exhibition; it’s a convergence of state-of-the-art products, groundbreaking technological solutions, a plethora of knowledge-sharing sessions, live product demonstrations, and extensive networking prospects. Carbon dioxide upcycling

India’s technical textiles sector is currently experiencing a rapid growth trajectory, driven by relentless research and development endeavors, bolstered by various government initiatives, and the expanding footprint of diverse industries. Inaugurating this illustrious event, Smt. Darshana Jardosh, Minister of State for Railways and Textiles, Government of India, underscored the nation’s imperative to attain self-reliance in research, development, and innovation, thereby diminishing reliance on high-performance fiber imports. She emphasized the pivotal role played by professional platforms like Techtextil India in nurturing industry growth by providing valuable insights into global and domestic trends, products, and innovations spanning the entire textile value chain.

The inauguration of Techtextil India 2023 witnessed the presence of distinguished figures, including Shri. Rajeev Saxena, Joint Secretary, Ministry of Textiles, and other key luminaries in the industry. Carbon dioxide upcycling

The event enjoys substantial support from the Ministry of Textiles, Government of India, and various industry associations, highlighting the sector’s paramount significance in the country’s economy.

The exhibition floor boasts an extensive array of exhibitors presenting a wide spectrum of offerings, ranging from machinery, equipment, accessories, fibers, yarns, non-wovens, filtration solutions, masterbatches, functional textiles, composites, coated textiles, and much more. Esteemed Indian companies such as Arvind Limited, Park Non-woven, Sarex Chemicals, Welspun, Reliance, and Aditya Birla Yarns are participating alongside international stalwarts hailing from China, Taiwan, South Korea, Germany, Italy, and the USA.

Techtextil India 2023 provides a pivotal platform for global business networking and fostering connections. It has attracted the participation of renowned companies such as Indorama Hygiene Group, Autefa Solutions, Brückner Textile Technologies, Georg Sahm, Karl Mayer, and many others, reinforcing its stature on the global stage.

The event commenced on a highly positive note, with exhibitors from around the world showcasing their finest products. Mr. Raj Manek, Executive Director and Board Member of Messe Frankfurt Asia Holdings Ltd, expressed optimism about the event’s potential to empower the textile industry. Carbon dioxide upcycling

He underscored the invaluable support from the Ministry of Textiles in promoting initiatives and projects aimed at propelling the growth of the textile sector.

Techtextil India 2023 also features the Techtextil Symposium, delving into critical industry topics, and the 3rd edition of MEDITEX TM, focusing on advancements in medical textiles.

Backed by numerous associations and centers of excellence, Techtextil India continues to serve as a comprehensive platform for professionals to forge trade relationships, gain insights into market trends, and share their expertise. Its ultimate aim is to position India as a global leader in the technical textile market, catalyzing growth and fostering innovation within the industry. Carbon dioxide upcycling

Sabic collaborates on bio-sourced in-mould labelling solution

Together with three partners, Sabic is producing mono-PP thin-wall containers with in-mould labelling in an integrated single-step injection moulding process.

A new initiative from Sabic in collaboration with three other partners has demonstrated that certified renewable polymers are also suitable for use in in-mould labelling food packaging applications.

The four companies, Saudi chemical manufacturing company Sabic, Dubai-based Taghleef Industries and the two Greek partners Karydakis IML and Kotronis Packaging, announced they successfully produced the first mono-polypropylene (PP) thin-wall containers with in-mould labelling made from a mass balanced, certified renewable resin. According to the partners, this was achieved without compromising on quality, safety, processability, or convenience. Carbon dioxide upcycling

Both the cups and the label film used for the containers have been made with mass balance certified bio-based feedstock from Sabic’s Trucircle portfolio. The label material for the IML containers is a biaxially oriented polyethylene (BOPP) film produced by film manufacturer Taghleef using a Sabic certified renewable resin tailored to the BOPP process. Taghleef ‘s transparent, white and metallised PP label films can be easily customised to fit the customer’s needs, and all can be produced using polymers with bio-based feedstock.

Sabic said the feedstock is derived from second-generation sources not competing with food or feed production. Besides using certified bio-based PP resins for both the moulded parts and the label film, the resulting packaging can be recycled in existing rigid PP recycling streams.

In-mould labelling technology, in which the label becomes an integral component of the packaging itself, eliminates the need for separately applied adhesive labels on the finished packaging product. Decoration of the product takes place inside the mould. The label is placed in the mould, after which plastic is injected over the label.

This forms a permanent, tamper proof bond between label and container right in the mould, said Augustinos Kotronis, General Manager at Kotronis Packaging. The end result is a decorated packaging part that is produced in a single step.

Demand for the technology is steadily increasing, with cost efficiency and sustainability playing a key factor. Carbon dioxide upcycling

MIT has unveiled a groundbreaking development: supercapacitor concrete infused with carbon black

This remarkable advancement holds the promise of reshaping structures like buildings and roads into colossal electric energy reservoirs, offering a transformative solution to the storage of renewable energy. Dive into the world of this innovative technology and witness its profound impact on the realm of sustainable energy.

MIT has introduced a groundbreaking achievement in the form of supercapacitor concrete infused with carbon black. This monumental breakthrough has the potential to revolutionize the concept of buildings serving as colossal electric energy reservoirs, effectively tackling the critical issue of renewable energy storage.

At the heart of this pioneering discovery lies a surprisingly simple ingredient: carbon black.

Carbon black, derived from the incomplete combustion of hydrocarbons, boasts outstanding resistance and conductivity properties, making it a widely utilized material across various industries. Carbon dioxide upcycling

Its incorporation into the supercapacitor concrete development process highlights how a commonplace element can redefine our approach to energy storage.

The Future of Renewable Energy with Supercapacitor Concrete

Clean energy stands as the linchpin to a sustainable future, yet the conundrum of efficient storage persists. A collaborative research endeavor between MIT and the Wyss Institute is poised to tackle this challenge head-on, quite literally under our feet. By amalgamating cement and carbon black with water, these researchers have crafted concrete featuring intricate, thread-like structures that form a fractal network of highly conductive carbon. This network, when infused with a conductive salt solution, facilitates the adhesion of charged particles from the electrolyte, culminating in a concrete-based supercapacitor.

In their experiments, the researchers interconnected three cement-carbon supercapacitors, yielding the equivalent of a 3 V battery. However, their ambitions reach higher; they aspire to design 12 V supercapacitors, connecting them to unleash even greater charging power. It is estimated that a 3.5-meter concrete block could potentially store up to 10 kWh of electricity, paving the way for homes and buildings to become vast repositories of renewable energy. Carbon dioxide upcycling

Applications of Carbon Black Cement for Energy Production

This groundbreaking material, capable of simultaneously generating energy, has the potential to clad virtually every residence and edifice worldwide. The scope of this innovation, however, extends beyond these horizons. Researchers are exploring the concept of constructing concrete roads equipped with the ability to provide contactless charging for moving electric vehicles. This paradigm shift could accelerate the transition toward a more sustainable world in unprecedented ways.

Nevertheless, it is essential to temper our enthusiasm, as MIT’s work remains ongoing. Challenges, such as the need to maintain the cement’s moisture levels when in contact with the electrolyte solution, persist.

However, this discovery brings us significantly closer to a sustainable future, addressing a pivotal challenge in the realm of clean energy that goes beyond traditional photovoltaic systems: efficient and accessible energy storage.

The supercapacitor concrete innovation offers a vivid glimpse into a world where our streets and homes are integral components of a groundbreaking green energy infrastructure. Carbon dioxide upcycling

Coca-Cola Europacific Partners (CCEP) has unveiled its second collaboration dedicated to exploring carbon dioxide (CO₂) upcycling technology

This innovative investment aims to pioneer sustainable packaging materials and will be conducted in partnership with researchers at Swansea University in the United Kingdom.

The primary objective of this research project is to revolutionize the manufacturing of ethylene, a fundamental component of plastics, including HDPE used for crafting plastic bottle caps. The initiative seeks to develop technology that can harness CO₂ extracted from the atmosphere, offering an eco-friendly alternative to the conventional use of fossil fuels in ethylene production. This advancement promises a more sustainable approach to plastic packaging creation.

This project marks the latest venture financed through CCEP’s innovation investment arm, known as CCEP Ventures (CCEPV). It is part of a series of investments geared towards fostering innovation and sustainability, aligning with CCEP’s ambitious goal of achieving net zero emissions by 2040.Carbon dioxide upcycling

Over a span of three years, the project will initially concentrate on refining an efficient and productive process for converting CO₂ into ethylene. Subsequently, it will assess options for scaling up production.

As a component of its sustainability agenda, known as “This Is Forward,” CCEP remains steadfast in its commitment to minimizing the environmental impact of its packaging and hastening the transition towards a circular economy for plastics. This investment builds on prior collaborations aimed at advancing cutting-edge climate technologies, including a recent partnership with the University of California, Berkeley (UCB) for scalable CO₂-to-sugar conversion methods and an investment in CuRe, a technology that breathes new life into hard-to-recycle plastic polyester waste.

These strategic investments are geared towards enhancing the long-term sustainability of critical raw materials and packaging, thereby accelerating efforts to reduce carbon emissions within supply chains, all while achieving cost savings in materials, transportation, and logistics. FCarbon dioxide upcycling

This announcement comes on the heels of the news that CCEP, in conjunction with The Coca-Cola Company and seven other global bottling partners, has launched a separate $137.7 million venture capital fund exclusively dedicated to sustainability investments. This fund will complement CCEP Ventures, which focuses on early-stage businesses, by investing in companies poised for commercialization in the sustainability sector.

For more information, please visit Coca-Cola Europacific Partners (CCEP).

U.S. Researchers Revolutionize Chemical Recycling Process with Table Salt Catalyst

Scientists at Michigan State University (MSU) have unveiled a groundbreaking breakthrough in chemical recycling using an unlikely catalyst: table salt, or sodium chloride (NaCl). Their discovery, detailed in the publication “Revolutionizing Plastics Chemical Recycling with Table Salt” in Advanced Sustainable Systems, highlights the superior performance of salt in comparison to expensive chemicals in the pyrolysis of polyolefins.

The MSU team employed table salt to facilitate the low-temperature pyrolysis of polyolefins, including high-density polyethylene (HDPE), low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), and polypropylene (PP), in a ratio of 4:2:2:3, respectively. Their findings were compared with the results obtained using platinum on carbon or aluminum as a catalyst.

Notably, while platinum boasts remarkable catalytic properties, it comes at an exorbitant cost of approximately $29,000 per kilogram, whereas table salt is an economical alternative at just $0.04 per kilogram. Carbon dioxide upcycling

The pyrolysis process using table salt as a catalyst yielded 86% liquid and 14% gas by weight, with no undesirable solid wax byproduct, in stark contrast to the use of platinum on carbon or aluminum, which resulted in 54% and 62% solid wax production, respectively. The wax derived from plastic pyrolysis is typically considered low-value and requires further refining processes such as cracking to yield useful chemicals, diesel, petroleum, and gasoline.

Muhammad Rabnawaz, an associate professor at MSU’s School of Packaging, expressed enthusiasm, stating, “This is really exciting. We need simple, low-cost solutions to address a significant challenge like plastics recycling.”

While the use of table salt as a catalyst shows promise in closing the plastic waste loop, the resulting pyrolysis oil is unsuitable for creating new polymers. Rabnawaz and his team observed that the oil generated when employing table salt as a catalyst primarily consists of hydrocarbon molecules similar to those found in diesel fuel. They believe that the process can be further refined to produce liquid products with more valuable applications than mere fuel combustion, as noted in an MSU statement. Additionally, the researchers acknowledged the need for further investigation to comprehensively characterize the gas emissions produced during the process. Carbon dioxide upcycling

The study also demonstrated the successful pyrolysis of metallized plastic using table salt, achieving remarkable conversion efficiencies. While table salt did not surpass a platinum-alumina catalyst, it delivered comparable results at a fraction of the cost.

According to a preliminary economic analysis supported by the U.S. Department of Agriculture and MSU AgBioResearch, the adoption of this innovative method in a commercial pyrolysis reactor could result in a 3.5-fold increase in revenues compared to pyrolysis without the use of salt.

Notably, the research received partial support from Conagra Brands, a U.S.-based consumer packaged goods company, further underscoring its potential for real-world application and impact.

The Russian packaging industry is confronting a unique set of obstacles in the midst of Western sanctions, as reported by Packaging-gateway

Unlike previous crises marked by universal trends such as dwindling demand and reduced purchasing power, the current landscape in the Russian packaging sector presents distinctive challenges.

Amid these sanctions, the industry contends with shortages in various packaging materials, including PET packaging, aluminum caps, moisture-resistant paper labels, and critical additives necessary for production. Since the commencement of Russia’s invasion of Ukraine, numerous companies have divested or offloaded their packaging operations in Russia, including Heineken, Mondi, and Smurfit Kappa.

These pressures are further compounded by regulatory scrutiny, which now extends to controlling prices not only for polymers but also for packaging and the products themselves. Carbon dioxide upcycling

On a global scale, approximately 3.9 billion tons of food are produced annually, with nearly one-third of it going to waste. Packaging plays an indispensable role in minimizing these losses. Despite ongoing efforts to protect the environment and enhance ecological sustainability, the global packaging industry is experiencing substantial growth. According to research by Horvath & Partner AG, a Swiss consulting firm, the sales of packaging products are projected to surge from $770 billion in 2021 to $1 trillion by 2025.

The majority of packaging materials used in the global food industry are derived from non-renewable resources, particularly polyolefin-class polymers like polyethylene and polypropylene. Polymer packaging, both flexible and rigid, constitutes a significant share of the market, both on the international stage and within Russia. Flexible packaging bio-sourced

More than 60% of flexible packaging worldwide finds application in the food industry, and experts predict that the global flexible packaging market will surpass $250 billion by 2024. According to a survey conducted by the Flexible Packaging Association in the United States, 83% of brands currently employ some form of flexible packaging. Moreover, 26% of these brands have increased their utilization of flexible packaging in the past five years, with an additional 31% planning to do so in the near future. Flexible packaging for food products is prevalent both in foreign countries and within Russia.

It’s worth noting that Russia is diversifying its list of crude oil buyers, as revealed by LSEG data and traders, by shipping its first crude oil cargo to Brazil.

This move comes in response to the severe limitations imposed by U.S. and EU sanctions, with Russia having heavily relied on India and China as its primary crude oil buyers following the imposition of European embargo and price cap policies in December of the previous year, subsequent to Russia’s actions in Ukraine, which Moscow describes as a special military operation. Carbon dioxide upcycling

The VDMA has projected a 2% decline in machinery production for both 2023 and 2024

This pessimistic outlook stems from the significant impact of a weakened global economy on the German machinery and plant engineering sector.

The most recent production forecast issued by the Association of German Engineering Industry (VDMA) paints a bleak picture for the latter half of 2023. The sector, heavily reliant on exports, faces challenges due to a stumbling global economy and a shortage of new orders.

Up to this point, companies have been enjoying the benefits of order backlogs, which resulted in a 1.7% real growth in production during the first seven months of the year. However, this buffer is gradually depleting, and the current year’s order intake, through July, is 14% lower than the previous year, exerting a negative impact on production. Dr. Ralph Wiechers, Chief Economist of VDMA, stated, “This decrease in orders will likely lead to a 2% decline in real production for the mechanical and plant engineering sector compared to the previous year.”Carbon dioxide upcycling

In the more stable three-month period from May to July 2023, orders experienced a substantial 12% year-on-year decrease in real terms. Domestic orders decreased by 6%, while foreign orders declined by 15%. Euro countries registered a 17% drop from the previous year, while non-euro countries saw a 14% decline.

Immediate improvement does not appear promising. The uncertainty prevails, as the duration and intensity of the current global economic weakness remain uncertain. According to Wiechers, global conditions might stabilize in 2024 and potentially witness growth from a new, albeit lower, level. However, he noted, “Currently, there is no momentum, either domestically or abroad, for a robust business resurgence. Stubborn inflation leading to stringent monetary policies by major central banks, the Ukraine conflict with its political and economic ramifications, ongoing geopolitical tensions between the USA and China, and the heated debate over competitive conditions all contribute to a lack of investor confidence and optimism.” He anticipates another real production decline of 2% in 2024 compared to the preceding year.

Despite these challenges, there are positive indicators. Capacity utilization remained nearly constant at a robust 88.8% in July, well above the long-term average, despite decreasing order numbers. Additionally, the core workforce saw a slight 1.5% increase in employment in June, totaling 1.02 million people (in companies with more than 50 employees). Exports exhibited notable growth, increasing by 11.5% in nominal terms and 3% in real terms year-on-year during the first half of 2023. Carbon dioxide upcycling

Wiechers concluded on a cautiously optimistic note, saying, “These factors demonstrate that the machinery and plant engineering sector is not in crisis mode; it remains exceptionally resilient. What would greatly benefit us now are a less tumultuous environment and politically astute decisions that address the numerous challenges and rekindle global customer confidence in investing in climate-neutral futures and transformative technologies.”

Carbon dioxide upcycling