Microplastic pollution CATL battery – Is Superfast Charging Battery the future? 19-08-2023 - Arhive

Microplastic pollution CATL battery

Xi Jinping’s Move: Market Shutdown and Crackdown on the Wealthy

The label of a “time bomb” affixed by Joe Biden onto China in the midst of increasingly conspicuous economic difficulties allows for diverse interpretations. This analysis will diverge from strict economic considerations, leaving to others the task of forecasting a potential oriental version of the Lehman Brothers crisis. Instead, the focus will be on deciphering the underlying causes of the crisis and envisioning its potential trajectory from Beijing’s perspective.

A noteworthy fact is the transformation of seventy-year-old Xi Jinping into a highly centralized figure in the Chinese political landscape, reminiscent of the levels of power consolidation seen during Mao’s era. In the wake of Deng Xiaoping’s “Get rich!” slogan, China had witnessed a gradual wane in its liberal trajectory, gradually succumbing to authoritarian control exerted by a Communist Party that had grown progressively less adherent to communist ideals.Microplastic pollution CATL battery

Guided by Xi Jinping’s input, the Communist Party has incrementally seized control of the Chinese economy. This neo-statist approach, constraining private enterprise and investment, emerges as a pivotal factor behind the present crisis. However, the West’s mounting apprehensions regarding Beijing’s unmistakable aspirations for global hegemony also contribute to this predicament. Beijing’s tactics in suppressing the potential democratization of Hong Kong, the formidable threats directed at Taiwan, viewed as a democratic alternative to mainland China, and the assertive expansionism in the South China Sea all instigate a natural inclination for distancing. The perils of maintaining overly proximate economic ties (including the supply of strategic resources) with Beijing become evident, particularly given Russia’s recent attempt to exert pressure on Europe through gas supplies amidst its aggression against Ukraine. The West’s response has involved diversifying manufacturing to new locations, chiefly India, or repatriating production facilities. Microplastic pollution CATL battery

Conventional wisdom dictated that Xi should ease his grip on state control as China’s youth unemployment soared beyond 20% according to official statistics. Yet, Xi Jinping is no proponent of liberalism. In tandem with Vladimir Putin, he aspires to dismantle the American-led global order and supplant it with an alliance of illiberal autocracies. Rather than revitalizing the economy by harnessing private initiative and capital, Xi has chosen an alternative route. In response to the disillusionment of young Chinese who grew up amidst the mirage of bourgeois prosperity, he employs a Maoist strategy: encouraging acceptance of modest but honorable manual labor and even advocating for work in rural areas or as volunteers. This approach unveils the regime’s true essence and underscores Xi’s willingness to undertake the associated risks.

Nonetheless, an unsettling prospect looms over China, one stemming from its prolonged period of rapid growth: internal tensions spilling over into external conflict or outright war. It holds significance that at the ripe age of one hundred, Henry Kissinger embarked on a journey to Beijing, delivering an impassioned plea. He implored the Chinese Dragon and the American Eagle to collaborate rather than engage in confrontation. Nevertheless, many analysts project an inevitable long-term clash between an ambitious Beijing and the United States, the master of maritime dominance. Microplastic pollution CATL battery

Should the ongoing crisis, grounded in tangible economic struggles, morph into a crisis of consensus concerning the absolute authority of the Chinese Communist Party, Xi may be tempted to disregard the advice of the US Realpolitik master and amplify the crescendo of his muscular nationalism. In the intricate tapestry of China’s complex trajectory, Xi Jinping’s decisions wield the power to reshape not only the nation’s economy but also the contours of global geopolitics.

The German Packaging Prize’s “Sustainability” category witnessed a definitive victor this year: the ShoulderFlex bottle, weighing an astonishingly low 5.9 grams

The weight of this innovative creation clinched the honor for the lightweight wonder, as it stood as a pioneering solution in the realm of sustainable packaging. What sets the ShoulderFlex apart is its remarkable ability to significantly curtail the carbon footprint attributed to water bottling. This feat is achieved by accomplishing a remarkable material reduction of up to 50 percent when compared to the standard 0.5-liter water bottles prevalent in the market.

At the heart of this achievement lies Krones’ ingenious bottle design, a design that seamlessly marries lightweight construction with a substantial positive impact. The benefits of this design, however, extend beyond its mere weight, manifesting themselves throughout the bottle’s entire lifecycle, from production to processing. Even without relying on the stabilizing influence of nitrogen pressurization, the ShoulderFlex bottles exhibit impeccable stackability, capable of accommodating an impressive topload of up to 40 kilograms. Microplastic pollution CATL battery

Central to Krones’ overarching vision is the concept of responsible packaging material usage, a philosophy that embraces the creation of sustainable packaging solutions that embody not only resource efficiency but also practicability. The ShoulderFlex stands as a prime embodiment of this vision, fulfilling these requisites in their entirety. Martin Loistl and Jochen Forsthövel, integral members of the development team behind this innovation, elaborate, “ShoulderFlex adeptly addresses the essence of our vision – judicious packaging material usage. It not only stands as a testament to our commitment to sustainability but also serves as a testament to the feasibility of such endeavors. Despite requiring reduced amounts of PET for production, these containers do not compromise on stability or convenience in comparison to the conventional bottles currently populating the market.”

The innovation, as championed by Krones, takes a substantial stride in advancing the cause of sustainable packaging solutions. The ShoulderFlex bottle encapsulates an impressive narrative of lightweight ingenuity that translates into tangible ecological benefits. The reduction in material consumption translates directly to a noteworthy decrease in the carbon emissions and resource utilization associated with conventional water bottling methods.

By reimagining the bottle’s construction, Krones has opened up a realm of possibilities where sustainability and practicality align seamlessly. Microplastic pollution CATL battery

For those seeking to delve deeper into this ground-breaking achievement, a visit to Krones is a must. Their dedication to pushing the boundaries of packaging innovation is evident through the ShoulderFlex, a product that not only embraces lightweight design but also champions the cause of environmental preservation. It is a testament to the transformative power of rethinking traditional methodologies and embracing visionary concepts.

In a world where sustainability has transcended the realm of buzzword to a dire necessity, the ShoulderFlex bottle signifies a pivotal turning point. It dismantles the assumption that lightweight equates to fragility, instead showcasing that substance and sustainability can thrive in harmony. Krones’ commitment to sustainable packaging is epitomized by this innovation, with the ShoulderFlex emerging as a beacon of progress in an industry that constantly seeks eco-friendly alternatives.

In conclusion, the ShoulderFlex bottle’s featherlight weight belies its significant impact on sustainability. Microplastic pollution CATL battery

Emerging triumphant in the German Packaging Prize’s “Sustainability” category, it offers a pioneering solution for reducing the environmental footprint associated with water bottling. Krones’ visionary bottle design not only redefines lightweight packaging but also resonates with the essence of responsible material usage. The ShoulderFlex bottle stands as a testament to Krones’ commitment to sustainable practices while demonstrating that practicality need not be compromised for the sake of conservation. A visit to Krones is an invitation to witness the future of packaging firsthand and to embrace the possibilities that lie at the intersection of innovation, sustainability, and convenience.

Scientists from the University of British Columbia have achieved a significant breakthrough in the fight against microplastic pollution in water bodies

Through innovative research, they have successfully developed an ingenious filter that employs biodegradable forest byproducts to effectively remove microplastics from water sources. This groundbreaking solution holds immense promise for mitigating the ecological and health hazards posed by these minute plastic particles.

Microplastics, diminutive plastic fragments measuring less than five millimeters in length, have emerged as a growing environmental concern due to their detrimental impacts on wildlife and potential threats to human well-being. Led by Orlando Rojas, the research team tapped into the potential of tannins – natural plant compounds commonly found in unripe fruits and often utilized as additives in winemaking – to engineer an efficient filtration system. By amalgamating these tannins with a layer of wood dust derived from residual materials of British Columbia’s lumber industry, they created a pioneering filter dubbed “bioCap.” Microplastic pollution CATL battery

This innovative filter demonstrated a remarkable capacity to selectively capture a substantial portion of microplastic particles suspended in water.

The implications of this discovery extend far beyond its initial success. Rojas envisions a wide spectrum of applications, ranging from the integration of this advanced filter into wastewater treatment plants to its incorporation as a domestic water purification mechanism. Even with ongoing global efforts to curtail plastic consumption, the ubiquity of microplastics in water bodies is anticipated to persist for years to come. These minuscule particles infiltrate water sources through sources like synthetic fabrics, disposable plastic goods, and even microbeads embedded in personal care products such as cleansers and cosmetics.

Detecting microplastics within water is a formidable challenge due to their pervasive dilution. Numerous scientific investigations have underscored the prevalence of microplastics in aquatic environments and underscored their pernicious effects on aquatic ecosystems. In a compelling illustration of this issue, the research team from UBC encountered microplastics in every water sample gathered during their expedition to Antarctica. Moreover, studies have confirmed that virtually all tap water sources are contaminated with microplastic particles, underscoring the urgent need for effective mitigation strategies. Microplastic pollution CATL battery

To validate the efficacy of their pioneering approach, the researchers systematically examined polypropylene microparticles encapsulated within tea bags. Their innovative technique achieved a remarkable trapping efficiency, ranging from 95.2% to 99.9%, thus effectively purifying a column of water from plastic contaminants. Furthermore, this revolutionary method exhibited an ancillary advantage by thwarting the accumulation of microplastics within the organs of mice.

The evolution of this remarkable filtration system signifies a dual triumph, addressing both environmental imperatives and the potential health hazards linked to microplastic exposure. With the world at the precipice of an environmental crisis posed by plastic pollution, solutions like the bioCap filter provide a ray of hope. As this research continues to mature, its successful integration into wastewater treatment infrastructure and domestic water purification systems could catalyze a transformative shift in our approach to safeguarding water bodies from the perils of microplastic contamination.

In conclusion, the pioneering work conducted by scientists at the University of British Columbia showcases a monumental stride in the battle against microplastic pollution. Through innovative deployment of biodegradable materials, they have harnessed the power of tannins and wood dust to create a groundbreaking filter that holds the potential to revolutionize water purification methods. Microplastic pollution CATL battery

As the world grapples with the persistent challenges posed by plastic pollution, this discovery emerges as a beacon of promise, offering a tangible solution to safeguard the environment and human health from the pervasive threat of microplastics.

CATL Unveils Revolutionary Shenxing Superfast Charging Battery, Paving the Way for EV Superfast Charging Era

NINGDE, China, August 16, 2023 /PRNewswire/ — On the 16th of August, CATL made history with the introduction of Shenxing, an unprecedented 4C superfast charging LFP battery. Capable of propelling electric vehicles (EVs) to cover 400 km with just a 10-minute charge and over 700 km on a single full charge, Shenxing is poised to vanquish range anxiety and usher in a new era of EV superfast charging.

With the evolution of battery technology and the remarkable enhancement of overall EV battery performance, the automotive sector has successfully achieved substantial driving ranges for electric vehicles. Presently, the primary hurdle hindering consumers from embracing EVs is fast charging anxiety. By delving into the very essence of electrochemistry, CATL continues its trailblazing efforts in material science, electrochemistry, and system architecture.Microplastic pollution CATL battery

This innovative approach results in superfast charging capabilities, elevated energy density, and heightened safety measures all coexisting harmoniously. Shenxing transcends the confines of LFP chemistry, catalyzing an epoch of innovation within the battery domain.

Redefined LFP Battery Design to Quell Charging Apprehensions

Accelerated lithium-ion extraction. Shenxing harnesses the prowess of super electronic network cathode technology and employs fully nano-crystallized LFP cathode material to establish a super electronic network. This network facilitates swift lithium-ion extraction and rapid response to charging signals.

Enhanced lithium-ion intercalation rate. In a pioneering move, CATL integrates its latest second-generation fast ion ring technology into graphite innovation. This transformation modifies the properties of the graphite surface, augmenting intercalation channels and shortening the distance that lithium ions must traverse. This culminates in a high-speed expressway for current conduction. Furthermore, the development of a multi-gradient layered electrode design achieves an exquisite equilibrium between fast charging and extended range. Microplastic pollution CATL battery

Reduced resistance to lithium-ion movement. CATL introduces an innovative superconducting electrolyte formula, effectively lowering electrolyte viscosity and thereby improving conductivity. Additionally, CATL refines the ultra-thin SEI (Solid-Electrolyte Interphase) film to mitigate resistance in lithium-ion movement.

Enhanced lithium-ion transmission rate. Through strategic separator modifications, CATL achieves reduced transmission resistance for lithium ions by enhancing porosity and shortening average transmission distances.

Holistic Enhancement of Charging Speed, Range, and Safety

Beyond its impressive 4C superfast charging feat, Shenxing boasts an extensive driving range, versatile fast charging across varying temperatures, and augmented safety levels courtesy of structural innovation and intelligent algorithms.

Exceeding 700 km range. Employing a groundbreaking all-in-one grouping technology atop the integration of CTP 3.0 technology’s internal crossbeam and end plates, CATL achieves seamless integration and heightened grouping efficiency. This innovation empowers Shenxing to attain a remarkable range exceeding 700 km, shattering the limitations of LFP chemistry performance. Microplastic pollution CATL battery

Cold temperature charging. At room temperature, Shenxing accomplishes 80% state of charge (SOC) in a mere 10 minutes. Leveraging cell temperature control technology at the system level, CATL ensures rapid heating of cells to their optimal operational temperature range. This enables a 0-80% charge within 30 minutes even in frigid conditions as low as -10°C, all while maintaining uncompromised 0-100 kph acceleration performance.

Safety at the forefront. An upgraded electrolyte and separator adorned with a highly secure coating form a dual protective barrier for the Shenxing battery. Employing intelligent algorithms to regulate the global temperature dynamics within cells, CATL pioneers a real-time fault detection system. This system successfully tackles challenges arising from swift refueling, bolstering safety for the Shenxing battery.

Anticipated Mass Production by Late 2023, Initiating the Superfast Charging Era

Dr. Wu Kai, Chief Scientist of CATL, remarked at the launch event, “The trajectory of EV battery technology must remain aligned with global technological frontiers while delivering economic benefits.” As EV consumers evolve from pioneers to mainstream users, the democratization of advanced technology becomes imperative, ensuring that the fruits of innovation are savored by all.

Leveraging its robust manufacturing capabilities, CATL seamlessly transitions technology from laboratory to market, facilitating the swift mass production of the Shenxing battery. Gao Huan, CTO of CATL’s China E-car Business, disclosed that mass production of Shenxing will be realized by year-end. Electric vehicles equipped with Shenxing will grace the market in the first quarter of the ensuing year. Microplastic pollution CATL battery

The unveiling of Shenxing marks yet another milestone in EV battery technology evolution and is poised to expedite global e-mobility transformation. Upholding the ethos of democratizing technology, CATL remains committed to propelling widespread adoption of advanced technologies, thereby leaving an indelible mark on the global energy transition.

SOURCE Contemporary Amperex Technology Co., Limited

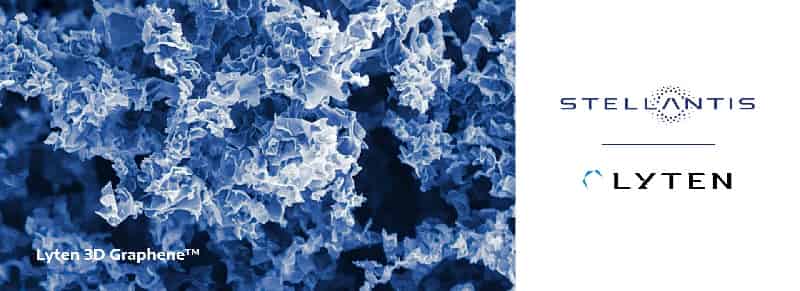

Stellantis Bolsters U.S. Lithium Production for Low Emissions with CTR Partnership

In a strategic move aimed at reinforcing its commitment to sustainable electric vehicle (EV) production, Stellantis N.V. has joined forces with Controlled Thermal Resources Holdings Inc. (CTR) in a groundbreaking initiative that involves a substantial investment of more than $100 million from Stellantis. The investment is set to propel the advancement of CTR’s ambitious Hell’s Kitchen project, touted as the world’s largest geothermal lithium undertaking, with the astounding capability to yield up to 300,000 metric tons of lithium carbonate equivalent annually. This innovative endeavor aligns harmoniously with Stellantis’ resolute drive towards achieving a greener automotive landscape while positioning its EVs for consumer incentives under the

U.S. Inflation Reduction Act (IRA). Microplastic pollution CATL battery

Central to this collaboration is the extension of the initial supply agreement between Stellantis and CTR, which has been substantially augmented. The augmented agreement now stipulates that CTR will deliver up to 65,000 metric tons of battery-grade lithium hydroxide monohydrate (LHM) each year over a decade-long contractual span. This augmented agreement seamlessly incorporates the foundational lithium supply arrangement inked by both entities in June 2022, which encompassed the provision of up to 25,000 metric tons of LHM per annum.

The pièce de résistance of this partnership lies within CTR’s Hell’s Kitchen project, nestled in California’s Imperial County. The project is set to extract lithium from geothermal brines utilizing renewable energy sources and steam, thereby orchestrating the creation of environmentally conscientious, “green” battery-grade lithium products through an intricately interwoven production process.

This method has the distinct advantage of obviating the necessity for the traditional, ecologically taxing evaporation brine ponds, open pit mines, and fossil fuel-dependent lithium processing methods. Microplastic pollution CATL battery

Carlos Tavares, the Chief Executive Officer of Stellantis, articulates the significance of this strategic maneuver, emphasizing its role as a cornerstone in the ongoing endeavor to curtail carbon emissions and embrace sustainable practices within the automotive domain. “The foundation of our industry-leading decarbonization drive includes low-emissions production and sustainable supply as the building blocks for our electric vehicles,” Tavares underscores, adding, “The latest agreement with CTR is an important step in our care for our customers and our planet as we work to provide clean, safe, and affordable mobility in North America.”

This initiative synergizes seamlessly with Stellantis’ larger Dare Forward 2030 strategic plan, a visionary roadmap designed to transition the company into a paradigm where 100% of passenger car sales in Europe and 50% of passenger car and light-duty truck sales in the United States are attributed to battery electric vehicles (BEVs) by 2030. To actualize these ambitious targets, Stellantis has meticulously orchestrated the securing of approximately 400 GWh of battery capacity, buttressed by a robust network of six battery manufacturing plants spanning North America and Europe. The company takes pride in its unwavering trajectory towards achieving carbon neutrality by 2038, encompassing all scopes of emissions and balanced by a mere single-digit percentage of residual emissions offset. Microplastic pollution CATL battery

In the words of Rod Colwell, the Chief Executive Officer of CTR, the significant infusion of capital by Stellantis into CTR serves as a pivotal landmark in the trajectory of both organizations. Colwell underscores the paramount importance of ethical battery material sourcing and production in an era marked by the rapid proliferation of EV adoption globally. He echoes the notion that by localizing the battery supply chain, it becomes feasible to mitigate supply chain vulnerabilities while simultaneously generating substantial employment opportunities in underserved communities. Colwell applauds the forward-thinking leadership of Stellantis and eagerly anticipates the emergence of new industry benchmarks in terms of reliability, efficiency, and ecological sustainability.

The collaboration between Stellantis and CTR is scheduled to bear tangible fruit with the commencement of battery-grade lithium hydroxide monohydrate supply to Stellantis in 2027. Microplastic pollution CATL battery

The venture holds the potential to create a significant economic impact, with the potential generation of 480 construction jobs through comprehensive project labor agreements and the ultimate projection of over 940 direct project-related employment opportunities upon full resource maturation. In essence, the alliance emerges as a testament to the transformative power of synergy, innovation, and commitment towards pioneering a cleaner, more sustainable automotive future.

Avantium, a pioneering technology provider in the realm of renewable chemistry and based in the Netherlands, has achieved a significant milestone by securing a substantial grant of €0.76 million from the EU Horizon Europe programme

This notable grant has been awarded in recognition of Avantium’s active involvement in the esteemed research and development initiative known as Rebiolution. The auspicious announcement of this accomplishment was made on the early morning of August 16th.

The overarching objective of the Rebiolution programme spans a three-year duration and centers on the intricate design and synthesis of innovative biobased and biodegradable polyester blends. These pioneering blends are anchored in the utilization of FDCA and other biobased monomers, strategically formulated for applications in plastic coatings for food packaging and agricultural mulch films. The funding, to be disbursed in multiple installments over a triennial timeline commencing in June 2023, will empower the realization of this transformative initiative. Microplastic pollution CATL battery

At the core of Avantium’s groundbreaking approach lies its proprietary technology, ingeniously named YXY. This innovative process ingeniously converts plant-derived sugars into the essential monomer known as FDCA. This versatile monomer can be skillfully polymerized alongside plant-derived mono-ethylene glycol (MEG) to generate a sustainable and eco-friendly plastic known as PEF.

FDCA, renowned as the second-ranking priority chemical by the US Department of Energy in its esteemed list of top 12 chemicals, has been earmarked for propelling the green chemistry industry of the future since 2004. Notably, FDCA serves as a pivotal building block for an extensive array of polymers, encompassing polyesters, polyamides, polyurethanes, coating resins, plasticizers, and various other chemical products. Capitalizing on this potential, Avantium is diligently constructing the world’s premier commercial FDCA facility, located in Delfzijl, the Netherlands. With an anticipated annual capacity of 5,000 tonnes, this pioneering plant is scheduled for inauguration in the year 2024.

As an active participant in the Rebiolution programme, Avantium assumes a pivotal role by contributing several hundreds of kilograms of FDCA. This precious resource will be directed towards the research, development, and production of an innovative biodegradable and compostable polyester blend. This blend stands poised to serve as a promising substitute for conventional PE in plastic coatings applied to diverse materials, including paper-based food packaging. Additionally, this breakthrough polyester blend exhibits immense potential as a fully biobased alternative for the widely prevalent PBAT, a partially fossil-based material extensively employed in mulch films. Microplastic pollution CATL battery

Kai Siegenthaler, the esteemed coordinator of the Rebiolution project and an authoritative figure in the realm of biopolymers research at BASF, elucidated the pivotal role of FDCA in the Rebiolution strategy. The unique attributes of FDCA, stemming from its plant-based origins and its structural likeness to the widely used commodity chemical PTA (purified terephthalic acid), lend it remarkable potential. This potential is harnessed through the strategic combination of FDCA with other biobased monomers, resulting in the creation of a fully biobased and biodegradable polyester that effortlessly aligns with stipulated criteria related to processing, longevity, performance, and cost-effectiveness.

Bas Blom, the director of Avantium Renewable Polymers, aptly summarized the significance of Avantium’s polymerization-quality FDCA in light of the Rebiolution project. Notably, this high-quality FDCA serves not only as a foundational element for the development of PEF, a plant-based plastic material, but also showcases diverse prospects across a spectrum of markets, as aptly evidenced by its integral role in this transformative project. Microplastic pollution CATL battery

Rebiolution, an acronym denoting ‘Novel biodegradable, REcyclable, BIO-based and safe plastic polymers with enhanced circuLar properties for food packaging and agricUltural applicaTIONs,’ stands as a testament to collaborative innovation. This visionary project, made possible through a substantial €4.9 million grant from the EU Horizon Europe programme, takes shape through a consortium comprising nine partners hailing from seven distinct countries. These esteemed collaborators include BASF SE (Germany), Organic Waste Systems (Belgium), Hydra Marine Sciences GmbH (Germany), Contactica S.L (Spain), Avantium Renewable Polymers BV (Netherlands), Tampereen Korkeakoulusaatio SR (Finland), Stora Enso (Finland), Centre Technique de l’Industrie Despapiers Cartons et Celluloses (France), and Eidgenoessische Technische Hochschule Zuerich (Switzerland).

This diverse amalgamation of expertise and perspectives underscores the far-reaching impact of the Rebiolution project on a global scale. Microplastic pollution CATL battery

Do biodegradable bioplastics provide a safe answer to plastic pollution?

Biodegradability is not something to be taken for granted

Biodegradable bioplastics are presented as a tool in the fight against pollution caused by the rapid rise in the generation of plastics and inadequate waste management. These bioplastics can come from renewable or fossil sources and are characterized by their ability to decompose, through the action of microorganisms, into carbon dioxide, water, mineral salts and new biomass. Known as biodegradation, this process can occur in controlled and open environments. Composting plants and anaerobic digesters are the main examples of controlled environments, whereas soil, rivers and the sea are natural open environments.

Products based on biodegradable bioplastics must pass a series of standardized tests to demonstrate that they are able to biodegrade within a certain time in specific environments. However, for these products to effectively contribute to the reduction of plastic waste, they must be designed to biodegrade in the most applicable environment, namely, their most logical end-of-life scenario. Microplastic pollution CATL battery

For example, for food products such as coffee capsules, tea bags and lightweight supermarket bags, the most recommended scenarios are composting plants because this waste can be industrially managed with organic waste streams to become compost. On the other hand, products for agricultural applications such as mulch films and controlled release fertilizer coatings, whose end of life is soil, should be biodegradable in this natural environment. Likewise, products used in aquaculture and fisheries, which often end up in rivers and the sea, being biodegradable in these media, could have a lower environmental impact compared to conventional plastic products.

While biodegradation is viewed as a major advantage in the fight against plastic pollution, the ability to claim any environmental benefits is possible only when it can be proven that these biodegradable products have no negative effects on the ecosystem.

This makes it important to assess any ecotoxicological effects of biodegradable plastics, given that additives, metabolites and secondary compounds may be released during product disintegration and biodegradation and may have a negative impact on the environment. Microplastic pollution CATL battery

Braskem, a prominent biopolymer producer, has joined forces with SCG Chemicals, a leading petrochemical company in Thailand and Southeast Asia, in a significant move to expand biopolymer production throughout the region

This collaboration has culminated in the establishment of a joint venture named Braskem Siam Company Limited. However, this endeavor is pending approval from relevant anti-trust authorities and the final investment decision from both partners. The primary objective of this joint venture is to manufacture bio-ethylene through bio-ethanol dehydration and subsequently introduce the commercialization of I’m green bio-based polyethylene (PE), utilizing the innovative EtE EverGreen technology. The development of this technology stems from a partnership agreement between Braskem and Lummus Technology, which sought to create and license this cutting-edge technology.

The hallmark of “I’m green” bio-based polyethylene is its composition derived from ethically sourced renewable raw materials, particularly ethanol derived from sugar cane. This departure from conventional fossil feedstocks like oil-based naphtha results in a remarkable reduction in the carbon footprint of the plastic. Consequently, this shift serves as a proactive measure against the adverse effects of climate change. The applications for I’m green bio-based polyethylene are diverse, encompassing an array of products ranging from food and beverage packaging to personal and household care items, toys, houseware, and plastic bags. Microplastic pollution CATL battery

An additional advantage lies in its recyclability, which can be executed either mechanically or chemically, paralleling the recycling process of conventional polyethylene.

The cornerstone of this partnership is the establishment of a bio-ethylene plant that holds the distinction of being the first of its kind outside of Brazil. Nestled in Thailand, this new plant holds the potential to nearly double the existing production capacity of I’m green bio-based polyethylene, effectively addressing the burgeoning global demand for biopolymers. A special focus is attributed to the rapidly escalating demand for sustainable products in the Asian market.

Braskem brings a wealth of expertise to the partnership, encompassing proven technology stemming from its collaboration with Lummus Technology. Additionally, Braskem contributes operational insights gained from the ethanol dehydration process, as well as the powerful brand recognition of I’m green in key global markets. Conversely, SCG Chemicals contributes its specialized proficiency in polyethylene grades tailored for diverse applications. Microplastic pollution CATL battery

Roberto Bischoff, the CEO of Braskem, underscores the commitment of the partnership to satisfying the mounting demand for sustainable solutions. He reiterates the alignment of this collaboration with Braskem’s overarching goal of producing one million tons of green products by 2030, which entails a transition from fossil-based feedstocks to renewable alternatives. This transition significantly contributes to mitigating the carbon footprint within the industry.

Tanawong Areeratchakul, the CEO and President of SCG Chemicals, emphasizes the company’s endeavor to foster green innovation and promote low-carbon solutions. SCG Chemicals aspires to expand its Green Polymer product portfolio to encompass a remarkable one million tons annually by 2030, adhering to rigorous ESG (Environmental, Social, and Governance) standards. Areeratchakul underscores the significance of this joint venture, highlighting its role in meeting the surging demand for environmentally friendly plastics in regions like Asia and Europe. The collaboration’s core focus is the production of sugarcane-derived bio-ethylene, an eco-conscious alternative to conventional fossil-derived ethylene. This pioneering effort aligns seamlessly with Thailand’s Bio-Circular-Green Economy (BCG) model, a testament to the venture’s commitment to sustainable development. Microplastic pollution CATL battery

Anticipated to be situated in Map Ta Phut, Rayong, Thailand, this project holds the potential to revolutionize biopolymer production in the Southeast Asian region. By capitalizing on the synergy between Braskem and SCG Chemicals, the joint venture, Braskem Siam Company Limited, is poised to shape the future of sustainable plastic production, thereby propelling the region toward a greener and more environmentally conscious trajectory.

PET Bottles into fibers -Will Ultra-Poly revolutionize automotive sustainability? 18-08-2023

Microplastic pollution CATL battery