Petrochemicals PET Bottles – Filament grade Bright chips domestic market 14-08-2023 - Arhive

Petrochemicals PET Bottles

- Polymers : PET – r-PET – Filament grade semidull chips -Filament grade bright chips – Ny6 – My66 – PP

- Feedstocks : PX – PTA – MEG – CPL – Adipic Acid – Benzene – ACN – Ethylene – Phenol – Naphtha

- Textile : Polyester POY – DTY – FDY – PSF – Recycled Polyester POY – Nylon POY – DTY – FDY Spandex 20-30-40 -Viscose Staple Fiber VSF Acrylic Staple Fiber

| Polyestertime | |||

| ITEM | 07/08/2023 | 14/08/2023 | +/- |

| Bottle grade PET chips domestic market | 7,050 yuan/ton | 7,050 yuan/ton | – |

| Bottle grade PET chips export market | 905 $/ton | 895 $/ton | -10 |

| Filament grade Semidull chips domestic market | 6,800 yuan/ton | 6,820 yuan/ton | +20 |

| Filament grade Bright chips domestic market | 6,830 yuan/ton | 6,860 yuan/ton | +30 |

| Pure Terephthalic Acid PTA domestic market | 5,810 yuan/ton | 5,845 yuan/ton | +35 |

| Pure Terephthalic Acid PTA export market | 800 $/ton | 790 $/ton | -10 |

| Monoethyleneglycol MEG domestic market | 3,995 yuan/ton | 3,940 yuan/ton | -55 |

| Monoethyleneglycol MEG export market | 467 $/ton | 462 $/ton | -5 |

| Paraxylene PX FOB Taiwan market

Petrochemicals PET Bottles |

1,055 $/ton | 1,077 $/ton |

+22 |

| Paraxylene PX FOB Korea market | 1,032 $/ton | 1,054 $/ton | +22 |

| Paraxylene PX FOB EU market | 1,200 $/ton | 1,180 $/ton | -20 |

| Polyester filament POY 150D/48F domestic market | 7,670 yuan/ton | 7,680 yuan/ton |

+10 |

| Recycled Polyester filament POY domestic market | 7,350 yuan/ton | 7,350 yuan/ton | – |

| Polyester filament DTY 150D/48 F domestic market | 9,225 yuan/ton | 9,200 yuan/ton | -25 |

| Polyester filament FDY 68D24F

Petrochemicals PET Bottles |

8,800 yuan/ton | 8,800 yuan/ton | – |

| Polyester filament FDY 150D/96F domestic market | 8,350 yuan/ton | 8,300 yuan/ton | -50 |

| Polyester staple fiber 1.4D 38mm domestic market | 7,350 yuan/ton | 7,450 yuan/ton | +100 |

| Caprolactam CPL domestic market | 13,150 yuan/ton | 12,850 yuan/ton |

-300 |

| Caprolactam CPL overseas market | 1,550 $/ton | 1,500 $/ton | -50 |

| Nylon 6 chips overseas market | 1,740 $/ton | 1,750 $/ton | +10 |

| Nylon 6 chips conventional spinning domestic market | 13,700 yuan/ton | 13,500 yuan/ton | -200 |

| Nylon 6 chips high speed spinning domestic market

Petrochemicals PET Bottles |

14,500 yuan/ton | 14,450 yuan/ton | -50 |

| Nylon 6.6 chips domestic market | 18,000 yuan/ton | 18,000 yuan/ton | – |

| Nylon6 Filament POY 86D/24F domestic market | 16,600 yuan/ton | 16,600 yuan/ton | – |

| Nylon6 Filament DTY 70D/24F domestic market | 18,800 yuan/ton | 18,800 yuan/ton- | – |

| Nylon6 Filament FDY 70D/24F | 17,500 yuan/ton | 17,600 yuan/ton | +100 |

| Spandex 20D domestic market

PPetrochemicals PET Bottles |

36,500 yuan/ton | 36,500 yuan/ton | – |

| Spandex 30D domestic market | 35,000 yuan/ton | 35,000 yuan/ton | – |

| Spandex 40D domestic market | 31,500 yuan/ton | 31,500 yuan/ton | – |

| Adipic Acid domestic market | 9,800 yuan/ton | 9,800 yuan/ton | – |

| Benzene domestic market

Petrochemicals PET Bottles |

7,750 yuan/ton | 7,650 yuan/ton | -100 |

| Benzene overseas market | 905 $/ton | 903 $/ton | -2 |

| Ethylene South East market | 810 $/ton | 810 $/ton | – |

| Ethylene NWE market | 620 $/ton | 624 $/ton | +4 |

| Acrylonitrile ACN domestic market

Petrochemicals PET Bottles |

8,400 yuan/ton | 8,300 yuan/ton | -100 |

| Acrylonitrile ACN overseas market | 1,200 $/ton | 1,200 $/ton | – |

| Acrylic staple fiber ASF domestic market | 13,600 yuan/ton | 13,600 yuan/ton | – |

| Viscose Staple Fiber VSF domestic market | 12,500 yuan/ton | 12,800 yuan/ton | +300 |

| PP Powder domestic market

Petrochemicals PET Bottles |

7,200 yuan/ton | 7,175 yuan/ton | -25 |

| Naphtha overseas market | 653 $/ton | 665 $/ton | +12 |

| Phenol domestic market | 8,100 yuan/ton | 8,212 yuan/ton | +112 |

r-PET high end eco-friendly chips =7,750 yuan/ton — 7,700 yuan/ton -50

- Petrochemicals r-PET adipic-acid – Can the car help the environment with the recycling of plastic? 07-08-2023

- New enzyme technology for environmentally friendly plastic recycling

Petrochemicals PET Bottles

Revolutionary chemical recycling process adds big value to ‘junk’ plastic waste

Although many Americans dutifully deposit their plastic trash into the appropriate bins each week, much of that material, including flexible films, multilayer materials and a lot of colored plastics are not recyclable using conventional mechanical recycling methods. In the end, only about 9% of plastic in the U.S. is ever reused. Equally discouraging, the products made from recycled plastic typically are low-value, meaning the high costs of recycling don’t necessarily yield great returns.

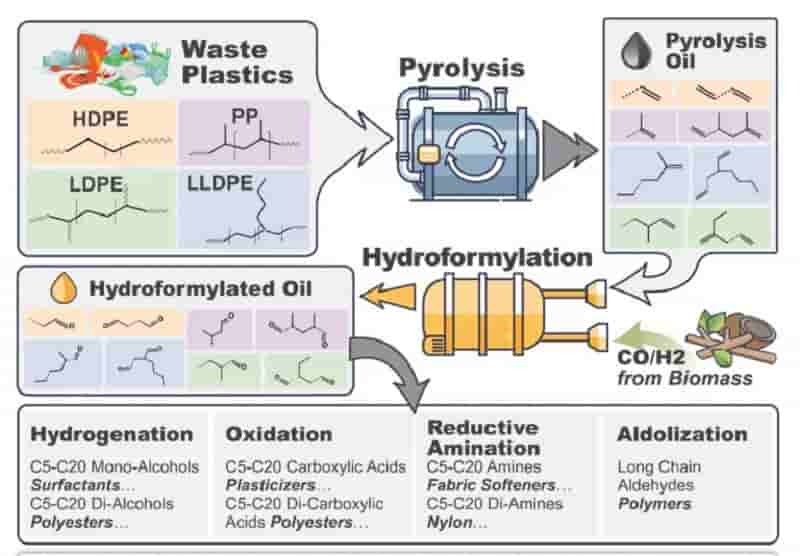

With a new technique, however, University of Wisconsin-Madison chemical engineers can turn waste plastic into high-value chemicals. The method relies on two chemical processes—pyrolysis and hydroformylation—which ultimately increase the economic incentives for plastic recycling and open the door to recycling new types of plastic.

The team estimates its methods could reduce greenhouse gas emissions from the conventional production of these industrial chemicals by roughly 60 percent.

The researchers, led by George W. Huber, a professor of chemical and biological engineering at UW-Madison and director of the Department of Energy-funded Center for the Chemical Upcycling of Waste Plastics, postdoctoral researcher Dr. Houqian Li and PhD student Jiayang Wu, described their methods in the August 11, 2023 issue of the journal Science.

The world is swimming in plastic waste—in some cases literally—with few options for recycling much of that material. One emerging method is pyrolysis, in which plastics are heated to high temperatures in an oxygen-free environment. The result is pyrolysis oil, a liquid mix of various compounds. Pyrolysis oil contains large amounts of olefins—a class of simple hydrocarbons that are the central building blocks of today’s chemicals and polymers, including various types of polyesters, surfactants, alcohols and carboxylic acids.

In current energy-intensive processes like steam cracking, chemical manufacturers produce olefins by subjecting petroleum to extreme high heat and pressure. In their new process, the UW-Madison team recovers olefins in the pyrolysis oil and then uses them in a much less energy-intensive chemical process called homogenous hydroformylation catalysis. The process converts olefins into aldehydes, which can then be further reduced into important industrial alcohols.

“These products can be used to make a wide range of materials that are higher-value,” says Huber. “You can make surfactants from them that are used to make soaps and cleaners. You could make other polymers from them that are of higher value than the original polyolefins. So, we’re really excited about the implications of this technology. It’s a platform technology to upgrade plastic waste using hydroformylation chemistry.”

The recycling industry could adopt the process soon; in recent years, at least 10 large chemical companies have built or announced plans for facilities to produce pyrolysis oils from waste plastics. Many of them run the pyrolysis oil through steam crackers to produce low-value compounds. The new chemical recycling technique could provide a more sustainable and lucrative way to use those oils. “Currently, these companies don’t have a really good approach to upgrade the pyrolysis oil,” says Li. “In this case, we can get high-value alcohols worth $1,200 to $6,000 per ton from waste plastics, which are only worth about $100 per ton. In addition, this process uses existing technology and techniques. It’s relatively easy to scale up.”