Plastic PET-Tray Sustainability – Must leverage AI, enzyme-based technology for sustainability: Ashok Chaturvedi 05-09-2023 - Arhive

Plastic PET-Tray Sustainability

Asia in Decline: Waning Enthusiasm for China and Escalating Inflation Concerns

In the world of Asian markets, a sense of unease hung heavy in the air on Tuesday. Chinese stocks, in particular, bore the brunt of investor anxiety, casting a shadow over the broader regional landscape. The day’s events unfolded against a backdrop of lingering concerns about China’s economic slowdown and a sagging housing sector, while inflation data from various Asian nations added fuel to fears of impending interest rate hikes.

Chinese stocks, perceived as the barometer of Asian market health, emerged as the day’s worst performers. Investors grew increasingly impatient with Beijing’s deliberate pace in implementing additional stimulus measures. Adding to the trepidation, a private survey indicated that China’s service sector activity in August had risen less than anticipated. Slower external demand, coupled with lackluster domestic spending, exerted further pressure on China’s economic engine. Plastic PET-Tray Sustainability

Both the Shanghai Shenzhen CSI 300 and the Shanghai Composite indices stumbled, each shedding about 0.6% of their value. Meanwhile, Hong Kong’s Hang Seng index bore the brunt of the downturn, slipping by 1.5%. Investors appeared to be capitalizing on recent gains in real estate and technology stocks. Additionally, concerns surrounding the beleaguered real estate giant, Country Garden Holdings, weighed heavily on sentiment. Although it had won approval to defer some debt payments, the firm still faced imminent bond payment deadlines later in the week.

The previous week had witnessed a surge in Chinese stocks, thanks to the government’s unveiling of favorable measures for the real estate sector and tax cuts on stock trading. Nonetheless, investors clamored for Beijing to take targeted fiscal action to prop up the economy, especially in light of the sharp deceleration in growth during the second quarter. The specter of China’s slowdown had a dampening effect on overall sentiment towards Asian equities.

Japan’s Nikkei 225 index also recorded a minor setback following data that revealed a more-than-expected slowdown in household spending in July. Meanwhile, futures for India’s Nifty 50 index hinted at a slightly weaker opening, suggesting that the anxiety extended beyond China’s borders. Plastic PET-Tray Sustainability

Further exacerbating the regional unease were inflation reports from South Korea and the Philippines, both of which surpassed expectations for August. These readings amplified concerns about broader inflation recovery in Asia. Rising oil prices and the potential for disruptions in global food supplies fueled worries of persistent inflation. Such signs of inflation sticking around can give central banks in the region the impetus to maintain a hawkish stance, a development that doesn’t bode well for equity markets.

Thailand’s inflation data was slated for release later in the day, with China set to report its own inflation figures later in the week. China stood as a stark exception among global economies, grappling with rampant disinflation as its economic recovery lost momentum.

Across the Tasman Sea, Australian equities experienced a 0.6% decline, mirroring the woes of their northern neighbor. Lingering concerns over Australia’s main trading partner, China, continued to cast a pall over the market. Investors were also anxiously awaiting an interest rate decision from the Reserve Bank of Australia (RBA). Market expectations leaned toward the RBA keeping rates unchanged, citing falling inflation and a slight cooling in the labor market.

Nevertheless, there remained a lingering possibility that the RBA might announce further rate hikes later in the year, given that inflation still remained well above the bank’s annual target. The intricate dance between China’s economic performance and Australia’s monetary policy added yet another layer of uncertainty to the region’s economic landscape.

In the face of these challenges, Asian markets found themselves navigating treacherous waters. The fading enthusiasm for China’s economic prospects and the mounting concerns about inflation’s resurgence painted a sobering picture for investors across the region. Uncertainty loomed large, and as central banks pondered their next moves, the fate of Asian equities hung in the balance.

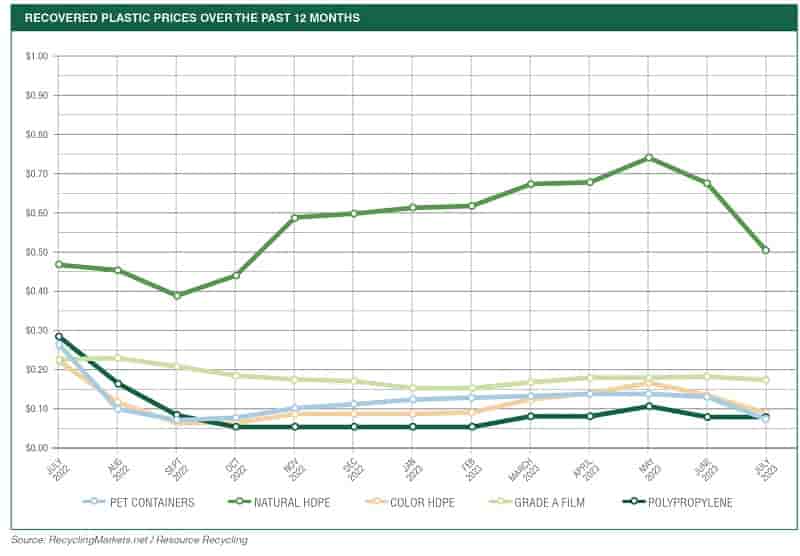

Plastic reclaimers grapple with ‘rock bottom’ pricing

Although depressed plastics prices have caused some companies to revise their earnings projections, many in the sector are optimistic about an upcoming rebound.

Recycled plastics prices are at their lowest levels in some time, putting significant strain on material processors. Meanwhile, some resin buyers are abandoning post-consumer resin to purchase virgin plastic instead.

The lower prices can be seen in the scrap bale market and, to varying degrees, in the recycled resin market.

“The price of resin has definitely dropped significantly and it all boils down to supply and demand,” noted Tony Moucachen, who leads a family of plastics recycling companies, including prominent Pacific Northwest reclaimer Merlin Plastics. Plastic PET-Tray Sustainability

“The supply of virgin PE, PP and PET is currently significantly higher than the demand,” Moucachen added, “and this is leading to a steep decline in market prices. This also has a negative impact on the whole supply chain.”

In some cases, the market is such that it’s leading to landfilling of recyclables.

“It’s not a fantastic time. We all know that,” Andrea Bassetti, senior analyst for plastics recycling at consulting and research firm ICIS, said during the 2023 Resource Recycling Conference earlier this month.

“The demand is just not there and the supply is high,” she added. “We have a lot of recyclers calling us, telling us, “You know what, we have bales in our warehouses. It’s cheaper for us to send it to the landfill with a one-time fee rather than selling it at these prices at which they are now.’”

Feeling the pinch at the curb

A number of data sources can be used to illustrate the steep drop in bale pricing that’s been experienced in recent months. Plastic PET-Tray Sustainability

For example, according to RecyclingMarkets.net, bales of PET, natural HDPE, color HDPE and PP from municipal recycling programs are averaging around 6.3 cents, 22.9 cents, 5.7 cents and 5.1 cents per pound, respectively. Those prices, which reflect the average across the U.S. (with some Canadian facilities also reporting) are down 55%, 69%, 65% and 51% since May, only three months ago.

Specific geographies are also showing the same general trend.

The Solid Waste Authority (SWA) of Palm Beach County, Fla. sends out the monthly results of bidding on bales from its publicly owned MRF. The details of these bids are publicly available.

For SWA shipments this month, Cellmark won several PET bales with its bid of 3.8 cents per pound and Gama USA won several PET bales with a bid of 4 cents per pound. Five months ago, in March, GP Harmon Recycling won PET with its bid of 16.5 cents per pound, roughly four times today’s price. Plastic PET-Tray Sustainability

And this month, GP Harmon Recycling had the highest bids for both natural and color HDPE at 27.8 cents and 10.6 cents, respectively. Back in March, Cellmark won natural HDPE at 74.6 cents per pound and Nathan H. Kelman Inc. won color HDPE at 17.3 cents per pound.

Canada is seeing the same dynamics. A price sheet produced by EcoCompass Inc. for the Continuous Improvement Fund (CIF), which is part of Ontario’s extended producer responsibility (EPR) system, noted that PET averaged 12.9 cents U.S. per pound during the first half of 2023, down 39% from the average last year.

The largest garbage and recycling companies in North America are feeling the pinch.

Waste Management (WM) is North America’s largest operator of materials recovery facilities (MRFs), which sort and bale curbside recyclables. When the company released its second-quarter earnings earlier this month, executives noted that depressed plastics pricing had forced them to re-evaluate their commodity sales expectations for the whole year.

The plastic impact on WM is particularly notable because paper and corrugated cardboard make up the largest percentage of weight handled by those companies, and markets for those materials have been slowly but steadily climbing this year.

“If you think about our fiber pricing, we’re expecting a slow ramp in fiber pricing, and that’s really being driven by some mill capacity coming on-line domestically,” Tara Hammer, WM’s chief sustainability officer, stated during a July 26 conference call with investors. “The bigger story really is on the non-fiber pricing and related to plastics, which is a smaller part of our volume but a higher-value commodity. And we’ve seen prices decline roughly 30% to 55% from May to July. Plastic PET-Tray Sustainability

So that’s what’s driving our recycled commodity price outlook for the second half of the year.”

Hemmer pointed to low virgin plastics prices pressuring the recycled resin pricing.

Republic Services, the second-largest garbage and recycling company on the continent, is also seeing volatility in bale pricing. Pete Keller, Republic’s vice president of recycling and sustainability, told Resource Recycling that a few factors are affecting PET pricing, including slowing of the U.S. textiles and carpet sector. Europe, which has historically imported PET, has reduced its consumption, he said. Plastic PET-Tray Sustainability

Evertis – Pioneering Closed-Loop PET Tray Sustainability

Introduction

Evertis is a trailblazer in the realm of sustainable PET trays, driven by an unwavering commitment to closing the loop on packaging materials. Their innovative approach, grounded in a circular integration strategy across three companies within the Group – Renascis, Evertis, and Selenis – has set new standards for the industry. This integrated approach supports the development of a closed-loop system by ensuring the efficient utilization of recycled materials, cutting-edge sustainable packaging solutions, and adherence to strict environmental and safety standards. In this article, we delve into Evertis’ four-step approach to close the loop on PET trays and their remarkable achievements. Plastic PET-Tray Sustainability

- Increasing Recycled Content

Evertis has embarked on a journey to continuously increase the utilization of recycled content in their PET films while maintaining stringent food safety standards. In 2022, the company achieved a milestone by incorporating 35% of non-virgin raw materials, equivalent to a staggering 33.5k tonnes of recycled content used in their processes. This monumental accomplishment is equivalent to repurposing over 1.3 billion PET water bottles or 1.9 billion PET trays. Evertis has set an ambitious target to reach 50% recycled raw materials by 2025.

The environmental benefits of this initiative are profound. Evertis has demonstrated significant reductions in greenhouse gases and carbon emissions, as well as a decrease in overall energy consumption for new product manufacturing. Life Cycle Assessment (LCA) studies reveal that every unit of recycled PET replacing virgin PET results in a 40% reduction in process and transport energy, a 75% decrease in energy demand, and a remarkable 60% decrease in greenhouse gas emissions[1].

- Promoting Tray-to-Tray Recycling

Evertis is steadfast in its commitment to promoting the tray-to-tray recycling circuit by increasing the incorporation of PET flakes from trays and advocating for innovative multilayer recycling technologies. To ensure the traceability of recycled materials, Evertis is seeking certification through the RETRAY Process, focusing on the incorporation of post-consumer flakes from the tray circuit. Plastic PET-Tray Sustainability

An exemplary initiative illustrating their dedication to the tray-to-tray model is their collaboration with key recycling stakeholders in Portugal for an R&D project. This project successfully demonstrated the benefits of a circular economy and tray-to-tray recycling. It assessed the feasibility of sorting PET trays, previously classified as mixed plastics, and reintegrating them into the PET stream, thus closing the loop more effectively.

- Facilitating Recyclability through Product Design

Evertis is committed to facilitating recyclability through innovative product design, offering monomaterial and other recyclable solutions that align with clients’ technical needs while enhancing packaging recyclability. Some of their recent product innovations include Evertis EcosealTM, EcopackTM HI, IR Black, and EcobarTM. Plastic PET-Tray Sustainability

What makes these innovations remarkable is the close collaboration between sister companies, Selenis (resin manufacturer), and Evertis. Together, they have successfully designed and developed new polyester resins that enhance the properties of final packaging without the need for additional structures, reducing material complexity and promoting easier recycling.

- Emphasizing Collaboration and Support

Evertis places a strong emphasis on collaboration and support throughout the value chain, working in tandem with partners to close the loop and aligning with policymakers to establish new guidelines. Their commitment extends beyond product development to a holistic approach to sustainability in the food industry.

Thanks to Evertis’ circular integration, the company has the capability to oversee the entire journey from resin design, ensuring the recyclability of their products, to the final stages of mechanical and chemical recycling of post-consumer PET materials. This enables them to supply innovative, recyclable films with a high percentage of recycled content, further advancing their mission to create a more sustainable packaging ecosystem.

Conclusion

Evertis’ four-step approach to closing the loop on PET trays reflects their unwavering dedication to sustainability, innovation, and collaboration. By continuously increasing recycled content, promoting tray-to-tray recycling, facilitating recyclability through product design, and emphasizing collaboration throughout the value chain, Evertis is setting a remarkable example in the industry. Plastic PET-Tray Sustainability

Their efforts not only reduce environmental impact but also contribute to the development of a more sustainable future for the packaging industry. With Evertis leading the way, the journey toward a circular economy in packaging materials is more promising than ever.

Tomra-CEO Participates in NPAP Plastic Talks Panel

Tomra, a leading player in the recycling industry, was recently invited to participate in the National Plastic Action Partnership (NPAP) Plastic Talks in Ha Noi, Vietnam. This event brought together experts, industry leaders, and government officials to address the pressing issue of plastic pollution, particularly focusing on Vietnam’s unique challenges and opportunities in this regard.

Vietnam, like many countries around the world, faces a significant plastic pollution problem. According to a report by the International Finance Corporation (IFC) and the World Bank, Vietnam loses nearly 3 billion U.S. dollars’ worth of recyclable plastics each year due to a lack of adequate waste management infrastructure. Of the 3.9 million tons of PET and polyolefins (PO) produced in Vietnam, only 33% are collected for recycling. This situation has far-reaching consequences, including environmental degradation and economic losses. Plastic PET-Tray Sustainability

In response to these challenges, Vietnam has set ambitious targets to combat plastic pollution and mitigate climate change. These goals include a 50% reduction in plastic litter leakage into the ocean by 2025, the introduction of Extended Producer Responsibility (EPR) policies, and the formalization of the informal waste sector. Vietnam’s commitment to these goals has earned it an invitation to join the High Ambition Coalition (HAC) to support the realization of the Paris Agreement.

Recognizing that plastic pollution is a global issue, the United Nations (UN) and its member states are actively working on an agreement to end plastic litter leakage. The UN Treaty on Plastic Pollution, first discussed in Nairobi in March 2022, holds the potential to address this crisis at scale and promote a circular economy for plastics worldwide.

To discuss Vietnam’s aspirations and engage industry experts in the context of the UN Global Plastic Treaty, the NPAP, in collaboration with the United Nations Development Program (UNDP), organized the NPAP Plastic Talks event in Ha Noi on August 28. This gathering served as a platform for governments and key stakeholders to share insights and ideas on how businesses can contribute to the success of a Global Plastics Treaty.

The agenda covered various topics, including the role of the private sector in defining the treaty’s framework, the implementation of legally binding agreements on plastic pollution, and how businesses can form partnerships to develop an ambitious and effective global agreement on plastics. Additionally, there were discussions about the opportunities and challenges facing plastic producers in Vietnam, with an emphasis on the positive opportunities available.

Tomra, a founding member of the Business Coalition for the Global Plastic Treaty and an influential player in the industry, played a crucial role in this event. Annupa Ahi, Vice President of Public Affairs at TOMRA Asia, delivered a presentation on “The Role of Asian and Vietnamese Enterprises in the UN Plastic Treaty.” Plastic PET-Tray Sustainability

Moreover, Tomra’s CEO, Tove Andersen, participated in a panel discussion alongside representatives from organizations such as the Ellen MacArthur Foundation, the Norwegian Embassy, the Ministry of Natural Resources and Environment (MONRE), and the Vietnam Plastics Association.

Tove Andersen highlighted the importance of waste management in Asia, emphasizing that the region has immense potential to improve its recycling efforts and reduce plastic waste. She commended Vietnam’s commitment to addressing these challenges and turning them into opportunities for both the country and society as a whole. Andersen expressed TOMRA’s dedication to collaborating with Vietnam and leveraging their partnerships to help implement the necessary waste management infrastructure and technologies to achieve these goals.

One of Vietnam’s key actions in tackling plastic pollution is the introduction of an EPR scheme in 2024, in line with its commitment to reducing greenhouse gas emissions and reaching its net-zero goals. TOMRA is actively supporting Vietnam in negotiating the treaty and fostering collaborations with the Norwegian Embassy, the Business Coalition, and the NPAP. With their advanced collection and waste sorting technologies, TOMRA aims to help Vietnam maximize its collection of recyclables, sort and recycle them into high-quality secondary materials, and contribute to the circular economy.

Tove Andersen concluded by stating TOMRA’s mission to create a world without waste and their commitment to welcoming opportunities and strategic partnerships to make this vision a reality. Plastic PET-Tray Sustainability

Vietnam’s journey towards managing its plastic waste more effectively will involve a holistic approach that encompasses the entire plastic value chain and addresses the full lifecycle of plastic. This will not only improve waste management practices but also integrate the informal waste sector into formalized waste management and recycling infrastructures.

The collaboration between TOMRA and Vietnam is not a recent development. In February 2023, TOMRA hosted a senior delegation from MONRE at its headquarters in Germany and Norway to review its state-of-the-art sorting machines for waste recycling and its deposit return system. These technologies have the potential to significantly increase recycling rates and promote circularity in Vietnam. TOMRA’s partnership with the Norwegian Embassy and MONRE includes proposals for a Deposit Return System (DRS) design tailored to Vietnam’s needs and further holistic waste management concepts.

Tove Andersen expressed her admiration for Vietnam’s dedication to combating plastic pollution and reiterated TOMRA’s commitment to supporting the country in transitioning to a circular economy. Plastic PET-Tray Sustainability

By advancing waste management practices and integrating the informal waste sector into a formalized system, TOMRA and Vietnam aim to create a healthier planet and generate additional job opportunities.

Following their participation in the NPAP Plastic Talks in Ha Noi, Tove Andersen met with the Minister of MONRE to reaffirm TOMRA’s commitment to collaborating with the Norwegian Embassy and supporting Vietnam in implementing the EPR system and achieving its NetZero goals as outlined at the UN Climate Change Conference of the Parties (COP26).

In conclusion, TOMRA’s involvement in the NPAP Plastic Talks in Vietnam highlights the critical role of industry leaders in addressing plastic pollution on a global scale. The event provided a platform for sharing insights, fostering partnerships, and accelerating progress towards a circular economy for plastics.

As nations around the world grapple with the challenges of plastic pollution, collaborations like the one between TOMRA and Vietnam serve as a beacon of hope for a more sustainable and plastic-free future. Plastic PET-Tray Sustainability

Researchers at Michigan State University have made a groundbreaking breakthrough in the realm of plastics, unveiling a novel type of plastic that possesses the remarkable ability to biodegrade completely on its own

This remarkable achievement represents a significant step forward in addressing the global plastic pollution crisis.

The foundation of this revolutionary plastic is PLA, or polylactic acid, a bioplastic frequently employed in packaging materials. The researchers at Michigan State University embarked on a journey to enhance the composting potential of PLA without compromising its usability. Their quest led them to blend PLA with bio-based thermoplastic starch, and after rigorous experimentation, they discovered a perfect combination that unlocked the plastic’s ability to decompose naturally.

Their groundbreaking findings were published in the June 20 issue of ACS Sustainable Chemistry & Engineering, garnering significant attention in the scientific community and beyond. The researchers’ primary objective was not only to address the shortcomings of conventional petroleum-based plastics but also to offer an eco-friendly alternative to existing biodegradable plastics. Plastic PET-Tray Sustainability

Conventional plastics derived from petroleum, while convenient, pose severe threats to human health and the environment. They can take centuries to decompose, and their production and disposal are major contributors to the greenhouse gases that exacerbate global warming. Shockingly, only a meager 5% to 10% of plastic in the United States undergoes recycling, rendering plastic recycling efforts largely ineffective. Greenpeace has even labeled plastic recycling as a “failed concept” since a significant portion of plastic still ends up as litter or accumulates in landfills, despite being placed in recycling bins.

Rafael Auras, the MSU professor leading this groundbreaking research, expressed his motivation, stating, “By developing biodegradable and compostable products, we can divert some of that waste.” The current landscape of biodegradable and compostable plastics, however, is plagued by complexity and confusion. Many of these alternatives are made from renewable materials like corn sugars, emit fewer heat-trapping gases, but typically require industrial-compost conditions to degrade properly, proving problematic even in industrial facilities. This complexity has left consumers perplexed about the proper disposal of bioplastics. Plastic PET-Tray Sustainability

The newly developed PLA-starch blend seeks to simplify this dilemma by enabling packaging materials to be truly compostable, even in a backyard compost bin. The addition of starch to the blend provides microbes in compost with a more accessible source of sustenance while the PLA breaks down, making the entire process more efficient and user-friendly.

Pooja Mayekar, a doctoral student and the first author of the research report, recalled the skepticism surrounding the concept of PLA home composting. She noted, “I remember people laughing at the idea of developing PLA home composting as an option because microbes can’t attack and consume PLA normally.” However, the research has shown that this skepticism was unfounded.

Promoting composting over recycling not only conserves valuable resources such as time, water, and energy used to remove contaminants but also simplifies the process since compostable containers often don’t require thorough cleaning of food residues.

Although the research demonstrates the possibility of “completely compostable” plastic, its commercial use may not materialize in the near future. Educating consumers about the composting conditions necessary for bioplastics to break down will be crucial to prevent misinterpretation of “biodegradable” labels as an excuse for littering. Nonetheless, this innovative development represents a significant stride towards addressing the plastic waste crisis, complementing efforts to reduce plastic production and encourage the reuse of existing containers. Plastic PET-Tray Sustainability

Pooja Mayekar aptly summarized the situation, stating, “There’s not going to be one solution to the entire problem of plastic waste management. What we’ve developed is one approach from the packaging side.” Changing the conversation about plastic management and actively seeking sustainable alternatives like this novel biodegradable plastic is a crucial step in mitigating the environmental impact of plastics.

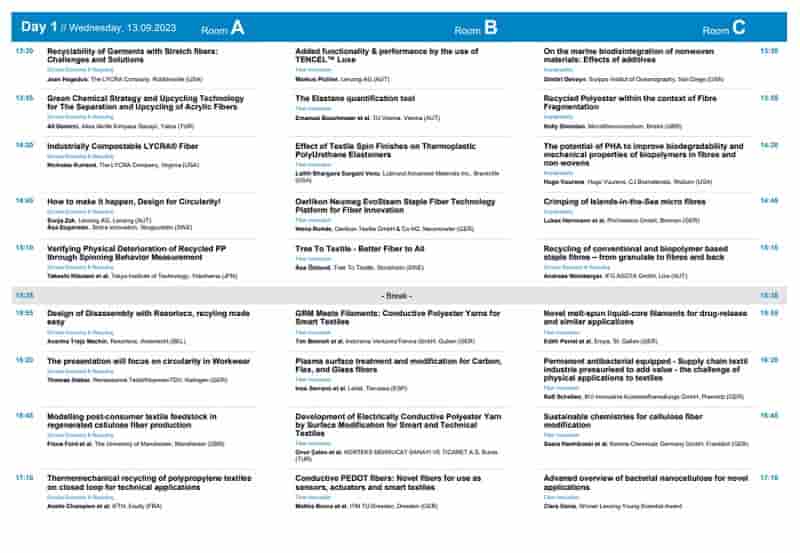

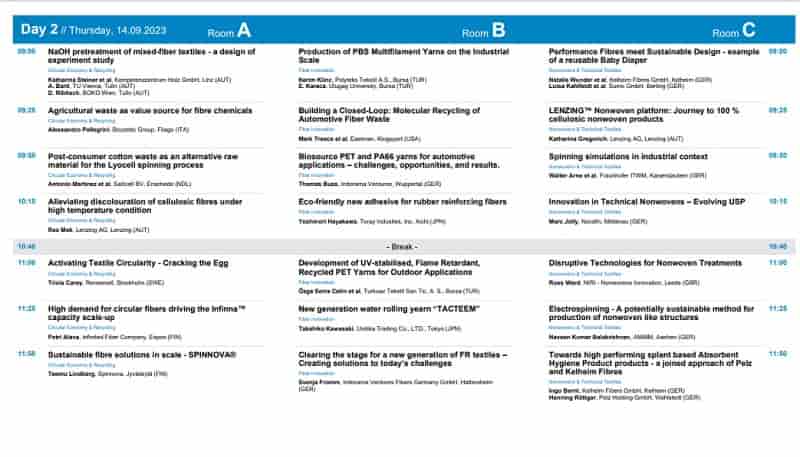

62ND DORNBIRN-GFC 2023

13- 15 September at the Kulturhaus Dornbirn, Austria

The 62st Dornbirn-GFC will take place from September 13 – 15 at the Kulturhaus in Dornbirn. As the world’s largest fiber innovation congress, the Dornbirn-GFC is once again an important meeting place for the public

Personal interaction is possible this year, in the usual form.

At Dornbirn-GFC 2023, more than 100 international speakers from industry and research will present the latest innovations in the fiber and textile industry.

As a generator of ideas and networks, the Dornbirn-GFC will offer young companies a stage for the second time. Plastic PET-Tray Sustainability

The 3rd Innovation Days offers the platform for the presentation of innovative ideas. Furthermore, 25 important partners of the fiber industry present their companies in the exhibition area. The presentation of the Young Scientis Award by Lenzing AG and the Paul Schlack Award in cooperation with CIRFS provide insights into the research topics of the next generation

Must leverage AI, enzyme-based technology for sustainability: Ashok Chaturvedi

In his keynote address at the 10th Speciality Films & Flexible Packaging Global Summit 2023, Ashok Chaturvedi, the founder, chairman, and managing director of UFlex Group, underscored the pivotal role of cutting-edge technologies such as artificial intelligence, machine learning, and enzymatic processing in driving sustainability within the flexible packaging industry.

This prestigious Elite Global Summit, held at the Reliance Jio World Convention Centre in Mumbai, commenced on August 31st and encompasses in-depth discussions on various facets, including the Indian economic landscape, prevailing trends in the FMCG sector, and their implications for packaging. Plastic PET-Tray Sustainability

During his speech, Chaturvedi reflected on the transformative journey of the plastics industry. He remarked, “In the 1960s, as chemical companies were establishing large-scale plastic production facilities, they coined the slogan: ‘If you want to save the planet, use plastic.’ Today, we firmly believe that the global accessibility of products is primarily facilitated by flexible packaging. Historically, back in the 1960s, chemical companies struggled with their value proposition, producing around 1500 tonnes of plastic per year. Now, production has skyrocketed to a million tonnes annually. Embracing multi-layer plastic (MLP) over mono-material packaging, along with a robust recycling ecosystem and bio-enzyme technology, will drive the industry into its next growth phase.”

Chaturvedi further stressed, “Today, everything we produce should be subject to recycling. At UFlex, we’ve made significant investments in industrial and MLP waste recycling facilities across our global locations.

Recently, we’ve also embraced enzyme-based delamination and recycling technology for aseptic packaging. While chemical recycling may not be fully realized today, it holds promise for the future.” Plastic PET-Tray Sustainability

Chaturvedi reiterated the importance of utilizing machinery and AI for waste collection and sorting, rather than relying solely on manual labor by waste workers. He emphasized, “This manual approach is neither efficient nor sustainable in terms of generating employment for marginalized waste workers. Waste collection and ensuring adequate access to post-consumer waste represent formidable challenges in India. It is essential to recognize that the primary hurdle in addressing plastic pollution lies not in the recycling process itself but in the efficient and comprehensive collection and management of plastic waste, forming the cornerstone of our battle.”

The summit comprises specialized sessions dedicated to sustainability, featuring panel discussions with esteemed speakers from institutions such as the Central Pollution Control Board of India (CPCB), the Ministry of Environment and Forests (MOEF), and the Government of India’s Central Pollution Control Board (CPCB), addressing critical issues facing the industry. Plastic PET-Tray Sustainability

Anticipations point towards an increase in oil prices during the latter half of this year

Most industry analysts foresee a strengthening of crude oil prices in the second half, but the notion of crude reaching the $100 per barrel mark by year-end has mostly been abandoned.

Presently, crude prices exhibit volatility, with North American diesel prices experiencing a significant upswing in recent weeks due to issues at American refineries.

Global oil demand has been on an upward trajectory, reaching unprecedented levels this summer, while production has also surged. This surge in production comes despite the efforts of the Organization of Petroleum Exporting Countries (OPEC+) and Russia to curtail their output. Plastic PET-Tray Sustainability

At various points this summer, demand has outpaced production, resulting in a tightening of global oil stocks. This tightening, observed in early August, led to an upturn in crude oil prices. However, concerns about the sustainability of this demand growth have lingered, owing to uncertainties surrounding China’s economy and the expectation of interest rate hikes by the U.S. Federal Reserve.

West Texas Intermediate crude oil has predominantly fluctuated within the $65 to $80 per barrel range this year. It briefly breached the low $80s in late July and remained elevated for a few weeks, driven by a reduction in global oil stocks and optimism that declining inflation would prompt central banks to halt their interest rate hikes.

Nevertheless, U.S. inflation rebounded to 3.2 percent in July after briefly dropping to three percent the previous month. In a recent speech, U.S. Federal Reserve Chair Jerome Powell emphasized that with inflation at 3.2 percent in July, it remains excessively high. The central bank is prepared to raise interest rates again and maintain them at elevated levels until inflation convincingly moves towards their target of two percent. Higher interest rates could dampen the buoyant American economy and reduce oil demand.

China, as the world’s other major economy, had initially been expected to drive soaring oil demand this year following the easing of COVID restrictions. However, China’s growth has fallen short of expectations, with particular concerns surrounding its real estate sector, which is burdened with excessive debt. This economic slowdown, coupled with the struggle to meet debt payments, could potentially lead to banking sector problems if developers default on their obligations. Plastic PET-Tray Sustainability

Despite these headwinds to global growth, crude oil demand reached a record high this summer, exceeding approximately 103 million barrels per day, an increase of slightly over three million compared to the previous year’s average, according to the International Energy Agency.

This summer, demand has outpaced global output because of OPEC+’s production constraints. OPEC+ currently produces 50.7 million barrels per day, a reduction of over two million barrels since the beginning of the year, as reported in the August update from the IEA. Non-OPEC+ producers have partially offset this decline, increasing production by 1.6 million barrels to 50.2 million barrels per day, with the U.S. accounting for the majority of the rise. Plastic PET-Tray Sustainabilityv

As the peak of the summer travel season winds down, demand is expected to moderate somewhat in the coming fall. Nevertheless, Saudi Arabia is likely to continue limiting its production, maintaining a tight supply-demand balance that could support prices near the year’s highest levels. A Wall Street Journal poll of oil analysts conducted in early August revealed an average expectation of WTI crude averaging $83 per barrel through the fall and into the first quarter of the next year. On August 25, WTI closed just below $80.

Meanwhile, diesel prices have seen a substantial increase after dipping to recent lows in June. The surge in diesel prices last year followed Europe’s discontinuation of diesel imports from Russia due to the Ukraine conflict. There were months of supply adjustments during a time when demand for fuel oil typically surges due to colder weather.

Though things settled down by June, diesel prices rallied again during the summer. Factors contributing to this rally include unplanned outages at U.S. refineries, particularly along the Gulf Coast, and production issues related to unusually high summer temperatures.

Outside of North America, the reduced supply of Saudi Arabian oil has had an impact. Saudi medium sour crude is favored for diesel production, but other types of crude yield lower diesel quantities.

Consequently, with diesel supply running below normal, the profit margins between crude oil and diesel prices remain notably high. Plastic PET-Tray Sustainability

Plastic PET-Tray Sustainability