PVC-recycled – Petrochemicals 25-07-2022 - Arhive

PVC-recycled – Petrochemicals

Petrochemicals – Polyester-filament

Crude Oil Prices Trend

-Mohinani Group to open first Bottle-To-Bottle rPET Plant in Ghana

Mohinani Group, the parent company of Poly Tanks (Gh) Ltd, is set to invest over $16 million to open Ghana’s first bottle-to-bottle recycling plant to supply food-grade rPET (recycled polyethylene terephthalate) of European standards. PET is the primary material found in plastic beverage bottles.

The plant will produce rPET by sourcing post-consumer PET bottles and these would be recycled into material that will then be used in producing new bottles. Mohinani Group will be sourcing used PET bottles locally (and eventually from neighboring countries) via alliances and through the Group’s own collection network.

The recycled food-safe rPET can be used to create high-quality food-grade packaging, produced as per global standards through the company’s own preform production lines. It will also be available in the market for other preform producers to help meet their sustainable packaging goals. PVC-recycled – Petrochemicals

The plant, which is expected to commence operations in late 2023 with full capacity reached in early 2024, will have a capacity to recycle 15,000 metric tonnes of plastic annually, with the overall group’s capacity increasing to 30,000 metric tonnes by late 2024.

The Mohinani Group has outlined that the investment was in line with the company’s commitment to meet both the Group and Ghana’s sustainability goals. In addition, the project will add to the number of jobs that the Mohinani Group has already created in the Ghanaian market.

The group encourages stakeholders in the “sustainability and recycling” space to also engage with it in forming alliances and partnerships to further tackle issues surrounding waste in Ghana, including reviewing existing legislation on this important subject. With this pioneering project, the Mohinani Group founded in Accra in 1966, emphasizes the importance of Ghana to the Group.

“Plastic Waste management is a huge topic all over Africa, as we cater to the plastics sector, it is a logical step for us to enter the plastics recycling industry. We want to close the loop for plastic packaging, and this is perfectly possible with bottle-to-bottle recycling. Especially in Ghana, where until now no closed-loop recycling exists, we are proud to be the first to do it,” Management for the Group said. PVC-recycled – Petrochemicals

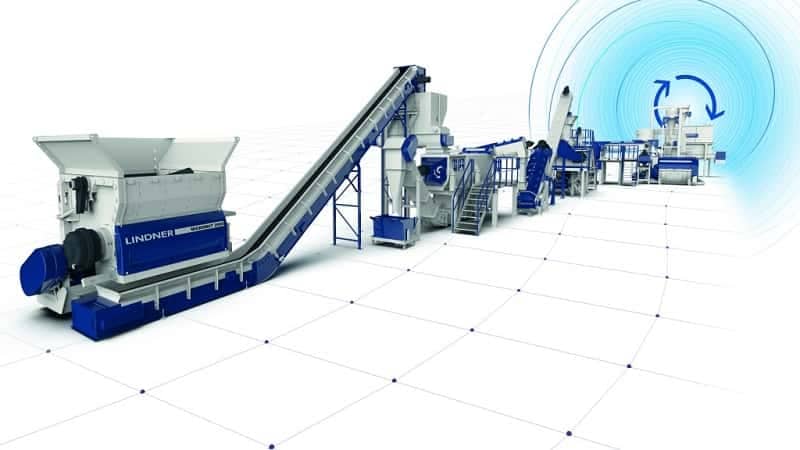

-Lindner to show new shredding, washing, and sorting equipment at K 2022

At K 2022, Lindner will present a range of products and highlight a new system to directly process post-consumer rigid plastics in an injection moulding process.

The circular economy and the growing importance of plastic recycling under the umbrella of climate protection are key topics at K 2022. Undoubtedly, there has been an upswing in plastics recycling for several years. The challenges facing the industry, however, continue to be multifaceted and complex: demand for recyclate quality is increasing as is the call for higher throughputs with minimal energy consumption and maintenance. The driving force behind this is clear: Plastic needs to be retained in the cycle for as long as possible and the aim is also to increase the use of recycled plastic material in the food sector. The key to recycling success lies in the coordination of the upstream processes of shredding, washing, and sorting. Lindner offers solutions to help with these steps while processing rigid plastics, film, and PET. PVC-recycled – Petrochemicals

Shredding waste plastic is right at the start of the plastics recycling process – an area in which Lindner can apply its experience in the processing of domestic, commercial, and industrial waste to obtain standard throughputs of 40 t/h and more. At K 2022, Lindner will be presenting the upgraded Jupiter BW series. The upgraded Jupiter BW series is focused on optimizing the handling of plastic films for the downstream NIR sorting process. In addition to a constant volume flow and homogeneous larger particles, this also includes optimizing the particle size for NIR sorting.

“With a particle size of DIN A4 to A3, we have been able to improve the performance of the NIR systems with our customer,” says Stefan Scheiflinger Ehrenwerth, head of product management at Lindner. “Every shredding process generates a certain proportion of fines along with the targeted ideal particle size. PVC-recycled – Petrochemicals

-EuPC to accept PVC recycled polymers for MORE platform

The platform was confirmed as an official Circular Plastics Alliance data collector earlier this year.

The Brussels-based European Plastics Converters (EuPC) group has extended the scope of its Monitoring Recyclates for Europe (MORE) platform to include polyvinyl chloride, or PVC, recycled polymers. The decision was made by the CPA Monitoring Secretariat and CPA Monitoring Working Group at the end of June. PVC-recycled – Petrochemicals

“With MORE, our industry has the opportunity to continue its efforts towards a circular plastics economy, and this scope expansion will allow us to include even more companies in our MORE family,” says EuPC Managing Director Alexandre Dangis.

The MORE platform was launched by EuPC in cooperation with its member associations in April 2019 to monitor and register the industry’s efforts to reach the EU target of 10 million metric tons of recycled polymers being used annually between 2025 and 2030.

Plastic-waste – Hydrogen-fuel-cell 23-07-2022

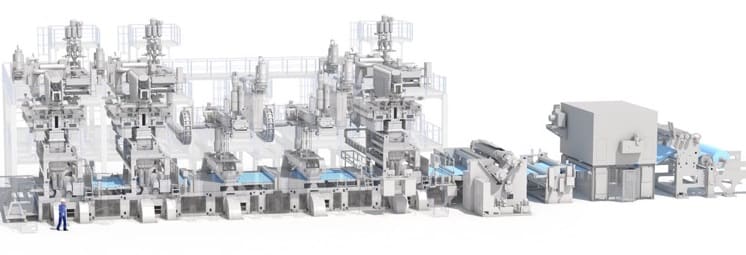

-Reicofil supplies two lines to Algeria

Sinaatec, a major new player in the nonwovens industry established in 2017 as a wholly owned subsidiary of Madar Holding Group, is taking delivery of two Reifenhäuser Reicofil lines, as the technology supplier’s first Algerian customer.

The two lines, a single-beam meltblown line and composite bico line, both with working widths of 3.2 metres, will target the medical and hygiene sectors.

“The demand for nonwovens remains high,” said Mohamed Lamine Bouchelouche, president and CEO of Sinaatec. We see further growth potential in the North and Central African markets.” PVC-recycled – Petrochemicals

The meltblown line is scheduled to be commissioned this September, while the start of the composite line is planned for Autumn 2023. Sinaatec’s local sites and infrastructure provide space for another plant, so further expansion is possible.

“We are very pleased to install our state-of-the-art production lines at Sinaatec’s advanced production facility for high quality nonwovens,” said Dr Boerge Wessling, Reifenhäuser Reicofil managing director.

-MOL Group Invests in Recycling and Waste Management Activities

Hungarian multinational oil and gas company MOL Group has acquired ReMat Zrt., a recycler with production plants located in Hungary, and a logistics hub in Slovakia.

According to the new owner, ReMat is a market-leading plastics recycler in Hungary with an annual processing capacity of 25,000 tons and almost 200 employees. The company, using plastic waste from communal and industrial sources, would prepare a wide range of polyethylene and polypropylene regranules and tailor-made products. With this acquisition, MOL would be able to develop tailor-made virgin and recyclate solutions to fulfill the ever-increasing demand of its customers for circular materials. “The transaction fits into MOL’s portfolio and its goal to become a key player in the low carbon circular economy in Central and Eastern Europe,” MOL Group underlined, which – due to its “Shape Tomorrow” 2030+ Strategy – intends to spend one billion US-Dollar in the next five years on new circular economy and green projects. Waste integration and utilization is a key element of the new sustainable approach. PVC-recycled – Petrochemicals

As reported, the MOL Group has implemented investments already and is “continuously seeking the opportunities to grow the share of recycled materials in its product portfolio”. In November 2019, the first step was taken with the acquisition of Aurora Kunststoffe GmbH, a recycled plastic-based compounder in Germany. “With a total combined annual capacity of 40,000 tons of Aurora and ReMat, MOL can offer a wide range of sustainable compounds and regranulates for the automotive and packaging industries.”

The Group also has established a strategic partnership with German company APK, “whose solvent-based process is capable of producing high-quality polymers from complex plastic waste”.

-Evergreen celebrates expansion growth in Clyde, Ohio

Evergreen, a preferred supplier of food and non-food grade rPET, will celebrate the completion of their building and production expansion in Clyde, Ohio on Friday, July 22, 2022 at a private event. PVC-recycled – Petrochemicals

The expansion began in August of 2021 as a $22M project with 3 lines and evolved due to increased customer and consumer demand for recycled PET plastic. The 54,000 square foot addition includes four extrusion lines with the ability to expand to six, processing 11.8 billion bottles a year resulting in local capacity of 113 million pounds of food grade PET per year. Evergreen processes 217 million pounds across is four North American facilities.

This expansion was made possible in part by American Beverage Association and the Ohio Beverage Association, in partnership with Closed Loop Partners, who announced in 2021 that Evergreen, would be a recipient of a significant investment under the beverage industry’s Every Bottle Back initiative.

The $5 million investment – half from the American Beverage Association in partnership with Closed Loop Partners and the other half from Closed Loop Partners’ Infrastructure Fund – has helped Evergreen evolve its business model, expanding its services to process recycled PET plastic into food-grade recycled rPET pellets used to manufacture new bottles, while creating a strong local market for recycled plastics.

“The team at Evergreen and our partners Ohio Beverage Association and Closed Loop Partners are looking forward to sharing this expansion project with our customers and community.” said Omar Abuaita, CEO of Evergreen. “What we are doing here reaches beyond Clyde, the state of Ohio, and the US.

We are committed to making a global impact to recycling and sustainability. With the financial and strategic support of The Sterling Group, we are able to respond to the demands of the consumer through growth and innovation and are preparing to share a first-of-its-kind industry announcement soon. Without The Sterling Group we would still be a 2-line plant in the middle of Ohio.” PVC-recycled – Petrochemicals

-Nylon filament yarn sees escalating contradiction in July?

In June, nylon raw materials market fluctuated sharply. The deep decline in the second half of June had given up all the gains since the beginning of May. A gap has formed between CPL contracts and spot prices. At the same time, downstream demand continued to be weak, and nylon 6 textile filament factories had not yet caught up previous increase in the cost, and had passively complied with the raw materials and transferred to the downward channel. PVC-recycled – Petrochemicals

- Decline in nylon raw materials restricts NFY sales, but also eases the pressure of loss

The rapid rise and fall of raw materials had the greatest impact on sales of nylon 6 filament factories this month. Early in the month, due to the limited recovery of orders in fabric mills, the price of fabrics was difficult to rise, and the resistance to the rise of nylon filament gradually strengthened with the sharp increase of raw materials. So it was difficult for nylon filament mills to receive orders at high quotation levels.

When the raw materials turned to fall in the middle and late period of June, fabric factories quickly entered a risk-averse wait-and-see state, reducing purchases or even reducing production. The pressure on filament factories was more prominent than when prices were rising. However, for filament mills that mainly purchased contract raw materials, the losses narrowed down as the settlement price was much lower than previous nomination.However, nylon filament stocks were still rising, and there were still many uncertainties about the trend of raw materials. For filament mills, the actual profit and loss of unrealized inventory is unknown. PVC-recycled – Petrochemicals

PVC-recycled – Petrochemicals