Pyrolysis Biopolymer recycling – Will the BRICS become more important than both the EU and the US? 26-07-2023 - Arhive

Pyrolysis Biopolymer recycling

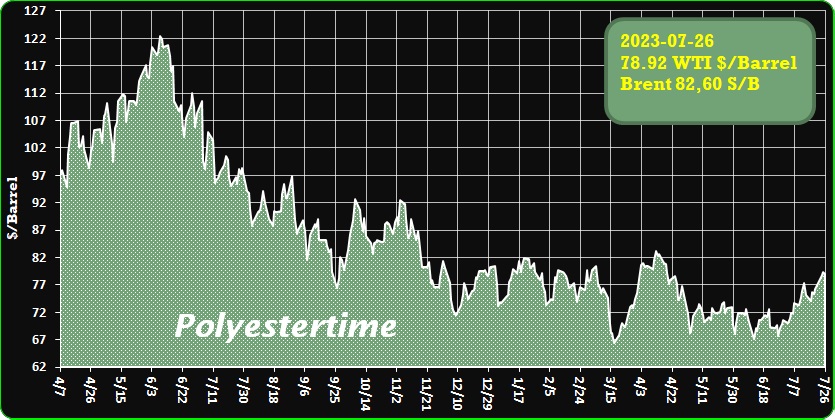

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

The University of Pittsburgh is embarking on a groundbreaking research endeavor, with a singular focus on revolutionizing waste recycling through the optimization of a promising technology known as pyrolysis

This cutting-edge method has the potential to transform waste plastics into valuable chemicals through a chemical process, heralding a new era in sustainable waste management.

Unlike glass, which boasts infinite recyclability, the recycling of plastic has long remained a vexing challenge due to its intricate molecular structure, tailored to meet specific needs. This has contributed to a dire situation, where a staggering 380 million metric tons of plastic are produced globally every year, exacerbating the environmental burden. Astonishingly, a mere 9% of all plastic waste is recycled, while approximately 12% is incinerated, and the rest, an alarming majority, finds its way into landfills and the natural environment, polluting and harming ecosystems. Pyrolysis Biopolymer recycling

Recognizing the pressing need for an innovative solution, the University of Pittsburgh’s esteemed researcher, Giannis Mpoumpakis, associate professor of chemical and petroleum engineering, has taken on the challenge. His pioneering research is centered on optimizing the potential of pyrolysis—a technology that can catalyze a chemical metamorphosis of waste plastics into valuable resources. Mpoumpakis expressed optimism about pyrolysis, citing its relatively low cost and its capacity to generate high-value products. With its existing commercial implementation, the real challenge now lies in determining the optimal operating conditions to ensure efficient transformation, reducing the reliance on trial-and-error experimentation.

As the production of plastics continues to surge, finding and perfecting sustainable recycling and reusing methods becomes imperative. This research, backed by funding from the National Science Foundation, marks a crucial step towards achieving sustainable waste management strategies and curtailing plastic pollution. The potential benefits of this work extend beyond the confines of the laboratory, with far-reaching positive consequences for both the environment and society. Pyrolysis Biopolymer recycling

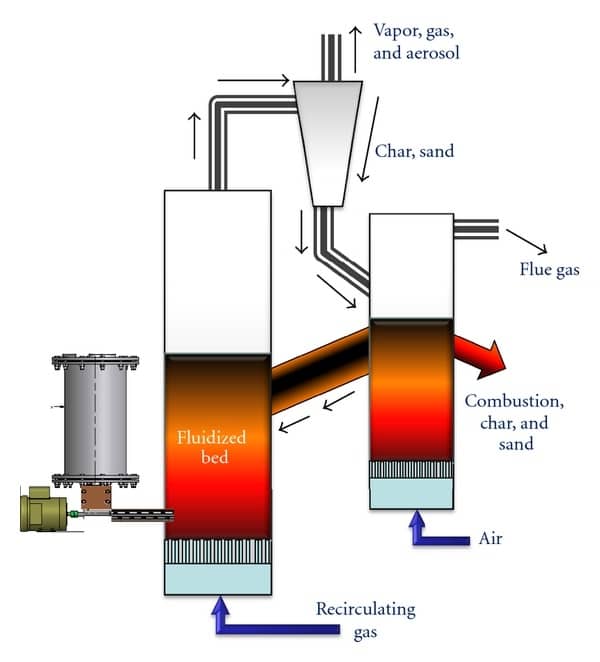

The concept of pyrolysis is not entirely novel; it involves subjecting plastic waste to intense heat in the absence of oxygen, causing it to decompose into simpler molecules. The resulting chemicals can then be harnessed to manufacture valuable products, essentially closing the loop in the plastic life cycle. However, despite its promise, pyrolysis has not yet reached its full potential.

This is where the University of Pittsburgh’s research plays a pivotal role—finding the optimal conditions for the transformation process to maximize its efficiency and minimize any negative environmental impacts. Pyrolysis Biopolymer recycling

Mpourmpakis and his team are striving to unlock the full potential of pyrolysis by studying the intricate interactions and reactions occurring during the process. Through advanced computational simulations and laboratory experiments, they aim to unveil the most efficient catalysts, temperature ranges, and reaction times. Armed with this knowledge, industries can adopt pyrolysis technology at a larger scale, reducing plastic waste and diverting it away from landfills and incinerators. Pyrolysis Biopolymer recycling

The significance of this research goes beyond its immediate environmental impact. Successful optimization of pyrolysis could potentially revolutionize the waste management industry, creating a circular economy where plastics are no longer discarded as mere waste but are instead considered valuable resources. This shift could open up new avenues for businesses and entrepreneurs, promoting the emergence of a vibrant and sustainable market for recycled plastic products.

The benefits of embracing pyrolysis extend to reducing our dependence on fossil fuels. As pyrolysis can produce valuable chemicals from plastic waste, it lessens the demand for raw materials derived from petroleum and natural gas. By conserving these resources, we can move closer to a greener and more resilient future. Pyrolysis Biopolymer recycling

Furthermore, the adoption of pyrolysis technology could bolster local economies by generating employment opportunities. As recycling facilities and pyrolysis plants become more prevalent, there will be a need for skilled workers to operate and maintain these systems. Moreover, the shift towards sustainable waste management can attract environmentally-conscious investors and businesses, driving innovation and economic growth in this sector.

As Mpoumpakis and his team advance their research, they are aware of the need to collaborate with policymakers and stakeholders. Establishing supportive policies and incentives will be instrumental in encouraging industries to invest in pyrolysis technology. Governments can play a significant role in creating an enabling environment that fosters sustainable practices and supports the growth of recycling infrastructure.

In conclusion, the University of Pittsburgh’s research on optimizing pyrolysis technology represents a critical step towards achieving sustainable waste management and combating plastic pollution. Pyrolysis Biopolymer recycling

By harnessing the potential of pyrolysis to chemically recycle waste plastics into valuable chemicals, this research has the power to transform our approach to waste and create a more environmentally friendly and economically viable future. With the support of policymakers, businesses, and communities, this groundbreaking work can pave the way for a circular economy where waste becomes a valuable resource, benefitting both the environment and society as a whole. Pyrolysis Biopolymer recycling

ALPLA Launches ALPLA recycling: A Sustainable Approach to Plastic Recycling

ALPLA Group, a prominent global player in plastic packaging, has been making significant investments in building its recycling capabilities since 2005. Today, the company operates 13 plants, including four joint ventures with regional partners, with an ambitious goal of processing at least 25% post-consumer material (PCR) by 2025. In recent years, ALPLA has invested over 50 million euros annually to expand its recycling activities worldwide, focusing primarily on mechanical recycling. As part of this expansion, the company has doubled its annual installed and projected output capacity to an impressive 350,000 tonnes of PCR material. Pyrolysis Biopolymer recycling

Under the new brand name ALPLArecycling, the company is consolidating all of its recycling activities, marking a significant step towards sustainability and environmental responsibility. ALPLArecycling’s focus remains on mechanical recycling, which has proven to be an effective and eco-friendly way to transform used plastic packaging into high-quality recycled PET (rPET) and recycled HDPE (rHDPE).

Currently, around 1,100 ALPLA employees work on recycling initiatives, operating in 13 plants worldwide. These facilities not only produce top-notch rPET and rHDPE but also emphasize the development of sustainable packaging solutions with high proportions of recycled materials, optimal recyclability, and reduced weight.

The ALPLArecycling website now serves as a hub of comprehensive information, offering insights into ALPLA’s recycling endeavors, available products, and locations of recycling plants and joint ventures. Pyrolysis Biopolymer recycling

Philipp Lehner, CEO of ALPLA, asserts that each year, the company produces more high-quality, affordable, and sustainable packaging from used materials. Their in-house production, material optimization, and development efforts ensure both quality and quantity while contributing to regional and national recycling loops. This not only reduces carbon consumption by up to 90%, but it also minimizes waste and fosters economic growth by creating jobs at recycling sites. Pyrolysis Biopolymer recycling

Dietmar Marin, the Managing Director of ALPLA’s Recycling division, emphasizes that the company’s extensive expertise and access to proprietary materials give their customers a competitive edge. The new brand, ALPLArecycling, showcases the company’s commitment to recycling and underscores their ambitious expansion plans in promising growth markets. ALPLA has been an active participant in the New Plastics Economy initiative, spearheaded by the Ellen MacArthur Foundation since 2018. This partnership further exemplifies the company’s dedication to plastic as a recyclable material and their belief in closed bottle-to-bottle loops to minimize waste. Pyrolysis Biopolymer recycling

As part of their sustainability drive, ALPLA aims to increase its PCR material processing from the current 20% to at least 25% by 2025, and ensure that all their packaging solutions are fully recyclable by the same target year. With their involvement in the Ellen MacArthur Foundation’s New Plastics Economy initiative, ALPLA strives to build recycling infrastructure in numerous countries, raise awareness about recycling, and create value for the environment, economy, and society. Pyrolysis Biopolymer recycling

ALPLArecycling’s commitment to recycling and sustainable packaging solutions resonates globally. The company’s expansion plans target regions like southern Africa, the Middle East, and the Asia-Pacific, where interest in sustainable packaging is burgeoning. As pioneers in these areas, ALPLA aims to become a strong partner for future solutions and pave the way for a more environmentally conscious and responsible future.

In conclusion, ALPLArecycling sets an inspiring example for the plastic packaging industry, demonstrating that recycling is not just an environmental responsibility but also a lucrative opportunity. With their relentless commitment to sustainability and circular economy principles, ALPLA is paving the way for a more eco-friendly and resource-efficient future. Through continuous investment, innovation, and collaboration with global partners, ALPLA is making strides towards a world with reduced plastic waste and a more sustainable approach to plastic packaging. Pyrolysis Biopolymer recycling

Encina Prevails in Legal Battle Over Pennsylvania Chemical Recycling Project

Encina, a prominent chemical recycling firm, is celebrating a recent victory as the Pennsylvania Environmental Hearing Board (EHB) dismissed a legal challenge against its proposed $1.1 billion facility. The facility aims to convert waste plastics into new chemicals, promoting a more sustainable and circular economy. The challenge, brought forth by the Philadelphia-based Clean Air Council (CAC), alleged that state officials made an error in exempting Encina’s Development Group LLC plant, located 55 miles north of Harrisburg, from solid waste permits. Pyrolysis Biopolymer recycling

The EHB’s ruling, issued on July 14, dealt more with administrative procedures than the technological merits of the project. However, it represents a pivotal moment in the ongoing national debate on how to regulate chemical recycling, also known as advanced recycling. Encina views this decision as critical for the advancement of its industry, as some interest groups attempt to use delaying tactics to hinder the progress of such technologies.

Alison Jahn, the Chief Communications Officer for Encina, expressed the significance of the ruling, stating, “This decision is meaningful for our industry and us because some special interest groups are using tactics like this to attempt to stall and/or prevent companies from bringing these technologies forward.” Pyrolysis Biopolymer recycling

Encina’s proposed plant aims to utilize waste plastics as feedstock to produce chemicals like benzene, toluene, xylenes, and propylene. These chemicals can then be used in the production of new plastics or other products, fostering a more sustainable approach to manufacturing.

However, the CAC, alongside some local residents, expressed concerns over potential harmful emissions from the facility and the production of hazardous ash as a by-product that may require off-site disposal. Pyrolysis Biopolymer recycling

The EHB’s ruling hinged on an administrative question, specifically whether letters from the Pennsylvania Department of Environmental Protection (DEP) to Encina constituted a decision that the CAC could appeal. The board determined that these letters were not a final agency decision but rather DEP officials offering their interpretations of relevant legislation.

Encina argued that, under a revised 2020 Pennsylvania law governing chemical recycling, the facility does not require a formal DEP decision for the “advanced recycling exemption” to apply. Pyrolysis Biopolymer recycling

The EHB clarified that Encina would still need to obtain air quality permits and other regulatory approvals outside the purview of the Solid Waste Management Act.

According to the EHB, Encina’s facility could potentially be the first advanced recycling plant proposed in Pennsylvania. It noted that it was not unusual for the DEP and Encina to engage in discussions about whether the facility met the definition of an advanced recycling facility and whether a permit was necessary under the Solid Waste Management Act.

Despite the legal victory, construction of the facility is still subject to other regulatory approvals, and Encina is anticipating commencing the first phase of construction later this year or in early 2024. Pyrolysis Biopolymer recycling

The dispute between Encina and the CAC underscores the ongoing challenges in regulating advanced recycling technologies. As more states explore alternative approaches to managing waste and promoting sustainable practices, the outcome of this legal battle could have broader implications for the future of chemical recycling in Pennsylvania and beyond.

Intecsa and gr3n to Construct World’s First Industrial-Scale MADE PET Recycling Plant

Intecsa Industrial, a distinguished engineering company from Spain with a strong international presence in executing industrial plants, has joined forces with gr3n, a Swiss PET chemical recycler, in a binding Memorandum of Understanding to establish a groundbreaking joint venture aimed at building an industrial-scale recycling facility in Spain. Leveraging their stake in gr3n, Intecsa recognizes the transformative potential of the recycling company’s technology, believing it has the power to revolutionize the recycling industry, as expressed by Ramiro Prieto, the Commercial and New Business Units Director at Intecsa Industrial. He confidently stated, “Their technology allows us to tackle things other technologies cannot.” Pyrolysis Biopolymer recycling

The technology in question, known as MADE – Microwave Assisted Depolymerisation, will form the foundation of a ‘First-of-a-Kind’ manufacturing facility, with the Engineering, Procurement, and Construction (EPC) phase set to commence in the fourth quarter of 2024. The ambitious goal of gr3n SA and Intecsa Industrial is to produce a remarkable 40,000 tons of recycled PET per year by 2027. MADE technology demonstrates its versatility by efficiently processing PET from various industries, including challenging-to-recycle textile waste, thereby closing the loop for hard-to-recycle PET applications.

Maurizio Crippa, the founder and CEO of gr3n, expressed his enthusiasm for this collaboration, acknowledging that the venture would allow gr3n to grow further and showcase the tangible benefits of enhanced recycling, specifically highlighting MADE’s potential to revolutionize the Microwave Assisted Depolymerization process and bring it to market. Pyrolysis Biopolymer recycling

Historically, scaling up enhanced recycling from the laboratory to industrial levels has faced economic challenges and skepticism from initial adopters. Therefore, the partnership with Intecsa, a shareholder with an in-depth understanding of gr3n’s operations, not only reflects their trust but also demonstrates the strength of the data and results generated by the technology. Pyrolysis Biopolymer recycling

The MADE technology developed by gr3n holds immense promise as a reliable and efficient enhanced recycling solution that closes the PET loop. It yields food-grade polymer material, processes a wide variety of waste, and substantially reduces the carbon footprint of materials that would typically end up in incineration or landfills.

Furthermore, the technology’s capacity to process an extensive range of PET waste expands the available raw material feedstock, accelerating the transition towards a circular economy. Pyrolysis Biopolymer recycling

Ernesto De La Serna, the director of new developments and innovation at Intecsa Industrial, firmly believes that the MADE technology will be a game-changer, revolutionizing the recycling industry and the entire polyester value chain. The technical concept behind the MADE plant involves breaking down PET into its primary monomers using microwave technology combined with alkaline hydrolysis, creating a financially viable approach to PET recycling. This innovative process breaks down all types of PET and polyester plastic into two core components – PTA and MEG monomers – which can then be reassembled to produce virgin-like plastics, facilitating endless recycling loops.

Such a revolutionary approach has the potential to transform PET recycling on a global scale, offering substantial benefits to the recycling industry and the polyester value chain.

The polymers obtained from this process can be used to produce new products, effectively replacing feedstock material derived from fossil fuels, and may even enable bottle-to-textile, textile-to-textile, or textile-to-bottle recycling within a truly circular system.

With the ultimate aim of becoming the world’s leading supplier of recycled PET and polyester, the collaboration between Intecsa and gr3n seeks to address the global demand for virgin plastics and drive a genuine circular approach to plastic recycling.

This visionary partnership represents a significant step forward in sustainable practices and the responsible use of resources in the pursuit of a greener future for our planet.

Pyrolysis Biopolymer recycling

Braskem Achieves 30% Expansion in Biopolymer Production, Investing US$ 87 Million

Braskem, the world leader in biopolymer production, has marked a significant milestone by increasing its bio-based ethylene facility’s production capacity by 30%. This celebrated expansion comes thirteen years after the global launch of Braskem’s revolutionary I’m greenTM bio-based plastics. The company recently concluded a substantial investment of US$ 87 million in its bio-based ethylene plant, situated in the Petrochemical Complex of Triunfo, Rio Grande do Sul, Brazil. The primary objective of this investment is to meet the surging global demand for sustainable products. With the expansion, the plant’s capacity has grown from 200,000 to 260,000 tons per year. Pyrolysis Biopolymer recycling

Braskem’s bio-based ethylene is derived from sustainably sourced, sugarcane-based ethanol, a process that actively removes CO2 from the atmosphere and embeds it within everyday use products.

This initiative is a significant step forward in Braskem’s commitment to enhancing biopolymer production, aiming to reach one million tons by 2030 and ultimately becoming carbon neutral by 2050. Walmir Soller, O/P VP for Europe and Asia, and the global leader of the I’m greenTM bio-based business, underscores the company’s dedication to sustainable development and innovation. He emphasizes that the successful expansion of bio-based ethylene capacity demonstrates the efficacy of Braskem’s strategy, which began with the launch of the world’s first industrial-scale bio-based polyethylene production and the introduction of proprietary technology. Pyrolysis Biopolymer recycling

The company’s vision is to cater to society’s and customers’ demands for environmentally-friendly products with reduced impact on the planet.

The significance of Braskem’s sustainable efforts is further highlighted by the fact that every ton of plastic resin produced from renewable feedstock results in the removal of three tons of CO2 from the atmosphere. Since the plant’s inception in 2010, over 1.2 million tons of I’m greenTM bio-based polyethylene have been manufactured. The recent increase in production capacity is expected to eliminate approximately 185,000 tons of CO2 equivalent per year.

Braskem’s bio-based resins have already gained worldwide recognition and adoption, with exports to more than 30 countries and use in products from over 250 major brands, including Allbirds, DUO UK, Grupo Boticário, Johnson & Johnson, Natura & Co, Nissin, and Tetra Pak. These versatile resins are utilized in the production of various items such as packaging, bags, toys, housewares, industrial cables and wires, packaging films, hockey fields, and reusable water bottles, among many others. Pyrolysis Biopolymer recycling

The development and production of ethylene and resins from bio-based sources are the result of Braskem’s continuous investment in disruptive innovation and technology. The company’s unwavering focus on research, digital transformation, and strategic partnerships serves as the bedrock for seeking and scaling sustainable solutions for society and the environment. Braskem’s current sustainability commitments include enhancing the circularity of plastics, promoting human-centric development, and spearheading the bio-based materials revolution.

In conclusion, Braskem’s recent 30% expansion in biopolymer production following an investment of US$ 87 million signifies a significant leap forward in the global effort to adopt sustainable practices. By utilizing bio-based ethylene made from renewable resources, Braskem not only meets the growing demand for eco-friendly products but also actively contributes to reducing carbon emissions. Pyrolysis Biopolymer recycling

The company’s commitment to achieving carbon neutrality by 2050 and increasing biopolymer production to one million tons by 2030 exemplifies its dedication to a greener and more sustainable future. As a global leader in the biopolymer industry, Braskem continues to pave the way for innovative and responsible solutions that benefit both people and the planet.

Sabic, Circularise partner on blockchain pilot

Can blockchain technology make emissions accounting more transparent, more efficient?

Dutch blockchain software provider Circularise and Sabic have partnered on a project in which Circularise’s blockchain technology is being used to trace the carbon footprint of specific material streams from end to end. Pyrolysis Biopolymer recycling

Sabic, a global leader in the chemicals industry, has launched a pilot project with Circularise, a blockchain software provider, to evaluate the use of its blockchain technology in tracing the carbon footprint of specific material streams from end to end.

The aim is to evaluate whether it offers a solution to the problem of acquiring the data needed to generate and report Sabic’s Scope 3 emissions, the companies said.

Acquiring accurate data on a company’s carbon footprint requires collaboration and data sharing across multiple value chain partners.

Using blockchain technology could enable the required transparency and accountability while minimising risk across supply chains. Pyrolysis Biopolymer recycling

The present project will capture emissions across the value chain by deploying a consistent methodological and reporting framework accepted by the industry. Scope 1 and Scope 2 data captured at the material level can be used to generate Scope 3 CO2 emissions for the full value chain of targeted industries.

Not only will this enhance transparency, the use of Circularise’s Smart Questioning technology will reduce the administrative efforts associated with the data collection and deliver access to upstream and downstream data provided by value chain participants, from recyclers to converters to original equipment manufacturers, among others. Smart Questioning is Circularise’s proprietary technology designed to allow a verifier, such as a brand owner, to ask a series of carefully curated questions of a prover, for example a supplier, in order to obtain relevant information about a product without disclosing any sensitive data. Pyrolysis Biopolymer recycling

“Accurately mapping emissions, especially Scope 3 emissions, will allow Sabic and others to identify and minimise hot spots along the value chain, a critical tool in our pathways to decarbonizsation,” said Waleed Al-Shalfan, vice president of Polymers Technology & Innovation at Sabic. “We encourage other upstream and downstream partners to join and consider how this technology can unlock sustainable growth at every level moving forward.”

This collaboration with Circularise is Sabic’s second blockchain application project. Last year, the company launched a pilot project with Finboot, Plastic Energy, and Intraplás to evaluate the use of blockchain technology in supporting end-to-end digital traceability of circular feedstock in customer products. Pyrolysis Biopolymer recycling

This project, aimed at tackling the challenges of Scope 1, 2, and 3 emissions accounting, including issues like information accessibility, confidentiality, and scalability of data sharing among suppliers, will help Sabic meet its commitment of becoming carbon neutral by 2050.

“As part of this project, Circularise aims to pilot blockchain-powered digital product passports and help businesses to track product emissions on a large scale and over time, generating comprehensive product life cycle emission reports,” added the company’s founder, Mesbah Sabur.

BRICS: A Growing Economic Bloc with Expanding Horizons

The BRICS economic bloc, comprising Brazil, Russia, India, China, and South Africa, has witnessed remarkable growth and influence since its inception. Originally coined as “BRIC” by economist Jim O’Neill in 2001, this group emerged as a symbol of optimism amid market pessimism following the September 11, 2001 terrorist attacks in the United States. Over the years, it has evolved into a tangible and influential alliance that now controls a major development bank. As BRICS prepares for its annual summit in Johannesburg, the bloc finds itself attracting significant interest from nations worldwide, with twenty-two countries formally applying for membership and an equal number expressing informal interest. Pyrolysis Biopolymer recycling

The genesis of BRICS was rooted in the shared interests and common challenges faced by Brazil, Russia, India, and China due to their rapid economic growth at the time. Recognizing the potential of combining their voices in a world dominated by the United States, these nations began their cooperation and held the first BRIC foreign ministers’ meeting in 2006. This eventually led to the inaugural leaders’ summit in 2009, and in 2010, South Africa joined the bloc, expanding its influence to yet another continent.

One of the most significant achievements of BRICS lies in the financial realm. The member nations agreed to pool $100 billion of foreign currency, establishing a liquidity facility that can be utilized during emergencies. This facility became operational in 2016, bolstering the bloc’s financial stability. Moreover, the establishment of the New Development Bank, inspired by the World Bank, has been a pivotal milestone for BRICS. Since its inception in 2015, the bank has approved over $30 billion in loans for various infrastructure projects, with countries like South Africa borrowing funds to combat the Covid-19 pandemic in 2020. Pyrolysis Biopolymer recycling

Furthermore, discussions are underway to explore the feasibility of a common BRICS currency, which could further strengthen economic ties between member nations.

China, with a GDP more than double the combined GDP of the other BRICS members, is undoubtedly the largest economic powerhouse within the bloc. However, India, with its significant population advantage, serves as a counterweight to China’s influence. This balance is evident in decisions such as BRICS not formally endorsing China’s Belt and Road Initiative due to objections from India regarding infrastructure projects in disputed territories held by Pakistan, India’s neighboring arch-rival. The New Development Bank is also a testament to the equality sought by BRICS members, with Beijing agreeing to the equal holdings advocated by New Delhi. Pyrolysis Biopolymer recycling

Beyond its economic achievements, BRICS represents a shift towards a more multipolar world, moving away from the dominance of the United States. The bloc aligns with the concept of the “Global South,” a term used to refer to relatively poor and developing countries, which contrasts with the “Global North” composed of wealthier nations in the US, Europe, and some parts of Asia and the Pacific. In this context, BRICS, like the Group of 20, aims to promote a more equitable global order.

As BRICS prepares for its summit in Johannesburg, the growing interest from other countries highlights the bloc’s rising stature and influence on the global stage. Formal applications from nations like Saudi Arabia and Iran, and expressions of interest from the United Arab Emirates, Algeria, Egypt, Bahrain, Indonesia, and others indicate the increasing appeal of BRICS’ economic cooperation and shared values.

However, as BRICS contemplates expanding its ranks, challenges and potential frictions may arise. Pyrolysis Biopolymer recycling

The diversity in political ideologies and national interests among prospective members could require careful navigation. BRICS must maintain a delicate balance between accommodating new entrants and preserving the cohesion that has been pivotal to its achievements thus far.

In conclusion, BRICS has come a long way from being a mere slogan to becoming a formidable economic bloc with significant achievements in the financial realm. The increasing interest from nations seeking to join the organization reflects its growing importance in shaping the global economic landscape. As it faces the challenge of expansion, BRICS has the opportunity to consolidate its position as a major force for promoting equitable development and fostering cooperation among emerging economies.

Plastic recycling Eco-Friendly – Revolutionary System Enables Tailoring of

Polymers with Unprecedented Precision 25-07-2023

Pyrolysis Biopolymer recycling